- Submissions

Full Text

Significances of Bioengineering & Biosciences

Analysis on the Technical Gap and Key Problems of Tea Picker in China

Wu Luofa1*, Shu Shifu1, Xu Guanghao1, Ye Chun1 and Wu Yanqi2

1Institute of Agricultural Engineering, Jiangxi Academy of Agricultural Sciences, China

2Department of Electronic Engineering, Eindhoven University of Technology, Netherlands

*Corresponding author:Wu Luofa, Institute of Agricultural Engineering, Jiangxi Academy of Agricultural Sciences, China

Submission: February 22, 2023 Published: March 15, 2023

ISSN 2637-8078Volume6 Issue1

Abstract

Tea picking is an important link in tea production. Manual tea picking accounts for more than half of the cost of tea production. Developing and popularizing tea-picking machine is beneficial to increase labor productivity, reduce labor cost, enhance the market competitiveness of tea products and promote the sustainable development of tea industry. The slope of tea garden in hilly and mountainous areas of China is large, and most of the tea gardens put into production adopt close planting pattern, and the row spacing of the tea garden is variable, the canopy surface is irregular, and the height difference of the side ditch of the tea garden is big, which is far away from the standard tea garden, it is difficult for large and medium-sized tea pickers to enter the garden, so small-sized self-propelled tea pickers can be suitable for China’s tea picking production. This paper compares and analyzes the sticking points or difficult problems to be solved by small self-propelled tea picker in China from five aspects, such as walking chassis, control of Picker, collection and storage of fresh leaves, equipment manufacturing technology and agricultural machinery agronomic integration, the paper puts forward five key directions, such as the optimization design of high-stability walking and control system, the research and development of tea profile picker and self-adaptive system, the innovation and development of small-scale and high-efficiency fresh leaf collecting and storing device, the integration and industrialization of whole machine and key components manufacturing technology, and the integration and application of self-propelled tea picker agricultural

Keywords:Keywords: Tea Picker; Technology gap; Direction; Planting pattern; Agronomic

Global Distribution of Tea Production

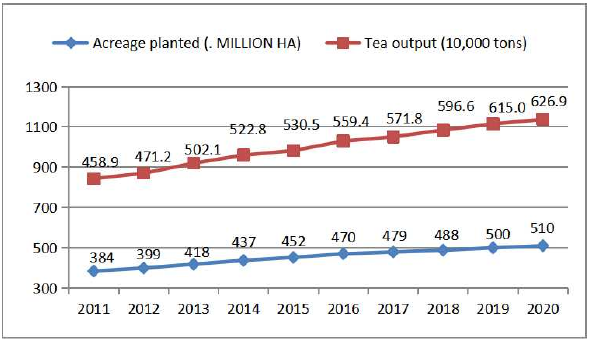

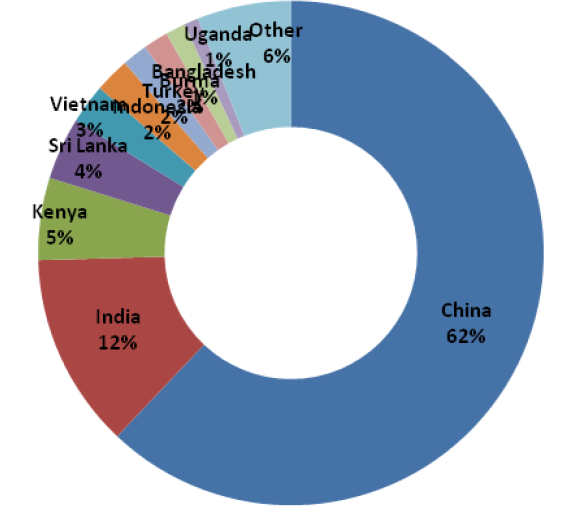

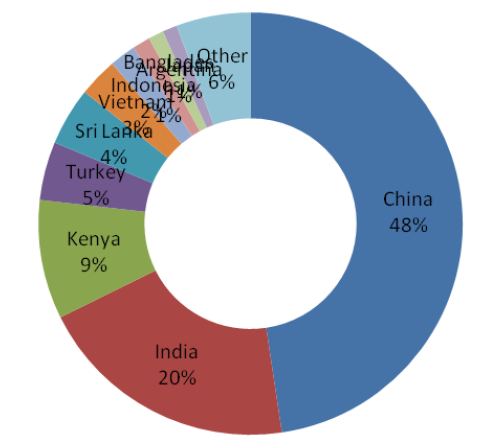

Tea is called one of the three big drinks in the world. About 71.4% of the world’s countries and regions, about one-third of the world’s people in tea. Tea is native to China [1]. China has been growing and drinking tea for more than 5000 years. Tea culture has a long history. Global tea cultivation is mainly distributed in tropical and subtropical regions (Figure 1). In 2020, global tea plantation hit a record high of 5.1 million hectares, an increase of 32.1 percent over 2011. In terms of countries, in 2020, China, India, Kenya, Sri Lanka, Vietnam, Indonesia, Turkey, Myanmar, Bangladesh and Uganda accounted for 94.0% of the world’s tea crop, China has 3.165 million hectares of tea, accounting for 62.1 percent of the world’s total, and India has 637,000 hectares, accounting for 12.5 percent of the world’s total, Kenya is the world’s second-largest tea plantation area of 269,000 hectares, accounting for 5.3% of the total global tea plantation area, the world’s third-largest. As global tea acreage increased, so did production, with global tea production reaching 6,269,000 tons in 2020, up 36.6 percent from 2011 (Figure 2). In terms of countries, in 2020, China, India, Nigeria, Turkey, Sri Lanka, Vietnam, Indonesia, Bangladesh, Argentina and Japan accounted for 94.3 percent of global tea production, China is the world’s largest tea producer with 2.986 million tons, accounting for 47.6 percent of the global total, while India is second with 1.258 million tons, accounting for 20.1 percent of the global total Kenya produces 570,000 tons of tea, accounting for 9.1 per cent of the world total and the third largest producer (Figure 3), [2-6]. The tea industry is a labor-intensive industry, the labor cost accounts for more than 60% of the tea production cost, especially the tea picking labor accounts for more than 50% of the total labor, and the tea picking seasonality is strong, the demand for mechanized tea picking is more urgent. Therefore, the research and development of tea-picking machine is beneficial to increase labor productivity, reduce labor costs, enhance the market competitiveness of tea products and promote the sustainable development of tea industry.

Figure 1:Changes in global tea production from 2011 to 2020.

Figure 2:Percentage of top 10 tea-growing countries in 2020.

Figure 3:Share of top 10 tea producing countries in 2020.

Development Trends of Tea Pickers in the World

The Japanese were the first to develop tea-picking machines and are now the world’s most Mechanization tea nation. From the mid-1950s in Japan began to pick tea machine development. In 1960, the Japanese joint-stock company invented the first mobile tea-picking machine, which began to be used in production, in 1966, in 1975, the Japanese developed the two-person tea-picking machine, and in 1975, the large self-walking and riding tea-picking machines were developed, and in different conditions of tea garden application. In 1979, 100,000 power tea-picking machines were installed in Japan, which accounted for 90% of the total output of tea in the country [7-10]. Up to now, the tea-picking machines in Japan have been operated by manual, electric and motorized one after another, and operated by single-person portable, doubleperson- lifting, self-propelled and sitting type The form of the blade is flat and arc, and the operating form of the blade is singleacting and double-acting, the rubber hardness of broken finger and the interdigital gap of fixed finger were discussed and tested. Kawasaki’s caterpillar-mounted tea picker, powered by diesel oil, has a working capacity of 0.1 hectare per hour, and has achieved mechanized production of management links such as cultivation, fertilization, pruning, picking and so on. In 1930, the former Soviet Union designed a three-wheel reciprocating cutting tea-picking machine [11-16]. In 1953, a broken tea-picking machine was put forward and put into practice. In 1965, a self-propelled tea-picking machine was developed, which combines the principles of breaking and cutting, in 1985, 28% of the total output was produced by machine, 32% by large self-propelled machine and 68% by twoman machine. Britain, France, India and other countries have also carried out the study of tea-picking machine, but until now, India and other countries basically remain in the manual tea-picking, tea-picking mechanization has not been made progress. Argentina although the area of tea garden in the world is not too large, but the country is after Japan after the basic realization of tea-picking mechanization of the country [17-20].

The Technical Gap of Tea Picker in China

History of tea-picking machine in China

Research on mechanized tea picking began in China in 1958. In 1959, the study of tea-picking machine was included in the national key research project. In 1960, China had three kinds of picking principles: cutting, breaking and pulling, including manual, electric, motorized 3 types of small-scale tea picker, animal power and mobile self-walking medium-sized tea picker, and tractor suspension form of tea picker. In this year, the manual south tea 702 reciprocating cutting machine, developed by the Tea Research Institute of Chinese Academy of Agricultural Sciences and the Nanjing Institute of Mechanized Agriculture, was the first tea picking machine in our country to be shaped [21]. In the 1970s, China carried out extensive research on large-scale mechanized tea-picking, and created various forms of tea-picking machines, including manual, motorized and electric horizontal hook-cutter cutting, spiral hob cutting and reciprocating cutting. In the early 1980s, China built Hangzhou tea-picking machinery plant, Nanchang tea-picking machinery plant and Wuxi tea-picking machinery plant, 4CD-33 single-player tea picker, NCCZ-1000 double-player tea picker and CS-100 double-player tea picker are produced respectively. The single-person carrying type tea-picking machine carries the power on its back and body, and transmits the power by the transmission soft shaft, but because of the factors such as the machine is small, the working width is small, the vibration is big, the labor intensity is big, and so on, tea picking is far less than tea demand, and the double-lift tea picking machine is more complex, from the gasoline engine, wind pipe, decelerating mechanism, cutter, rack five parts, although the cutting range can meet the operational requirements, but in the actual operation, it needs two people on each

side to lift the tea-picking machine, and 1-2 people to hang the leaf-collecting bag behind the tea-picking machine, which is convenient for collecting the tea leaves. The artificial cost is too high and the efficiency is low, so also not suitable for modern tea garden tea picking. In 1990, China imported funds and technology from Kawasaki machinery and joint-stock company, and established Zhejiang Kawasaki Tea Machinery Co., Ltd. In 2013, the company began to produce the KJ4N. The riding tea picker is not only expensive (more than 500,000 yuan), but can only be used in standardized tea gardens, while the slopes of tea gardens in China’s hilly and mountainous areas are large, and most of the tea gardens put into production are densely planted, and the trenches in the tea row are uneven, because of the variable row spacing, irregular canopy, and large height difference in the side ditches of tea rows, the tea garden is far away from the standard tea garden, which makes it difficult for large and medium-sized tea pickers to enter the garden. Therefore, small self-propelled tea picker is more suitable for China’s tea garden picking production.

Major technology gaps

At present, small self-propelled tea pickers need to solve the difficulties:

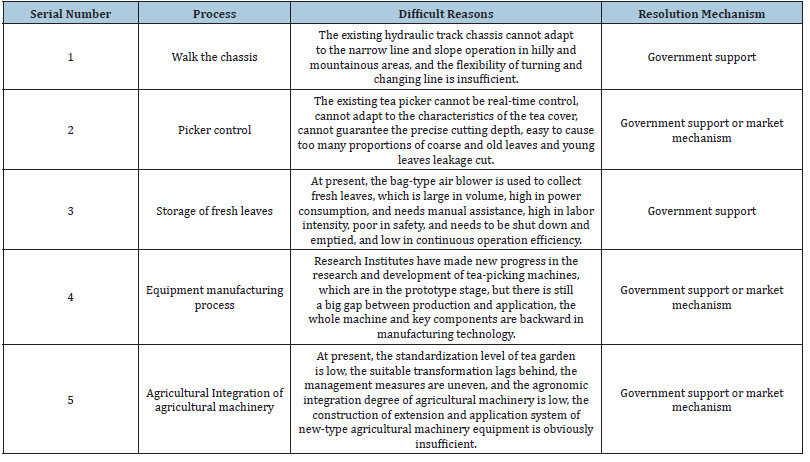

Walk the chassis:China has a smaller gap with foreign countries in terms of chassis. The existing wheel chassis and crawler chassis are more mature, but the existing hydraulic crawler chassis cannot adapt to the hilly and mountainous tea garden narrow line and slope operation, the turning, line changing flexibility is insufficient, the wheeled chassis cannot meet the requirements of the stability of tea garden operation, and the adaptability in different areas and different operating environments needs to be improved. Therefore, it is necessary to jointly tackle the key problems of the chassis with narrow row distance which is suitable for hilly and mountainous areas.

Picker control: There is a big gap between China and foreign countries in picker and its control. The blade made in Japan can reduce the damage rate of green leaves to a low point by nitriding quenching, and the picking head can control the picking height automatically. The blade (picking head) can be solved by market mechanism (purchase from abroad) , and the picking head automatic control technology needs the support of the state to carry out joint research.

Storage of fresh leaves:There is a big gap between China and foreign countries in collecting and storing fresh leaves. At present, the bag-type air blower is used to collect fresh leaves, which is large in volume, high in power consumption, and needs manual assistance, high in labor intensity, poor in safety, and needs to be shut down and emptied, and low in continuous operation efficiency. Therefore, it is necessary to develop independent leaf-collecting unit and realize automatic leaf-shedding to prevent the damage of fresh leaves.

Equipment manufacturing process: There is a big gap between China and foreign countries in equipment manufacturing technology. The reason is that scientific research units are out of touch with manufacturing enterprises, which can be solved by local support or market mechanism.

Integration of agricultural machinery and agronomy:There is a big gap between China and other countries in the field of tea garden transformation and production-study-promotion system construction, but it can be solved by local support or market mechanism (Table 1).

Table 1:The sticking points or difficulties of small self-propelled tea picker in China.

Key Research and Development of China’s Tea- Picking Machine

Tackling target

In view of the technical bottleneck of mechanized tea picking in hilly and mountainous areas of China, a joint research on small self-propelled tea pickers suitable for hilly and mountainous areas is organized, we will focus on solving the problems of key components such as walking devices, picking devices and fresh leaf collecting devices, cultivate leading enterprises, and enhance the R&D and manufacturing capabilities of small self-propelled tea pickers, break through the small self-propelled tea-picking machine production capacity and level, the formation of scientific and Enterprise Coordination Mechanism (R&D, enterprise production and application), and large-scale production and application, to solve the problems of inorganic and organic tea picking in hilly and mountainous areas, and to promote the level of mechanization of tea picking.

Main technical indicators

a. Loss rate≤1%.

b. Leakage recovery≤1%.

c. Productivity≥300 kg/(m·h).

Specific direction of key research

a. Topic 1:high-stability walking and control system optimization design To study the adaptability of different walking patterns (crawler, wheel) in different areas (Jiangbei District, Jiangnan, southwest), different slopes (flat land, gentle slope, steep slope) and tea garden conditions, the corresponding power, stability, earthing pressure and climbing ability were determined, and the power chassis of the existing self-propelled tea picker was optimized and improved to reduce the labor intensity of the tea picker, the automatic control system of tea-picking machine is developed, which has a good man-machine interface and can realize the functions of turning, walking and tea-picking operation, etc., to improve the self-propelled tea-picking machine to adapt to health and safety.

b. Topic 2:Research and development of tea profile picker and adaptive system based on the typical characteristic parameters of height, arc and width of tea canopy in different areas, the tea garden in hilly and mountainous areas was investigated, the optimum number and arrangement of copying cutters (reciprocating, horizontal rotating hook cutter and spiral hob cutter) and different support structures (single cantilever, double cantilever) were selected by simulation, based on the technology of image recognition and machine learning, a sensor system suitable for tea canopy is designed, which has accurate recognition accuracy and response speed, the picking height can be automatically adjusted according to the signal of the height sensing unit to improve the picking quality.

c. Topic 3:Innovative Research and development of small and efficient fresh leaf collecting and storing device Consider for different models of tea picking machine, design different types (blow type, negative pressure suction type) non-destructive collection of fresh leaves, storage, bagging units. Through the simulation and verification tests, the pneumatic layout of the air supply channel is optimized to ensure the air flow unobstructed in the pipeline and air passage and to prevent the phenomenon of the accumulation and blockage of the fresh leaves, thus solving the problem of the efficient collection of the fresh leaves, to achieve the efficient continuous operation of the machine [22].

d. Topic 4:integration and industrialization of whole machine and key components manufacturing process The project is a collaborative effort between scientific research institutes and tea-picking enterprises to form a coordination mechanism between them, through the optimal combination of different walking modes, different carrying modes of pickers, and different types of fresh leaf collection and storage units, integrated innovation of different self-propelled tea picking machine and key components of the manufacturing process, to adapt to different areas, different slopes of tea garden tea picking requirements, so as to comprehensively solve the problem of inorganic availability, organic is not easy to use. At the same time, in accordance with the requirements of “Research and development, while testing, while improving, while production, while promoting”, the enterprise is fully responsible for the whole machine products and key components of the production and manufacturing, scientific research units shall cooperate with the promotion and application of new products to realize the transformation and industrialization of scientific research results at an early date.

e. Topic 5:self-propelled tea harvester agricultural machinery integration promotion and application According to the typical characteristics of tea garden, such as topography, row spacing, tea age, tea vigor, etc., to conduct research and demonstration on tea plantation management techniques, oriented cultivation techniques of teahouse, pruning techniques of tea crowns, and suitable transformation techniques of tea plantations, and to formulate the operating regulations of small self-propelled tea pickers for bulk tea in hilly and mountainous areas, opening up the whole industrial chain of supply, production, sales and aftersales, exploring the industrialization mode of small self-propelled tea picker, construction of “Scientific Research Units + production enterprises + Extension Agencies + agricultural machinery cooperatives” new type of agricultural machinery extension and application system, to promote the development of agricultural machinery industry to provide reference.

References

- Yu H, Hongru X, Qin G (2014) Study on the development of tea picking machinery at home and abroad. Chinese Journal of Agricultural Machinery Chemistry 35(2): 20-24.

- Wong F, Yangming W, Hung W (2019) The present situation and development trend of tea mechanized picking technology in our country. Jiangsu Agricultural Sciences 47(12): 48-51.

- Yang Li, Chunwang D, Jianneng C (2022) Research progress and prospect of intelligent tea picking technology. Chinese Tea 44(7): 1-9.

- Wenyu Yi, Fangping C, Yunqiao Q (2020) Research status and development trend of single-player tea picker machine. Chinese Journal of Agricultural Machinery Chemistry 41(11): 33-38.

- Wenming W, Hongru X, Zhiyu S (2020) Research status and prospects of tea production mechanization technology. Chinese Journal of Agricultural Machinery Chemistry 41(5): 226-236.

- Kai-ae K (2018) The development of tea-picking machinery and the development of tea-picking mechanization in our country. Chinese Tea 8: 14-17.

- Zeyong L, Jian C, Jingjing F (2020) Current situation and development suggestions of tea garden planting mechanization in hilly and mountainous areas. Agricultural Mechanization Research 2: 1-7.

- Yujie Z, Qiang W, Leiying H, Runmao Z, Jiangming J, et al. (2022) Design and experiment of intelligent picking robot for famous tea. Chinese Journal of Mechanical Engineering 58(19): 12-23.

- Pan W, Wenyu Y, Changguo X (2022) Design and test of 4CJZ-1000 self-propelled tea picker. Journal of Southwest University Science 44(11): 228-233 .

- Yu H, Hongru X, Guangming Q (2013) Latest research situations and trends about tea garden machinery during 2012 in China. Chinese Journal of Agricultural Machinery Chemistry 34(3): 13-16.

- Guangming Q, Ying Z, Hongru X (2014) 4CZ-12 intelligent tea harvest robot design and field experiment. Chinese Journal of Agricultural Machinery Chemistry 35(1): 152-156.

- Yiping T, Wang H, Guo J (2016) Design and experiment of intelligentized tea-plucking machine for human riding based on machine vision. Journal of agricultural machinery 47(7): 15-20.

- Mu-fang S, Jing-Ming N, Zheng-Zhu Z (2017) Study on mechanized picking of famous tea. Tea Bulletin 39(4): 180-184.

- Huahua C, Zhangqing N, Yunhua Z (2016) Research progress on mechanized picking technology of famous tea. Silkworm Tea Communication 1: 23-25.

- Yang-Yang S, Wei-Ning L, Bing L (2020) Design and test of crawler type intelligent tea picker, research on agricultural mechanization. 8: 123-127.

- Siu-ming T, Suk-hong H (2013) Left secondary school. analysis of factors affecting the applicability of tea-picking machine. Sichuan Agriculture and Agricultural Machinery 3: 36-37.

- Qiufeng L, Tingting H, Yinglu W (2020) Comparison experiment of picking effect of portable single tea-picking machine. Southern Agriculture 14(16): 65-67.

- Xiankun W, Bing L, Xiaoyong W (2017) Design and analysis of single knapsack tea plucking machine. Agricultural Mechanization Research 8: 92-101.

- Xiaoyong W, Dandan T (2022) Research progress on mechanical tea plucking. Journal of Tea 56(4): 275-282.

- Zhe D, Yongguang H, Sheng W (2018) Simulation and experiment of reciprocating cutter kinematic of portable tea picking machine. Journal of Agricultural Machinery 49(11): 221-226.

- Min-tzu M, Sheng-hong Z (2014) Problems and countermeasures in the application of tea machine in Lishui. Zhejiang Agricultural Sciences 1(4): 483-486.

- Zhi S, Runqiang L, Jianyun R (2010) The application effect of two-man tea picker in mechanized picking of famous green tea. Chinese Tea 32(6): 19-20.

© 2023 Wu Luofa, This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)