- Submissions

Full Text

Aspects in Mining & Mineral Science

Processing of Used Aluminium Coffee Capsules as a Contribution to Closed-Loop Recycling

Stefan Wibner*, Sebastian Samberger, Stefan Tichy and Helmut Antrekowitsch

Chair of Nonferrous Metallurgy, Technical University of Leoben, Austria

*Corresponding author:Stefan Wibner, Chair of Nonferrous Metallurgy, Franz Josef-Strasse 18, 8700 Leoben, Austria

Submission: October 28, 2025: Published: November 06, 2025

ISSN 2578-0255Volume14 Issue 3

Abstract

This case report investigates the recycling of used aluminium coffee capsules to maximise melting yields without adding primary aluminium, thereby promoting closed-loop recycling. Capsules differing in comminution degree and thereby organic content were dried, partly pyrolysed and remelted in a crucible induction furnace with NaCl-KCl-CaF₂ salt flux. Melting yields ranged from 50-95wt.%, with pyrolysis significantly enhancing performance. The recovered metal consisting of approx. 98wt.% Al was successfully rolled into 0.1mm thin sheets in a mini rolling mill by applying intermediate annealing steps. The study demonstrates an effective route for aluminium capsule recycling, right through to the production of new aluminium sheets.

Keywords:Aluminium recycling; Coffee capsules; Pyrolysis; Smelting salt; Remelting; Closed-loop recycling

Abbreviations:NFM: Nonferrous Metallurgy; Approx: Approximately; Al: Aluminium; Si: Silicon; Fe: Iron; Cu: Copper; Mn: Manganese; NaCl: Sodium Chloride; KCl: Potassium Chloride; CaF2: Calcium Fluoride; wt.%: Weight Percent; mm: Millimeter; °C: Degree Celsius

Introduction

Aluminium recycling is essential for reducing environmental impact and conserving resources. In this context, the energy demand for recycling is only around 5-10% of that required for primary Al production [1,2]. The recycling of used aluminium coffee capsules poses unique challenges due to the high amount of organic coffee residues and coatings compared to the low proportion of metallic Al. According to Gökelma et al. [3], the metal content of one capsule is about 7wt.%, which corresponds to approx. 1 gram. Other components of used capsules are 53wt.% water, 39wt.% coffee residues and 1wt.% coatings. Due to the high organic content, direct remelting in an aluminium recycling plant would not be possible without prior processing. In Austria, collected used capsules are sent to the company Höpperger, where the coffee grounds are separated from the packaging material through shredding and washing processes. The raw materials obtained are aluminium, which is returned to the cycle, and organic coffee residues, which can subsequently be used to produce biomethane [4]. This case report describes the processing of previously differently treated capsule materials at the Chair of Non-Ferrous Metallurgy in order to recover a high amount of metallic Al. In this context, the aim is to avoid the addition of primary aluminium during remelting, thereby enabling closed-loop recycling. The produced ingots are further processed into thin sheets. The latter could then be used again in capsule production, but investigations in this field are not part of the study.

Case Presentation

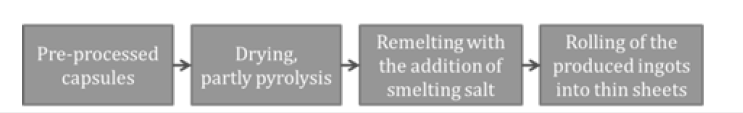

As part of the project at NFM, capsule materials that have been pre-processed in different ways were provided by an industry partner. The upstream processing steps are designed to partially separate the adhering coffee residues. The input materials used for further experiments differ both in terms of their organic content and their degree of comminution. This means that the settings in the upstream comminution unit (e.g. shredder) are different in each case. In addition, some of the input materials are also compacted into briquettes. The process flow for the recycling of used capsules, how it is fully illustrated at NFM, is shown in Figure 1. The drying and partial pyrolysis of various input materials is carried out at NFM by using a drying chamber and a pyrolysis furnace. The first process takes place at 105 °C for 24 hours to remove any moisture. The second requires a temperature of about 500 °C for some hours under nitrogen atmosphere to volatilise organic components and is only partly applied (Figure 2(1)). After this, the raw materials are converted into metallic aluminium through remelting processes with the addition of smelting salt (Figure 2(2)). This step is carried out in a crucible induction furnace. Here, a salt mixture consisting of NaCl, KCl and CaF2 is necessary. The functions of the salt can be summarised as follows: [1,2].

Figure 1:Process flow for recycling of coffee capsules an NFM.

Figure 2:Representation of (1) Pre-processed capsules, (2) Aluminium ingot after remelting by adding a salt mixture, (3) Smaller ingots after cutting and remelting, (4) Produced aluminium sheets.

a. Absorption of impurities,

b. Protection against oxidation by the ambient atmosphere,

c. Breaking up of oxide layers, thereby promoting

coagulation into an aluminium melt.

It is important to note that there is no dilution with primary aluminium, i.e. only capsules are recycled. Melting yields for preprocessed materials reached 50-95wt.%, with pyrolysis enhancing yields significantly. Briquetting input materials prior to melting showed no significant improvement in yields but increased reaction intensity. The chemical composition of the extracted metal is 0.35wt.% Si, 0.62-0.65wt.% Fe, 0.15wt% Cu, 0.65-0.68wt.% Mn and approx. 98wt.% Al as well as traces of other elements. Due to their sizes, the ingots produced in this step must be cut into smaller sections using a band saw. These are then recast in another induction furnace to form ingots weighing approx. 100grams, which serve as the starting material for the final rolling process (Figure 2(3)). The forming takes place on a mini rolling mill at the Chair of NFM, where the aluminium is rolled into sheets with a final thickness of 0.1mm (Figure 2(4)). Due to the work hardening that occurs, appropriate heat treatments are also necessary.

Discussion

The investigations presented in the case report show that a significant increase in melting yield is possible through appropriate preparation of the capsule materials. A high degree of comminution leads to improved separation of coffee residues and thus to a higher melting yield. If these materials are additionally pyrolysed, the highest melting yields of approx. 95wt.% are achieved. The lowest yields result with a limited degree of comminution, which means that the organic matter is only partially separated, and without applying pyrolysis. Compacting the material does not increase the yields. Tichy [5] has conducted similar experiments on a smaller scale with capsules and coffee pods, in which the coffee grounds were emptied before remelting. These showed that the pyrolysis of the capsules increases the melting yield from 70 to 95wt.% and has an even greater effect on the coffee pods. The aluminium ingots produced in the experiments of this case report are subsequently rolled into thin sheets, with intermediate annealing required between the individual rolling passes due to work hardening. The aim would be to use the sheets produced to manufacture capsules, but it is not part of this investigation. The entire study makes a significant contribution to the closed-loop recycling of Al capsules, as it shows that aluminium sheets with a thickness of 0.1mm can be produced without the addition of primary aluminium.

Acknowledgement

The authors thank ARAplus GmbH and Constantia Teich Austria for providing materials and funding.

References

- Krone K (2000) Aluminum recycling: from raw material to finished alloy. Beuth, Düsseldorf, Germany.

- Schmitz C (2006) Handbook of aluminium recycling. Vulkan Verlag, Essen, Germany.

- Gökelma M, Dian D, Oner IE, Friedrich B, Tranell G (2020) An assessment of recyclability of used aluminium coffee capsules. Light Metals pp. 1101-1109.

- Lebensraum Tirol, Success Stories: Hö

- Tichy S (2025) Aluminium coffee capsule recycling: improving metal recovery. European Metallurgical Conference, Hamburg, Germany.

© 2025 Stefan Wibner. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)