- Submissions

Full Text

Advancements in Civil Engineering & Technology

Properties of Light Weight Concrete Produced with Calcium Carbide Waste (CCW) and Palm Kernel Shells (PKS) as Partial Replacements for Cement and Coarse Aggregate

Daniel Amoh1, Humphrey Danso2* and Elijah Kusi1

1Department of Construction Technology and Management Education, Akenten Appiah- Menka University of Skills Training and Entrepreneurial Development, Ghana

2Department of Civil Engineering, Akenten Appiah-Menka University of Skills Training and Entrepreneurial Development, Ghana

*Corresponding author:Humphrey Danso, Department of Civil Engineering, Akenten Appiah-Menka University of Skills Training and Entrepreneurial Development, Kumasi, Ghana

Submission: March 17, 2025;Published: August 20, 2025

ISSN: 2639-0574 Volume7 Issue 1

Abstract

The residue, calcium carbide waste (CCW), is mostly disposed of carelessly as waste in the environment that sooner pollutes the soil. To reduce environmental pollution, attempts have been made to utilize CCW sustainably, especially for building material applications. Currently, the construction industry is searching for alternate materials and products that are environmentally friendly to contribute towards the reduction of Carbon dioxide (CO2) emissions into the atmosphere. This study investigates the properties of concrete produced with CCW and palm kernel shells (PKS) as partial replacements for cement and coarse aggregates, respectively. CCW was substituted at 0, 5, 10, 15 and 20%, while PKS was kept constant at 5%. Concrete cubes (100 × 100 × 100 mm) and cylinders (200mm × 100mm) were prepared, totalling 150 specimens, and cured for 7, 14, 21 and 28 days. The findings revealed that the specimens with a 5% replacement of CCW and 5% PKS recorded the optimum results compared to 10, 15 and 20% CCW replacement levels. The compressive strength of the control was 16.49 N/mm2 as compared to the 5% CCW replacement which was 19.03N/mm2, representing a 15.4% improvement. The tensile strength of the control specimen was 1.74N/mm2, compared to 5% CCW replacement which was 1.93N/mm2, representing 10.9% improvement. Density and water absorption were 1844.87kg/m3 and 1.56% for control compared to 1759.74Kg/m3 and 1.82% for 5% CCW replacement. The abrasion results obtained were 1.05% and 0.89% for control and 5% CCW replacement, respectively. The study concludes that the use of CCW and PKS as partially replacing cement and coarse aggregates respectively enhances the properties of concrete and is suitable for lightweight concrete structural works. Further studies are recommended on the thermal properties of concrete produced with CCW and PKS. The use of CCW and PKS in concrete promotes sustainable construction by addressing waste management issues and reducing environmental pollution.

Keywords:Abrasion; Calcium carbide waste; Compressive strength; Density; Palm kernel shells; Sustainable construction; Tensile strength; Water absorption

Introduction

Concrete is the most commonly used material employed for construction purposes in the world today [1,2]. The general importance of concrete application in construction projects and civil works cannot be overemphasized [3]. The overwhelming demand for concrete in construction adopting normal weight aggregates (NWAs), such as gravel and sand has led to tremendous depletion in naturally occurring aggregates causing damages to the environment which are irreparable [4]. As a result, the need to search for more sustainable and renewable materials has been intensified. Some waste agricultural materials such as sawdust, maize cob, rice husk, coconut shell, PKS, etc. can serve as a good substitute [5,6]. One way to reduce the environmental impact of concrete is to use alternative materials for concrete production. According to Armah and Danso [7] & Bature et al. [8], a typical example of such alternative material is palm kernel shells (PKS). PKS is a waste material from the palm oil industry [9]. PKS is a lightweight and porous material that can be used as a full or partial replacement for coarse aggregate in concrete production [10]. Ibrahim [11], probed the feasibility of incorporating agricultural waste, including PKS in concrete production. The study shed light on potential advantages, including reduced environmental impact, associated with utilizing waste materials in the concrete formulation. Calcium carbide waste (CCW) is a material generated from oxy-acetylene gas used in welding [12]. CCW is abundant in our environment and research has been conducted to determine its use as a civil engineering construction material [13]. Adamu et al. [14], investigated the effects of calcium carbide residue-fly ash binder on the mechanical properties of concrete and observed that the hardened concrete produced from calcium carbide residue– fly ash mixtures had mechanical properties similar to those from normal Portland cement concrete. Gong et al. [15], conducted a study on the recycling and utilization of CCW. In the study, it was established that CCW is a renewable and sustainable material that can be used in various construction activities. A study by Olufemi et al. [16], investigated the flexural strength of concrete mixes with up to 100% PKS as a replacement for coarse aggregate. The flexural strength of concrete decreased with an increase in the percentage of PKS, but the strength was within the acceptable limit for concrete used in non-structural applications. Although numerous studies have been conducted on CCW and PKS separately, no work has been done so far on combining them for lightweight concrete production. The study therefore sought to investigate some of the physical and mechanical properties of concrete produced with CCW and PKS as a partial replacement for cement and coarse aggregate, respectively.

Literature Review

Calcium carbide waste (CCW) as a cement substitute

The increasing generation of agricultural and industrial waste is the major concern in developed countries as it could result in an unmanageable environmental pollution. It is clearly known that cement is one of the conventional materials used in the construction of civil engineering infrastructures. However, the price of cement has rapidly increased due to the sharp increase in the cost of energy. The over-dependence on the utilization of industrially manufactured Ordinary Portland Cement (OPC) has kept the cost of construction of concrete structures high. This has prevented underdeveloped countries from meeting their infrastructure needs of their citizens [17]. To reduce the cost of material and construction to an affordable rate, many research works have been directed towards the utilization of cheap and readily available local materials such as industrial and agricultural by-products as substitutes for aggregate or binder in construction materials [18]. Similarly, to reduce environmental pollution, attempts have been made to use CCW in more useful ways, especially in the building industry. Research findings such as that of Wang and Le [19] have indicated that CCW when combined with certain pozzolanas such as fly ash, silica fume, etc., containing high silicon dioxide and aluminum oxide could be due to pozzolanic reactions which yield final products that are similar to those obtained from cement hydration process. Ogork and Ibrahim [20] assessed the effect of CCW as an additive on the properties of cement paste and concrete and reported that the addition of CCW in concrete showed an increase in compressive strength with increase in CCW additive up to 0.5 % and decrease in compressive strength with further increase in CCW content. They also found CCW addition increased the consistency, but decreased drying shrinkage and setting times of cement paste, and could be used as an accelerator. Furthermore, they indicated that CCW addition also slightly increased the workability of concrete..

Palm kernel shell (PKS) as coarse aggregate substitute

Palm kernel shell (PKS) also referred to as oil palm kernel shell (OPKS) and oil palm shell (OPS) in literature are highly lignocellulosic biogenic waste generated from the processing of crude palm oil [21]. This is the shell parts that remained after the nut has been removed and after crushing in the palm oil mill and is obtained as residual waste in the extraction of the kernel from the nut. It is obtained as crushed pieces after threshing or crushing to remove the seed which is used in the production of palm kernel oil. Abdullah [22] expressed that palm oil processing has six stages, namely; sterilization, threshing, pressing, depericarping, separation of kernel and shell and clarification. PKS is obtained as crushed pieces, the sizes of which vary from fine to coarse aggregates, after crushing of palm kernel to remove the seed, which is used in the production of palm kernel oil [23]. The colour of the shell ranges from dark grey to back with a variety of shapes such as curved, flaky, angular, polygonal, elongated, roughly, parabolic and other irregular shapes depending on the breaking pattern of the nut [22].

The surface of the shells is fairly smooth for both the concave and convex faces with rough and spiky broken edges. PKS are hard in nature and do not deteriorate easily when used for concrete or leach to produce toxic substances [24]. The thickness varies and depends on the species of palm tree from which the palm nut is obtained and ranges from 0.15-8mm [25]. According to Mohd et al. [26] PKS possesses a hard characteristics as coarse aggregate traditionally used for concrete production. Danso and Appiah-Agyei [27] studied the properties of lightweight concrete manufactured with different sizes of PKS and found that size differences of PKS as replacement of coarse aggregate have impact on the properties of the concrete. Jackson et al. [28] investigated the strength properties, workability and density of concrete produced with PKS and coconut shells, and recorded up to 13.29 MPa compressive strength. Azunna [29] studied the compressive strength and water absorption properties of concrete produced with PKS as partial replacement of coarse aggregate and found between 4.44 and 4.78 MPa compressive strength and between 10 and 25% water absorption.

Concrete and its properties

According to Courland [30], concrete is the most commonly used material employed for construction purpose in the world today. Azunna [29] expressed that the high cost of concrete constituents such as cement, fine and coarse aggregate has necessitated the need to search for alternative construction materials. The present consumption of concrete is over 10 billion tons a year, more than 10 times the consumption of steel by weight and it is the most inexpensive and the most readily available material [31]. According to Naik [32], the cost of production of concrete is high compared with other engineering construction materials. Concrete is a lowtemperature bonded inorganic material and its reaction occurs at room temperature [33]. Concrete conducts heat slowly and can store considerable quantities of heat from the environment [34]. Concrete can be used as a protective coating for steel structures, besides being an ideal construction material [19]. Concrete is not entirely impervious to moisture and contains soluble salts which may cause efflorescence [35]. The overwhelming demand for concrete in construction adopting normal weight aggregates (NWAs), such as gravel and sand has led to tremendous depletion in naturally occurring aggregates causing numerous damages to the environment which are irreparable [29]. The properties of concrete are influenced by its composition, including the type of cement, aggregates, water, and any admixtures. Several studies highlight key properties of concrete, such as mechanical (compressive strength, and tensile strength), workability, and durability.

Compressive strength is the most significant mechanical property of concrete [36]. It is obtained by measuring concrete specimen after curing for 28days [37]. Some of the factors that influence the concrete strength include aggregate quality, cement strength, water content and water/cement ratio [38]. Compressive strength is the capacity or the ability of a material or structure to withstand loads tending to reduce size [39]. The compressive strength of concrete can be calculated by dividing the load applied to the concrete cube at the point of failure by the cross-section area of the cube on which the load was applied [40]. The concrete compressive strength for normal construction work varies from 15 to 30 MPa and more in commercial and industrial structures [41]. The strength of concrete depends on factors such as the watercement ratio, the strength of cement use, the quality of concrete materials, quality control during the production of concrete, etc. [42]. A compressive strength test of concrete is performed to check the compressive strength of concrete [43]. Various standard codes recommend concrete cylinder or concrete cube as the standard specimen for the test [44]. The American Society for Testing Materials of construction ASTM C39/C39M provides standard test method for the compressive strength of cube and cylindrical concrete specimens. Compressive strength test is mechanical test measuring the maximum amount of compressive load a material can bear before fracturing [45]. The test piece, usually in the form of a cube, prism, or cylinder, is compressed between the platens of a compression-testing machine by a gradually applied load [46].

Tensile strength is the stress, or force per unit area, required to cause concrete to fail in tension, that is, to pull or split it apart [47]. Tensile strength is remarkably sensitive to the concrete microstructure, and it makes it a valuable parameter to measure in research into the structure and behavior of concrete [48]. The tensile strength of a concrete is of little interest in civil engineering, where it usually assumed to be zero, as concrete are maintained under compressive loads and are not meant to fail anyway [49]. In the SI system, tensile strength is usually determined in mega pascals (MPa) or one newton per square meter (nm) [50]. For reference, one newton is the force needed to accelerate one kilogram of mass at the rate of one meter per second squared in the direction of the applied force [51].

Workability refers to how easy it is to handle and place fresh concrete. It is impacted by the size, shape, and texture of the aggregates as well as the water-cement ratio. Tekle [52] asserts that well-graded aggregates help reduce the amount of water and cement needed to achieve the desired workability. The use of plasticizers and superplasticizers can improve workability without affecting the water-cement ratio [53].

Durability is the concrete’s ability to withstand environmental conditions such as weathering, chemical attack, and abrasion while maintaining its structural integrity. The durability of concrete is primarily influenced by its permeability, which in turn is determined by the water-cement ratio and curing methods. The use of materials like fly ash and slag can improve durability by reducing permeability and enhancing resistance to sulfate attacks and freeze-thaw cycles [54]. The use of airentraining agents can further improve resistance to freeze-thaw damage, making concrete more durable in cold climates.

Materials and Methods

Materials

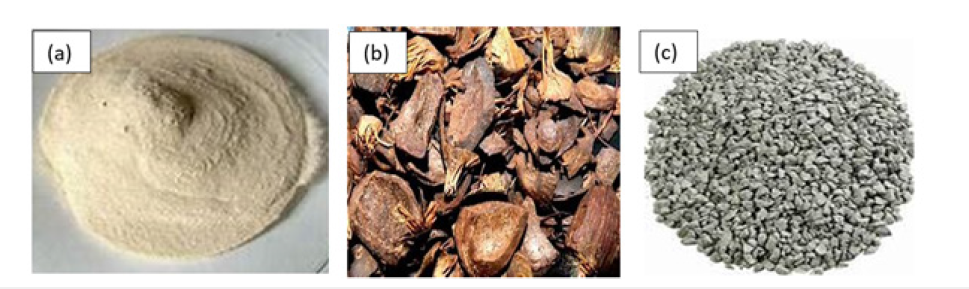

Calcium carbide waste (CCW), palm kernel shell (PKS), cement, fine aggregate (pit sand), coarse aggregate (crushed granite), and water were the materials used for the experimental work. The CCW was obtained from a welding shop in Kumasi, Ghana. The CCW was deposited behind the welding shop as a residue from the production of acetylene gas. It was air dried, crashed into fine particles with a metal bar, and sieved with 2mm sieve before use. Sample of the CCW is shown in Figure 1a. The PKS as illustrated in Figure 1b was obtained from an oil palm factory in Assin Fosu in the central region, Ghana. It was obtained after the palm nut was cracked and the shell was removed and dumped as waste. The shell was collected, washed in warm water and sun-dried for two weeks ready to be used. The coarse and fine aggregate used in this study were purchased from a building materials vendor in Kumasi, Ghana. The coarse aggregate is shown in Figure 1c. The cement used for the study was a Portland cement manufactured by GHACEM Cement in Ghana. Portland cement grade 32.5R conforming to BS EN 197-1: 2011 [55] standard was used as the binding material in experimental work. Water used for mixing materials for concrete production was obtained from the construction laboratory tap stand water conforming to BS EN 1008: 2002 [56] standard.

Fgure 1:Material for experimental work (a) calcium carbide waste, (b) palm kernel shells, (c) coarse aggregate.

Specimen preparation

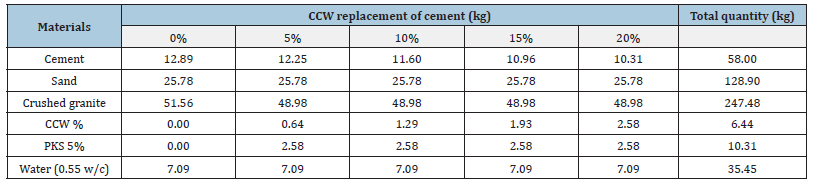

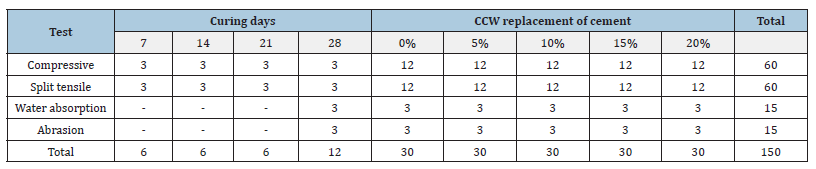

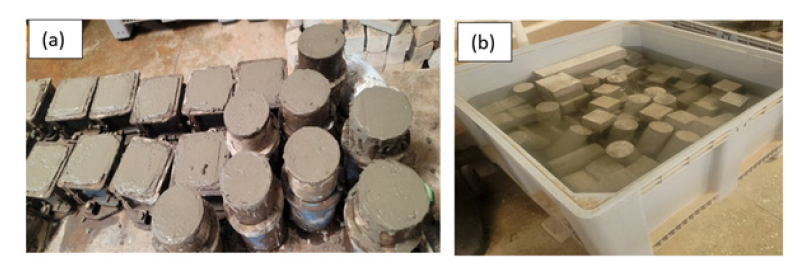

The concrete specimens were prepared with varying proportions of CCW at 0, 5, 10, 15 and 20% replacement of cement and 5% PKS constant replacement of coarse aggregate. A mix proportion of 1:2:4 with a water-cement ratio of 0.55 was used. The quantities of materials used are illustrated in Table 1. The concrete was mixed mechanically using a pan mixer. The mixed concrete was used to prepare cube (100 × 100 × 100mm) and cylinder (length of 200mm and a diameter of 100mm) specimens as illustrated in Figure 2a conforming to BS EN 12390-1: 2021 [57]. A total of 150 specimens were prepared, consisting of 90 cubes and 60 cylinders as shown in Table 2. The specimens were cured in water conforming to BS EN 12390-2: 2019 [58] for 7, 14, 21, and 28 days as shown in Figure 2b.

Table 1:Quantities of materials used.

Table 2:Total number of specimens prepared.

Fgure 2:Specimens preparation (a) moulding, (b) curing in water.

Testing of samples

The specimens were tested for density, compressive strength, and tensile strength after curing for 7, 14, 21, and 28 days. Water absorption and abrasion tests were conducted following 28 days of curing. The specimens’ densities were determined following BS EN 12390-7: 2019 [59]. Three replicates were selected from each mix variable, oven-dried, their volumes measured, weighed and the densities calculated for each variable and their averages were used for plotting a graph. Density was calculated using the formula:

where D is density, m is mass/weight of the concrete, and V is the volume of the concrete.

The compressive strength test was conducted using a computerized Universal Testing Machine (UTM) of a maximum capacity of 1000KN following BS EN 12390-3: 2019 [60]. Three replicates were selected from each mix variable, placed in the UTM and force applied till they crushed. The compressive strength values that were automatically generated by the UTM were observed and recorded.

The split tensile strength was conducted following BS EN 12390-6: 2019 [61] standard. Three replicates were selected from each mix variable, placed in the UTM with splitting jigs placed centrally on top and bottom and a force exerted till they split. The tensile strength values that were automatically generated by the UTM were observed and recorded.

The water absorption test was conducted on the cubes after the 28-day curing period following BS 1881-122:2011+A1: 2020 [62]. Each cube was oven-dried for 24 hours and weighed for the oven dry weight (W1) after which they were immersed in water for thirty minutes (30min) and finally weighed for the saturated surface dry weight (W2). The weight result recorded was then used to determine the amount of water absorbed by each cube. The percentage of water absorption was calculated using the formula:

where WA is water absorption, W1 is oven-dried weight, W2 is the saturated weight.

In accordance with ASTM D559-03: 2003 [63], specimens were tested for abrasion resistance (wetting and drying) after 28 days of curing using the surface wire brushing method. Each specimen was immersed in water till saturation, removed and oven-dried for 24hrs. 18 vertical wire brush strokes of approximately 13.3N force were applied to each side of the specimen and 4 strokes to each end to complete a cycle. The abrasion resistance of the specimens was expressed as percentage of dry weight reduction after 12 cycles relative to the original weight.

Data analysis

Data from the research was analysed using Microsoft Excel. Tables and charts were used to show the data with the use of both descriptive and inferential statistics. A One-way ANOVA analysis was conducted to establish any statistically significant differences between the variables, and the Pairwise Multiple Comparison procedure was used to determine the differences.

Results and Discussions

Density

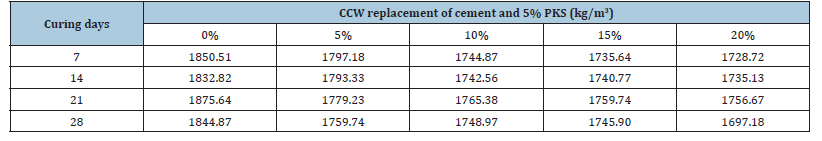

The test results indicate that the average densities of the concrete specimens decreased as the percentage of CCW increased. Densities initially rose with curing progressing to 21 days before declining. The control specimens (0% CCW) recorded the highest densities throughout, while 5% CCW exhibited higher densities compared to 10, 15 and 20% CCW. Table 3 shows the densities of concrete. On the 7th day of curing, the densities ranged from 1850.51 to 1728.72 kg/m³, with the control showing the highest value. By the 21st day of curing, densities ranged from 1875.64 to 1756.67 kg/m³ and on the 28th day of curing, they ranged from 1844.87 to 1697.18 kg/m³. The results showed that as CCW content increased, densities decreased, reflecting the influence of material properties on strength. The optimal density was achieved with 5% CCW and 5% PKS replacement, with the reduction in density attributed to the inherent low specific weight properties of CCW and PKS. The findings align with previous studies. Findings of this study is consistent with the study of Shafigh et al. [25], who observed that concrete incorporating PKS has lower densities, ranging from 1700 to 2000kg/m3, making it suitable for lightweight concrete applications. Another study by Danso and Appiah-Agyei [27] on the properties of lightweight concrete manufactured with different sizes of PKS as replacement of coarse aggregate obtained densities between 1447.27 and 1714.27kg/m3.

Table 3:Average densities of the concrete specimens.

The density values of between 1697.18 and 1844.87 kg/m3 obtained in this current study are within the recommended values for structural lightweight concrete [64] standard. According to American Concrete Institute [64], lightweight concretes should have densities lower than 2000kg/m3. This suggests that the density values attained for the concrete specimens made with CCW and PKS met the requirement of lightweight concrete for structural application.

Compressive strength

The test results revealed that the compressive strength of concrete specimens increased with curing time, reflecting normal strength development due to the hydration of cement. The partial replacement of cement and coarse aggregate with CCW and PKS enhanced compressive strength up to a 5% CCW replacement level before decreasing as shown in Table 4. The results demonstrated that specimens with 5 and 10% replacements outperformed the control specimens in compressive strength, while 15 and 20% replacements showed reduced performance. The average compressive strength recorded for the concrete specimens on the 7th day of curing ranged from 12.37 to 9.17N/mm2 for the mix designs with CCW, while the control recorded a strength of 11.59N/ mm2. On the 14th day of curing, the average compressive strength recorded was 14.24, 13.98, 12.86 and 12.56N/mm2 for 5, 10, 15 and 20% respectively, while the control specimens recorded 13.09N/ mm2. On the 28th day of curing, the compressive strength values were 19.03, 17.77, 16.38 and 16.25N/mm2 for 5, 10, 15 and 20% respectively, while the control was 16.49N/mm2.

Table 4:Compressive strength of concrete.

The study also highlighted percentage improvements compared to the control. For instance, 5 and 10% CCW replacements showed compressive strength improvements of 15.40 and 7.76% on the 28th day of curing, over the control specimens. The results suggest that material properties, particularly the strength of CCW and PKS influenced the compressive strength trends, with 5% CCW replacement providing the optimum result.

The findings of this study align with previous research involving materials similar to those used in the current study. Ogork and Ibrahim [20] investigated the effect of CCW as an additive in cement paste and concrete, and found that compressive strength increased with CCW content up to 0.5%, but decreased with higher CCW content. Additionally, Aderinola et al. [65] assessed the use of Calcium Carbide Waste Powder (CCWP) and bamboo leaf ash (BLA) as partial replacements for cement in concrete. The study reported peak compressive strengths of 13.23N/mm² and 15.97N/ mm² at 28 and 56 days, respectively, when 5% CCWP and 5% BLA were combined. The study concluded that using CCWP and BLA in concrete is both economical and a sustainable method for waste disposal, a finding that resonates with the present study’s results.

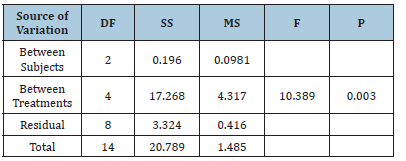

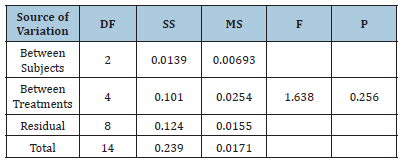

An analysis of variance was conducted on the compressive strength results to determine which of the factors considered had a significant effect on the compressive strength of the concrete. The results of the statistical analysis as shown in Table 5, indicated that the independent factors and their interactions had significant effects on the compressive strength of the concrete at a 95% confidence level (p=0.05). This indicates that whenever any of the factors are varied, the compressive strength of the concrete changes, and the degree of the variation is proportional to the magnitude of the change. The p-value of 0.003 was found to be less than the alpha level of 0.05. Statistically, the effect of different percentage content of CCW and 5% PKS aggregate on the compressive strength was found to be significant.

Table 5:One–way ANOVA of compressive strength.

DF = Degree of Freedom, SS = Sum of Squares, MS = Meas Square, F = F Value, P = P – Value

Table 6:Pairwise comparison between P-values for compressive strength.

T = T-Test, P = P-Value

Similarly, a Pairwise Multiple Comparison Procedure (Holm- Sidak method) was conducted to show a comparison amongst the various percentage variations of the CCW and 5% PKS aggregate used in the experiment for compressive strength test results. From Table 6 when matching the percentage replacement of CCW with 5% PKS aggregate, all the mix designs of the CCW with the 5% PKS were insignificant except 5% vs. 20%, 5% vs. 15%, and 5% vs. 0% which were significantly different.

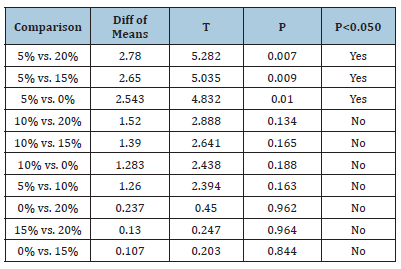

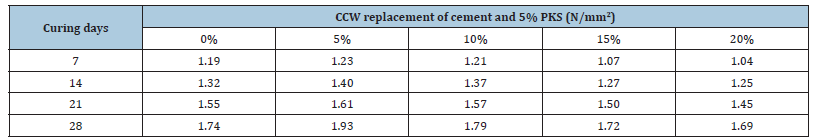

Tensile strength

The split tensile strength test results reflected the trends observed in the compressive strength test. The results showed that split tensile strength increased with curing time, reflecting normal strength development due to hydration. Table 7 shows the tensile strength of the concrete. The test results recorded tensile strength of 1.23, 1.21, 1.07 and 1.04N/mm2 for 5, 10, 15 and 20% CCW replacement, respectively, while a tensile strength of 1.19N/ mm2 was achieved for the control specimens on the 7th day the of curing. On the 14th day of curing, the tensile strength recorded was 1.40, 1.37, 1.27 and 1.25N/mm2 for 0, 5, 10, 15 and 20% CCW replacement, respectively, as compared to 1.32N/mm2 achieved by the control specimens. The split tensile strength obtained on the 21st day of curing ranged from 1.61 to 1.45N/mm2. On the 28th day of curing, the tensile strengths were 1.93N/mm² (5% CCW replacement), 1.79N/mm² (10% CCW replacement), 1.72N/mm² (15% CCW replacement) and 1.69N/mm² (20% CCW replacement) as compared with 1.74N/mm² (control). The result of 5% CCW and PKS replacements yielded the highest split tensile strength, followed by 10% which outperformed the control specimens. In contrast, 15 and 20% CCW replacements resulted in progressively lower strengths. The 5 and 10% replacements showed significant strength improvements over the control, with increases of 10.92 and 2.87% on the 28th day of curing, respectively. However, 15 and 20% replacements showed declines of -1.15% and -2.87%, indicating that higher CCW content adversely affected tensile strength. These trends suggest that the properties of CCW and PKS influenced the strength outcomes, with the 5% CCW replacement providing optimal performance.

Table 7:Tensile strength of the concrete.

The findings of this study align with previous research using similar materials. Ghavami et al. [66] reported that CCW replacement at 5% achieved the highest splitting tensile strength, slightly exceeding the control mix due to pozzolanic reactions, while 10% replacement showed comparable strength. Shafigh et al. [25] observed that PKS replacement at 10% resulted in a tensile strength reduction of less than 5%, while 20 and 40% replacements led to reductions of 10-15% and 30-35%, respectively. Both studies indicate that higher replacement levels decrease concrete strength which also confirms the findings of this research that highlight the potential of agricultural and industrial wastes as effective, sustainable alternatives in concrete production.

Table 8:One Way ANOVA for split tensile strength.

An analysis of variance test was conducted to determine which of the factors had a significant effect on the split tensile strength of the concrete. The results of the statistical analysis as shown in Table 8 indicates that the independent factors and their interactions had no significant effects on the split tensile strength of the concrete at a 95% confidence level (p=0.05). This indicates that the independent factors and the degree of their variations had an insignificant change in the tensile strength of the concrete. The p-value of 0.256 was found to be higher than the alpha level of 0.05. Statistically, the effect of different percentage content of CCW and 5% of PKS aggregate on the tensile strength was found to be insignificant.

Water absorption

The water absorption test results after 28 days of curing and oven-drying are shown in Table 9. The results show that the control sample had reduced porosity, with a water absorption rate of 1.56%. The water absorption levels for specimens with CCW and PKS replacements were 1.82, 2.00, 2.23 and 2.26% for CCW replacement of 5, 10, 15 and 20%, respectively. Among the specimens with CCW and PKS aggregates, the specimens with 5% CCW and 5% PKS replacement recorded the lowest water absorption rate compared to the 10, 15 and 20% replacements. The test results indicated that the control specimens yielded lower water absorption compared to 5, 10, 15 and 20% replacements, with increases of 16.67, 28.21, 42.95 and 44.87%, respectively. It is evident that as the percentage of CCW replacement increased, the water absorption level also increased.

Table 9:Water absorption.

The findings of this study align with previous research by Azunna [29] and Makaratat et al. [67]. Azunna [29] reported that PKS replacements of 10 and 25% resulted in acceptable water absorption rates without significantly affecting concrete strength, highlighting its sustainability. Similarly, Makaratat et al. [67] demonstrated that using calcium carbide residue and fly ash in concrete without Portland cement yielded satisfactory properties comparable to conventional concrete. These studies support the present research, which shows that partial replacement of cement and coarse aggregates with CCW and PKS produces results suitable for lightweight concrete applications. The water absorption of between 1.56 and 2.26% observed in this study is far better than the 12% recommended by BS 2028: 2000 [68].

Abrasion resistance

Concrete with 5% CCW and 5% PKS showed the strongest resistance to abrasion, achieving a value of 0.89%, while the 20% CCW mix exhibited the weakest resistance as shown in Table 10. The study found that the concrete’s abrasion resistance generally reduced as the percentage of CCW in the mix increased. Abrasion resistance values for 5, 10, 15 and 20% CCW replacement were 0.89, 0.97, 1.09 and 1.12%, respectively as compared with the control value of 1.05%. The results indicate a correlation between higher compressive strength and stronger abrasion resistance. Compared to the control, the 5 and 10% CCW replacements demonstrated stronger abrasion resistance, with improvements of 15.24 and 7.62%, respectively. Conversely, the 15 and 20% CCW replacements showed weaker resistance compared with the control. These findings suggest that the optimal abrasion resistance occurs with a 5% replacement of cement with CCW.

Table 10:Average abrasion resistance.

The findings from this test are consistent with the study of Mannan and Ganapathy [69] who analyzed PKS concrete at replacement levels of 0, 25, 50, 75 and 100%. It was found that abrasion resistance showed a decreasing trend with increased PKS content. The study suggested that keeping the PKS replacement level at or below 25% can help maintain acceptable abrasion resistance for practical applications [70].

Summary and Conclusion

The study investigated the properties of concrete produced

with CCW and PKS as partial replacements for cement and coarse

aggregates, respectively. The findings of the study are summarized

as follows:

A. The study found that concrete specimens incorporating CCW

and PKS as a partial replacement for cement and coarse

aggregate produced density values within the acceptable range

for lightweight concrete, making them suitable for applications

requiring lightweight concrete.

B. The study achieved higher compressive and splitting tensile

strengths with 5 and 10% CCW replacements of cement and

5% PKS replacement of coarse aggregate than the control.

The compressive strength yielded improvements of 15.40 and

7.76% respectively for 5 and 10% CCW replacements over the

control on the 28th day of curing. The tensile strength recorded

10.92 and 2.87% improvement, respectively for 5 and 10%

CCW replacements over the control on the 28th day of curing.

C. The study also found that the concrete specimens with 5%

CCW replacement of cement and 5% PKS replacement of

coarse aggregate exhibited stronger abrasion resistance and

acceptable water absorption levels for concrete production.

The study concludes that the use of CCW and PKS as partially replacing cement and coarse aggregates respectively enhance the properties of concrete and is suitable for lightweight concrete structural works. The study recommends to practitioners the use of 5% CCW replacement of cement and 5% PKS replacement of coarse aggregate for use. Further studies are recommended on the thermal properties of concrete produced with CCW and PKS as partially replacing cement and coarse aggregates respectively. The use of CCW and PKS in concrete promote sustainable construction by addressing waste management issues and reducing environmental pollution, and the same time enhance the properties of concrete.

References

- Antoh JN, Danso H, Afrifa RO (2025) Exploring metakaolin and coconut shells as sustainable alternatives in concrete: Physical, mechanical and microstructural properties. Advancements in Civil Engineering & Technology 6(4): 1-14.

- Rashid K, Rehman MU, De Brito J, Ghafoor H (2020) Multi-criteria optimization of recycled aggregate concrete mixes. Journal of Cleaner Production 276: 124316.

- Alengaram UJ, Jumaat MZ, Mahmud HB (2019) Flexural strength of concrete with partial replacement of coarse aggregate by palm kernel shell. Journal of Civil Engineering and Architecture 13(4): 356-363.

- Arabi N, Meftah H, Amara H, Kebaïli O, Berredjem L (2019) Valorization of recycled materials in the development of self-compacting concrete: Mixing recycled concrete aggregates–Windshield waste glass aggregates. Construction and Building Materials 209: 364-376.

- Borbi E, Danso H, Appiah-Kubi E (2024) Effect of lateritic stone aggregate and coconut husk fiber on the properties of concrete. Open Journal of Civil Engineering 14: 240-257.

- Gouda SK, Saranga H (2020) Pressure or premium: What works best where? Antecedents and outcomes of sustainable manufacturing practices. International Journal of Production Research 58(23): 7201-7217.

- Armah SK, Danso H (2025) A study on grounded palm kernel shells (GPKS) as a partial replacement for sand in mortar. Studies In Engineering and Exact Sciences 6(1): 1-16.

- Bature AS, Abdulrahman MD, Abbas H (2020) Evaluation of the compressive strength of concrete containing palm kernel shell as a full replacement for coarse aggregate. Journal of Sustainable Cement-Base Material 9(1): 48-59.

- Yaro NSA, Sutanto MH, Habib NZ, Napiah M, Usman A, et al. (2022) Application and circular economy prospects of palm oil waste for eco-friendly asphalt pavement industry: A review. Journal of Road Engineering 2(4): 309-331.

- Ogundipe KE, Ogunbayo BF, Olofinnade OM, Amusan LM, Aigbavboa CO (2021) Affordable housing issue: Experimental investigation on properties of eco-friendly lightweight concrete produced from incorporating periwinkle and palm kernel shells. Results in Engineering 9: 100193.

- Ibrahim A, Bin Marsono AK, Kamaruddin I, Abdul Rahman S (2019) A review on the use of palm kernel shell in concrete. Journal of Cleaner Production 221: 898-913.

- Makaratat N, Norrarat P, Jaturapitakkul C, Songpiriyakij S (2019) Influence of high-volume ternary blend from fly ash and ground granulated blast furnace slag on concrete properties. Journal of Thailand Concrete Association 7(2): 1-13.

- Teong SP, Zhang Y (2020) Calcium carbide and its recent advances in biomass conversion. Journal of Bioresources and Bioproducts 5(2): 96-100.

- Adamu M, Ayeni KO, Haruna SI, Mansour YEHI, Haruna S (2021) Durability performance of pervious concrete containing rice husk ash and calcium carbide: A response surface methodology approach. Case Studies in Construction Materials 14: e00547.

- Gong X, Zhang T, Zhang J, Wang Z, Liu J, et al. (2022) Recycling and utilization of calcium carbide slag-current status and new opportunities. Renewable and Sustainable Energy Reviews 159: 112133.

- Olufemi OS, Afolayan TO, Adesanya DA (2021) Investigation of the compressive strength of concrete made with palm kernel shell as a replacement for coarse aggregate. Journal of Material Research and Technology 10: 672-678.

- Abdurrauf MG, Ogork EN, Haruna SI (2017) Effect of calcium carbide wastes as admixture in mortar. Scholars Journal of Engineering and Technology 5(11): 655-660.

- Elinwa AU, Ejeh SP, Akpabio I (2005) Using metakaolin to improve sawdust ash concrete. Concrete International 27(11): 49-52.

- Wang K, Le H (2023) The development of cement-based, intumescent and geopolymer fire-retardation coatings for metal structures: A Review. Coatings 13(3): 495.

- Ogork EN, Ibrahim TS (2017) Properties of cement paste and concrete containing calcium carbide waste as additive. Nigerian Journal of Technology 36(1): 26-31.

- Alengaram UJ, Mahmud H, Jumaat MZ (2010) Comparison of mechanical and bond properties of oil palm kernel shell concrete with normal weight concrete. International Journal of Physical Science 5: 1231-1239.

- Abdullah AAA (1996) Palm oil shell aggregate for lightweight concrete. In: Waste Material Used in Concrete Manufacturing, Elsevier, Amsterdam, pp. 624-636.

- Olutoge FA (2010) Investigations on sawdust and palm kernel shells as aggregate replacement. ARPN Journal of Engineering and Applied Sciences 5(4): 7-13.

- Basri HB, Mannan MA, Zain MFM (1999) Concrete using waste oil palm shells as aggregate. Cement and concrete Research 29(4): 619-622.

- Shafigh P, Mahmud HB, Jumaat MZ, Zargar M (2014) Agricultural wastes as aggregate in concrete mixtures–A review. Construction and Building Materials 53: 110-117.

- Mohd A, Ortjohann E, Schmelter A, Hamsic N, Morton D, et al. (2008) Challenges in integrating distributed energy storage systems into future smart grid. IEEE International Symposium on Industrial Electronics, Cambridge, pp. 1627-1632.

- Danso H, Appiah-Agyei F (2021) Size variation of palm kernel shells as replacement of coarse aggregate for lightweight concrete production. Open Journal of Civil Engineering 11(1): 153-165.

- Jackson EN, Mustapha Z, Kotey S (2019) Compressive strength of concrete produced with proportions of coconut and palm kernel shells. International Journal of Architecture, Engineering and Construction 8(1): 35-41.

- Azunna SU (2019) Compressive strength of concrete with palm kernel shell as a partial replacement for coarse aggregate. SN Applied Sciences 1: 342.

- Courland R (2022) Concrete planet: The strange and fascinating story of the world’s most common man-made material. Rowman & Littlefield.

- Gencel O, Karadag O, Oren OH, Bilir T (2021) Steel slag and its applications in cement and concrete technology: A review. Construction and Building Materials 283: 122783.

- Naik TR (2020) Sustainability of the cement and concrete industries. In: Sustainable construction materials and technologies, CRC Press, pp. 19-25.

- Ajoku CA, Turatsinze A, Abou-Chakra A (2023) Properties of calcium silicate-based inorganic phosphate cement at room-controlled conditions. Journal of Building Engineering, 64: 105719.

- Liu KG, Sharifzadeh Z, Rouhani F, Ghorbanloo M, Morsali A (2021) Metal-organic framework composites as green/ sustainable catalysts. Coordination Chemistry Reviews 436: 213827.

- Bochen J, Słomka-Słupik B, Ślusarek J (2021) Experimental study on salt crystallization in plasters subjected to simulate groundwater capillary rise. Construction and Building Materials 308: 125039.

- İpek S, Ayodele OA, Mermerdaş K (2020) Influence of artificial aggregate on mechanical properties, fracture parameters and bond strength of concretes. Construction and Building Materials 238: 117756.

- Nguyen TT, Dinh K (2020) An artificial intelligence approach for concrete hardened property estimation. Journal of Science and Technology in Civil Engineering (STCE)-HUCE 14(2): 40-52.

- Panda S, Sarkar P, Davis R (2020) Effect of water-cement ratio on mix design and mechanical strength of copper slag aggregate concrete. In IOP Conference Series: Materials Science and Engineering 936(1): 012019

- George M, Sathyan D, Mini KM (2021) Investigations on effect of different fibers on the properties of engineered cementitious composites. Materials Today: Proceedings 42(Part 2): 1417-1421.

- Bello I, González-Fonteboa B, Wardeh G, Martínez-Abella F (2023) Characterization of concrete behavior under cyclic loading using 2D digital image correlation. Journal of Building Engineering 78: 107709.

- Jan L, Kumar A (2023) Experimental investigation of the properties of concrete by partially replacing fine aggregates with sea shell powder and Mersey silt. International Journal of Innovative Research in Engineering & Management 10(4): 41-48.

- Ahmed M, Mallick J, AlQadhi S, Ben Kahla N (2020) Development of concrete mixture design process using MCDM approach for sustainable concrete quality management. Sustainability 12(19): 8110.

- Farooq F, Nasir Amin M, Khan K, Rehan Sadiq M, Javed MF, et al. (2020) A comparative study of random forest and genetic engineering programming for the prediction of compressive strength of high strength concrete (HSC). Applied Sciences 10(20): 7330.

- Dharmaraj R, Siva Kumar B (2021) A feasibility study on cement with addition of Prosopis Juliflora ash as in concrete. Materials Today: Proceedings 37(Part 2): 1212-1217.

- Jiao Y, Zhang Y, Guo M, Zhang L, Ning H, et al. (2020) Mechanical and fracture properties of ultra-high-performance concrete (UHPC) containing waste glass sand as partial replacement material. Journal of Cleaner Production 277: 123501.

- Talaat A, Emad A, Tarek A, Masbouba M, Essam A, et al. (2021) Factors affecting the results of concrete compression testing: A review. Ain Shams Engineering Journal 12(1): 205-221.

- Vasseghi A, Haghshenas E, Soroushian A, Rakhshandeh M (2021) Failure analysis of a natural gas pipeline subjected to landslide. Engineering Failure Analysis 119: 105009.

- Ruan B, Zhou T, Yuan Z, Singh J, Teng J, et al. (2023) Effects of curing conditions on splitting tensile behavior and microstructure of cemented aeolian sand reinforced with polypropylene fiber. Materials 16(19): 6347.

- Wang G, Wang Z, Ye Q, Wei X (2020) Particle breakage and deformation behavior of carbonate sand under drained and undrained triaxial compression. International Journal of Geomechanics 20(3): 04020012.

- Budynas RG, Sadegh AM (2020) Roark's formulas for stress and strain. McGraw-Hill Education.

- Welty J, Rorrer GL, Foster DG (2020) Fundamentals of momentum, heat, and mass transfer. John Wiley & Sons.

- Tekle A (2015) Properties of aggregates in concrete: A literature review. Journal of Materials in Civil Engineering 27(6): 1-7.

- Neville AM (2011) Properties of concrete. In: (5th edn), Pearson Education.

- Mehta PK, Monteiro PJM (2014) Concrete: Microstructure, properties, and materials. In: (4th edn), McGraw-Hill Education.

- BS EN 197-1 (2011) Cement. Composition, specifications and conformity criteria for common cements. Standard, British Standards Institution, London.

- BS EN 1008 (2002) Mixing water for concrete. Specification for sampling, testing and assessing the suitability of water, including water recovered from processes in the concrete industry, as mixing water for concrete. British Standards Institution, London, UK.

- BS EN 12390-1 (2021) Testing hardened concrete - Shape, dimensions and other requirements for specimens and moulds. British Standards Institution, London, UK.

- BS EN 12390-2 (2019) Testing hardened concrete. Making and curing specimens for strength tests. British Standards Institution, London, UK.

- BS EN 12390-7 (2019) Testing hardened concrete-density of hardened concrete, British Standards Institution, London, UK.

- BS EN 12390-3 (2009) Testing hardened concrete. Compressive Strength of Test Specimens. British Standards Institution, London, UK.

- BS EN 12390-6 (2009) Testing hardened concrete. Tensile Splitting Strength of Test Specimens. British Standards Institution, London, UK.

- BS 1881-122:2011+A1 (2020) Testing concrete method for determination of water absorption, British Standards Institution, London, UK.

- ASTM D559-03 (2003) Standard test methods for wetting and drying compacted soil–cement mixtures. ASTM International, West Conshohocken, PA, USA.

- ACI Committee 213 (2003) ACI 213R-87. Guide for structural lightweight aggregate concrete. American Concrete Institute, Farmington Hills.

- Aderinola OS, Omolola OE, Quadri AI (2018) Effect of calcium carbide waste powder on some engineering properties of bamboo leaf ash concrete. Open Access Library Journal 5(11): 1-15.

- Ghavami M, Khorami M, Ali M (2017) The use of calcium carbide waste as partial replacement for cement in mortar. Construction and Building Materials 154: 159-170.

- Makaratat N, Jaturapitakkul C, Laosamathikul T (2010) Effects of calcium carbide residue–fly ash binder on mechanical properties of concrete. Journal of Materials in Civil Engineering 22(11): 1164-1170.

- BS 2028 (2000) Specification for precast concrete blocks. British Standard Institution, London, UK.

- Mannan MA, Ganapathy C (2004) Concrete from an agricultural waste-oil palm shell (OPS). Building and Environment 39(3): 441-448.

- Wałach D (2020) Analysis of factors affecting the environmental impact of concrete structures. Sustainability 13(1): 204.

© 2025 Humphrey Danso. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)