- Submissions

Full Text

Research & Development in Material Science

Technical Review on Various Separation Methods Used in Mineral Ore Processing Plant

Vipin Kumar Sharma1,2*, Sunil Kumar Thamida1 and Naveen Kumar Reddy B2

1 Department of Chemical Engineering, Indian Institute of Technology, India

1Uranium Corporation of India Limited, India

*Corresponding author:Vipin Kumar Sharma, Department of Chemical Engineering, Indian Institute of Technology, Tirupati, Pin Code -517619, Andhra Pradesh, India

Submission: September 04, 2025;Published: September 26, 2025

ISSN: 2576-8840 Volume 22 Issue 3

Abstract

Separation methods are advanced techniques to segregate several components based on their characteristics and phases i.e. solid, liquid, or gas. Mineral ore processing contains proper usage of a series of chemical and mechanical operations. It helps in the extraction of the desired product from its initial stage. Several chemicals are used during the entire process. In this technical paper authors choose alkali and acidic leaching-based unique pitchblende ore for a case study of separation methods. Leaching is the heart of pitchblende mineral ore processing. It is a method for extracting desired products from the solid to liquid phase [1]. Based on ore characteristics, two types of leaching are involved i.e. acidic leaching and alkali leaching. Sodium Carbonate is the main reagent used for the pressurized alkali leaching process of pitchblende ore whereas sulphuric acid is used for acid leaching. In addition to this, several advanced separation techniques i.e. filtration, clarification, thickening, and drying are also performed for the extraction of the final product. This technical paper provides a glimpse of all the main separation techniques involved during mineral ore processing.

Keywords:Advanced separation techniques; Mineral processing; Leaching; Filtration; Chemical plant

Literature Survey

Laboratory-scale investigation conducted to emphasize the key factors impacting the efficiency of a belt filter press. They assessed this efficiency by measuring parameters such as the dry solid content of the final cake, the percentage of solids recovered, and the lateral movement of sludge on the belt [2]. In a separate study, detailed explanation provided for the operational principles and modeling techniques used in thickeners and clarifiers within the mineral processing industry [3]. Valuable insights into mineral ore processing within the context of India offered [4]. Furthermore, the historical progression of fine screening technology was reviewed, tracing its evolution from the early 20th century to contemporary methods. They underscored the economic benefits of modern fine classification techniques, particularly those utilizing the patented Stack Sizer technology [5]. Development of strategies was delved and tools aimed at enhancing the efficiency of mining facilities, thereby improving the utilization of raw materials from both natural and man-made deposits [6]. Comprehensive study was conducted on grinding and mineral separation processes frequently employed in mineral processing industries [7]. Research centered on cesium removal, exploring various separation technologies like chemical precipitation, solvent extraction, membrane separation, and adsorption [8]. Recent Life Cycle Assessment (LCA) studies related to mining and mineral processing operations reviewed meticulously, with a focus on addressing methodological challenges [9]. Under specific SMR conditions, including a roasting temperature of 520 °C, CO flow rate of 4.0m³/h, N2 flow rate of 2.0m³/h, and a feeding rate of 100kg/h, they were able to achieve an iron concentrate with a total iron grade (TFe) of 60.18% and an iron recovery of 90.17% [10]. Valuable insights into several advanced separation techniques commonly applied in mineral processing industries were provided [11]. It was concluded that, from economic and environmental perspectives, magnetic separation stands out as the most effective method for recovering iron oxides. However, it necessitates the modification of the magnetic properties of weakly magnetic iron ores [12]. It was aimed to equip researchers and industrial practitioners with structured knowledge regarding the state of machine learning applications within the field of mineral processing [13]. Furthermore, detailed information on the development of solvent extraction processes designed to separate and recover cobalt and nickel from secondary resources over the past decade was offered [14]. Advanced treatment techniques, including advanced oxidation processes (such as photolysis, ozonation, and catalytic/ UV light-based degradation), membrane filtration, reverse osmosis, and adsorption methods were explored [15]. It was concluded that innovative hybrid processes, which combine two or more treatment methods, are promising for reducing energy consumption and enhancing treatment efficiency [16]. Study was conducted on existing technologies for recovering precious metals from industrial waste streams, focusing on sustainability considerations [17]. Review of microwave heating applications in separation and purification processes in chemical engineering, emphasizing its unique features, including rapid heating, selective heating, and specific microscopic effects was provided [18]. Three most explored and mature separation techniques identified between 2015 and 2020, encompassing both solid and liquid phases: leaching, solvent extraction, and plasma. Top three fields of study: chemistry, engineering, and metallurgy are also highlighted. Additionally, it was noted that the predominant method for Rare Earth Elements (REE) separation across various research domains involved the use of acids, bases, ionic liquids, and salts for leaching REEs [19]. It was found that, through optimization, leaching efficiency of 79.85% can be achieved under the optimal conditions for physical separation products [20].

Introduction to mineral ore processing

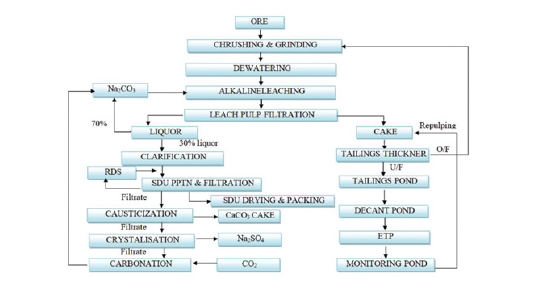

Figure 1 describes a detailed flow sheet of mineral ore processing which includes several advanced chemical separation processes mainly dewatering, filtration, clarification, crystallization, drying, thickening, etc [21].

Figure 1:Process flow sheet of mineral ore processing plant [21].

Methods of separation techniques used in mineral ore processing industries

Detailed explanations about these process steps are mentioned

as follows:

Screening (solid-solid separation): Ore mining is a critical

process that is being done by several specific mining methods. Big

boulders are mined out from underground using belt conveyors

or mine ore trucks as per convenience and further processed in a

series of chemical operations. Crushing and screening is an initial

size reduction operation. Desired ore size material moves further

through a series of belt conveyors for chemical processing whereas

oversized ore moves for recycling after screening operation. Jaw

crushers and cone crushers are the main size reduction equipment

used in mineral ore processing industries. In this way solid-solid

separation takes place.

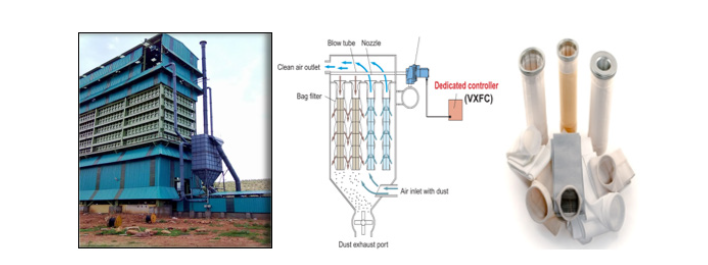

Dust extraction system (gas-solid separation): Crushing

operations in mineral ore processing industries cause dust

generation. Fine dust can be harmful to working employees if

crosses permissible limits provided by regulatory bodies i.e. CPCB,

AERB, MoEFCC, DGMS, etc. Bag filters and cyclone separators are

mainly used as dust extraction systems to control dust emissions

in crushing and screening units. Bag filters are commonly used in

such industries which are connected through DE (dust extraction)

fans through pipelines. During the operation of equipment, dust is

extracted from generation places and further sticks on the surface

of specific bags of bags filters. Due to frequent timer/intervals, dust

passes through the bottom chutes of bag filters and is recycled in the

system through belt conveyors. Figures 2(a), 2(b) & 2(c) describe

the overall view of the DE system, cross-sectional view, and types

of filter media used in mineral ore processing industries [22-25].

Figure 2:(a). DE System at mineral ore processing industry [22,23], (b). Cross-section view [24], (c). Types of filter media [25].

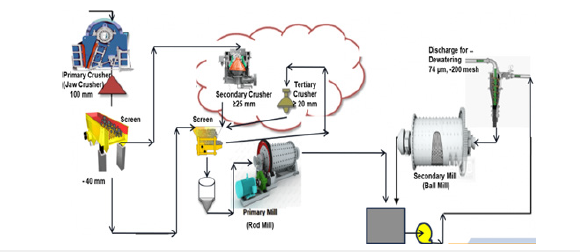

Grinding: It is one of the important mineral processing steps. Leaching is main heart of most of the chemical processing industries. Leaching directly depends on the surface area of the particles. Grinding helps in increasing the surface area of the particles [26,27]. Crushed ore of desired input size enters into the primary mill. Rods are used as grinding media in the primary mill (rod mill). Discharge of primary and secondary mills (ball mill) is being collected in the discharge tank. Figure 3 represents the overall view of grinding circuits in mineral processing industries.

Figure 3:Grinding circuit with various mineral processing plant operations.

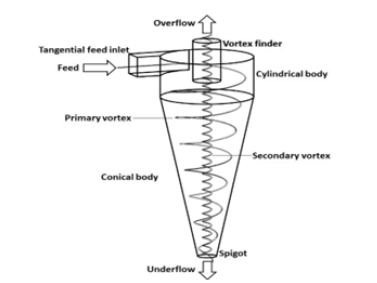

Figure 4:Cross sectional diagram of hydro cyclone.

Hydrocyclone (liquid-liquid separation): A hydrocyclone consists of a cylindrical feed section with a tangential inlet; an upper section with a vortex finder; and a conical part with an apex. Substance from the mill discharge reservoir is pumped into the hydrocyclone tangentially under specific pressure [28]. This initiates a centrifugal motion, propelling the denser phase outward and downward along the conical section’s surface. The hydro cyclone’s discharge serves as the input for the secondary rod mill, while the underflow is directed to subsequent dewatering processes as mentioned in Figure 4.

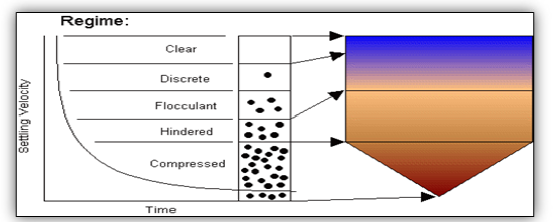

Hi-rate thickener (solid-liquid separation): Another separation unit, HRT (high rate thickener) is used in plants to increase the solid concentration of feed subjected to leaching by sedimentation. The addition of flocculating agent in HRT improves the sedimentation process. After hydrocyclone operations, the slurry enters into a thickener in which clear overflow water is recycled back to the plant and thickened underflow goes for further processing on horizontal belt filters. Settling regimes depend upon the closeness of particles to each other which is defined in Figure 5; [29].

Figure 5:Graph: settling velocity vs time [29].

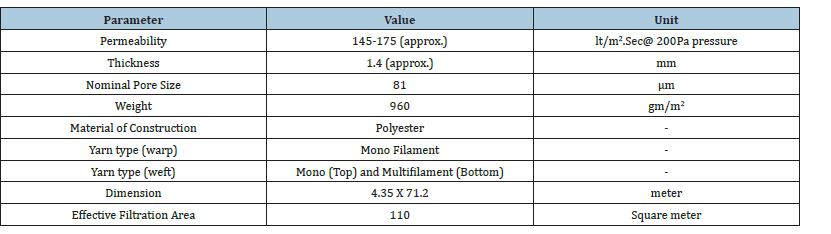

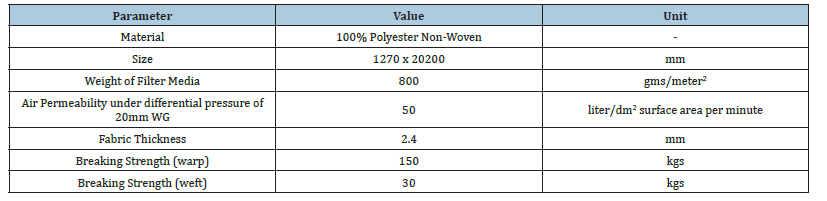

Filtration (solid-liquid separation) before leaching: The plant employs a horizontal vacuum belt filter as a device for separating solids from liquids, primarily used for dewatering neutral and leached slurries. The filtration process primarily involves passing a set of filtering fabrics and belts through a series of rollers. The system takes slurry as input and segregates it into a filtrate and a solid cake. Decreasing the belt speed enhances the filtration rate. To ensure the plant’s capacity is not compromised, the optimal speed is consistently maintained in all horizontal vacuum belt filters (HBFs). Neutral slurry passes on HBF (horizontal belt filter). After filtration, the cake goes for a leaching operation, and the filtrate goes for recycling to hi rate thickener. Table 1 represents the basic technical specifications required for polymeric filtration media in mineral processing plants [30].

Table 1:Technical specification of neutral and alkaline filter media [30].

Figure 6:Schematic representation of pressurized alkali leaching into autoclaves [34].

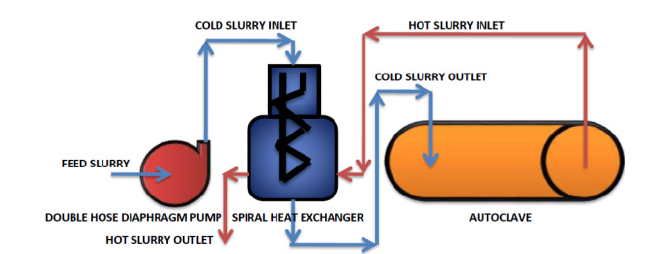

Pressurized alkali leaching into autoclaves (solid-liquid

extraction): This mineral processing step is the heart of the entire

process. Slurry passes through a double hose diaphragm pump, and

spiral heat exchanger and enters into a pressurized autoclave at

~90 oC. Exothermic reactions take place inside autoclaves at ~140

oC temperature and 8 bar pressure [31,32] as mentioned in Figure

6. The main chemical reactions [33,34] are as follows:

(1) UO2 + ½O2 → UO3

(2) UO3 + 3Na2CO3 + H2O → Na4UO2(CO3)3 + 2NaOH

(3) NaHCO3 + NaOH → Na2CO3 + H2O

(4) SiO2 + 2NaOH → Na2SiO3 + H2O

Leaching is a chemical process for extraction of required minerals from its ore using certain reagents, oxidation material, etc. Before leaching, minerals used to be in ore in the form of a solid. After leaching, it converts from solid to liquor form due to certain chemical reactions in the presence of desired process parameters.

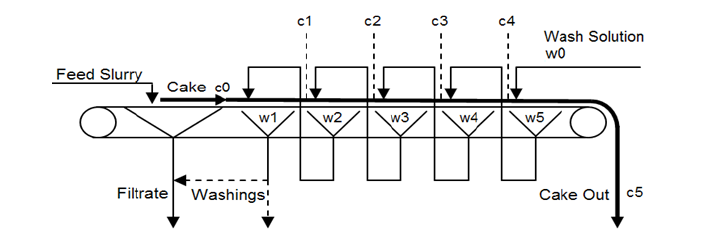

Filtration (solid-liquid separation) after leaching: After leaching, the leached slurry is filtered again using HBF for extraction of the desired mineral from solid to liquor form. Solid with unleached mineral goes to tailings for disposal and filtrate moves for further chemical processing. Figure 7 represents a description of several counter-current steps being used to increase the concentration of liquor. It is very important in the case of low-grade ore. The required concentration of liquor helps in the precipitation of fine particles more efficiently [35]. In Figure 7, c0, c1, c2, c3, c4, and c5 are five stages for counter-current washing zones of HBF, and w0, w1, w2, w3, w4, and w5 are known as weak liquor filtrates being collected from all zones.

Figure 7:Technical specification of precoat / drum filter [36].

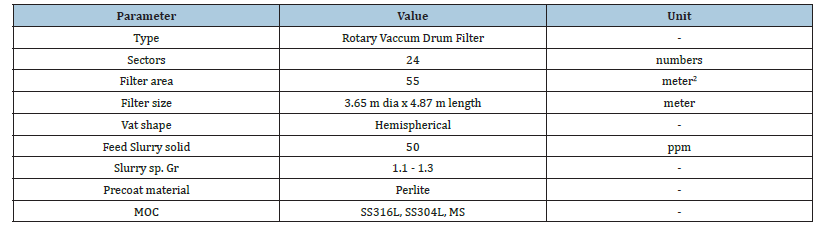

Precoat/drum filter (solid-liquid separation): After filtration of leached slurry over HBF, filtrate goes for further settling into the clarifier. After initial clarification into the clarifier, the overflow of the clarifier is passed through a precoat / vacuum drum filter. Clarified liquor is obtained from the drum filter after the removal of desired solid particles. Table 2 provides technical specifications of an ideal precoat / vacuum drum filter used in mineral ore processing industries [36].

Table 2:Technical specification of precoat / drum filter [36].

Mineral ore precipitation: Clarified liquor goes for further

precipitation for extraction of the desired mineral from the ore.

A required chemical of a particular concentration is used for

precipitation reaction. Chemical reaction 5 represents usage of

47% conc. NaOH solution for extraction of Na2U2O7 from mineral

ore with suitable retention time of liquor inside vessels [37].

(5) 2Na4UO2(CO3)3 +6NaOH → Na2U2O7 +6Na2CO3 +3H2O [38]

Product horizontal belt filtration (solid-liquid separation): Precipitated liquor further goes for thickening operation after the addition of suitable flocculent. Overflow liquor of thickener is used for recycling in circuits after extraction of byproduct. Underflow precipitated slurry of thickener moves on horizontal belt filter for removal of the filtrate by using sufficient vacuum from pumps and further recycling in plant circuit. Product discharge cake is repulped inside the tank by the addition of water. Water addition helps in product-grade purification. Table 3 provides technical specifications of filter media used for product belt filters in mineral ore processing industries [39].

Table 3:Technical specification of neutral and alkaline filter media [30].

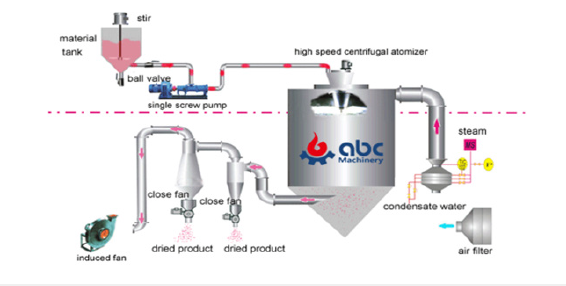

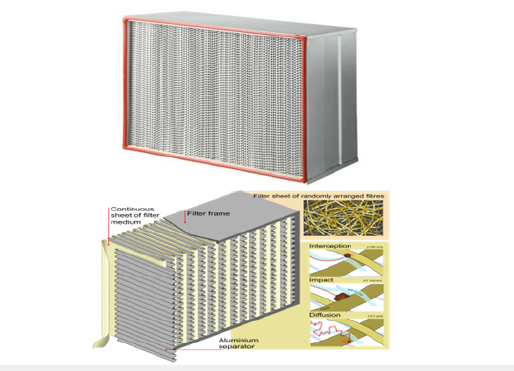

Product drying (solid-moisture separation): Repulped product cake enters into the drying chamber/atomizer from the top as mentioned in Figure 8. Hot air passes from one end with the help of an FD fan. Product slurry converts into powder form within a fraction of a second due to the very high rotation speed of the motor situated at the top of the atomizer. A bag filter and HEPA filter are being used in between drying operations [40,41].

Figure 8:Product drying operation in mineral processing industries [41].

Figure 9:Manufacturing details of HEPA filter for gas-solid separation; (a). Outer view of HEPA filter [42,43], (b). Cross-sectional view of HEPA filter [41].

HEPA, which stands for high-efficiency particulate arrestance, is a standard for the effectiveness of air filters. A HEPA air filter is required to eliminate no less than 99.95% (according to ISO and European standards) or 99.97% (as per ASME and the U.S. DOE) of particles with a 0.3μm diameter as they pass through it. The filtration efficiency increases for particles with diameters smaller or larger than 0.3μm. HEPA filters are constructed from a nonuniformly distributed mat of fibers, as depicted in Figures 9(a) & 9(b) [42,43].

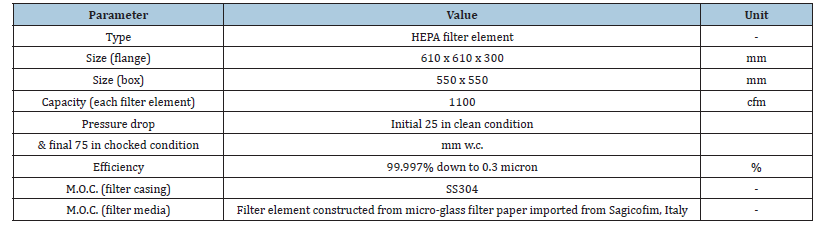

The fibers are usually made of polypropylene or fiberglass and have diameters ranging from 0.5 to 2.0 micrometers. To prolong the lifespan of the costlier HEPA filter, a HEPA bag filter can be employed alongside a pre-filter, typically activated carbon. In this arrangement, the initial phase of the filtration process involves the use of a pre-filter, which effectively eliminates the majority of larger dust, hair, PM10, and pollen particles from the air. The drying chamber helps in the removal of moisture completely from the product slurry and the dried product is being collected in drums for further packing and dispatch. The technical specification of a typical HEPA filter is mentioned in Table 4.

Table 4:Technical specification of HEPA filter [39].

Results and Discussion

The results and discussions section of this technical review on various separation methods employed in mineral ore processing plants presents a comprehensive analysis of the findings obtained through literature review and empirical data. Through meticulous examination, it becomes evident that several separation techniques, including froth flotation, magnetic separation, gravity separation, and electrostatic separation, play crucial roles in the efficient extraction of valuable minerals from ores. Each method offers distinct advantages and limitations, influencing its applicability in different scenarios. The discussion delves into the factors influencing the selection of a particular separation method, such as mineral properties, particle size distribution, and economic considerations. Furthermore, the section explores recent advancements and emerging trends in mineral processing technology, shedding light on potential future developments that could enhance separation efficiency and sustainability in ore processing operations. This comprehensive analysis serves to deepen understanding and guide decision-making processes in the optimization of mineral processing plants. In the field of mineral ore processing, separation is one major process that is being done through several methods and advanced techniques. This case study is based on low-grade nuclear ore found at Andhra Pradesh in India [44-47]. Several technical papers were reviewed and found that purification of the technical grade of the final product and maximum recovery depends on the proper handling of mineral ore at several step-by-step procedures of mineral ore processing [48-51]. Among all these chemical processing steps, advanced separation techniques play a vital role from start to end. Due to continuous experience in the field of such industries, there is always a huge scope for improvement in the case of technical specifications of filter media and processing equipment. Characteristics of filter media used to change from time to time based on necessary modifications required for process recovery enhancement. In the case of alkali leaching, the concentration of salts used to be more in process liquor which can further chock the filter cloth of the horizontal belt filter. Based on operations it was found that a few steps were very helpful for improvement in the case of maximum solid liquid separation i.e. (a). Usage of hot liquor for counter-current wash on HBF, (b). The pore size of HBF filters media to be modified for maximum extraction of filtrate, (c). MOC of polymer filter media to be modified based on liquor characteristics, (d). Design of washing nozzles for HBF cloths should be specific for proper washing, (e). Proper lab tests are required for the evaluation of the filtration rate for suitable flocculent and suitable filter media.

Conclusion

Thus, the mineral ore processing plant includes several advanced novel separation techniques as briefly mentioned in Figure 10. An overall combination of separation methods includes all three major forms of chemicals i.e. solid, liquid, and gas. The latest research helps in modifications of equipment used for separation techniques [52-55]. Technical specifications of filtration media are also used to change accordingly. This technical paper describes an overall combination of those advanced separation techniques used in several mineral ore processing industries all over the world [56-59]. In addition to this, research is being done in the field of extraction of CO2 from flue gas generated by mineral processing industries [60-63]. The boiler is used in all mineral ore processing industries for the usage of steam in several steps of the chemical plant. These boilers emit a sufficient number of SOX, NOX, COX, and particulate matter in the atmosphere [64-66]. Although, these emissions are as per permissible limits defined by regulatory boards further scope of extraction of these gaseous components was found by Vipin et al. [34] for useful purposes in mining and mineral ore processing industries. In conclusion, this comprehensive technical review has elucidated the diverse array of separation methods integral to mineral ore processing plants. From traditional techniques like gravity separation and flotation to more advanced methods such as magnetic separation and electrostatic separation, each approach offers distinct advantages and limitations in efficiently extracting valuable minerals from ore deposits [67-72]. Through meticulous analysis and comparison of these techniques, it is evident that a combination of methods tailored to specific ore characteristics and processing requirements yields optimal results. Moreover, ongoing advancements in technology continue to enhance the efficacy and sustainability of mineral separation processes, promising further innovation and optimization in the field. As mineral processing remains a cornerstone of various industries, the insights gleaned from this review serve to inform future research and development endeavors aimed at maximizing resource utilization and minimizing environmental impact in ore processing operations.

Figure 10:Types of separation techniques in mineral processing plant.

References

- Sarkar S, Kannan JD (2022) A view on advanced separation techniques used in various uranium processing plant of Uranium Corporation of India Limited (UCIL). Institute of Chemical Technology (ICT) 22-26: 33.

- Olivier J, Vaxelaire J (2005) Municipal sludge dewatering by belt filter press: effect of operating parameters. Journal of Chemical Technology and Biotechnology 80: 948-953.

- Teerikoski Sakari (2017) Optimal control of clarifier-thickeners. Uppsala Universitet Examensarbete, p. 30.

- Kain Vivekanand SDK, Asnani CK (2022) Atomic minerals: the journey of India to self-sufficiency. Special Section: Homi Bhabha, Current Science 123(3).

- Barkhuysen NJ (2009) Implementing strategies to improve mill capacity and efficiency through classification by particle size only, with case studies. The South African Institute of Mining and Metallurgy, Base Metals Conference.

- Abdurashidovich UA (2020) The condition of general development of the mineral resource base in Uzbekistan. The American Journal of Applied Sciences 02(12-01): 1-6.

- Chelgani SC, Parian M, Parapari PS, Ghorbani Y, Rosenkranz J (2019) A comparative study on the effects of dry and wet grinding on mineral flotation separation-a review. J Mater Res Technol 8(5): 5004-5011.

- Wang J, Zhuang S (2019) Removal of cesium ions from aqueous solutions using various separation technologies. Rev Environ Sci Biotechnol, Springer Nature.

- Segura-Salazar J, Lima MF, Tavares ML (2019) Life cycle assessment in the minerals industry: Current practice, harmonization efforts, and potential improvement through the integration with process simulation. Journal of Cleaner Production 232: 174-192.

- Zhang X, Yuexin H, Yongsheng S, Li Y (2019) Innovative utilization of refractory iron ore via suspension magnetization roasting: A pilot-scale study. Powder Technology 352: 16-24.

- Moreira VR, Lebron YAR, Santos LVS, De Paula EC, Amaral MCS (2020) Arsenic contamination, effects, and remediation techniques: A special look onto membrane separation processes. Process Safety and Environmental Protection 148: 1-75.

- Jianwen Y, Yuexin H, Yanjun L, Peng G (2019) Recent advances in magnetization roasting of refractory iron ores: A technological review in the past decade. Mineral Processing and Extractive Metallurgy Review 41(5): 349-359.

- McCoy JT, Auret L (2018) Machine learning applications in minerals processing: A review. Minerals Engineering 132: 95-109.

- Alvial-Hein G, Mahandra H, Ghahreman A (2021) Separation and recovery of cobalt and nickel from end of life products via solvent extraction technique: A review. Journal of Cleaner Production 297: 126592.

- Gopal G, Alex AS, Chandrasekaran N, Mukherjee A (2020) A review on tetracycline removal from aqueous systems by advanced treatment techniques. The Royal Society of Chemistry 10: 27081-27095.

- Sahu P (2021) A comprehensive review of saline effluent disposal and treatment: conventional practices, emerging technologies, and future potential. Water Reuse 11(1): 33-65.

- Krishnan S, Zulkapli NS, Kamyab H, Taib SM, Din MFBM, et al. (2021) Current technologies for recovery of metals from industrial wastes: An overview. Environmental Technology & Innovation 22: 101525.

- Li H, Zhao Z, Xiouras C, Stefanidis GD, Li X, et al. (2019) Fundamentals and applications of microwave heating to chemicals separation processes. Renewable and Sustainable Energy Reviews 114: 109316.

- Opare OE, Struhs E, Mirkouei A (2021) A comparative state-of-technology review and future directions for rare earth element separation. Renewable and Sustainable Energy Reviews 143: 110917.

- Pan J, Nie T, Hassas BV, Rezaee M, Wen Z, et al. (2020) Recovery of rare earth elements from coal fly ash by integrated physical separation and acid leaching. Chemosphere 248: 126112.

- Rana BK, Molla S, Dhumale MR, Jha SK, Kulkarni MS (2023) The behavior of mill tailings produced from a uranium extraction plant adapted an indigenously developed alkaline leaching assisted process. Radiation Protection and Environment 45(3&4): 158-169.

- Rajesh L (2018) Safety management at tummalapalle mill. 35 : 1-4.

- Rajesh L (2019) Case study of air quality at tummalapalle mill and effective actions for improvement. 36 : 2-6.

- https://smc-fluidcontrol.com/impulsventile-fuer-staubfilteranlagen/

- https://www.flsmidth.com/en-gb/products/emission-control/filters/

- Sharma VK, Sarkar S, Rao MS (2023) Technical modifications of alkali leaching circuit to improve slurry throughput into the autoclave. Suranaree J Sci Technol 30(4): 1-7.

- Sharma VK, Thamida SK, Reddy BNK (2023) Engineering study of water jacket system in place of a spiral heat exchanger at mining and mineral ore processing industry. European Chemical Bulletin 12(7): 1507-1512.

- https://en.wikipedia.org/wiki/Hydrocyclone.

- Christian B (1994) Improve clarifier and thickener design and operation. Chemical Engineering Progress 90(7): 50-56.

- Filter cloth for horizontal belt filter of size 71.2 Mtr. X 4.35 Mtr. With SS316 clippers (Polyester) as per the enclosed technical specifications (TMPL/PUR/005/216/017). Uranium Corporation of India Limited, Annexure-7.

- Suri AK (2008) Uranium processing-a new alkaline route. Trans Indian Inst Met 61: 1-6.

- Singh AK, Sharma AK, Giriyalkar AB, Hubli RC, Chakravartty JK (2014) Studies on precipitation and separation of sodium di-uranate from leach liquor of tummalapalle uranium ore. BARC Internal Report No. BARC/2014/I/015: 1-31.

- Siddique S, Srinivas K, Mandre NR, Srivastava SK (2013) Experiences in construction and operation of alkaline pressure leaching autoclaves for processing uranium ore in India. MPT 2013 Bhubaneshwar India.

- Rao MS, Sarkar S (2019) Effective use of LDO fired boiler flue gas in carbonation of process liquor at alkali leaching based Tummalapalle Mill CEM India International Conference. Asian Environmental Technology Journal 23(4): 37-39.

- https://help.syscad.net/Belt_Filter

- Complete Precoat Filter, Purchase Tender, Uranium Corporation of India Limited, Department of Atomic Energy.

- Suri AK, Sreenivas T, Anand Rao K, Rajan KC, Srinivas K, et al. (2014) Process development studies for the recovery of uranium and sodium sulfate from a lowgrade dolostone hosted strata bound type uranium ore deposit. Mineral Processing and Extractive Metallurgy, Trans Inst Min Metall C 123(2): 104-115.

- Rao MS, Sarkar S (2021) Technical modifications of alkali leaching circuit to improve slurry throughput into the autoclave. CHEMCON, 74th Annual Session of Indian Institute of Chemical Engineers (IIChE), DMFDPD-183, CSCE, p. 877.

- Technical specifications. Purchase Tender. Uranium Corporation of India Limited.

- (2023) Pre-Feasibility Report for 13.5 lakh TPA Expansion of Uranium Project at Tummalapalle, Dr. YSR Reddy district, Andhra Pradesh of M/s. UCIL, ©, 2016, MECON LIMITED.

- (2023) Working diagram of spray drying machine. Anyang Best Complete Machinery Engineering Co., Ltd.

- https://en.wikipedia.org/wiki/HEPA

- https://www.afprofilters.com/product/hpg-serie-hepa-filter/

- Sreenivas T, Chakravartty JK (2016) Alkaline processing of uranium ores of Indian origin. Trans Indian Inst Metals 69: 3-14.

- Siddique S, Srinivas K, Srivastava SK (2015) Improvements in autoclave heat recovery circuit in uranium ore processing mill at Tummalapalle, India. Transactions of the Indian Institute of Metals 68 : 665-668.

- Rao KA, Patel AB, Gujral M, Karan R, Kumar MA, et al. (2022) Development and scale-up of chemical process for conversion of impure sodium diuranate to uranium peroxide. Jour Geol Soc Indi 98: 1145-1151.

- Singh AK, Iyer TS, Sharma AK, Kain V, Krishnan M (2018) Development of an efficient precipitation process for product recovery from leach liquor of a low-grade dolostone hosted uranium ore ALTA 2018. Uranium-REE-Lithium Proceedings 66-77.

- Naveen BKR, Thamida K, Sunil, Sharma KV (2024) Carbonation and modeling study for process liquor in batch mode using flue gas in the mining and mineral processing industry. Chemical Papers 78 : 1-11.

- Thamida KS, Naveen BK, Vipin KS (2023) Case study on advanced separation techniques used in alkali leaching based mineral processing. Plant IIT Patna, AIJR Publisher, ICSPT 2023.

- Jha Chandan DD (2023) Proactive efforts to maintain the safety culture and role of technology in the enhancement of safety performance. 39th DAE SOHPM, 1-37.

- Rao MS, Sarkar S, Sriharsha P (2023) Process intensification in post alkali leached liquor precipitation circuit using re-dissolution of sodium diuranate slurry. 77th ATM IIM, KIIT Bhubaneswar.

- Sarkar Suman Rao MS, Reddy TCS (2023) Effectiveness of autoclave agitator in alkali leaching based ore processing plant. 77th ATM IIM, KIIT Bhubaneswar.

- Rao MS (2019) Management of alkali leaching based uranium tailings at Tummalapalle Andhra Pradesh. IAEA website, UPC, UMREG Presentations, 1-8.

- Sharma KV, Sunil ST, Naveen BRK (2023) Detailed calculations for rainwater recharge system, considering the stormwater runoff and geological formation. PEEC-2023, JNAFAU Hyderabad & Pure Earth Foundation.

- Sunil TK, Naveen BRK (2022) Evaluation of evaporation characteristics concerning environmental parameters for recycled water facility in mineral processing industry. 9th Digital Earth Summit-2022, ISDE, Anna University, Chennai, Tamilnadu, India, p. 74.

- Sharma VK (2008) Evaluation of air pre-heater system on vis-breaker heaters. National Conference on Emerging Trends & Innovations in Chemical Engineering (AICTE, Govt. of India), Peter’s University, Avadi, Chennai, Tamilnadu, India.

- Rani N (2009) Instrumental analysis of corrosion on stainless steel. Conference Proceedings of CHEMTECHNIK’09, Satyabama University, Chennai, Tamilnadu, India.

- Sharma VK (2008) Advancement in biological waste water treatment. Conference Proceedings of NCRTWWT 2008, SRM University, Kancheepuram, Tamilnadu, India.

- Tiwari R, Sharma VK (2008) Pump efficiency evaluation & overview of catalytic cracking unit. Conference Proceedings of PANSOPHY'08, Sri Venkateswara College of Engineering, Sriperumbudur, Tamilnadu, India.

- Sharma VK (2022) Climate action through CO2 capture in nuclear & mineral industries. World Earth Day 2022 Guest lecture, Climate Change Research Institute, New Delhi, India.

- Sharma VK (2020) Environmental benefits of nuclear energy. National Webinar on World Environmental Day 2020, SRMIST, Kancheepuram District, Tamil Nadu, India.

- Sharma VK (2025) Aspects in mining & mineral science for nuclear fuel production in India. Aspects in Mining & Mineral Science 13(5): 1629-1630.

- Kannan JD, Rao LK (2025) Enhanced safety protocols for pressurized autoclaves in alkali leaching of low-grade uranium ore. Advances in Science and Technology of Water Resources 9(5) : 185-216.

- Reddy TCS, Rao MS (2025) Optimizing material of construction for agitators in high-temperature, high-pressure leach reactors handling abrasive mineral slurries. Research & Development in Material Science 21(5): 2629-2631.

- Kumar M (2025) Liquefied petroleum gas: A comprehensive review of its manufacturing and refining routes. Progress in Petrochem Science 7(2) : 785-792.

- Sriharsha P, Sarkar S (2025) Trial of pilot scale nanofiltration unit for improvement of precipitation circuit at tummalapalle mill. Current Natural Sciences & Engineering Journal (CNS&E) 2(1).

- Sharma VK, Sriharsha P, Rao MS (2025) Process intensification in precipitation of uranium from post alkali leach liquor using re-dissolution of sodium diuranate slurry: A short review of laboratory and pilot scale test results. Hydrometallurgy 235 : 106491.

- Sinha R (2025) An overview of the hydrocarbon sector in india for carbon capture scope. Advances in Environmental and Engineering Research 6(2).

- Sunil KT, Reddy BNK (2025) Scaled-up carbonation of pitchblende and uraninite process liquor using flue gas: Kinetic modelling and comparative analysis.

- Reddy BNK, Sunil KT (2025) Study of waste management treatment facilities using advanced Membrane Bio Reactor (MBR) technology, Pollution Study. Asia Pacific Academy of Science Pte. Ltd., 6(2).

- Reddy TCS, Rao LK, Sarkar S (2025) Mitigation strategies for mechanical seal failure in autoclave agitators operating at high temperature and pressure: A case study. 78th Annual Technical Meeting The Indian Institute of Metals (IIM).

- Kanna JD (2024) Development of a secured landfill for near surface disposal of uranium tailings: A pilot scale study. 78th Annual Technical Meeting the Indian Institute of Metals (IIM).

© 2025 © Vipin Kumar Sharma. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)