- Submissions

Full Text

Evolutions in Mechanical Engineering

3D-Printed Composite Cushions for Use in Flexible Jaw Coupling Mechanisms

Vasileios Papageorgiou1*, Gabriel Mansour1, Ilias Chouridis2 and Michel Mansour1

1 Department of Mechanical Engineering, Aristotle University of Thessaloniki, Greece

2 Department of Industrial Engineering and Management, International Hellenic University, Greece

*Corresponding author:Vasileios Papageorgiou, Department of Mechanical Engineering, Aristotle University of Thessaloniki, 54124 Thessaloniki, Greece

Submission: September 17, 2025;Published: October 16, 2025

ISSN 2640-9690 Volume6 Issue3

Abstract

The aim of the present study is to create end-use parts for coupling mechanisms using additive manufacturing. Cushions for flexible jaw couplings have been redesigned and manufactured using PA6 enhanced with carbon fibers to create cushions with enhanced damping and strength characteristics.

Keywords:Additive manufacturing; 3D-printing; Couplings; Flexible jaw coupling; PA-6; Carbon fiber; Composites; Reverse engineering; Mechanisms

Introduction

Additive manufacturing has radically altered product manufacturing. It enables the fabrication of customized objects with complex geometries, while keeping the manufacturing costs relatively low [1-3]. The present article focuses on the fabrication of composite polymer cushions for flexible jaw couplings using additive manufacturing. The mechanical properties of the composite material used have been evaluated through mechanical and vibration damping tests [4,5]. Additionally, a FEM model has been created to calculate the equivalent stresses exerted on the cushions’ surface during operation. Results showed that the 3D printed cushions can withstand the exerted stresses, while the materials enhanced vibration damping capability, contributes to the smoother function of the coupling in real time operating conditions.

Materials and Methods

Flexible jaw coupling

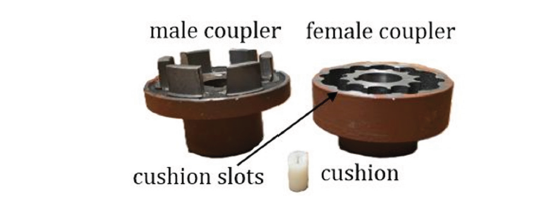

In the present research, a flexible jaw coupling was studied made of GG20 cast iron and the cushions of the coupler are originally made of neat Polypropylene (PP), as shown in Figure 1. The coupling can transfer up to 12kW of rotational power.

Figure 1:Flexible Jaw coupling with polymeric cushions.

Material and fabrication parameters

The material used for the impeller fabrication is Polyamide-6 reinforced with carbon fibers (Spectrum PA6-CF15, Spectrum Filaments, Pęcice Małe, Poland) in a weight percentage of 15% [6]. The fabrication of the cushions was achieved through a Raise Pro 2 3D printer (Raise 3D Technologies, Inc., Shanghai, China) via the Material Extrusion (MEX) method. Idea maker software v4.4.3 Alpha (Raise 3D Technologies, Inc., Irvine, CA, USA) was used to define the printing parameters of the fabricated parts, as summarized in Table 1. Considering that composite filaments are extremely abrasive, a 0.80mm hardened steel nozzle was used for their fabrication. To ensure the best overall mechanical properties, the filament was dried at 90 °C for 6h before printing. The printed cushion along with the original one are presented in Figure 2. The mechanical properties as well as the dynamic behavior of both PA6- CF15 and neat PP are summarized in Table 2 [7-10].

Table 1:AM Impeller printing parameters.

Table 2:Mechanical properties and dynamic behavior of PA6-CF15 and neat PP.

Figure 2:Injection molded neat PP cushion (left), 3D-prinded PA6-CF15 cushion (right).

Coupling design and computational structural analysis

The coupling was 3D-scanned using a using an Einscan HX 3D Scanner (Shinning 3D, Hangzhou, China) at 0.05mm resolution. The digital twin of the original coupling was designed in SolidWorks 2023 (v. SP05) software and the final 3D model of each part had a less than 0.1mm deviation from the original part. The models were exported for further computational and simulation testing via a FEM model using ANSYS 2025 R1 software.

Results and Discussion

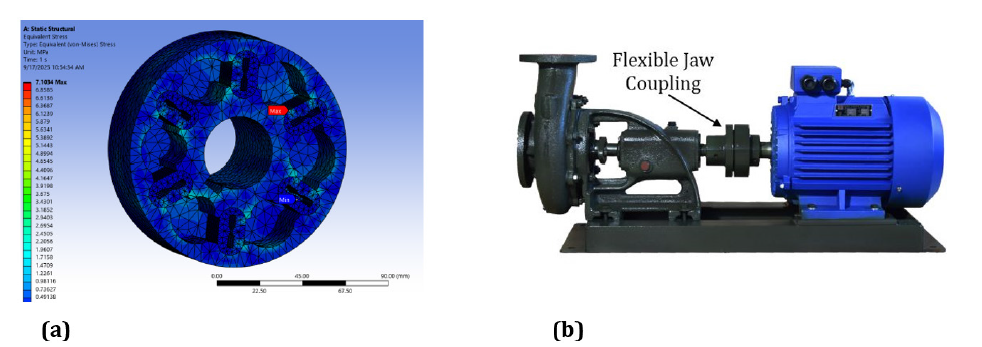

The maximum rated torque of the coupling was calculated at 36Nm according to the manufacturer’s specifications [11]. The generated mesh consists of 48540 elements. The equivalent stresses exerted on the coupling are presented in Figure 3. The maximum stress exerted on the cushions of the coupling was found to be around 7MPa, while the equivalent strain for the PA6-CF15 was 0.003mm. Results showed that PA6 composite could replace the neat PP as a construction material for coupling cushions. After the simulation test, a flexible jaw coupling with PA6-CF15 cushions was tested in real time operation. The startup of the electric motor was smoother, 4dB quieter than the original operation with PP cushions, which produces 83dB.

Figure 3:(a) Equivalent stress exerted on the coupling cushion; (b) Flexible jaw coupling with PA6-CF15 cushions operation setup.

Conclusion

Additive manufacturing provides a wide variety of applications for materials with enhanced mechanical properties. The use of PA6- CF15 as a fabrication material for coupling cushions has been found to be a suitable alternative of the original material. Furthermore, the enhanced dynamic behavior of the composite contributes to a quieter operation with less vibrations.

Acknowledgement

The authors would like to thank Chrysafi Pumps for providing the impellers for the present study, as well as technical information about the centrifugal pump impeller characteristics.

Conflict of Interest

The authors declare no conflicts of interest.

References

- Attaran M (2017) The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus Horiz 60(5): 677-688.

- Roscoe S, Cousins PD, Handfield R (2023) Transitioning additive manufacturing from rapid prototyping to high-volume production: A case study of complex final products. J Prod Innov Manag 40(4): 554-576.

- Kaikai X, Yadong G, Qiang Z (2023) Comparison of traditional processing and additive manufacturing technologies in various performance aspects: A review. Archives of Civil and Mechanical Engineering 23: 188.

- Mansour G, Papageorgiou V, Tzetzis D (2024) Carbon fiber polymer reinforced 3D printed composites for centrifugal pump impeller manufacturing. Technologies 12(4): 48.

- Papageorgiou V, Tsongas K, Mansour MT, Tzetzis D, Mansour G (2025) Mechanical properties and vibrational behavior of 3D-printed carbon fiber-reinforced polyphenylene sulfide and polyamide-6 composites with different infill types. J Compos Sci 9(2): 59.

- Spectrum filaments-technical specifications of PA6-CF15.

- Material data sheet PA6 CF15 BLACK roffelsen plastics general information.

- (2025) Polypropylene (PP).

- Mazurkiewicz M, Kluczyński J, Jasik K, Sarzyński B, Szachogłuchowicz I, et al. (2022) Bending strength of polyamide-based composites obtained during the Fused Filament Fabrication (FFF) Process. Materials 15(14): 5079.

- Maddah HA (2016) Polypropylene as a promising plastic: A review. American Journal of Polymer Science 6: 1-11.

- (2025) 11Kw electric motor specifications.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)