- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

ERP in Indian Textile Industry

Saminathan R*

Associate Professor, Department of Textile Technology, Kumaraguru College of Technology, Coimbatore India

*Corresponding author:Saminathan R, Associate Professor, Department of Textile Technology, Kumaraguru College of Technology, Coimbatore India

Submission: September 11, 2025;Published: October 15, 2025

ISSN 2578-0271 Volume11 Issue 2

Abstract

The textile industry in India is second only to agriculture in terms of employment, economy and is closely related to its history and culture. The modern facet is updated with latest technology and software. This article reveals how ERP (Enterprise Resource Planning) is changing how the industry functions. The reader is made aware of key components of the program, its requirements, benefits and challenges.

Keywords:ERP; Customization; Textile applications; Benefits; Challenges

Introduction

The Indian textile industry is one of the oldest and most significant sectors of the economy, contributing around 2% to India’s GDP, 12% to industrial production, and nearly 10% to total export earnings. It employs more than 45 million people directly, making it the second-largest source of employment after agriculture. Despite its strengths, the industry faces challenges including global competition, fluctuating raw material costs, complex supply chains, and rising sustainability demands. ERP (Enterprise Resource Planning) systems have emerged as a solution to address these challenges by integrating all business processes into a unified system [1-4].

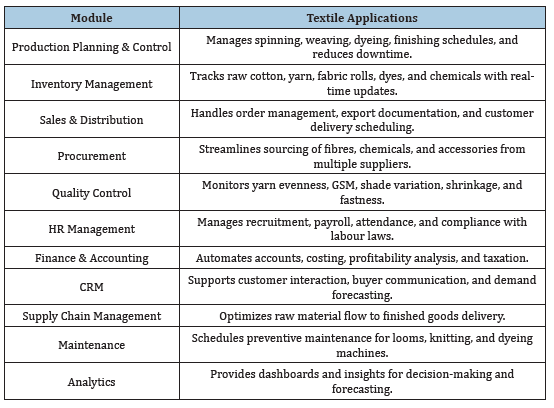

ERP is a set of generic software modules where each module can function by itself or in conjunction with other modules. The various modules and their applications are outlined in Table 1.

Table 1:ERP modules and application areas.

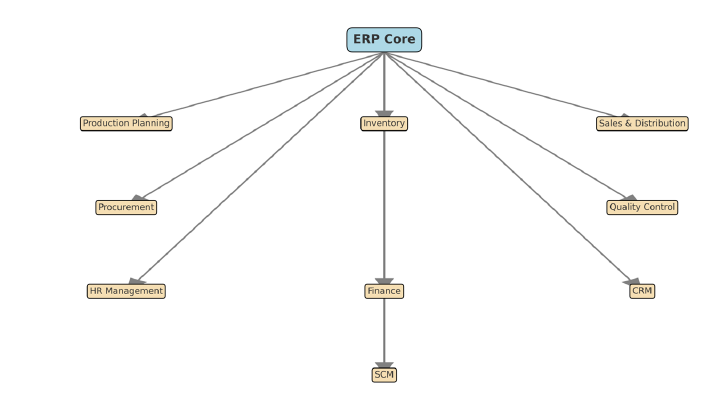

This interconnection is depiced in Figure 1. It is clear that ERP can be integrated into almost any aspect of the industry.

Figure 1: Integration of ERP in diverse areas.

Customizability

ERP is adaptable to the section of usage and this would include:

• Area-specific modules for spinning, dyeing, or garmenting.

• Scalability for SMEs and large integrated firms.

• Integration with legacy systems (payroll/accounting).

• Local language support and user-friendly dashboards.

This flexibility allows widespread use of ERP solutions to tackle the myriad issues of textile manufacturing. Further the modules can interconnect to present management with a holistic view of the status of the organization and take informed decisions [5].

Requirements

ERP implementation requires technological, organizational,

and human resource readiness:

• Technological: Servers, cloud solutions, secure

networking.

• Organizational: Leadership commitment, standardized

processes.

• Human Resources: Training programs, ERP teams,

consultants.

The overall investment could be significant at the beginning. Hence, a careful analysis of cost and benefitsneeds to be undertaken before starting. Additionally, long term management commitment is needed for successful ERP implementation [6].

Benefits and Challenges Benefits

ERP offers several benefits to Indian textile enterprises:

• Enhanced operational efficiency through automation.

• Real-time inventory optimization and reduced wastage.

• Cost reduction through accurate costing and budgeting.

• Improved quality assurance and reduced customer

complaints.

• Better decision-making with analytics dashboards.

• Regulatory compliance and easier audits.

Challenges

Challenges faced in ERP adoption include:

• High initial investment costs.

• Complex implementation due to diverse processes.

• Employee resistance to workflow changes and a steep

learning curve.

• Risk of over-customization.

• Data migration and downtime risks.

• Skill gaps in using advanced ERP features.

Conclusion

The Indian textile industry stands to gain significantly from ERP adoption. ERP ensures integration, visibility, cost reduction, and compliance, making it a strategic enabler of growth. Despite challenges such as cost, complexity, and resistance, ERP adoption is increasingly becoming essential for competitiveness and sustainability. Looking ahead, ERP in India is evolving with AI, IoT, and blockchain, further enhancing predictive capabilities and supply chain transparency.

References

- Devaraja TS (2011) Indian textile and garment industry-An overview. Department of Commerce Post Graduate Centre University of Mysore, Hassan, India.

- Kumar RS (2018) Indian textile industry: opportunities, challenges and suggestions. International Journal of Trade and Global Business Perspectives 7(02): 189-193.

- Prakash Y, Charwak B, Kumar PV (2020) Textile industry in new India: challenges and opportunities. International Journal of Indian Culture and Business Management 21(4): 435-458.

- Kar M (2012) National and global aspects of India’s textiles and apparel industry and trade: an overview. South Asian Journal of Macroeconomics and Public Finance 1(1): 81-133.

- Rambola R, Jatkar M (2018) An effective synchronization of ERP in textile industries. In: 2018 Second International Conference on Electronics, Communication and Aerospace Technology (ICECA) pp: 969-973.

- Singh A (2016) Using Information Technology to Enhance Industry Effectiveness: The ERP software for textile industry.

© 2025 Saminathan R. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)