- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Implementation of Industry 4.0 in Textile Production: Possibilities of 3D Printing of Clothes

Nebojša Ristić*, Aleksandra Mičić, Ivanka Ristić and Ivana Aleksandrov

Academy of Applied Studies Southеrn Serbia, Department High School of Technological and Arts, Serbia

*Corresponding author:Nebojša Ristić, Academy of Applied Studies Southеrn Serbia, Department High School of Technological and Arts, Vilema Pušmana 17, Leskovac, Serbia

Submission: October 06, 2025;Published: December 05, 2025

ISSN 2578-0271 Volume11 Issue 3

Abstract

The textile industry is a branch of industry that deals with the processing of fiber raw materials and the production of fabrics, knitwear and clothing. A turn in the fashion industry in the direction of sustainable fashion is necessary, which implies a reduced consumption of natural resources and the application of a circular business model. This paper discusses the possibility of using 3D printing technology in the clothing industry as a technological innovation for the purpose of developing a new concept of the fashion industry. Used in techniques 3D printing, materials for 3D textile printing as well as advantages and limitations in 3D printing are described. Three-dimensional (3D) printing creates 3D objects quickly and efficiently- layer by layer, based on computer aided design (CAD) and computer aided manufacturing (CAM). Technology 3D printing allows designers to experiment with complicated patterns and structures that are difficult to achieve with traditional textile production methods. Fashion designers can use 3D printing to achieve greater design freedom and thus push the boundaries in the design of fashion products.

Keywords:3D printing; CAD; CAM; Thermoplastic filaments; Fashion industry

Introduction

3D printing technology is one of the most significant technologies of the fourth industrial revolution in many industries, and the fashion industry is no exception [1]. 3D printing technology is an advanced form of combination of computer assisted design (CAD) and computer assisted manufacturing (CAM) technology. It is used to make an end product or part of it in a layer-by-layer fashion employing a digitized model using liquid or rigid substances. Fashion has always been used to express various social and cultural issues. In itself it is a tool of nonverbal communication which can provide a plethora of information about the wearer. Moreover, recent advances in robotic and sensory technologies have presented new opportunities for the world of fashion.

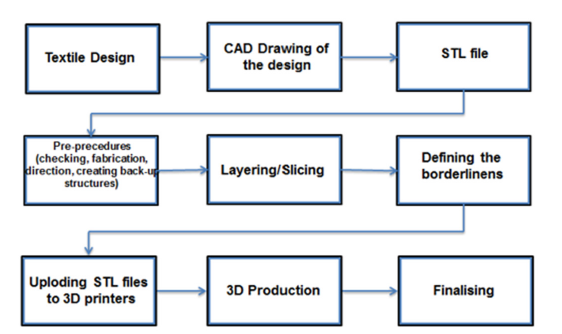

The design and production process with three-dimensional printers begin with determining the intended purpose of textile and modelling studies. In the second stage, threedimensional drawings of textile design are being prepared in the features and sizes set by the appropriate CAD programs. Then, the created designs are converted into the STL file format. The STL file format is “an unsorted triangle surface list that represents the outer surface of the design” [2]. The data contained in this file is subjected to some pre-processing, such as error checking and building direction, creating support structures if necessary [3].

Finally, geometric textile data is printed by being sliced and sent to the printing machine, which is considered suitable for production (Figure 1). Textiles produced with a three-dimensional printer may be dimensionally incorrect when compared to conventional technologies. Therefore, “the surfaces of critical objects are finally cleaned, cured and brought to final size” [4].

Figure 1:3D Textile production stages [4].

Traditional textile production often creates significant waste due to the cutting and assembly process. 3D printing minimizes waste by making garments and fabrics directly from digital draft, using only the exact amount of material needed. This additive approach not only reduces textile waste, but also supports sustainability efforts by promoting more efficient use of resources. 3D printing enables on-demand manufacturing, reducing the need for largescale production runs and inventory management. Consumers can personalize their clothing by choosing specific designs, colors and sizes, leading to a more customized and satisfying shopping experience. This on-demand approach also helps brands respond quickly to changing trends and customer preferences.

3D printing techniques in the fashion industry

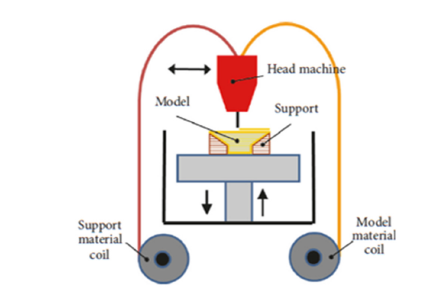

There are several different types of 3D printing techniques, each with their own advantages and limitations. Some of the most commonly used techniques in the fashion industry are: Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS) and Stereolithography (SLA). FDM (Fused Deposition Modeling) the technology is used in approximately 70% of 3D printing cases world wide. The FDM method involves melting a thermoplastic material using a temperature-controlled nozzle. The molten material is automatically pushed into the print head and exits in a thin layer onto the print table to form the model. A schematic diagram of the FDM 3D printer is shown in Figure 2 [5].

Figure 2:Schematic diagram of FDM 3D printing.

FDM uses thermoplastic polymers such as: ABS (acrylonitrile butadiene styrene), PA (polyamide), PLA (polylactic acid) and PET (polyethylene terephthalate). The characteristics of this technique are low cost, ease of use, easily available materials and rough surface [6].

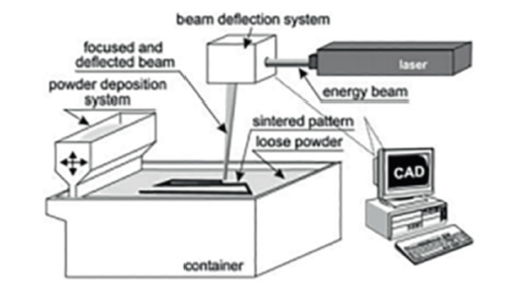

Selective Laser Sintering (SLS): This approach uses a laser to selectively fuse powdered material together to form the object. This is often used for creating functional parts and components. Figure 3 shows a schematic representation of SLS printing [7], and this method is also known as powder fusion. The SLS technique uses thermoplastic materials such as polyamide, polystyrene, elastomers and composites. The remaining powders can be reused. The positive sides of the technique are great freedom in design, durable products, while the disadvantage is poor surface treatment and high price [6].

Figure 3:Schematic diagram of SLS 3D printing.

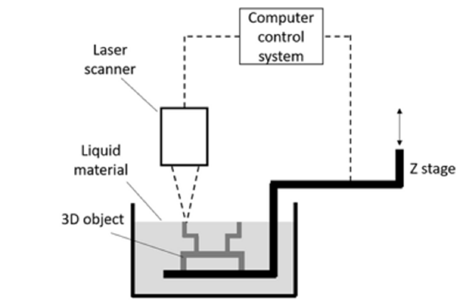

Stereolithography (SLA): This technique uses a liquid resin that is solidified layer by layer using a laser or UV light. This is a popular tool for creating high-detail prototypes, small-scale production runs, and jewelry accessories. The schematic diagram of the SLA 3D printer is shown in Figure 4 [8].

Figure 4:Schematic diagram of SLA 3D printing.

The SLA technique uses PE (polyethylene), PP (polypropylene), ABS and PC (polycarbonate). High resolution, precise and detailed outer edges and high surface finish are the advantages of this technique. The disadvantages include the need for auxiliary materials, high cost [9].

Pioneers in 3d fashion

Iris van Herpen is a Dutch designer known for her futuristic, scifi aesthetic that mixes with natural motifs. Her marvelous creations are pure art that unites fashion, science and technology. In 2011, she made a splash when she debuted a 3D printed dress, one of her first 3D printed pieces, at Paris Haute Couture Week [10]. Van Herpen was the first designer to introduce 3D printed fashion on the runway. Since then, 3D printing has become a popular new tool in the fashion industry for major designers, who create garments with geometric shapes as well as solid and shiny embellishments. The white parts are made of polyamide and are made by a selective laser sintering process. The black part is also 3D printed from polyamide and finished with black lacquer (Figure 5).

Figure 5:Fashion creations by designer Iris van Herpen.

Danit Peleg is a fashion designer and a pioneer in 3D printed fashion. In 2015, she made international headlines for being the first designer in the world to create an entire collection using desktop 3D home printers for her graduate project at Shenkar College of Engineering and Design. Danit Peleg presented his first fashion collection in 2015 “Liberty Leading The People”. What’s so special about her show is the fact that she made the models for her collection at home, on a 3D printer, without any previous experience in 3D printing, which makes this project even more impressive. Most fashion items from the collection are made up of multiple 3D printed parts (Figure 6). By using a mesh design on the dress, she achieved the necessary flexibility of the garments. In 2016, she was invited by the Paralympic Games to design a 3D-printed dress for Amy Purdy, a double-leg amputee dancer, who performed at the Opening Ceremony in Rio [11].

Figure 6:3D printed dress by fashion designer Danit Peleg.

After unveiling her first 3D printed clothing collection, Peleg has created another impressive collection- “The Birth of Venus”. Her ultimate goal was to make 3D printed fashion accessible. To achieve this, she introduced the first 3D printed garment available for purchase - a jacket sold on her website. The 3D printed jacket is limited to just 100 pieces due to the capacity and speed of the 3D printer, but is a perfect example of how 3D printing can become a mass customization adaptation (Figure 7).

Figure 7:3D printed jacket without seams.

The Pangolin 3D printed dress uses a nano-enhanced elastomer 3D printing material, which gives it both flexibility and durability (Figure 8). It was created in collaboration between three ASFOUR, Stratasys, and architect Travis Fitch. The dress was printed on 10 printers and took 500 hours to complete. After printing, all the “chain-like” parts were connected together to form the dress. The creators claim that each unit of the dress functions by itself in order to produce a 3D effect while moving [12].

Figure 8:3D printed jacket without seams.

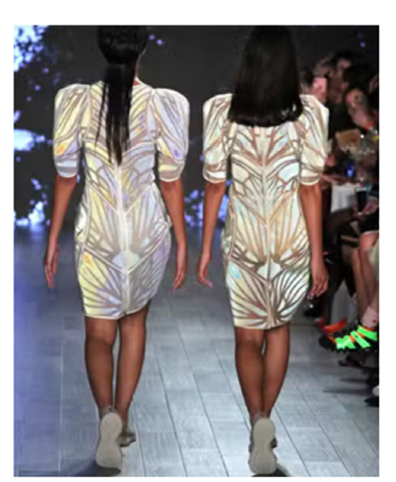

The fashion house, three ASFOUR presented at the 2019 New York Fashion Week its “Chro-Morpho” collection created using a new style of 3D printing directly on fabric [13]. Until then, clothing was mostly either fully printed or assembled after printing. Direct 3D printing onto fabric opens up a whole new world of possibilities, especially when it comes to creating stylish, functional wearables. Working in collaboration with Stratasys and Travis Fitch, three Asfour’s fashion designers created its Chro-Morpho collection, which took the NYFW runway by storm. The collection, inspired by the iridescent and microscopic colors created by light filtering through butterfly and insect wings, was created using a novel technique of 3D printing directly onto fabric (Figure 9).

Figure 9:3D printed jacket without seams.

Challenges and limitations of 3d printing in fashion

Although the potential of 3D printing in fashion is huge, there are still several challenges and limitations that need to be overcome to enable mass production and greater availability. One of the main challenges of 3D printing in fashion is the limited selection of available materials. Although there have been advances in printing fabrics and other flexible textile structures, most 3D printed fashion is still made using rigid plastics, which limits the variety of textures, colors and finishes that can be achieved with 3D printed clothing and accessories. Due to the limitations of raw materials, it is difficult to achieve the pore structure and air permeability of traditional textiles. Therefore, the development of new raw materials similar to natural fibers or soft fabric structures is of great importance. Additionally, most wearable clothing produced using 3DP technology is currently limited to works of art or “high fashion.” These garments include complex geometric designs and special, colorful effects, which are always time-consuming to produce. It is necessary to design clothing with a low price that is suitable for everyday life. One of the emerging trends in 3D printing is the use of sustainable and biodegradable materials. Designers and researchers are exploring alternative materials, such as algae-based filaments and recycled plastics, to create more environmentally friendly 3D printed fashion material. A recently published paper describes the possibility of using biomaterials in 3D printing textiles as part of a sustainable development strategy [14].

Conclusion

The speed of changing fashion trends determines the need for constant innovation. The desire for faster and more cost-effective production is a trend that does not subside, however, the creation of completely new ways of production is slowly taking precedence. In recent years, 3D printing has emerged as a revolutionary technology with transformative potential in various industries. In the fashion sector, 3D printing is leading a new wave of innovation, reshaping the way fabrics and clothing are designed, produced and consumed. 3D printed fashion also offers a sustainability advantage. Instead of traditional mass production, which often results in excess material and unused inventory, 3D printing enables “on-demand” production, reducing waste and contributing to environmental sustainability.

Acknowledgment

None.

Conflicts of Interest

None.

References

- Kim S, Seong H, Her Y, Chun JA (2019) Study of the development and improvement of fashion products using a FDM type 3D printer. Fashion and Textiles 6: 9.

- Huang SH, Zhang LC, Han M (2003) CS File-An improved interface between CAD and rapid prototyping systems. International Journal of Advanced Manufacturing Technology 21: 15-19.

- Celebi A, Tosun H, Oncag CA (2017) Manufacturing a damaged skull with 3d printer an implant design. International Journal of 3D Printing Technologies and Digital Industry 1: 27-35.

- Fatma Bulat F, Basaran N (2022) Investigation of performance characteristics of 3D printing textiles in terms of design and material. Tekstil Ve Konfeksiyon 32: 162-172.

- Jimenez M, Romero L, Dominguez IA, Espinosa MdM, Dominguez M (2019) Additive manufacturing technologies: An overview about 3D printing methods and future prospects. Complexity.

- Chakraborty S, Biswas MC (2020) 3D printing technology of polymer-fiber composites in textile and fashion industry: A potential roadmap of concept to consumer. Composite Structures 248: 112562.

- Kruth JP, Mercelis P, Van Vaerenbergh J, Froyen L, Rombouts M (2005) Binding Mechanisms in Selective Laser Sintering and Selective Laser Melting. Rapid Prototyping Journal 11(1): 26-36.

- Huang J, Qin Q, Wang J (2020) A review of stereolithography: processes and systems. Processes 8(9): 1138.

- Chatterjee K, Ghosh TK (2020) 3D printing of textiles: Potential roadmap to printing with fibers. Advanced Materials 32(4): 1902086.

- https://i.materialise.com/blog/en/iris-van-herpens-new-3d-printed-escapism-couture-collection-for-mgx

- https://www.oneclub.org/awards/adcawards/-judge/4472/danit-peleg

- https://all3dp.com/2/3d-printed-fashion-the-state-of-the-art-in-2019

- https://www.voxelmatters.com/threeasfour-chro-morpho-3d-printed-fashion/

- Polewka M, Enz F, Jennißen M, Wirth E, Sabantina L, et al. (2023) 3D Printing with biomaterials- The new sustainable future of textiles? Engeneering Proceedings 37(1): 59.

© 2025 Nebojša Ristić. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)