- Submissions

Full Text

Aspects in Mining & Mineral Science

Mining in the New Era

Andreas Benardos*

Professor, School of Mining and Metallurgical Engineering, National Technical University of Athens, Greece

*Corresponding author:Andreas Benardos, Professor, School of Mining and Metallurgical Engineering, National Technical University of Athens, Greece

Submission: July 28, 2024: Published: September 19, 2025

ISSN 2578-0255Volume14 Issue 1

Opinion

The global shift toward green development and the increasing demand for critical raw materials make the mining industry more relevant than ever. The new era requires not only increased output but also more sustainable and responsible mining operations. In this context, technological advancements serve as the catalyst for the sector’s necessary transformation. Innovation has always been an integral part of the extractive industry, which consistently adopted pioneering scientific developments and their applications. From the innovation in water storage and reuse in the ore-washing plants of arid ancient Lavrion, to the first commercial use of the steam engine in underground coal mines in Great Britain in the 1700s for water drainage, from Nobel’s invention of dynamite in the 1800s, to the use of the first computers for mining research in the early 1980s [1], our industry has always been there to test, design, and benefit from the potential of new technological tools.

Today we stand at the beginning of a new technological revolution (Industry 4.0), characterized not by a single innovation, but by the seamless integration of a range of systems, tools, and innovations capable of recording, analysing, understanding, and ultimately optimizing production characteristics. This digital transformation process is reshaping not only how we work, but the very essence of the production process.

Machine Learning is the core of this transformation, offering the fusion of information (data fusion), i.e., the integration of all data from various sources to create autonomous structures for analysis, understanding, and prediction of the desired outcome. In the case of mining and metallurgy, new developments can offer:

a. Introduction of automation and robotics: Through the implementation of process automation and autonomous or semi-autonomous robotic systems, it becomes possible to improve efficiency, productivity, and safety, reducing human presence to only the most essential tasks. This is currently the most widely adopted technological domain in mining operations and likely the one with the greatest advancement in the coming period.

b. Internet of Things (IoT) and data: Machine learning algorithms can be used to establish a fully controlled working environment, transmitting real-time operational data of equipment, its condition, usage, and productivity, as well as the prevailing conditions in the mine (e.g., stability, ventilation). These data can be analysed to optimize processes, predict maintenance needs, and improve overall operational performance.

c. Optimization of exploration and deposit targeting: Unlike traditional exploration methods that require significant resources and time, the analysis of historical exploration records, geological, lithological, and other spatial data and correlations can offer targeted site identification, increasing the chances of successful discovery. This reduces exploration costs, resource commitments, and simultaneously the environmental footprint of exploration activities.

d. Improved recovery and exploitation of low-grade

deposits: Full knowledge and modelling of the deposit through

digital twins, creating a dynamically evolving system, can lead

to optimal exploitation design through targeted high-precision

solutions. This allows for maximum recovery, reduced

redundant works, increased selective mining, and lower

beneficiation costs.

e. Minimization of environmental footprint: The

development of smart and targeted solutions by reducing

intervention areas or minimizing required works in exploitation,

and the use of digital twins or machine learning algorithms for

the automatic regulation of metallurgical process parameters,

help lower energy needs and the overall environmental

footprint of operations.

f. Virtual and augmented reality (VR/AR): VR and

AR technologies can be used for training, simulation, and

remote support in mining operations. They allow workers to

visualize complex mining environments, plan operations more

effectively, and solve problems in real time.

g. Blockchain technology: The application of blockchain

can improve transparency and traceability in the supply chain,

ensuring ethical sourcing of minerals and metals. It can also

enhance transactions, contracts, and payments between mining

companies, suppliers, and customers.

Recent examples, such as the use of machine learning algorithms in Rio Tinto’s copper mines or autonomous drilling in Sweden by LKAB, demonstrate the practical application and benefits of these technologies (Figure 1).

c. Increase the preheat and interpass temperature of HY-100 steel prior to welding in order to allow hydrogen to escape the weldment.

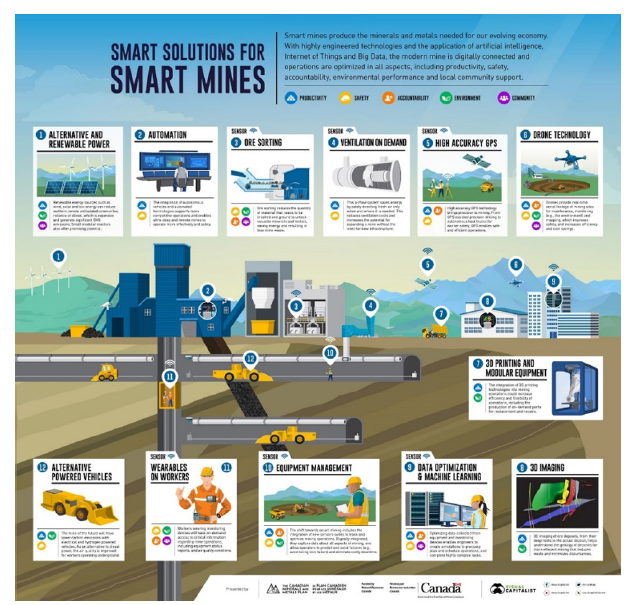

The Canadian Minerals and Metals Plan had already identified these technological trends early on, as presented graphically in Figure 2 [2]. Although artificial intelligence had not yet fully matured and many of its disruptive innovation features haven’t been introduced at the time, many aspects of the plan are now being realized in practice. These capabilities are only some of the disruptive innovations that are emerging in the mining industry, bringing significant new potential. However, they are accompanied by high-level challenges and, most importantly, prerequisites that are critical for their successful implementation.

Figure 1:Computer - mainframe IBM4341 - usage in Harmony mine (South Africa) in the 1980’s [1].

Figure 2:New opportunities emerging in mining through the adoption of advanced technologies.

The first and most essential requirement is understanding that the application of AI (or ML) is not reduced only to software implementations that offer easy solutions materialized with the mere clicking of a button. On the contrary, the crucial initial step involves the collection of a large volume of clearly defined and well-documented data which will be capable of capturing the patterns and behaviour of the evaluated process or phenomenon [2]. This, in turn, requires extensive fieldwork and investigation campaigns that will enable the collection of sufficient data for the model training. More importantly, in cases involving complex phenomena, the data pre-processing is required, along with the development of new indicators and indices or features based on primary data that can better reflect the patterns emerging. This feature engineering process necessitates a deep knowledge of the modelled phenomenon, something that cannot be done by a software engineer, but rather by experts having familiarity and an in-depth understanding of the subject at hand.

The second issue is about the correct interpretation of AI (or ML) outcomes/generalizations. Obviously, this is vital for the evaluation and application of the developed models. Machine learning can offer valuable predictions and solutions, but these must be critically assessed and not adopted blindly just because they “are produced from the model.” Interpreting results requires engineering judgment (Human-in-the-Loop), which includes the understanding the outputs, the recognition of inherent limitations and the evaluation of potential practical consequences. In this way, the reliability and applicability of the results are assessed, ensuring that machine learning contributes to a better decision-making process and will be facilitating towards the solution of real-world problems.

In summary, the application of machine learning in the mining industry offers vast opportunities for performance and efficiency improvement. However, it faces numerous challenges, such as the need for reliable and extensive data, the development of new data processing methods, and the requirement for sound engineering judgment for the interpretation of the results. With the right approach, machine learning can become a powerful tool for process improvement and industry development, while at the same time providing solutions to key mining challenges.

References

- Emere GTG (1983) A computerized labour-control system for Harmony Gold Mine. Journal of the South African Institute of Mining and Metallurgy pp. 105-112.

- The Canadian Minerals and Metals Plan – CMMP (2019) Smart solutions for smart mines, infographic.

© 2025 Andreas Benardos. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)