- Submissions

Full Text

Academic Journal of Engineering Studies

Fall Protection Prevention and Recommendations to Improve Safety in Construction Industry: for Michigan and the U.S.

Arezki Mekhaldi1, Kasim Korkmaz1* and Mohamed El-Gafy2

1Eastern Michigan University, Construction Management, Ypsilanti, Michigan, USA

2Michigan State University, Construction Management, East Lansing, Michigan, USA

*Corresponding author:Kasim Korkmaz, Eastern Michigan University, Construction Management, Ypsilanti, Michigan, USA

Submission: February 24, 2023; Published: March 15, 2023

.jpg)

ISSN:2694-4421 Volume3 Issue2

Abstract

Falls are the leading cause of fatalities in the construction industry, and fall protection was the immediate response to many fatalities on job sites. It has received attention from legislators and government agencies such as the Occupational Safety and Health Administration (OSHA). This paper examines several fall protection systems, the history of OSHA’s standards and regulations related to fall protection, define some fall protection systems proven efficacy in decreasing fatalities of the workers in the construction industry, discuss some misconception about the protection system, and finally how to optimize safety within the context of the engineering, and human factors. Further, the methodology to engage is comparing fall fatalities in the U.S. and the State of Michigan in the construction industry and all combined industries as well, based on data from the bureau of labor statistics. the information was categorized according to their types of industry. The paper compares fall fatalities in the construction industry and all combined industries. The third level of the research profiles MIFACE investigation reports of only the construction industry according to; age, type of exposure, causes, circumstances, and observation of the OSHA’s inspectors. The research provides recommendations for the safety protection systems that improve safety in the construction industry.

Keywords:Occupational Safety and Health Administration (OSHA); Fall Protection Systems (FPS); the U.S. Bureau of Labor Statistics (BLS); Michigan Fatality Assessment and Control Evaluation (MIFACE)

Introduction

The growing economy has improved the job market outlooks for construction workers. The increase in employment opportunities has exposed workers to more severe hazards and fatal injuries (Asfaw et al., 2011; Davies et al., 2009; Boone & Van Ours, 2006). Falls remain a leading cause of fatal injury to construction workers (BLS, 2016, Dong et al., 2014). An effort to evaluate fatalities among Michigan construction workers within all industries and benchmark it with national U.S. statistics has indicated that 13% of Michigan fatalities are construction related compared to 15% of the U.S. fatalities nationally. Additionally, Bunn et al. (2006) have concluded that investigating the characteristics of fatal injuries is essential for preventing failure accidents. The secretary of labor adopted construction standards, which have been issued under the construction safety act in 29 Code 0f Federal Regulations (CFR) Part 1518, as OSHA standards following section 6(a) of the OSH act (36 FR 10466, May 29, 1971). The safety and health regulations for construction were redesigned as part of 1926 and later in 1971 (36 FR 25232, December 1971). OSHA adopted several regulations related to fall protection under section 6(a) of the OSHA act. The agency consolidated all requirements, except where it is provided in subpart M [51 FR 42718], on November 25, 1986. The regulations were revised on August 5, 1992 (57 FR 34656), considering new information submitted by the Precast/Prestressed Concrete Institute (PCI) relating to fall protection. The agency updated the safety act on March 29, 1993 (58 FR 165515) to respond to issues raised by the concrete construction industry on August 5, 1992. The final regulation, rule 29 CFR part 1926, subpart M, which was enforced on February 6, 1995, provided general fall protection requirements for the construction industry [1]. According to the bureau of labor statistics, the 2017 database shows 336 fall fatalities out of 971 cases of construction fatalities. To prevent these fatalities, OSHA’s construction fall standard 29 CFR 1926 subpart M has several options to choose from to protect workers. Employers must select from these protection systems depending on job conditions.

?Unprotected sides and edges can protect workers when they are exposed to falls from unprotected sides and edges on horizontal or vertical walking/working surfaces 6-ft higher or more above the lower level, the option to choose from one of the conventional three types of fall protection systems such as guardrail systems, safety net systems and personal fall arrest systems. OSHA expects employers to implement one of them before starting the construction work until the project is completed to eliminate and reduce exposure to falling hazards [2].

Like the unprotected sides and edges when constructing leading edges which are considered unprotected sides and edges during periods when the site is empty, with the condition of 6-ft high or more above a lower level. The employer must protect the workers or strangers. Fall fatalities can be caused by slipping into holes, tripping over holes, and falling objects through a hole. The employer must protect the worker from these hazards and must install covers over the hole, erect a guardrail system around the hole or use personal fall arrest systems. The holes are considered any type of opening, such as a roof skylight or under construction building staircases. Workers performing overhead bricklaying with the same high condition must use one of the conventional fall protection systems or controlled access zones that defines the area implemented to the analysis part [3]. Fall protection is the active means to protect workers who experience gravitational forces that cause workers to hit lower levels or objects. There are some misconceptions about fall protection; when workers in the construction industry are exposed to fall hazards more than 6 feet in height, they must be protected by conventional fall protection systems. Guardrail systems and net safety systems could be considered more passive systems, and reasons that BFAS is not used universally to eliminate total fatalities include biased assumptions that fall protection systems are not required by OSHA, performing work with fall protection systems that would be costly for the construction industry comparing to other determinants, and the requirement for more training.

Fall protection systems were not widespread due to a lack of information about fall protection, even though it has been used for decades. Once the demand for a fall protection system increased, the manufacturers started collaborating with job site workers and promoting research on user regulations. Today, numerous guidance and resource documents are available from OSHA, NIOSH, CPWP center for construction research and training. The use of fall protection systems requires a few measures to be taken into consideration; industry associates, manufacturers, and employers can determine the use of each system for each trade; therefore, they must provide online tools [4]. Further, understanding the limitations of using the fall protection system is by simply reading the manufacturer’s component instructions. Also, the possibility to enlarge the use of the fall protection system, such as a lanyard attached to an anchor, which might be used for other industries or occupations like steelworkers, rolling stock workers, and the fall protection system can be used in different situations, either the roof system is open or closed. Finally, the management-Ownersupervisor commitment could help understand the fall protection system, which is based on the combination of fall protection components in any given situation rather than deciding infeasibility based on the inability to apply only one of the fall protection components in the given situations and conditions defined before the analysis started.

This paper analyzes the U.S. Bureau of Labor Statistics census fatalities data over four years. Additionally, it examines the Michigan Fatality Assessment and Control Evaluation (MIFACE) assessment of the Michigan Occupational Safety and Health Administration (MIOSHA) Inspection database. The paper compared fall-fromheight fatalities in the State of Michigan and national data and categorized fatality rates according to fatality hazard exposure. Additionally, the paper analyzes the insightful information on fatality causation and circumstances provided in MIFACE’s investigation. Incident reports were qualitatively analyzed based on the worker’s age, job title, and incident circumstances on MIFACE’s inspection report’s recommendations to improve protection safety. The paper structured to give the methodology and data collection first, then data analysis part is given to explain the analysis and to give the results of the analysis. The results are given in comparison. Recommendations are provided according to the data analyses. The last part of the paper is the conclusion to finalize the paper [5].

Methodology and Data Collection

The paper inspects fatalities investigation reports. It focuses on the Michigan fatalities compared to national fatalities using data from the U.S. The Census of Fatal Occupational Injuries (CFOI), and Michigan Fatality Assessment and Control Evaluation (MIFACE). The scope of the analysis documents and benchmarks fatalities in all industries in the state of Michigan and the U.S by monitoring and comparing the fatalities in the construction industry, coded by (236XXX), which covers ten super-sector codes that start from 236000, 236100, 236110, 236115, 236116, 236117, 236118, 236200, 236210, and 236220 over a four-year study period to explain the situation and condition over the period investigated [6]. Additionally, the paper investigates the root causes of fatalities of Michigan workers by collecting information from the cases experienced and related to fall from elevation fatalities in the state of Michigan and in the construction industry in the state, prepared by MIFACE.

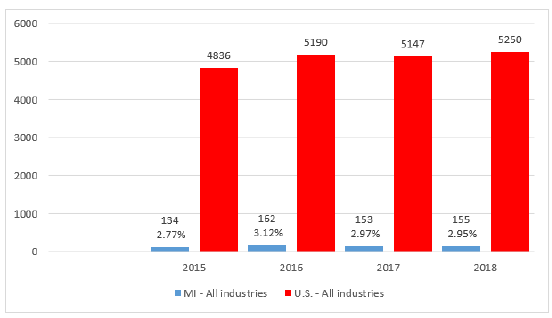

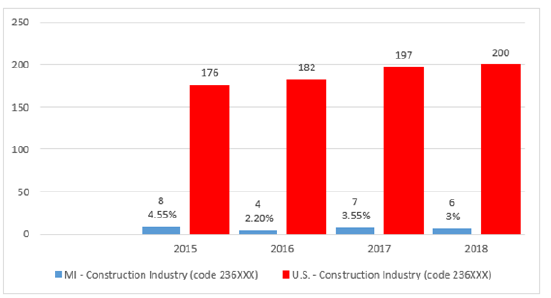

In the study, fatality rates have been collected for Michigan and nationwide. Data revealed that the highest number of fatalities in the Michigan population in all industries varied between 134 cases in 2015, which represents 2.77% of the U.S. fatality cases, followed by 162 cases (3.12%) in 2016, then 153 cases (2.97%) in 2017, and finally 155 cases (2.95%) in 2018. For the construction industry, Michigan Fatalities includes 8 fatalities represent the rate of 4.55% of U.S. fatality cases in 2015, followed by 4 cases (2.2%) in 2016, then in 2017, the case number rose to 7 (3.55%), and in 2018, there were 6 cases (3%). For fall from elevation fatalities in Michigan, the data collection narrowed the field of analysis of all chosen cases and divided them into five categories of falls: 1) FTLL: Fall to Lower Levels; 2) FFCSE: Fall from Collapsing Structure & Equipment; 3) FFSO: Fall from Surface or Opening; 4) FFSS: Fall from Scaffolds or Staging; and 5) FFR: Fall from the Roof..

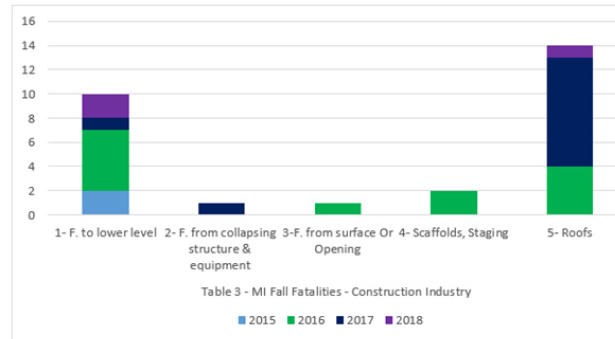

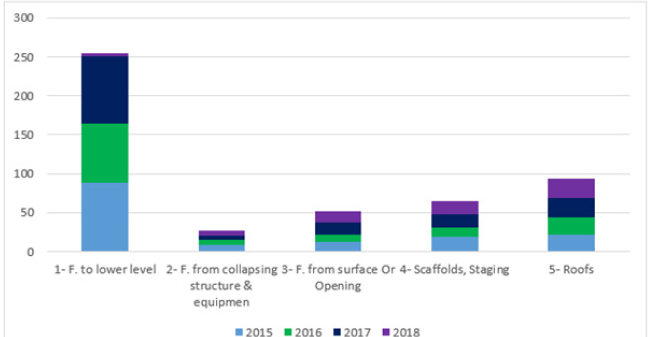

The database of MIFACE supported by inspection reports, contains detailed information about the cases and describes the type of fatality [7]. According to fall exposure results in Michigan, the highest number of falls under category 5 (falls from the roof) represent 75% of the cases in 4 years. Then, falls to lower levels (category 1) define 5 cases (41.66%), and the third place in category 4 (fall from scaffolds or staging) represents 33.33% of the overall falls registered. However, a few lower rate fall categories represent one or two cases for the remaining three categories, which vary between 8.33% and 16.67% consecutively. On the other hand, the highest number of cases nationwide, in the fall category, the fall to lower levels, which is the highest number, represents 88 cases (55.06%), then fall from the roof, which is the secondhighest number, vary depending on the years from 14.09% in 2015, 18.25% in 2016, 16.67% in 2017, and 37.31% in 2018. Followed in the third place is falling from scaffolds or staging, with 19 cases (12.75%) in 2015 and 17 cases (11.33% and 25.36%) in 2017 and 2018 [8]. Also, falling from a surface or opening represents 16 cases (10.67%) in 2017 and 15 cases (22.39%) in 2018. The remaining falling exposure categories vary from 12to 5 cases (8.05%-3.33%) within the four consecutive years 2015-2018.

Data Analysis

Figure 1 illustrates the ratio of Michigan fatalities compared to the U.S. fatalities in all industries. The data ranged from 2.77% in 2015 and 3.12% in 2016. These results might be attributed to the legal requirements to comply with the OSHA rules and regulations helped maintain the lower fatalities rates. Figure 2 illustrates the ratio of fatalities in Comparison between Michigan and the U.S. in all industries is lower than those in the construction industry. The percentages vary between 2.2% in 2016 and 4.55% in 2015. The trend of construction industry ratio is steady for the four years [9].

Figure 1:Michigan fatalities vs. U. S. fatalities.

Figure 2:Michigan fatalities vs. U.S. fatalities.

The above figures illustrates that the trend of all industries fatalities ratio is slightly lower than the fatalities ratio of the construction industry, but it is considered steady over the designated years. By investigating these data further, we can identify the major contributors of these fatalities in Michigan and Nationwide. Figure 3 identifies Michigan fatalities of falling from roofs represent the highest number of mortalities of 14 cases in the construction industry in the span of 4 years (2015-2018). Then, (falling to a lower level) in the second row at 10 cases. The third place in the number of mortalities represents category 4, falling from scaffolds or staging, which resulted in 2 cases. Finally, the fourth fatality number shared between the two remaining categories of exposure 2 and 3; falling from collapsing structure or equipment and falling from a surface or into an opening consecutively resulted in 1 victim each. Figure 4 shows the difference of the of the U.S. trend of fatalities compared to the trend in Figure 3. The number of fatalities in the U.S. is shown for the five categories of hazard exposure. The highest number of fatalities represents category 1 (falling to a lower level), resulting in more than 250 cases. The second is category 5 (falling from roofs), which resulted in almost 100 cases. The third hazard exposure is (falling off scaffolds or staging-category 4), which resulted in more than 60 cases. Next, falls from the surface or openings (category 3) resulted in around 50 cases. Lastly, the least fatal of all-hazards exposure was category 2, falling from collapsing structure or equipment and resulting in less than 30 cases. Additionally, it reveals that there are no incidents registered by the U.S. labor statistic for falling exposure types 2, 3, and 4 for almost five consecutive years, as displayed in Figure 3.

Figure 3:Michigan fatalities: Hazard exposure.

Figure 4:U.S. fatalities: Hazard exposure.

Finally, all fatalities resulting from falls in the MIFACE investigation report confirmed that employers did not develop, maintain, or coordinate an accident prevention program with the victims. A copy of this program should always be available on site [10]. Workers have failed to use protective measures such as protected edges with guardrail systems, safety net systems, or protect the victim himself by using a personnel fall arrest system or other alternatives for fall protection in case of infeasibility, which requires the employer to develop or implement a fall protection plan that meets the requirements of safety code and the regulations of OSHA. The investigation reports also highlights the lack of training in fall protection. Falling is considered a human failure factor that is not the sole cause of significant incidents, but it includes technical and organizational failures that lead to the outcome (HSE, 2005) [11].

Recommendations

The U.S. labor of statistics stated and revealed the facts without

speculating the root cause of the incidents. MIFACE investigation

reports demonstrated the incidents in more detail, showing incident

circumstances to allow the researchers to understand and improve

by using their recommendations to improve workplace safety. The

analysis of this paper disclosed the following suggestions.

a. Implementing more safety measures and a fall protection

system and coordinating with the companies to plan in advance

the fall hazard protection, propose solutions and integrate

these solutions, and finally control and monitor the proposed

safety measures for each working place with the participation

of both employer and employees to improve current working

place conditions and promote safety.

b. Implementing all conventional measures of the fall

protection system and open a line of communication for

construction companies, safety tools manufacturers, and

government agencies to get together to improve existing

equipment, tools, and safety rules and regulations, and more

importantly, invent more adequate procedures and safety

protection to respond to the current reality of the workplace

and improve the safety of the workplace.

c. Integrating behavior-based safety in comprehensive

safety approaches is described in several elements; the frontline

supervisors’ behavior and actions towards protection directly

affect workers’ perception of safe conduct and actions.

d. Supervisors should demonstrate leadership and safe

behaviors and comply with safety site policies.

e. Construction companies need to determine incident

causation and investigate unsafe behaviors, and this will help set

priorities for reorganizing or controlling occupational hazards

and identifying and correcting management measurement

deficiencies.

f. Focusing on regulatory compliance will not be enough to

prevent incidents, as regulation cannot anticipate all workplace

conditions and circumstances that may lead to an accident.

Conclusion

This paper examines several fall protection systems, the history of OSHA’s standards and regulations related to fall protection, define some fall protection systems proven efficacy in decreasing fatalities of the workers in the construction industry, discuss some misconception about the protection system, and finally how to optimize safety within the context of the engineering, and human factors. The paper compared fall fatalities in the construction industry. The results of the paper indicate that the fatality rates in the U.S. and Michigan are slightly different over the four-year paper period. The high mortality records are different between the US and Michigan. “Falling to lower levels” is the highest fatality hazard exposure in the U.S. In Michigan, the highest fatality hazard exposure is “Falling from roofs”. Despite the rules and regulations mandated by MIOSHA to ensure workplace safety, MIFACE investigation reports revealed information on ordinary circumstances of fall fatalities recorded in Michigan. Many employers and employees failed to comply with fall fatalities requirements. At last, the paper provides recommendations for the safety protection systems that improve safety in the construction industry.

References

- Al-Bayati AJ, York DD (2018) Fatal injuries among Hispanic workers in the US construction industry: Findings from face investigation reports. J Safety Res 67: 117-123.

- Anoymous (2017) Fall protection in construction 1926.501. Industrial Safety & Hygiene News 51(1): 42.

- Bethancourt J (2017) Fall protection: Overcoming misconceptions in residential construction. Professional Safety 62(03): 58-64.

- Bethancourt J, Cannon M (2015) Fall protection structural efficacy of residential structures for fall protection systems. Professional Safety 60(05): 58-64.

- Byrd B (2019) Understanding: Leading edge fall protection. Professional Safety 64(3): 26-28.

- Dong XS, Largay JA, Choi SD, Wang X, Cain CT, et al. (2017) Fatal falls and PFAS use in the construction industry: Findings from the NIOSH FACE reports. Accid Anal Prev 102: 136-143.

- Hamel K (2018) Fall protection beyond construction: Complying with OSHA's walking-working surface standard. Industrial Safety & Hygiene News 52(10): 38.

- Ivensky V (2017) Optimizing safety engineering, systems, human factors: Part 1. Professional safety 62(01): 36-45.

- Ivensky V (2017) Optimizing safety engineering, systems, human factors: Part 2. Professional Safety 62(02): 46-51.

- Stromme MH (2019) Guardrails, nets & fall arrests. Ishn 53(9): 16-16.

- Zlatar T, Lago EM, Soares WD, Baptista JD, Barkokébas B (2019) Falls from height: Analysis of 114 cases. Systematic Review 29: e20180091.

© 2023 Kasim Korkmaz. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)