- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Recent Advances and Development Trends of Multi Core Fiber Based Shape Sensing Technologies

Rui WU, Weiping CHEN, Bo Zhang, Wei GAO, Yabin PI, Zhenggang LIAN*

Yangtze Optical Electronic Co. Ltd., Wuhan 430205, China

*Corresponding author:Zhenggang Lian, Yangtze Optical Electronic Co. Ltd., Wuhan 430205, China

Submission: October 16, 2025;Published: October 30, 2025

ISSN 2578-0271 Volume11 Issue 2

Abstract

Multi core fiber (MCF)-based shape sensing has emerged as a promising technology for real time, three dimensional reconstruction of complex structures. By integrating multiple light guiding cores within a single cladding, MCF sensors enable simultaneous measurement of curvature, twist, and strain, providing superior spatial resolution and robustness compared with traditional single core configurations. This review summarizes recent progress in MCF design, interrogation techniques, and reconstruction algorithms, and discusses current challenges and future development trends toward high precision, miniaturized, and intelligent sensing systems for medical, robotic, and structural applications.

Keywords:Multi core fiber; Shape sensing; Distributed sensing; Curvature sensing

Introduction

Shape sensing has become a key enabling technology in minimally invasive surgery, soft robotics, and structural health monitoring [1-6]. Traditional reconstruction methodsincluding fiber Bragg gratings (FBGs) or interferometric arrays-often face limitations in spatial continuity, cost, wiring complexity, and susceptibility to environmental fluctuations [7-9].

Multi core fiber (MCF) embeds several light guiding cores symmetrically within a single cladding. Each core experiences a distinct strain profile during bending or twisting, allowing determination of local curvature and torsion via differential phase or wavelength measurements [10-12]. Over the past decade, MCF based shape sensors have evolved rapidly, offering compact, flexible, and sensitive alternatives to conventional strain networks.

Principles of multi core fiber shape sensing

The basic principle relies on detecting optical path length changes among multiple

cores. When the fiber bends, the outer cores undergo different elongations or compressions,

producing measurable phase shifts or spectral changes [13]. Common interrogation

techniques include:

Rayleigh based Optical Frequency Domain Reflectometry (OFDR), enabling distributed

strain and curvature reconstruction with sub millimeter spatial resolution [14,15]; FBG

array-based methods for localized sensing but with discrete sampling [16]; Brillouin based

systems, which offer temperature insensitive strain and twist measurement [17]. Geometric

algorithms estimate curvature vectors along the fiber and integrate them to recover the global

3D shape.

Recent progress and representative advances Fiber structure and materials

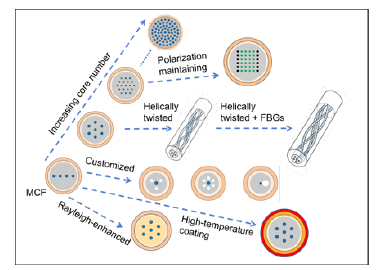

Advances in fiber drawing have produced seven core, nineteen core [18], and helically twisted MCFs with continuous Bragg gratings [19], improving torsion resolution and cross sensitivity discrimination. Some designs introduce polarization maintaining (PM) cores [20] or tailored dopant distributions for temperature stability (Figure 1).

Figure 1: Recent trending research areas in multi-core fiber development.

Interrogation systems

Optical frequency domain reflectometry (OFDR) is now a major tool for high resolution distributed shape sensing, enabling simultaneous curvature and twist retrieval; FPGA based processing reduces latency for real time monitoring [21].

Reconstruction algorithms

Machine learning assisted calibration and Kalman filter based dynamic tracking improve accuracy under complex deformations. Hybrid approaches that combine physical models with data driven priors provide noise suppression and better generalization [22].

Application demonstrations

Medical: MCF sensors integrated into catheters and guidewires enable accurate 3D tracking in minimally invasive procedures [23].

Soft robotics: Embedding MCFs in continuum robots enables self sensing feedback for closed loop control [24,25].

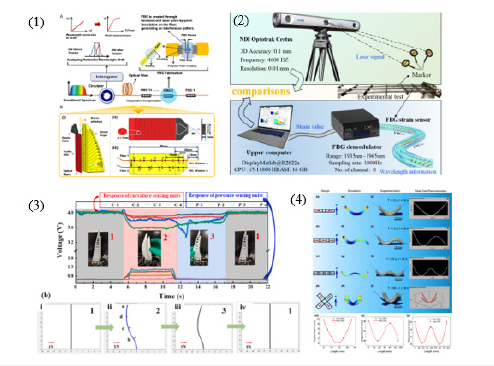

Structural monitoring: Large scale MCF networks monitor deformation in aerospace and flexible structures [26] (Figure 2).

Figure 2:(1) Sensing system and structure of the biomimetic soft finger [24]. (2) Experimental verification system of discontinuous deformation monitoring of smart aerospace structure [26]. (3) Response of the electronic skin [27]. (4) Complex deformation and shape reconstruction in magnetic structures [25].

Challenges and future trends

Despite rapid progress, several challenges remain before multi-core fiber (MCF) shape sensing can achieve large-scale applications. Temperature-induced cross-sensitivity must be mitigated through hybrid sensing schemes or optimized core geometry. Accurate system calibration is equally essential, as even minor geometric deviations among cores can accumulate into significant reconstruction errors. Robust fan-in/fan-out packaging and seamless integration are required for long-term reliability, while the massive data volume from distributed interrogation calls for efficient compression and intelligent analysis algorithms [10,27-30].

Recent research trends also emphasize Rayleigh scattering enhancement through controlled core doping or artificial scattering centers, which can improve signal-to-noise ratio and spatial resolution in OFDR-based sensing. In parallel, the development of high-temperature-resistant coatings and protective buffer layers is vital for ensuring environmental adaptability, enabling stable performance under harsh or thermally dynamic conditions.

Future directions include: (i) integration with silicon photonics for compact modules; (ii) AI based real time 3D reconstruction; (iii) specialty fibers that combine sensing and actuation; and (iv) further miniaturization for endoscopic and robotic deployment.

Conclusion

The development of MCF-based shape sensing signifies a transformative stage in modern fiber-optic sensing. Advances in fiber design, interrogation architecture, and algorithmic modelling are collectively driving improvements in accuracy, compactness, and intelligence, reinforcing its potential for integration into nextgeneration medical, robotic, and structural sensing platforms.

References

- Zijuan LIU, Yongqian LI, Lixin Z, Haijun FN (2022) Research on the development of shape sensing based on optical fiber sensing. LASER Technol 46(6): 760-766.

- Lu Y, Lu B, Li B, Guo H, Liu Y (2021) Robust three-dimensional shape sensing for flexible endoscopic surgery using multi-core FBG sensors. IEEE Robot and Autom Lett 6(3): 4835-4842.

- Monsberger CM, Lienhart W (2021) Distributed fiber optic shape sensing of concrete structures. Sensors 21(18): 6098.

- Floris I, Adam JM, Calderón PA, Sales S (2021) Fiber optic shape sensors: A comprehensive review. Opt Lasers Eng 139(2021): 106508.

- Tian Y, Dang H, Liu W, Cui J, Li Y (2023) Structure shape measurement method based on an optical fiber shape sensor. Meas Sci Technol 34: 085102.

- Moore JP, Rogge MD (2012) Shape sensing using multi-core fiber optic cable and parametric curve solutions. Opt Express 20(3): 2967-2973.

- Theodosiou A (2024) Recent advances in fiber bragg grating sensing. Sensors 24(2): 532.

- Yassin MH, Farhat MH, Soleimanpour R, Nahas M (2024) Fiber Bragg grating (FBG)-based sensors: A review of technology and recent applications in structural health monitoring (SHM) of civil engineering structures. Discover Civil Engineering Vol. 1.

- Kok SP, Go YL, Wang X, Dennis Wong ML (2025) Advances in Fiber Bragg Grating (FBG) Sensing: A review of conventional and new approaches and novel sensing materials in harsh and emerging industrial sensing. IEEE Sensors Journal 24(19).

- Chen W, Yuan L, Zhang B, Yu Q, Lian Z, et al. (2024) Applications and development of multi-core optical fibers. Photonics 11(3): 270.

- Zhao Z, Dang Y, Tang M (2022) Advances in multicore fiber grating sensors. Photonics 9(6): 381.

- Yao Y, Zhao Z, Tang M (2023) Advances in multicore fiber interferometric sensors. Sensors 23(73): 3436.

- Duncan RG, Froggatt ME, Kreger ST, Seeley RJ, Gifford DK, et al. (2007) High-accuracy fiber-optic shape sensing. In: Sens Syst Netw Phenom Technol Appl NDE Health Monit 2007, SPIE, 2007, pp. 487-497.

- Ito F, Fan X, Koshikiya Y (2012) Long-range coherent OFDR with light source phase noise compensation. J Lightwave Technol 30(8): 1015-1024.

- Wegmuller M, von der Weid J, Oberson P, Gisin N (2000) High resolution fibre distributed measurements with coherent OFDR. High Resolution Fiber Distributed Measurements With Coherent OFDR.

- Lunwei Z, Jinwu Q, Linyong S, Yanan Z (2004) FBG sensor devices for spatial shape detection of intelligent colonoscope. In: IEEE Int Conf Robot Autom 2004 Proc. ICRA 04 2004, pp. 834-840.

- Ba D, Chen C, Fu C, Zhang D, Lu Z, et al. (2018) A high-performance and temperature-insensitive shape sensor based on DPP-BOTDA. IEEE Photonics J 10(1): 1-10.

- Matsuno Y, Sugizaki R, Takahashi M (2025) Uncoupled 19-core multicore fiber with highest core density by homogenous cores. J Light Technol 43(15): 7344-7350.

- Fu C, Xiao S, Meng Y, Shan R, Liang W, et al. (2024) OFDR shape sensor based on a femtosecond-laser-inscribed weak fiber Bragg grating array in a multicore fiber. Opt Lett 49(5): 1273-1276.

- Khalil Y, Grimm M, Klenke A, Bahri M, Jauregui C, et al. (2024) 35 core polarization-maintaining multi-core fiber for high power operation. EPJ Web Conf 307: 02052.

- Wang H, Zhai T, Wang Y, Liu Y, Zhou R, et al. (2024) Real-time sensing approach for optical frequency domain reflectometry using an FPGA-based high-speed demodulation algorithm. Opt Express 32(19): 33247-33261.

- Manavi Roodsari S, Freund S, Angelmahr M, Seppi C, Rauter G, et al. (2024) Deep learning-based approach for high spatial resolution fibre shape sensing. Commun Eng 3: 19.

- Park J, Seo B, Jeong Y, Park I (2024) A review of recent advancements in sensor-integrated medical tools. Adv Sci 11(20): 2307427.

- Mao B, Zhou K, Xiang Y, Zhang Y, Yuan Q, et al. (2024) A bioinspired robotic finger for multimodal tactile sensing powered by fiber optic sensors. Adv Intell Syst 6(8): 2400175.

- Han W, Gao W, Wang X (2024) Enhanced magnetic soft robotics: Integrating fiber optics and 3D printing for rapid actuation and precision sensing. ACS Appl Mater Interfaces 16(23): 30396-30407.

- Chen K, Fan H, Bao H (2024) Discontinuous deformation monitoring of smart aerospace structures based on hybrid reconstruction strategy and fiber bragg grating. Sensors 24(11): 3603.

- Meng X, Tang H, Lü X, Shi Y, Bao W (2024) Electronic skin with shape sensing and Bending-Insensitive pressure sensing for soft robotic grippers object recognition. Measurement 234: 114819.

- Meng Y, Sui R, Liang W, Zhong H, Shan R, et al. (2024) Multicore fiber shape sensing based on optical frequency domain reflectometry parallel measurements. J Light Technol 42(10): 3909-3917.

- Yang C, Wang Z, Xiao K, Ushakov N, Kumar S, et al. (2024) Portable optical fiber biosensors integrated with smartphone: technologies, applications, and challenges [Invited]. Biomed Opt Express 15(3): 1630-1650.

- Zou Y, Ren Z, Xiang Y, Guo H, Yang GZ, et al. (2024) Flexible fiberbotic laser scalpels: Material and fabrication challenges. Matter 7(3): 758-771.

© 2025 Zhenggang Lian. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)