- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Standardisation of Dyeing Conditions for Salt-Free Dyeing of Soya-Based Bio- Cationized Cotton Fabric with Catechu as Natural Anionic Dye

Pubalina Samanta1,2*, Asis Mukhopadhyay2, Amiya Kumar Singha2 and Adwaita Konar3

1BFAD Dept, Rani Birla Girls’ College, 38 Shakespeare Sarani, India

2Dept of Jute and Fibre Technology, University of Calcutta, India

3Govt. College of Engg. & Textile Technology, India

*Corresponding author:Pubalina Samanta, BFAD Dept, Rani Birla Girls’ College, 38 Shakespeare Sarani, Kolkata-700 017, WB, India

Submission: August 22, 2025;Published: November 13, 2025

ISSN 2578-0271 Volume11 Issue 2

Abstract

Instead of using metallic-salt-based chemical mordants for natural dyeing, eco-friendly newer approaches /routes of cotton fabrics were bio-cationised with deoiled waste soyabean seeds for salt-free dyeing of cotton with anionic catechu (Acacia catechu) dye with or without additional use of natural ore-based Fitkari or potash alum (K-alum) to enhance its dyeability and overall colour fastness. It is observed from this study that bio-cationization with acid-hydrolysed deoiled waste soya bean seed extract is found to be very effective with the addition of K-alum as an additional mineral ore-based natural mordant. In the present part of the work, optimum dyeing conditions were standardised for eco-friendly salt-free dyeing of soyabased bio-cationized cotton (SB-Cotton). The standardized optimum conditions/parameters were found as (i) optimum concentration of waste soya seed extract: 10% owf, (ii) concentration of natural potash alum pre mordants: 10% owf, (iii) Optimum concentration of dye (anionic tannate based catechu natural dye): 30% aqueous extract ( on the oven-dry mass of catechu powder), (iv) optimum material: liquor ratio: 1:20,(v) optimum pH of dye liquor: 4, (vi) optimum temperature of dyeing: 70 °C, (vii) Optimum time of dyeing: 60 min and Salt concentration: Nil ( i.e without any salt (for this eco-friendly salt free dyeing ).

Keywords:Acacia catechu; Bio-Cationization; Bio-mordanting; Catechu natural dye; Cotton; Colour fastness; Colour strength; Standardisation of dyeing conditions

Introduction

Most of the natural dyes are non-substantive; to any textiles, particularly to cotton cellulose and hence an additional step of mordanting is essential to fix natural dyes to cotton or any other natural textile materials. Some of the metallic mordants like Copper sulfate, Potassium dichromate, etc., are not eco-safe and hence are not being used nowadays. Rather, researchers are in search of eco-safe natural bio-mordants to apply [1].

Hence, there is a continuous search for an alternative route for eliminating /minimising the need application of metallic mordants, which are not eco-safe. Salt-free reactive dyeing or direct dyeing of cationized cotton and jute is reported by many researchers [2]. Application of catechu on jute fabric [3] has been studied earlier, but not on cotton fabric via the said biocationising as a newer route. First time, a report on bio-cationising of cotton with chitosan [4] has been reported recently for natural dyeing with anionic catechu natural dye, as a preliminary first part of our work on bio-cationization is reported elsewhere. But no reports are still available on bio-cationizing cotton utilising deoiled waste soya bean seeds extract (producing a mixture of natural amino acids from soya bean seeds waste). Hence, it is thought appropriate to undertake the present work as a second part of such bio-cationisation of cotton for salt-free dyeing of cotton/oxy cotton to dye with anionic catechu natural dye and also particularly study on standardization of such dyeing conditions for application of anionic catechu natural dye on soya-based bio-cationized cotton, which is not reported yet. Hence, it is thought appropriate to study the bio-cationization of cotton for subsequent salt-free dyeing with catechu as an anionic natural dye, with and without some natural metallic mordanting using natural potash alum (Fitkari) as a mineral ore-based natural eco-safe mordant /bio-mordant, as catechu has both anionic character and also mordantable character (having its mordantable coordinate bond formation ability to form ‘fibre-mordant-natural dye insoluble complex, to fix catechu dye on cotton) and hence, catechu can be fixed to cotton in both ways.

Natural dye like catechu fixation on cotton can also be enhanced by another pre-treatment approach, like enzyme pretreatment [5]. In the present study, natural dyeing of cotton with catechu dye by this newer route of soya-based bio-cationization using acidic hydrolyzed amino acids extract from waste deoiled soya bean seeds have the major objectives to achieve enhanced colour depth and improved colour fastness to wash and rubbing and also to standardize each dyeing parameters/variables to adopt easily this newer route of catechu natural dyeing of soya-based biocationized cotton (SB-Cotton). Thus, soya-based bio-cationization of cotton is expected to lead to salt-free dyeing of cotton with catechu with or without pre-mordanting with natural potash alum (K-alum), with an expected enhanced colour depth and improved wash and rubbing fastness, for dyeing cotton fabrics with tanninbased catechu natural dye. As alum itself is antimicrobial and catechu itself has inherent antimicrobial and antioxidant character, if the catechu dyed SB-cotton fabrics are further finished with any natural bio-finish like eucalyptus leaves extract, the antimicrobial and UV resistant property of catechu dyed SB-cotton may be further improved for its potential use as coloured medical textiles.

The present work, therefore, deals with the two types of biocationization routes of scoured and bleached cotton with or without pre-oxidation by dilute aqueous solution of K2S2O8 for producing pre-oxidised cotton (oxy-cotton) substrate and subsequent treatment with acid hydrolysed waste deoiled soyabean seeds extract, followed by pre-mordanting with natural potash-alum before catechu dyeing of said SB-cotton.

With the advent of advanced research in this direction, recent advancements in natural dye applications [6] over and above known traditional processes of mordanting, extraction, and natural dyeing have been modified, or newer other eco-friendly approaches of catechu dyeing, printing and finishing are reported [7-9] recently, except for studies on soya based bio-cationization route for catechu dyeing on soya-modified cationic cotton.

However, some scanty reports on cationization of cotton khadi and jute fabrics with different synthetic cationic agents or synthetic amino acids, etc, are available in literature for salt-free dyeing with synthetic anionic direct dyes and reactive dyes [10-15], without any such work reported on soya-based bio-cationization of cotton for salt-free dyeing with anionic natural dyes like catechu. Moreover, as the present study relates to salt-free dyeing of soyamodified cationic cotton to dye with anionic catechu natural dye, it needs standardisation of dyeing conditions to achieve uniform and reproducible dyeing and improved colour fastness results.

Materials and Methods

Fabric

100% Cotton fabric having plain weave structure after desized, scoured, and bleached pre-treatment with 84 ends per inch (20 ends per cm) with a warp count of 9.8 tex (60Ne) and 74 picks per inch (19 Picks per cm) with weft count 10.7 tex (55Ne), with fabric areal density of 145 g/m2, was used.

Natural materials used

Fitkari, i.e mineral ore-based natural potash alum(K-alum) [KAl(SO2)4-12H2O] was used as a pre-mordant. Aqueous extract of Catechu powder /Cake (Acacia catechu) as tannin and flavonoidrich catechin-based anionic and mordantable natural dye, and aqueous extract of eucalyptus leaf (Eucalyptus globulus Labill.) extract as plant-based natural bio-finishing agents were obtained from M/S Ama Herbal Laboratory, Lucknow and M/S Kangalai Charan Dutta & Sons, Kolkata. Deoiled waste soybean seed was collected from an oil mill in Burdwan, WB.

General and textile chemicals and auxiliaries used

Commercial grade Hydrochloric acid, acetic acid and sodium

acetate (for adjusting the pH), ethanol, sulfuric acid, Potassium

persulfate, and Sodium carbonate were obtained from E-Merck

(India);

Textile chemicals used in fabric preparation, such as a nonionic

wetting agent and amylase enzyme, were obtained from Resil

Chemicals Pvt. Ltd. (Ahmedabad) and were used in this study.

Methods of pre-treatments, bio-cationizing, mordanting, natural dyeing and bio finishing

Pre-treatment of cotton fabric (Enzymatic desizing, scouring and bleaching): The cotton fabric underwent 3 stages of sequential preparatory processes [16] one by one, as follows: Enzymatic desizing was done using 2ml/L of amylase enzyme, 5g/L NaCl, and 2g/L non-ionic wetting agent, with a MLR of 1:20, at a temperature of 50-55 °C for 60 min followed by alkaline scouring with 2% NaOH with 5gpl nonionic detergent at boil for 2hrs and then further followed by standard H2O2 bleaching of desized and scoured cotton fabrics using 1.0 vol concentration (0.67% ) of H2O2, at pH 11, at a temperature 80 °C for 1hr ( generating copper number 0.5 from 0.2 i.e. generating few aldehyde groups in bleached cotton). After all the 3 stages of pre-treatments were over, the pretreated cotton fabric samples were thoroughly washed in hot water for 15 min, followed by rinsing and then drying in the sun in air.

Pre-oxidation of cotton fabrics: The control desized, scoured and bleached cotton fabric was subjected to mild pre-oxidation treatment to generate few more aldehyde groups in cotton celluloses by mild oxidative treatment with 1% K2S2O8 solution at room temperature (27±3 oC) for a period of ½hr, batched at room temperature with material: liquor ratio(MLR) 1:20. Finally the said K2S2O8-treated pre-oxidised cotton fabric (oxy-cotton) was then washed in running water followed by air drying to obtain a very low degree of pre-oxidised cotton fabric (oxy-cotton) particularly as required for bio-cationization of cotton with amino content finish.

Extraction of mixed amino acids from de-oiled waste soya bean seeds: De-oiled waste soya-bean seeds (the remaining part of the soya mass after de-oiling) were ground in a laboratory model pulveriser. 200gm of grounded de-oiled waste soya-bean seed was pre-soaked in acidified water using dilute 10% HCl and was batched for 24hrs at room temperature (27+3 oC) and then the filtrate (acid hydrolyzed solution of waste soya seeds) was neutralized gradually, if required, using soda ash solution and adding suitable buffer solution, to bring to pH 5.0. The total amino acid content of HCl hydrolysed waste soya bean seeds is found to be 20.01% which constitutes a mixture of 17 different natural amino acids, where glutamic acid and arginine contents are found to be on the higher side than other soya extracted amino acids present.

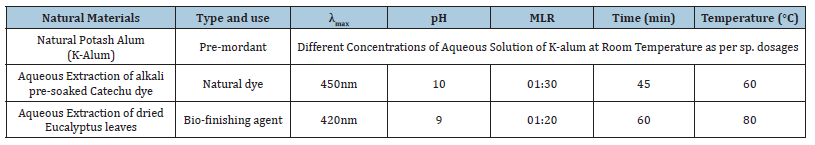

Extraction of bio-mordant, natural dye and bio-finishing agents: All materials from natural resources like Mineral orebased Fitkari (natural potash alum), Deoiled Waste soyabean seeds (collected from an oil mill), Catechu dye powder/cake and eucalyptus leaves were dried in the sun and powdered using a pulveriser. Extraction of the several constituents from the natural source was done under aqueous conditions under specific optimised conditions shown below: 30% aqueous extract of catechu is found as equivalent to 3% shades of pure catechu (studied earlier), as revealed by the test of purity of the source catechu dye taken, which is found to be 10% of the weight of dry source material of catechu powder/cake (Table 1).

Table 1:Extraction conditions of different natural bio-materials used.

Bio-cationization of cotton with de-oiled waste Soya bean

seed extract: Desized, Scoured and H2O2 oxidative bleached cotton

fabric samples were immersed and batched for 30 min in a liquid

aqueous extract of 5-20% deoiled waste soya bean seeds extract

after its acid hydrolysis for overnight (for treatment of cotton

cellulose with natural soya bean seed-based mixed amino acids) in

presence of citric acid (1/5

Pre-mordanting with Natural Potash alum (FITKARI) after bio-cationization: SB-Cotton (Soya-based bio-cationised)/Preoxidised Oxy-cotton fabrics were pre-mordanted subsequently with K-alum separately before dyeing under varying or prefixed dosages and following pre-mordanting conditions/parameters, i.e. concentrations of K-alum - 5-20% owf concentration (expressed as of, i.e. on dry weight of the solid source material), with varying one parameter and the other parameters were kept constant by mordant concentration: 10%, MLR: 1:20, pH: 9, Temperature: 70 °C and time - 60 min. After the treatment, the fabric was squeezed and dried in the air without washing to keep it ready for subsequent catechu dyeing.

Bio-finishing with Aqueous extract of eucalyptus leaves: Soya-based bio-cationised /Pre-oxidised oxy-cotton fabrics dyed with 30% aqueous extract of catechu (at optimised conditions) were further finished following a pad-dry-cure process using 10% (owf) aqua-ethanolic extracts of eucalyptus leaves as bio-finishing agents with 5gpl lemon juice as acid catalyst (1/5th the weight of the finishing agents) by pad-dry-cure method, maintaining a wet pick up of 100% and drying at 100 °C for 10 minutes, followed by curing for 3 minutes at 120 °C. Finally, the samples were cooled and dried in air.

Test methods

Measurement of colour strength and related colour interaction parameters: Colour strength (K/S) of the control and dyed cotton samples was estimated using the Kubelka Munk equation [17], and all other colour interaction parameters like total colour difference (ΔE), lightness/darkness (ΔL*), redness/ greenness (Δa*), blueness/ yellowness (Δb*), change in chroma (ΔC*), and change in hue (ΔHab), were measured following CIE-1976 formula [17] and metamerism index (MI) was calculated as per LABD equation [17]. Colour difference index (CDI) was determined by an established empirical equation [18] available in literature.

Evaluation of colour fastness to wash, light, rubbing and perspiration:

a) Wash fastness of the dyed cotton samples was assessed

by Launder o Meter by IS: 764-1984 method [19].

b) Light fastness was tested as per IS: 2454-1984 method

[19] by SDL-MBTF Microscale Fade-o-Meter;

c) Dry and wet rubbing fastness were assessed using the

IS: 766-1984 method [19] by digital crock meter.

Result and Discussion

Chemical and physical interactions for Soya-based biocationization of control /oxy cotton

On pre-treatment of cotton cellulose / preoxidised oxy-cotton, with acid hydrolysed extract of deoiled waste soyabean seeds in the presence of citric acid as catalyst, there is formation/addition of nucleophilic amino /aldimine group-based cation to cotton, incorporating acidified quarternary amino functionality in cotton to produce soya-based bio-cationized cotton (SB-Cotton). This soya-based bio-cationization of cotton, is expected to enhance the substantivity of this soya modified cationic cotton to attract anionic natural dyes, like catechu, for eco-friendly salt-free dyeing, in a cleaner and greener environment, with or without the use of K-alum (potash alum) as an additional natural metallic pre-mordant to improve its dyeability and colour fastness to washing and rubbing.

Acid hydrolyzed waste soyabean extracted amino protein based bio-cationized cotton / oxy-cotton having been incorporated with -NH3+ ( in cotton ) or -CH=NH+- ( in oxy cotton) cationic groups in bio-cationized cotton/oxy-cotton, creates an ionic attraction of anionic catechin (from catechu) dye molecules by soya-based biocationised cotton (SB-Cotton) facilitating salt free acid bath dyeing to fix the anionic catechin by forming dye fiber ionic bonds, besides the additional natural potash alum pre-mordanting on SB-cotton /SB-oxy-cotton incorporates mordantable aluminium metallic element to facilitate conventional ‘Fibre-Mordant-Dye’ complex formation amongst SB-cotton /SB-oxy -cotton -Al mordant and Polyphenolic mordantable catechin, to fix more and more polyphenolic catechin dye molecules by the coordinated complex formation too. Thus, when both types of dye fixation mechanisms co-occur (due to cationic attraction /fixation of anionic catechu dye by SB cotton and additional K-alum mordanting based coordinated covalent bond based complex formation for fixation of catechu dye molecules to SB -Cotton and SB-Oxy cotton, it gives enhanced K/S value (colour strength) and improved fastness to wash and rubbing.

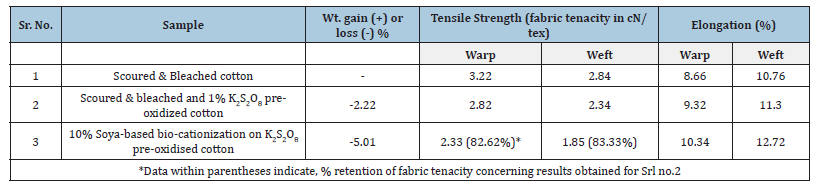

Relevant data for weight loss, treatment shrinkage, changes in fabric tenacity and breaking extension % data for the said treatments are shown in Table 2. Corresponding data from Table 2 show that pre-oxidation treatment of cotton with 1% potassium persulfate (K₂S₂O₈) resulted in a weight loss of 2.22%, showing fabric tenacity value as 2.82cN/tex in the warp direction and as 2.34cN/tex in the weft direction, along with minor increase in breaking extension values in both warp and weft directions. Whereas, subsequent soyabased bio-cationization of the pre-oxidised oxy-cotton fabric leads to a higher weight loss of 5.01%, with somewhat higher reduction in fabric tenacity, showing fabric tenacity of SB-oxy cotton as 2.33cN/tex (warp) and as 1.85cN/tex (weft), accompanied by some further increase in breaking extension values in both warp and weft directions, Vide Data in Table 2.

Table 2:Results of tensile properties of cotton fabrics before and after treatments.

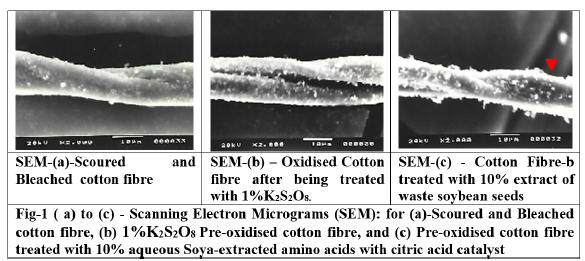

Figure 1:(a) to (c) - Scanning Electron Micrograms (SEM): for (a)-Scoured and Bleached cotton fibre, (b) 1%K₂S₂O₈ Pre-oxidised cotton fibre, and (c) Pre-oxidised cotton fibre treated with 10% aqueous Soya-extracted amino acids with citric acid catalyst.

Further, from investigation of Scanning Electron Microscopic (SEM) pictures of untreated (control-scored and bleached), K₂S₂O₈-based mild pre-oxidised and soya-based bio-cationized cotton fibres (taken out from corresponding fabrics), as shown in Figure 1a to 1c, the physical changes of their surface topology for corresponding samples are observed.

SEM micrograph-a for the control cotton fibre sample shows a clear picture of convoluted cotton fibers, which are loosened to a reasonable extent after pre-oxidation by treatment with 1%K₂S₂O₈, whereas corresponding SEM microgram-c indicates a milky white granular deposition on fiber surface after treated with 10% extract of soya based amino acids (obtained by acidic hydrolysis of soya). Partly covering up the loosened convoluted structure of cotton, with a surface deposition of amino acid moieties.

Effects of varying dyeing conditions on colour parameters for salt-free dyeing of SB-cotton with catechu

To standardise the effect of each of the dyeing conditions/ parameters on K/S value and related data on all other associated colour parameters, for dyeing of soya-based bio-cationized cotton and oxy-cotton (SB-Cotton and SB-Oxy-Cotton) for eco-friendly salt-free dyeing with anionic catechu natural dye. Thus, the role of each of the dyeing parameters for the said dyeing results under varying dyeing conditions for each dyeing variable, the observed dyeing results like colour strength value and colour differences and colour fastnesses, etc, are discussed here. Corresponding data for change in hue, chroma, metameism index and brightness index and colour difference index value, etc, for varying each of the dyeing conditions are also shown and discussed to understand the role of varying each dyeing condition.

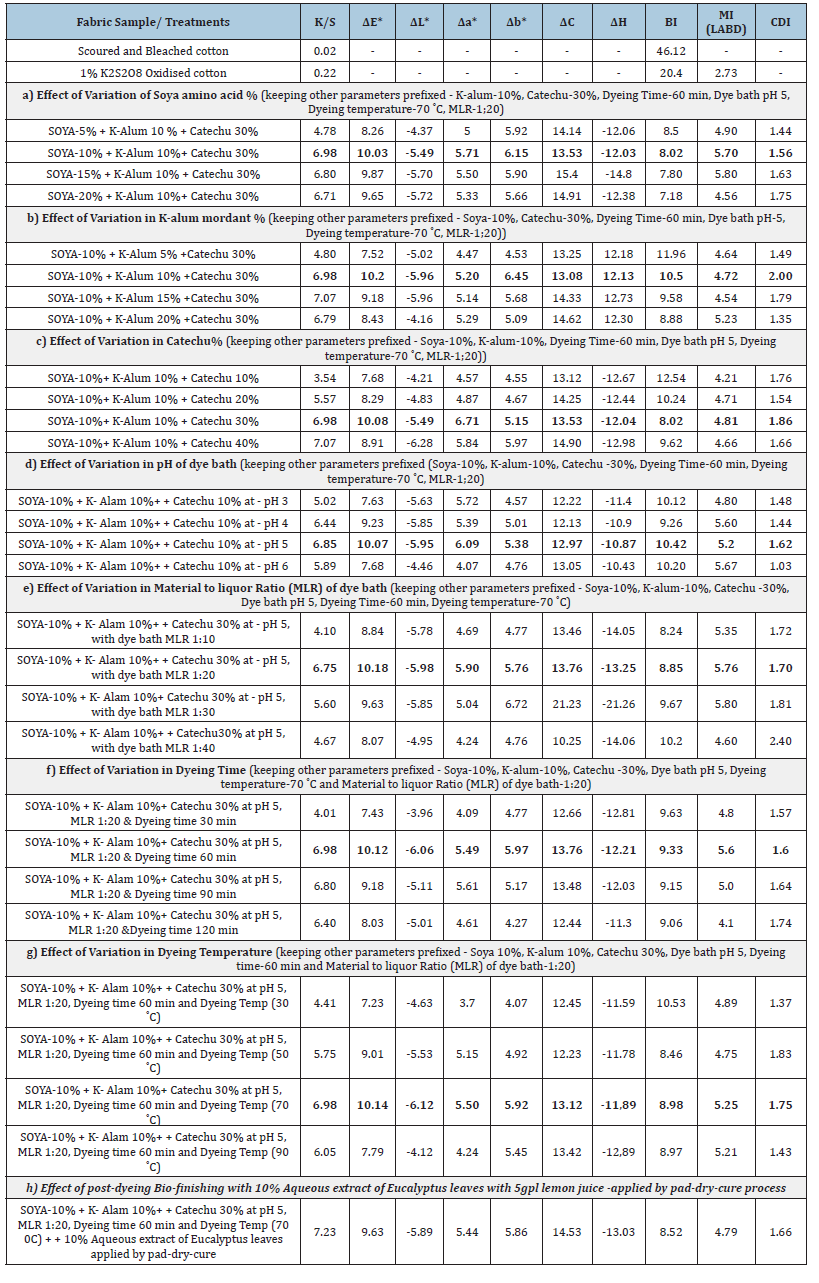

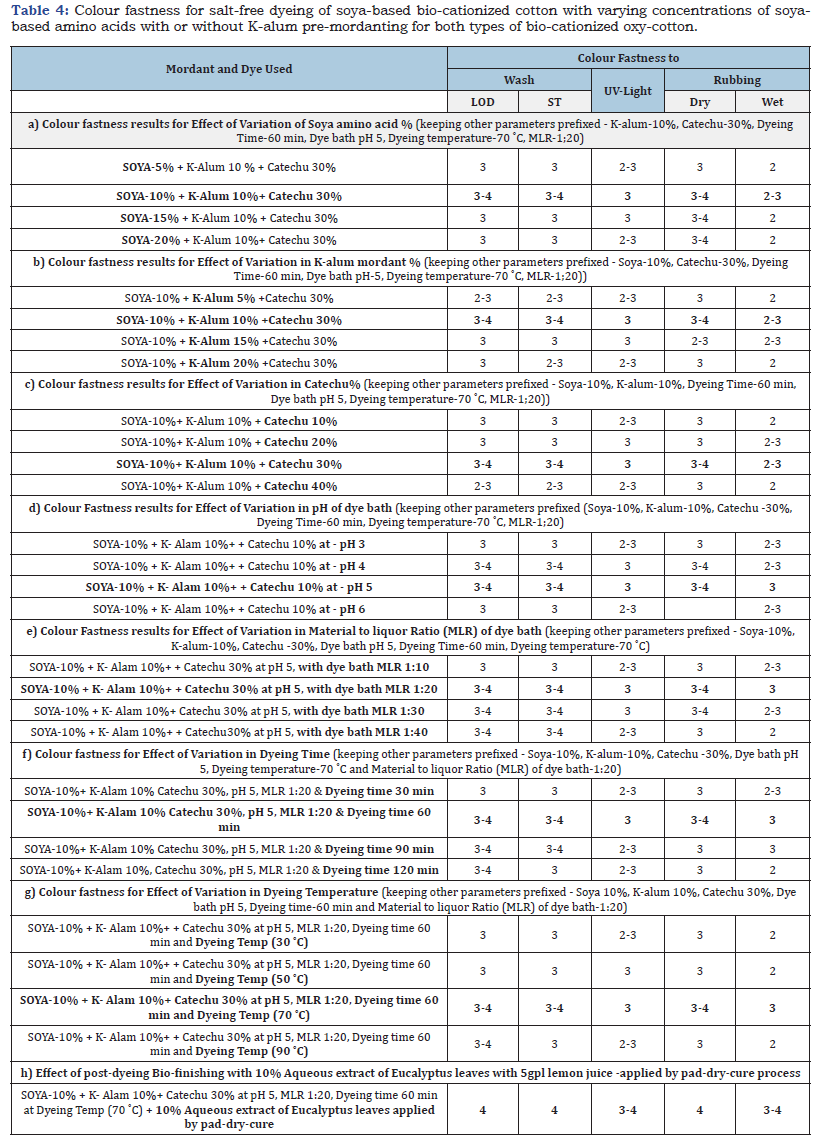

So dyeing results of the series of dyeing experiments carried out here by varying each dyeing conditions /parameters, were tabulated and shown in Table 3 and corresponding colour fastness data are shown in Table 4, for (i) varying concentrations of hydrolyzed soyabased amino acids (5,10,15 and 20%) (ii) for varying concentration of natural potash alum pre-mordant (5,10,15 and 20%), (iii) for varying concentrations of aqueous extract of catechu dye ( 10,20,30 and 40%), (iv) for varying pH of dye bath liquor (3, 4, 5 and 6), (v) for varying Material to Liquor ( MLR) (1:10, 1:20.1:30 and 1:40), (vi) For varying time of dyeing (30, 60, 90 and 120 min) and (vii) For varying temperature of dyeing (30, 50,70 and 900C), without application of any salt, to find out the optimized dyeing conditions for each dyeing parameter.

Table 3:Results of tensile properties of cotton fabrics before and after treatments.

Table 4:Results of tensile properties of cotton fabrics before and after treatments.

It is evident from the relevant data in Table 3 that there is some increase in K/S values of the dyed samples after bio-cationized with 5 to 20% soya hydrolysed-amino acids mixtures dyed with 30% catechu as natural dye under acidic pH in salt-free condition.

With an increase in dosages of soya-extracted amino acid treatment without dyeing, the color strength values are found to increase from 0.6 to 1.24 as compared to the K/S value of control pre-oxidized cotton (oxy-cotton) fabric as 0.22 ( where K/S value of only scoured and bleached control cotton fabric is 0.02 before pre-oxidation with 1% K2S2O8 ), along with gradual reduction of CDI ( Overall color difference index) and BI ( Brightness indices) values and the corresponding increase in ΔE ( Total color difference ), ΔC( chroma values) and MI ( metamerism index) values.

On subsequent salt-free dyeing at acidic pH, using 30% aqueous extract of catechu natural dye applied on the said 5-20% varying concentration of soya hydrolyzed natural amino acid treated oxycotton, the K/S values are found to further increase from 3.74 to 4.88 with some increase in ΔE and ΔC values having small increasing trend in CDI, with noticeable and reasonable decrease in BI values (Table-3).

The enhancement in K/S values, ΔE and ΔC follows the same trend, for each parameter, for varying concentration of soya Extract % for Soya-treated bio-cationized oxy-cotton fabric samples.

The normal process of natural dyeing needs a metallic salt or another mordanting or co-mordanting compound for anchoring natural colourants on cellulose or any such fibres. Hence, oxycotton fibres are also pre-mordanted with varying concentrations of natural potash alum pre-mordanting for subsequent dyeing with 30% extract of catechu, for both scoured-bleached cotton and preoxidised cotton and also for soya aminated bio-cationized cotton and consequent dyeing results are shown in the same Table 3. Relevant results indicate that with only K alum pre-mordanting up to 10% dosages, there is appreciable enhancement in K/S, ΔE, and ΔC parameters. Moreover, both the treatment of soya-based biocationization of oxy cotton and subsequent K-alum pre-mordanting with 10% potash alum showed appreciable enhancement in colour fastness to wash and rubbing too (Table 4).

10% soya aminated bio-cationized oxy-cotton and 10% K-alum pre-mordanted oxy-cotton render better results of colour fastness to wash and rubbing (Table 4), for subsequent 30% catechu natural dyeing carried out at comparable dyeing conditions. It is observed that in both cases, the K/S values and corresponding other colour parameters like ΔE and ΔC values are found to increase further and reach saturated optimum values for 10% soya treatment + 10% K-alum pre-mordanting treatment for natural dyeing SBoxy- cotton sample to dye with 30% catechu extract, showing K/S value increasing maximum up to 6.75 to 6.98. ΔE and ΔC values are increased up to 10.03 and 13.53, respectively, with CDI values obtained up to 1.56 to 1.75 (maximum) within an acceptable limit of CDI for uniform dyeing (CDI value below 5.00 is acceptable as uniform dyeing), vide data in Table 3.

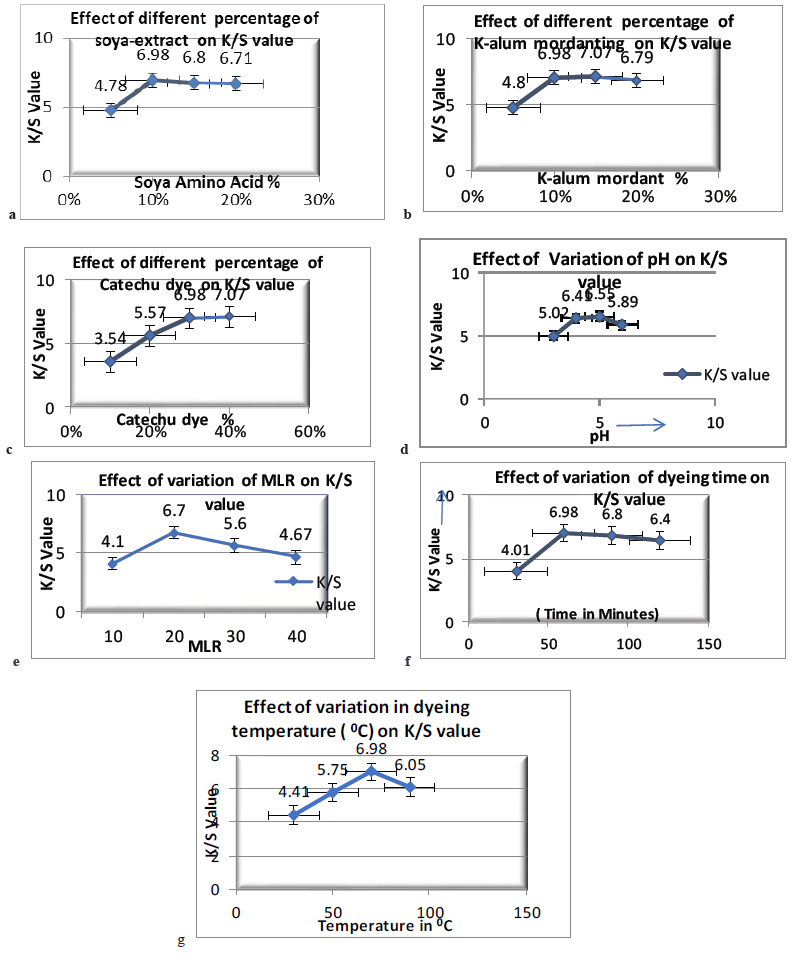

Also, the effects of varying dyeing conditions on K/S value were plotted and shown separately in Figure 2a -2g, for varying each dyeing condition one by one, keeping other conditions of dyeing as fixed, and the role of each dyeing condition on colour yield or K/S values is discussed.

Figure 2:(a) to (g): Plots for study on the Effects of variations of dyeing process parameters on K/S value for dyeing of soya-based bio-cationized cotton and oxy-cotton fabrics for dyeing with catechu natural dye. Plot-2 (a,b,c,d,e,f and g) indicating the effect of variation of concentration Soya% %, K-alum% %, concentration of dye ( catechu), dye bath pH, dye bath MLR, dyeing time and dyeing temperature for dyeing of Soya-protein modified bio-cationized cotton with K-alum natural metallic mordant for dyeing with 30% catechu extract for dyeing Soya modified + K-Alum pre-mordanted cotton fabric under varying dyeing process conditions.

Effect of varying concentrations of hydrolysed amino acids from waste soya extract

Plot 2a in Figure 2 and corresponding data in Table 3, shows that with increase in concentrations of hydrolyzed amino-acid mixture of soya as bio-cationising agent applied on cotton or oxycotton, there is an initial enhancement of K/S value of the biocationized cotton subsequently dyed with prefixed 30% extract of catechu natural dye up to 10% concentration of the soya protein based hydrolyzed amino acids (used for bio-cationization), While with an increase of concentrations of soya -extract beyond 15%, the K/S value levels off or starts decreasing. An initial increase of K/S value up to 10% soya extract is due to increased dye attraction and fixation by ionic bonding, while beyond 10% of Soya extract, i.e. at 15% and above soya extract %, the levelling off of K/S value is due to saturation effect at 10% and beyond the concentration of soya extract.

Effect of varying concentrations of natural Potash alum (K-Alum) as additional mordant

With an increase in the concentration of potash alum as an additional pre-mordanting agent, till 10-% application of K-alum pre-mordant, K/S values are found to increase, and later, it levels off or marginally decreases (plot 2b in Figure 2, and corresponding data in Table 3) beyond 10% and above the concentration of K-alum. An increase in the potash alum concentration from 5 to 10% is obvious for additional complex formation amongst Cotton /Oxy Cotton Fibre-Soya Protein amino acids-Al from potash alum -Catechu dye, till it reaches saturation. Resulting increased K/S value up to 10% K-alum addition. But use of Potash alum beyond 10% concentration or above, probably extra potash alum concentrations. Beyond 10% application of K-alum, it cannot add more complexing with catechu dye due to saturation.

Thus, K/S values of 10% soya-protein modified bio-cationized cotton are observed as the highest color yield when dyed after additional pre-mordanting with 10% Potash alum pre-mordanting (Hydrolysed Soya extract 10% + Potash Alum -10% applied in sequence respectively one by one, i, e. ( Soya + K-Alum 50: 50 or 1;1) show best-standardized dyeing results with K/S value as 6.98 with maximum ΔE (10.2) value and higher ΔC value (13.08) and ΔH as 12.13 having ΔL, Δa and Δb values as -5.96, 5.20, 6.45 respectively with metamerism index within 5 ( 4.72) and brightness index(BI) as 10.5 and CDI value up to 2.00 (Table 3).

Effect of varying concentrations of catechu as natural dye extract

Plot 2c in Figure 2 and corresponding data in Table 2, show enhancement of K/S value with the increase in the concentration of catechu dye extract % (having catechin and catechol and flavonoids are the main color components in it) till 10-30% concentrations, above which, there is no further increase in K/S values, probably due to achieving saturation and hence it almost levels off. An increase in the catechu dye concentration from 10 to 30% is obvious for the availability of more colorant molecules in the dye bath, till it reaches a saturation ionic bonding for soya-treated biocationized cotton, and complex formation amongst Cotton-K-alum and catechin dye occurs simultaneously. However, use beyond 30% of catechu dye extract, i.e. at 40% concentration or above, the extra dye concentrations beyond 30% are superficially adhered on the fibre surface by additional hydrogen bonding, which may be easily washed-out during washing and rubbing, and light fading.

Effect of varying pH in aqueous dye bath:

Plot 2d in Figure 2 and corresponding data in Table 3 show that keeping other dyeing process variables constant, for varying acidic pH 3 to 6, higher K/S values are observed at pH 4.5 to 5 for catechu natural dyeing of 10% Soya modified bio-cationized cotton with 10% potash alum pre-mordanting for dyeing with 30% catechu extract. Plot 2d in Figure 2 for pH vs K/S shows the highest K/S value of 6.85 at pH -5.0, considered here as the optimum dye bath pH. pH plays an important role in the acid bath dyeing of soya protein-based bio-cationized oxy cotton, i.e. cationic cotton, to dye it by ionic bonding with anionic catechin dye molecule.

Lesser pH than 4, i.e. at pH 3.0, due to more acidity, there is a chance of acidic degradation of cotton/bio-cationized cotton or oxy-cotton and higher acidity causes more anionization of its dye component like catechin resulting in quicker absorption of those anionic dye molecules by soya based cationized cotton /oxycotton, rendering non-uniform dyeing/ and patchy dyeing, This corroborates with an earlier finding in the case of studies for dyeing cotton with catechu extract after 10% total concentration of K-alum + Harda (50;50) double mordanted or Gallnut + K-alum dual premordanted cotton as mentioned in our earlier report published elsewhere [9] for eco-friendly dyeing .and finishing of cotton with dual-bio-mordanting for improving wellness behaviour of the wearer. .

Effect of varying MLR of aqueous dye-bath:

Plot 2e in Figure 2 and corresponding data in Table 3 indicate that initially at low materials: liquor ratio (i.e. at MLR 1:10 in exhaust bath salt-free dyeing with anionic catechin for Soya-based bio-cationized cotton and oxy-cotton, K/S values are found to be lesser than MLR value 1:20, where K/S value is observed to improve than the results obtained at MLR value 1:10. But an increase in MLR value more than 1:20, i.e. at MLR 1 30 or 1:40, K/S values get further decreased with the increase of MLR beyond 1:20. This decrease of K/S value at higher MLR beyond 1:20 may be considered an effect of dilution due to more water content in dye bath at higher MLR Thus, MLR 1;20 is considered as optimum or standardised MLR in this case.

Effect of variations in dyeing time:

Plot 2f in Figure 2 and corresponding data in Table 3 indicate that with an increase in dyeing time, K/S values are found to increase initially till 60 min, where they show the highest K/S value reaching maximum colour depth, before achieving saturation. However, with a further increase in dyeing time, K/S values start to slowly diminish. Maximum K/S values are observed for a dyeing time of 60 min, considered as optimum, in this case, to complete saturation of dye absorption and diffusion, within 60 minutes only. However, the decrease of K/S values for the use of higher dyeing time, more than 60 min, is considered as the effect of partial desorption of the weakly fixed/ H-bonded dye particles from the surface of the dyed fibre, due to longer dyeing time of dyeing at the said dyeing temperature causing breaking of hydrogen bonds/desorption of loosely fixed dyes.

Effect of varying the temperature of dyeing:

Plot 2g in Figure 2 and corresponding data in Table 3 show that with an increase in the temperature of dyeing, K/S value is observed to increase up to a certain limit until the requisite activation energy is achieved to complete the dyeing reactions involved, The observed initial increase in K/S values for dyeing temperature from 40 °C - 70 °C may be due to the effect of increasing the dye transportation rate /strike rate, promoting dye absorption rate with the increase of the dyeing temperature until activation energy of dyeing by fixation of dye molecules to the soya based bio cationized cotton occur completing the saturation of dye absorption leading to reach dyeing equilibrium.

But with further increase of dyeing temperature beyond 70 °C, K/S values are observed to reduce noticeably (plot-2g in Figure 2), due to possible thermal degradation of the smallest colour component of low molecular weight in catechu, known as catechol (red), a minor color component of catechu is susceptible to degrade above 72.9 °C, as evident from our earlier study of DSC of pure catechu reported elsewhere.

Ultimately, summary of each elsewhere: [20]. of the sustainable salt free dyeing conditions for catechu dyeing of soya based biocationized cotton are standardized one by one for determining the optimum dyeing conditions as follows: (i) waste soyabean seed extracted mixed amino acid concentration 10% (owf), (ii) K-alum Concentration: 10% (owf), (iii) Catechu dye concentration: 30% ( based on the oven-dry mass of catechu powder), (iv) Dyeing pH 5, (v) material: liquor ratio: 1: 20, (vi) Time of dyeing 60 min (vii) Temperature of dyeing 70 °C without use of any salt., which renders good dyeing results with maximum possible colour strength and overall moderate to good colour fastness.

Effects of bo-cationization of oxy-cotton with soybeanbased amino acids on colour fastness for salt-free dyeing with catechu with or without Potash alum Premordanting

On comparison of colour fastness to soap-wash, rubbing, and sunlight (UV-light) exposure, as shown in Table 4, for soya aminated bio-cationized oxy-cotton on subsequent dyeing with 30% catechu extract at optimised dyeing conditions for salt-free dyeing with catechu at acidic pH. But the corresponding same colour fastness properties are found to be ½ to 1 grade higher, showing overall moderate colour fastness results for only K-Alum or only Soya hydrolysed amino acid treated bio-cationized cotton, and also for combined soya hydrolysed amino acids + K-alum treated oxy-cotton on subsequent dyeing with 30% catechu extract at comparable and same conditions of salt-free dyeing with 30% Catechu.

Both variations of catechu dye % and the addition of varied concentrations of natural potash alum for pre-mordanting before dyeing on both types of bio-cationized oxy-cotton fabrics have noticeable influences on the results of colour interaction parameters and fastness of colour. Amongst the two types of biocationizing agents used, 10% soya aminated bio-cationized oxycotton subsequently pre-mordanted with 10% K-alum renders higher K/S values (Table 3) and moderate to good overall color fastness results for washing (Table 4) for salt-free catechu dyeing at acidic pH, indicating the higher amount and better colorant binding of catechu dye molecules due to higher degree of ionic bonding between soya aminated bio-cationized oxy-cotton and anionic catechu dye, with more and more complex formation amongst [SBbio cationised oxy cotton -K-alum mordant -catechu dye] for fixing catechu dye on soya aminated bio-cationised cotton/oxy-cotton fiber with K-Alum pre mordanting.

Catechu dyeing after soya based bio cationization, with K-alum natural metallic pre-mordanting, renders darker shades with acceptable good wash fastness enabling it to attract more anionic catechu dye with the additional incorporation of aluminum ions in bio-cationized fiber after it absorbs catechu dye besides intensified attraction of anionic catechu dye molecules, where additionally K-alum mordant helps to form (Fibre-M -Dye ) larger complex, rendering a noticeable ½ to 1-grade improvement in the color fastness to washing for catechu dyeing on soya protein hydrolyzed based bio cationized cotton / oxy-cotton with subsequent application of K-alum pre-mordant for dyeing of bio-cationized oxycotton or cotton with catechu dye component Table -3.

Conclusion

The present study concludes that 10% soya-based biocationized oxy-cotton fabric could be effectively dyed by ecofriendly salt-free dyeing in acidic pH with 30% aqueous extract of anionic catechu dye using potash alum as additional pre-mordant, achieving high colour yield and overall good colour fastness to wash and rubbing to achieve colour strength (K/S) up to 6.75 to 6.98 with corresponding ΔE value around 10.12 with ½ to 1 grade improvement of wash and rubbing fastness.

Standardisation of the dyeing conditions ensures optimum dyeing conditions for salt-free, sustainable, and eco-friendly dyeing of catechu (catechin) for soya-modified bio-cationized cotton/ oxy-cotton, using a standardised ready recipe and conditions to implement/adopt this process easily in industry.

Sandardized optimum dyeing conditions for acid bath saltfree sustainable eco-friendly dyeing of catechu (catechin) for soya-modified bio-cationized cotton /oxy-cotton are 10% (owf) Concentration of soya extract pre-treatment for bio cationization, with 10% (owf) concentration of potash alum for subsequent premordanting of soya based bio-cationized cotton /oxy-cotton and 30% (owf ) optimum concentration of catechu dye (on basis of ovendry mass of dried dye source materials), with optimum material: liquor (MLR) is 1:20, optimum pH 5, optimum temperature of dyeing 70 °C, and optimum time of dyeing 60 min, without the use of any salt for acid bath dyeing of soya based bio-cationized cotton/ oxy cotton fabrics with natural K-alum pre-mordanting without any salt.

Further application of 10% eucalyptus leaf extract bio-finish on catechu dyed soya-based bio-cationised oxy-cotton fabrics cannot enhance colour strength much, but improves the light fastness, and wash fastness noticeably.

References

- Samanta AK (2020) Bio-dyes, bio-mordants, and bio-finishes: Scientific analysis for their application on textiles. In: Samanta AK et al. (Ed.), Chemistry and Technology of Natural and Synthetic Dyes and Pigments, Tech Open publisher, London, UK, 1: 3-39.

- Chattopadhyay DP (2001) Cationization of cotton for low salt or salt-free dyeing. Indian J Fibre Text Res 26(1): 108-115.

- Datta M, Konar A, Samanta AK, Datta S (2014) Natural dyeing of jute fabric with Catechu. Int J Appl Eng Res 9(4): 451-467.

- Pubalina S, Mukhopadhyay A, Konar A (2024) Development of naturally coloured cotton fabric based bio-medical textiles for human wellness behaviour using chitosan, catechu and eucalyptus leaves as natural bio-chemical agents. African Journal of Bio-Medical Research 27(4s): 12870-12885.

- Samant L, Jose S, Rose NM, Shakyawar DB (2022) Antimicrobial and UV protection properties of cotton fabric using enzymatic pretreatment and dyeing with Acacia Catechu. J Nat Fibres 19(6): 2243-2253.

- Shahid M, Mohammad F, Shahid-ul-Islam (2013) Recent advancements in natural dye applications: A review. Journal of Cleaner Production 53: 310-331.

- Vankar PS, Tiwari V, Shankar R (2002) Commercial dyeing with aqueous extract of Acacia catechu (Katha) using eco-friendly mordants. Asian Textile Journal 11(9): 60-61.

- Klaichoi C, Mongkholrattanasit R, Sarikanon C, Intajak P, Saleeyongpuay W (2012) Eco-Friendly printing of cotton fabric using natural dye from acacia catechu weld. In: The book of paper RMUTP International Conference: Textiles & Fashion, Bangkok, Thailand, pp: 1-5.

- Pubalina S, Mukhopadhyay A, Konar A (2024) Eco-friendly dyeing and finishing, for improving colour fastness and wellness properties of cotton. In: Gupta D, Majumdar A, Gupta S (Eds.), Functional Textiles and Clothing, ICFTC 2023, Springer Proceedings in Materials, 42: 113-146.

- Sinnur HD, Samanta AK, Kar TR, Kaware R, Bhagwat MM (2026) Salt-free reactive dyeing of cotton khadi fabric by cationizing with different types of cationizing compounds. Indian Journal of Natural Fibres 3(1): 81-102.

- Samanta AK, Kar TR, Mukhopadhyay A, Shome D, Konar A (2015) Studies on dyeing process variables for salt-free reactive dyeing of glycine (amino acid) modified cationized cotton muslin fabric. Journal of Institution of Engineers (India)-Series-E, Chemical & Textile Engg 96(1): 31-44.

- Bhoumick NS, Samanta AK, Konar AK, Ray AN (2016) Studies on dyeing Process variables and colour interaction parameters for application of direct dyes on jute. Indian Journal of Natural Fibres3(1):1-10.

- Samanta AK, Bhaumik NS, Shome D, Roy AN, Konar A (2015) Studies on reactive dyeing of natural amino acid modified cationized jute fabric: Colour interaction parameters and colour fastness properties. Journal of Materials ASSCIT, USA, 1(4): 89-97.

- Konar A, Samanta AK, and Mukherjee S (2014) Effects of amino-acid modification of jute fabric on its textile-related properties and dyeability with selective reactive dyes. Int Rev Appl Eng Res 4: 45-61.

- Konar A, Samanta AK, Mukherjee S (2014) Salt-free reactive dyeing of amino-acid modified jute. Indian J Nat Fibre 1: 15-28.

- Daberao AM, Gupta K, Jain MM (2021) Effect of process (Desizing, Scouring and Bleaching) chemicals on the properties of the fabrics used (Cotton and Viscose) during Pre-Treatment. J Fashion Technol Textile Eng 9(3): 1-8.

- Shah HS, Gandhi RS (1990) Instrumental colour measurements and computer-aided colour matching for textiles. Mahajan Book Distributors. Ahmedabad, India, pp: 76-116.

- Samanta AK, Agarwal P, Singhee D, Dutta S (2009) Application of single and mixtures of red sandalwood and other natural dyes for dyeing of jute fabric: Studies on colour parameters/colour fastness and compatibility. J Text Inst 100(7): 565-587.

- (1986) Handbook of Textile Testing, BIS, (1st edn), 1982; rev edn], Bureau of Indian Standards, New Delhi, India.

- Pubalina S, Asis M, Adwaita K (2025) Standardization of dyeing conditions of gallnut and k-alum dual bio-mordanted cotton fabric using catechu natural dye and evaluation of its antimicrobial and UV resistance properties. J of Institution of Engineers, Series-E, Springer-Nature, pp: 1-22.

© 2025 Pubalina Samanta. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)