- Submissions

Full Text

Aspects in Mining & Mineral Science

Role of Nanotechnology in Enhancing Mineral Exploration and Processing: A Mini Review

Himanshu Prasad Mamgain1*, Shivani2 and Reema Rawat3

1Department of Physics, Applied Science, School of Advanced Engineering, India

2Himalayan Institute for Learning and Leadership (HILL), India

3Health Technology Cluster, School of Health Sciences and Technology, India

*Corresponding author:Himanshu Prasad Mamgain, Department of Physics, Applied Science, School of Advanced Engineering, UPES, Dehradun-248007, Uttarakhand, India

Submission: November 18, 2025: Published: December 12, 2025

ISSN 2578-0255Volume14 Issue 4

Abstract

Nanotechnology has emerged as a game-changing tool in the mining and mineral processing industries, providing new solutions for effective exploration, enhanced recovery, and sustainable operations. Nanomaterials’ distinct features, such as high surface area, customizable chemistry, and extraordinary reactivity, allow for improved sensing, selective separation, and efficient treatment of mining waste. Nano sensors and nano-enabled geophysical devices improve mineral signature detection sensitivity, and nanoparticle tracers improve subsurface mapping. Nanotechnology in mineral processing improves flotation efficiency, facilitates selective adsorption, and speeds up catalytic processes for ore beneficiation. This brief study covers current advances and future potential for nanotechnology in mineral discovery and processing.

Keywords:Nanotechnology; Mineral processing; Mining; Rare earth elements; Surface engineering

Introduction

Demand to increase resource efficiency, lessen environmental effect, and find new deposits in deeper and more complicated geological conditions is mounting on the mining and mineral processing industries. Sensitivity, selectivity, and sustainability are frequently lacking in conventional exploration and beneficiation techniques. With its capacity to work with materials at the molecular and atomic levels, nanotechnology offers a way around these restrictions [1]. Nanomaterials, nano sensors, and nano-enabled chemical additives are increasingly being investigated to improve detection accuracy, enhance mineral recovery, and reduce waste during processing [2].

Nanotechnology in Mineral Exploration

Nano-enhanced geophysical techniques

There is growing demand in the mining and mineral processing sectors to find new deposits in deeper and more complicated geological settings, decrease their environmental effect, and increase resource efficiency. The sensitivity, selectivity, and sustainability of traditional exploration and beneficiation techniques are frequently lacking. Because nanotechnology can change materials at the molecular and atomic dimensions, it offers a way around these restrictions.

Nano sensors for trace mineral detection

Ultra-low concentrations of mineral indicators including gold, copper, rare earth elements, and sulfide can be detected via nano sensors based on Carbon Nanotubes (CNTs), graphene, and metallic nanoparticles. More precise detection of concealed deposits is made possible by their strong conductivity and chemical reactivity.

Nano-assisted remote sensing

Nanocoating’s on satellites and drones improve imaging resolution by enhancing optical sensitivity and reducing noise. This leads to more reliable identification of alteration zones and mineralized structures from aerial and space-based platforms [3,4].

Nanotechnology in Mineral Processing

Nano-flotation agents

Flotation efficiency can be significantly improved using nanoparticle-based collectors and frothers. Gold nanoparticles, silica nanoparticles, and alumina nanoparticles enhance bubbleparticle interactions and increase surface hydrophobicity, leading to better recovery rates and improved selectivity.

Nano-adsorbents for selective separation

Nanomaterials such as nano-Fe₃O₄, TiO₂ nanoparticles, and graphene oxide exhibit exceptional adsorption capabilities. These materials selectively bind valuable metals (e.g., gold, copper, cobalt) or remove unwanted gangue minerals, enabling improved beneficiation [5].

Nano catalysts in ore beneficiation

Nano catalysts accelerate leaching and mineral dissolution processes by increasing reaction rates. For example, silver or gold nanoparticles enhance cyanidation efficiency, while TiO₂- and ZnObased nano catalysts improve photocatalytic leaching under UV or visible light.

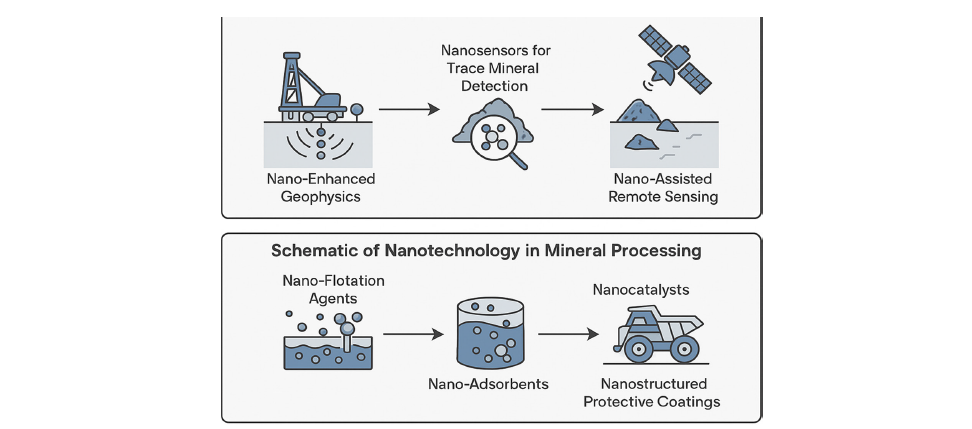

Nanostructured protective coating

An important use of nanotechnology in mining is the development of nanostructured protective coatings, which provide improved defence against chemical, abrasive, and corrosion damage. Superior hardness, decreased wear, and longer service life are offered by nano-ceramic and nano-composite coatings for mineral-processing equipment, pipelines, conveyor parts, drilling tools, and crushers. Furthermore, Figure 1 illustrates how nanoengineered hydrophobic and anti-fouling coatings reduce surface contamination, slurry adhesion, and scaling, enhancing equipment dependability, energy efficiency, and overall operating performance.

Figure 1:Key applications of nanotechnology in mineral exploration, processing, and environmental management.

Nano-flocculants for solid-liquid separation

Polymer-based nano flocculants enhance sedimentation and clarification processes. Their high reactivity and large surface area result in faster settling, improved dewatering, and cleaner process water.

Environmental Applications in Mining

Heavy-metal removal with nanomaterials

a. A range of nano-based adsorbents-such as ironoxide

nanoparticles, CNTs, and chitosan-derived

nanomaterials-are used to capture toxic metals including

arsenic, lead, cadmium, and mercury.

b. These nanomaterials provide a larger active surface

and stronger binding ability than many conventional

adsorbents, making them highly effective for treating

mine wastewater.

Nanofiltration and advanced membrane systems

a. Nanometre-scale membranes allow selective separation of

dissolved ions and impurities.

b. Such filtration systems enhance water recycling in mining

operations and help reduce the dependence on freshwater

sources, while also lowering pollutant discharge.

Nano-enhanced phytoremediation

a. Certain metallic nanoparticles can boost the uptake of

contaminants by plants grown on polluted mine sites.

b. This approach helps accelerate soil rehabilitation and supports

faster ecological restoration.

Challenges and Future Prospects

Key issues that currently limit the wider use of nanotechnology

in mining include:

a. Insufficient knowledge about long-term environmental and

health impacts of nanomaterials.

b. High costs involved in producing and applying nanoparticles

on an industrial scale.

c. Difficulty in developing large-scale manufacturing processes

that meet mining industry requirements.

d. Lack of clear regulations or guidelines regarding the safe use of

nanoparticles in open and sensitive environments.

Conclusion

a. Nanotechnology is steadily reshaping mineral exploration and

processing by improving detection methods, enhancing ore

recovery, and supporting cleaner operational practices.

b. The use of nanostructured protective coatings adds further

value by increasing the durability of machinery and lowering

maintenance demands in harsh mining conditions.

c. Although several challenges remain particularly regarding

cost, scalability, and safety the continuous progress in

nanomaterials and surface engineering indicates strong

potential for broader adoption across the mining sector.

References

- Morrison SJ, Tripathi A (2011) Nanotechnology in the mining industry: Applications and implications. Minerals Engineering 24(6): 506-513.

- Hosseini MR, Ahmadi A, Ghasemi E (2018) Nanotechnology in mineral processing: Fundamentals and applications. International Journal of Mineral Processing 170: 1-12.

- Wang L, Li X, Chen J (2017) Nanosensors for geological and mineral exploration. Sensors and actuators B: Chemical 243: 673-684.

- Peng Y, Grano S (2010) Use of nanoparticles in flotation systems. Minerals Engineering 23(11-13): 917-926.

- Zhou Z, Meng X (2015) Magnetic nano-adsorbents for selective removal of heavy metals from mining wastewater. Journal of Hazardous Materials 300: 358-365.

© 2025 Himanshu Prasad Mamgain. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)