- Submissions

Full Text

Strategies in Accounting and Management

Ergonomic and Chemical Risks in Ecuadorian Floriculture Production

Mario Paguay García*

Department of Production, Universidad Técnica Particular de Loja, Ecuador

*Corresponding author:Mario Paguay García, Department of Production, Universidad Técnica Particular de Loja, Loja 1101608, Ecuador

Submission:November 13, 2025;Published: December 08, 2025

ISSN:2770-6648Volume5 Issue 5

Abstract

This report analyzes ergonomic and chemical risks in the flower production process at a company located in Quito, Ecuador. Using the methodology of the National Institute for Occupational Safety and Health (INSST, Spain), the main hazards associated with awkward postures, repetitive movements, and handling of chemical products were identified. The results highlight the need to strengthen preventive management and redesign tasks to improve worker well-being and productivity. This case represents an example of how the application of structured methodologies can reduce occupational risks in the floriculture sector, a key industry for the Ecuadorian economy.

Keywords:Industrial safety; Ergonomics; Floriculture; Occupational risks; Ecuador

Introduction

The floriculture sector is one of the pillars of the Ecuadorian economy, generating rural employment and contributing significantly to exports (ProEcuador 2023). However, this sector faces high levels of exposure to occupational risks arising from the use of agrochemicals, manual handling of loads, and inadequate postures during prolonged work shifts [1]. This report presents an applied analysis of occupational risk management in the floriculture sector, using the methodology of the National Institute for Occupational Safety and Health (INSST) to identify, assess, and propose corrective measures in the sowing, harvesting, and packing processes, with the aim of strengthening occupational safety and health conditions for workers. The International Labour Organization (ILO Homepage | International Labour Organization, n.d.) [2] notes that, worldwide, occupational diseases and accidents represent one of the main causes of loss of productivity and well-being, especially in agricultural and manufacturing activities. From this perspective, the present case study constitutes a significant contribution to the field of occupational safety and health, since it provides practical evidence on the application of preventive methodologies and their effectiveness in reducing ergonomic and chemical risks, thereby supporting decision-making in similar production environments within the Ecuadorian agricultural sector.

Methodology

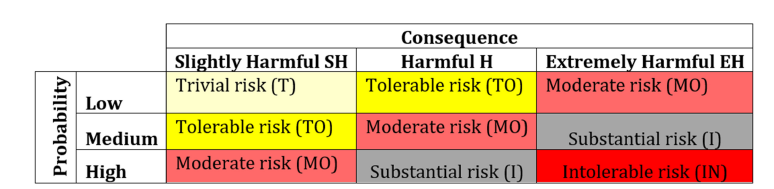

A descriptive study with a mixed-methods approach was carried out, based on direct observation, interviews, and risk assessment according to the INSST methodology (National Institute for Occupational Safety and Health) [3] Four areas were analyzed: administration, sowing, harvesting, and packing. The assessment considered the probability of occurrence and the severity of harm (Figure 1) to establish a risk level. Priority was given to those risks classified as “intolerable” or “important.”

Figure 1:Assessment matrix considering probability of occurrence and severity of harm (INSST).

Results

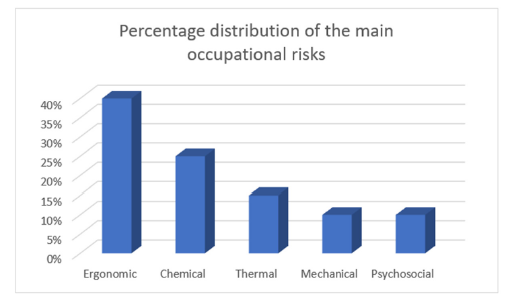

The most critical risks were identified in the operational areas

(Figure 2):

A. Ergonomic risks: Awkward postures and repetitive

movements with a risk rating of “intolerable,” associated with

cutting, collecting, and packing flowers.

B. Chemical risks: Exposure to pesticides and fertilizers

during sowing, exacerbated by deficient use of Personal

Protective Equipment (PPE).

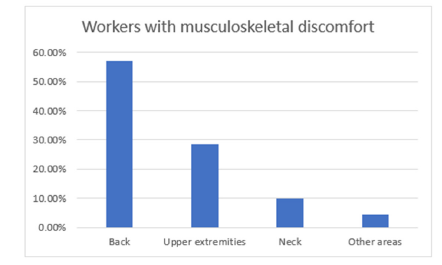

C. Thermal risks: High temperatures inside greenhouses with

limited natural ventilation. Seventy percent of workers reported

musculoskeletal discomfort, particularly in the back and upper

extremities (Figure 3), consistent with what is reported by the

(ILO Homepage | International Labour Organization, n.d.) [2]

regarding ergonomically-related diseases in agricultural work.

Figure 2:Critical risks identified in the production process.

Figure 3:Musculoskeletal discomfort reported by workers.

Discussion

The combined exposure to ergonomic and chemical factors demonstrates the need for a comprehensive preventive approach in the Ecuadorian floriculture sector. Applied ergonomics can reduce occupational injuries by up to 40% and increase productivity by 15% [4]. The Esperancita case shows that small floriculture enterprises, lacking specialized personnel in industrial safety, require technical assistance to implement occupational safety and health management systems in line with Executive Decree 255 [5]. Likewise, task redesign, job rotation, and active breaks are low-cost, high-impact measures to mitigate the effects of repetitive effort and awkward postures [6].

Conclusion

The study confirms that ergonomic and chemical risks are the most relevant in floriculture production. It is recommended to prioritize preventive ergonomics, ongoing training in the use of PPE, and technical control of chemical exposure. The application of the INSST methodology enables systematic assessment that contributes to continuous improvement in the safety and health of workers in this sector. The case also demonstrates the usefulness of combining quantitative risk assessment tools (such as the INSST matrix) with qualitative information obtained through worker interviews, allowing a more comprehensive understanding of the real working conditions and the perception of risk in floriculture activities. Finally, this experience highlights the need for public policies and sectoral programs that specifically address occupational risks in floriculture, promoting incentives for the implementation of occupational health and safety management systems in small and medium-sized enterprises in the agricultural sector in Ecuador.

References

- González A, Bonilla-Santos J, Quintero M, Reyes C, Chavarro A (2016) Analysis of the causes and consequences of accidents occurring in two construction projects. Construction Engineering Magazine 31(1): 5-16.

- ILO homepage (2025) International Labour Organization. (n.d.).

- (2023) National institute for occupational safety and health - INSST. (n.d.).

- Carrasco J, Irene A, Asqui L, Estatal U, Guaranda -Ecuador M, et al. (2023) Ergonomic risks and their influence on work performance. LATAM Latin American Journal of Social Sciences and Humanities 4(2): 3294-3306.

- Decree 255 May 2024: Occupational Health and Safety Regulations. (n.d.).

- Reátegui-Inga ME, Reátegui D, Reátegui R, Cabrejos J, Para Correspondencia A, et al. (2021) Ergonomic risk and job satisfaction in administrative workers of the Luyanda district municipality in the period 2021. Pakamuros Scientific Journal 9(3): 98-109.

© 2025 Mario Paguay García. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)