- Submissions

Full Text

Academic Journal of Engineering Studies

Managing Cracks in Large Concrete Coffee Drying Yards

Fairbairn MRE1* and Moura PMR2

1Professor, COPPE/The Federal University of Rio de Janeiro, Civil Engineering Department, Brazil

2Rural producer, Systems Engineer, Fazenda Trapiá, Minas Gerais, Brazil

*Corresponding author:Eduardo MR Fairbairn, Professor, COPPE/The Federal University of Rio de Janeiro, Civil Engineering Department, Brazil

Submission: March 29, 2023; Published: April 11, 2023

.jpg)

ISSN:2694-4421 Volume3 Issue2

Abstract

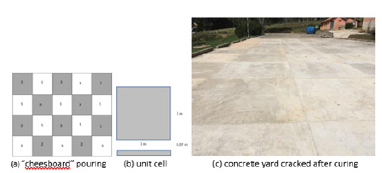

This paper presents a case study on the construction of a concrete patio for drying coffee in the Mantiqueira range, state of Minas Gerais, Brazil. It is demonstrated that the appearance of cracks in a structure of this type is inevitable. A “chessboard” construction scheme was then used in which the cracks will appear at the weakest point, which is the point where the “black and white squares” touch each other. No materials were used to create expansion joints, as they naturally appeared without the need for wooden or plastic strips. The use of such strips could compromise the proper functioning of the yard due to their aging. Crack opening was calculated for the standard cell. After construction, the calculation hypotheses were verified, and the yard has been regularly used for drying coffee beans since 2016.

Keywords:Young´s modulus; Poisson´s ratio; Hydration; Coffee beans; Tensile strength

Introduction to Injections

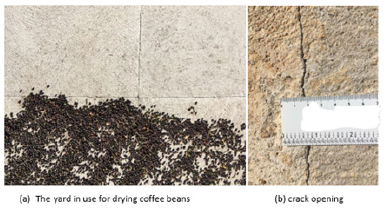

In the coffee-growing regions in Brazil, coffee beans are typically dried in the sun on large concrete patios (Figure 1). The engineering used to build these patios is not very sophisticated, basically using traditional techniques without great technological control. To prevent uncontrolled cracking of the concrete, square plates are defined by placing wooden joints at regular intervals. However, over time, the wood rots, and leaves voids where coffee beans can become lodged. As a result, these beans can begin to rot and cause further issues (Figure 2). Instead of using wooden slats, other solutions can be envisaged such as using thinner and more durable plastic bars. However, plastic bars subjected to the weather variations (sunshine, rain, strong ambient temperature gradients) also age and become brittle. This article proposes a solution to this problem using straightforward techniques that are based on traditional regional techniques and verified through fundamental concepts in the mechanics of cementitious materials. As the properties of the materials could not be determined through laboratory analysis and the construction techniques are handmade, the magnitudes of the properties of the materials involved in solving the problem were estimated based on common sense and bibliographical references. The solution was applied to a coffee drying yard on a coffee plantation farm in the south of the state of Minas Gerais in Brazil. The crack openings were measured, and it was verified that the order of magnitude was calculated with the available default values. It was verified that the drying yard fulfills its role, and the construction is carried out in a very simple way with the use of unskilled labor and unsophisticated equipment.

Figure 1:Coffee drying in concrete patios (Trapiá Farm in the Mantiqueira Range, MG, Brazil).

Figure 2:Rotten wooden joints with coffee beans in the voids.

Mechanical Analysis

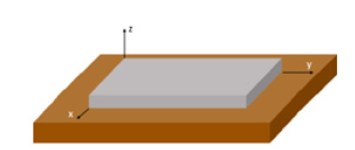

Figure 3:Idealization of concrete floor on the ground.

There are several causes of cracking in concrete depending on the use, construction techniques, boundary conditions, types of loading, environmental conditions, chemical attack, etc. For a floor of considerable size, one of the most important causes is the physical-chemical- mechanical phenomena that take place in the early ages. Concrete is a porous media chemically reactive [1] and at its early ages the effects of hydration are very significant. Mechanical properties such as Young’s modulus and strength evolve with hydration. The water in the pores participates in the hydration reaction causing autogenous shrinkage and evaporates causing shrinkage by drying. These shrinkages, depending on the restrictions to which the structure is submitted, can cause stress. On the other hand, casting concrete outdoors subjects the structure to spatial and temporal thermal gradients that can induce stress due to environmental conditions. If the stresses exceed the concrete’s tensile strength at a given age (hydration), cracks will appear and evolve according to the loads imposed on the structure [2]. Considering that no stresses can develop in the z axis of the floor (Figure 3), and that the distortions are negligeable, the plane stress equations for linear elastic material can be written as.

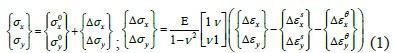

where 𝜎 is the total stress, 𝜎 0 is the initial stress, Δ𝜎 is the stress variation, 𝐸 is the Young´s modulus, 𝜈 is the Poisson´s ratio, Δ𝜀 is the variation of the total (measurable) strain, Δ𝜀sub>𝑆=Δ𝜀𝑆,𝑑+Δ𝜀𝑆,𝑎 is the variation of the shrinkage strain (drying+autogenous) and Δ𝜀𝜃 is the variation of thermal strain. Concrete cracks when 𝜎=𝑓𝑐𝑡, 𝑓𝑐𝑡 being the tensile strength of concrete. To formulate the problem at hand without using sophisticated laboratory techniques and numerical modeling, several simplifying assumptions were made: (i) The initial stresses were assumed to be equal to zero; (ii) The Young´s modulus, the Poisson´s ratio and the tensile strength do not vary with time (hydration); (iv) The strains are equal in the x and y directions (𝜀=𝜀𝑥=𝜀𝑦) giving rise to equal stresses in these two directions (𝜎=𝜎𝑥=𝜎𝑦); (v) We consider that the concrete floor may slip relative to the soil in the x and y directions. However, there are internal constraints that are imposed by differential shrinkage and thermal strains along the height z of the concrete slabs. Moisture evaporation, hydration, and thermal deformations are not constant along the height z, being more pronounced on the surface in contact with the air. There may also be differential displacements between regions of the slab in the x and y directions due to different incidences of sunlight and consequent temperatures. Therefore, as an upper bound configuration, we will consider the total measurable strains Δ𝜀 to be equal to zero. It is important to consider that the more the concrete is cured, and hydration progresses, the greater the tensile strength and the smaller the physical differences between the different regions of the structure. Taking into account the above considerations, equation (1) can be rewritten as:

It is interesting to note that the thickness of the floor is not part of the above equations. It is well known that in problems whose loading is mainly imposed strains, as is the case of the problem formulated here, varying the thickness does not improve the cracking resistance of the structure. Thickness is mainly responsible for resistance to bending caused by soil settlement and other actions that may cause bending in the concrete yard.

Case Study

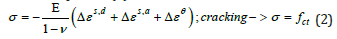

The case study presented in this paper is the construction of a concrete coffee drying patio (approximately 1500m2) in the Trapiá coffee plantation farm in the Mantiqueira mountain range, in the south of the State of Minas Gerais, Brazil, in 2016. The region is known for its high-altitude climate, which creates ideal conditions for producing high-quality coffee. To verify the tendence to crack of the yard we used equation (2) estimating the following parameters: We considered some concrete with 𝑓𝑐𝑡=2𝑀𝑃𝑎, 𝐸 =20𝐺𝑃𝑎 and 𝜈=0.2. We took from the literature [3] values for Δ𝜀𝑆,𝑑= 500∙10−6 and Δ𝜀𝑆,𝑎=100∙10−6 corresponding to low strength concrete. We estimated a temperature variation of Δ𝜃=15𝑜𝐶 and used a common value for the coefficient of thermal dilatation 𝐶𝑇𝐷=10−5⁄𝑜𝐶 giving Δ𝜀𝜃=𝐶𝑇𝐷∙Δ𝜃=150∙10−6. With this values, equation (2) gives:

Equation (3) indicates that the calculated stress is much greater than the tensile strength. This means that even if the values of the parameters that characterize the restrictions (boundaries), the concrete and thermal variations are erroneously estimated, cracking will inevitably occur. In any case, the stresses originated by each of the deformations taken separately (drying, autogenous and thermal shrinkage) would be sufficient to crack the concrete. In view of the inevitability of cracking (see, for instance [4]), the main idea is that expansion joints will not be made at all (whether with wood, plastic, or other material), but that cracking will be induced to occur in predetermined places. For this, a traditional, regionally performed technique was employed, whereby concrete was cast in the form of a “chessboard”. Following this method, the “white squares” were poured first, with the “black squares” added at a later stage (Figure 4a). In this way, cracks will appear at the weakest points of the structure, namely on the vertical surfaces where the “white” and “black squares” touch. It is now necessary to verify whether the crack openings will be compatible with the use of coffee drying patios. A simple calculation indicates that an approximate value can be obtained by multiplying the imposed strains (upper-bound) by the edge size of the square, which is 3m (Figure 4b). This gives a relative displacement between squares of:

Figure 4:Chessboard” concrete pouring.

𝑤=(500+100+150)10−6∙3000mm=2.25mm (4)

The yard was built with non-reinforced concrete and the cracks appeared exactly in the points where they were expected as indicated in Figure 4c. The cracks showed an opening of the order of magnitude of 2mm as predicted, being compatible with the use of patios for drying coffee beans (Figure 5). The cracks have an opening that does not allow the penetration of coffee beans.

Figure 5:Cracks in the concrete patio.

Concluding Remarks

This paper presents a case study of the construction of a concrete coffee drying patio in which a construction technique was used that avoids the use of contraction joints. Basic concepts of the mechanics of cement-based materials were used to predict the place of appearance of cracks and the order of magnitude of their opening. In this way, the cracks themselves functioned as natural joints given that, as predicted by theory, cracks are inevitable in this type of construction. It is also important to consider that, as concrete is not reinforced, cracks (i.e., joints) are not a potential way for water to corrode the reinforcement and deteriorate the concrete what improves the durability of the structure. The concrete coffee drying yard presented this aper has been used successfully since 2016

Acknowledgment

The authors are grateful to Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brasil (CAPES)- Finance Code 001.

References

- Fairbairn EMR, Azenha M (2019) Thermal cracking of massive concrete structures. (1st ), Springer International Publishing, New York City ,US.

- Lim Z (2021) How big a concrete floor slab can be casted without cracks? American Concrete Institute Malaysia Chapter, Malaysia.

- Isović MS, Markovski G, Ćećez M (2012) Shrinkage strain of concrete-causes and types, Gradevinar 64(9): 727-734.

- Acker P (2013) Cracking of concrete parts 1. Concrete 46: 60-62.

© 2023 Fairbairn MRE. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)