- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Effect of Repeated Laundering Up to 50 Cycles on the Spectrum of Color in Naturally Colored Cotton for Apparel Products

Jessie H Chen-Yu1* and Siwon Cho2

1Apparel, Housing, and Resource Management, School of Design, Virginia Tech, USA

2Fashion Studies Program, School of Architecture, Southern Illinois University, USA

*Corresponding author:Jessie Chen- Yu, Apparel, Housing, and Resource Management, Virginia Tech, 240 Wallace (0410), Blacksburg, Virginia, USA

Submission: August 04, 2025;Published: August 18, 2025

ISSN 2578-0271 Volume11 Issue 1

Abstract

This study investigates the impact of repeated laundering up to 50 cycles on the color spectrum of naturally colored cotton fabrics for apparel. It aims to understand how laundering affects color lightness and intensity, addressing a gap in prior studies that often tested only a few laundry cycles and lacked detailed color metrics. The study also assesses whether color changes in naturally colored cotton meet ASTM standard requirements for acceptable color retention in clothing. Two naturally colored cotton jersey knit fabrics in the same light brown (Vicuña) shade, but different weights were tested. AATCC standard test methods were followed. The fabrics were washed and dried on “normal” settings. Color was measured at multiple intervals (0, 1, 5, 10, 20, 30, 40, 50 cycles) by a spectrophotometer for L* (lightness), a* (redness), and b* (yellowness) values. Color difference (ΔE) was calculated, and visual assessments were conducted with the AATCC Gray Scale by three assessors under controlled lighting. This study quantified these changes using statistical analysis and revealed that color change significantly increased as the number of laundry cycles increased. The two fabrics in different weights exhibited similar color retention characteristics. Initially, the fabrics darkened slightly after 1 to 10 cycles, then became significantly lighter after 20 cycles, with further lightening observed after 50 cycles. Using the AATCC Gray Scale, evaluators detected significant darkening after 5 cycles and further lightening after 20 cycles, with no significant changes beyond 30 cycles. The color intensity of both redness and yellowness significantly weakened with more laundry cycles, particularly after 20 cycles for redness and progressively across multiple cycles for yellowness. The results confirm that naturally colored cotton is a great choice for apparel products because of its ability to meet the ASTM standard requirement for acceptable color retention after repeated laundering up to 50 cycles.

Keywords:Naturally Colored Cotton; Color; Repeated Laundering; Color Lightness, Color Intensity

Introduction

Cotton is the most used natural fiber in the world [1], and about 80% is used for apparel products [2]. The heavy use of pesticides during the cultivating processes and the release of toxic chemicals during the artificial dyeing processes are major sources of environmental pollution [3]. Due to such ecological concerns, the interest in naturally colored cotton has increased recently. Naturally colored cotton plants have better resistance to diseases and pests than conventional cotton and thus may be grown organically without the use of pesticides [4]. The use of environmentally harmful bleaches, pigments, and dyes can be eliminated because naturally colored cotton has inherent natural colors. Therefore, the production of naturally colored cotton fabrics can be a sustainable solution for apparel manufacturers, marketers, and consumers who seek ways to protect and preserve natural resources and ecosystems [5]. In addition, garments made with naturally colored cotton, free from dyes and chemicals, are suitable for individuals with sensitive skin [6]. Naturally colored cotton offers a soft texture and silky appearance and provides superior flame resistance and ultraviolet (UV) protection than conventional white cotton [7,8].

Color is the most important aesthetic characteristic, and retaining original color after laundering is crucial for the appearance and longevity of textiles. However, only a few studies examined the color retention of naturally colored cotton after laundering. Willams and Horridge [9] examined the effects of nine laundering pretreatments, such as chlorine beach and ammonia, on the colors of brown and green naturally colored cotton knit fabrics for over 15 laundry cycles. However, they did not report how the color lightness and intensity changed with the number of laundry cycles.

Aliei et al. [6] examined the effects of detergents, water, and temperature on the color changes of woven fabrics constructed of a conventional cotton warp and a naturally colored cotton weft in the colors of Topaz, light ruby, and dark ruby. The results indicated that water hardness was the primary factor affecting color changes in the fabrics, and color changes increased with increasing washing temperature. However, the fabrics were washed only for five cycles. Laundering itself was not the focus of the study, and there was no report on the effect of the number of laundry cycles on color changes.

Zhou et al. [10] studied how elevated water temperatures, typically used in European home laundering, affect the color of a knit fabric composed of 70% conventional white cotton and 30% brown naturally colored cotton and with a weight of 174.1g/m2. The test fabric was washed up to 20 cycles. The findings showed that the first laundry cycle caused the most color change and darkened the fabric. Color changes in the fabric increased with increasing number of laundering cycles and washing temperature. In this study, the fabric was not dried after each wash unlike typical home laundering in the United States, quantitative analyses were not used to determine if the color changes were statistically significant, and the maximum number of laundry cycles used was nowhere near the wear life of 35 to 50 laundry cycles of an average shirt [11]. Hence, it is important to set a target of 50 laundry cycles when testing the color retention of clothing fabrics.

Previous studies on color retention in naturally colored cotton after laundering have been limited to a small number of laundering cycles (up to 20) and lacked comprehensive analysis of color changes in terms of lightness and intensity. The present study sets a target of 50 laundering cycles to better simulate the wear life of typical apparel. To examine the effect of repeated laundering up to 50 laundry cycles on the spectrum of color in naturally colored cotton fabrics for apparel, we propose a hypothesis with two subhypotheses as follows.

H1: The color of naturally colored cotton fabrics changes with

the number of laundry cycles.

H1a: The color lightness of naturally colored cotton fabrics

changes with the number of laundry cycles.

H1b: The color intensity of naturally colored cotton fabrics

changes with the number of laundry cycles.

In addition, according to ASTM Standard Performance Specifications D3780-22, D4154-22, D4155- 22, D4232-23, D7019- 20, and D7020-22 [12-17], the minimum requirement for change of color after laundering for various garments is Grade 4 of the AATCC Gray Scale for Color Change. In this study, we examined if the changes of color of naturally colored cotton fabrics after repeated laundering up to 50 cycles meet the requirement.

Material and Methods

Materials

To examine the hypothesis and increase the reliability of the study, we used two naturally colored cotton jersey knit fabrics in the same light brown color (Vicuña). One was a lightweight fabric (105g/m2 or 3.10oz/yd2) made with 40 cotton count single-strand yarns, and the other was a midweight fabric (209g/m2 or 6.16oz/ yd2) made with 20 cotton count single-strand yarns. The test fabric was purchased from Naturtex in Peru. Naturtex specializes in sustainably sourced cotton and alpaca fibers. The company has obtained organic certifications and the Sustainable Textiles Certification under the Global Organic Textile Standard.

The CIELab values show that the color of the lightweight fabric is L* = 74.11, a* = 5.78, b* = 15.49 and the color of the midweight fabric is L* = 71.91, a* = 5.46, b* = 15.97. The redness (a* value) and yellowness (b* value) of the two fabrics are similar, indicating that the two fabrics have a similar intensity of brown color. However, the midweight fabric is slightly darker than the lightweight fabric. An L* value of 100 denotes white, while a value of 0 corresponds to black; therefore, a higher L* value signifies a lighter color. Heavier fabrics, due to their denser structure, which allows less light to pass through, increases light absorption, and reduces light reflection [18], tend to appear darker than lighter ones containing the same pigment. As a result, heavier fabrics exhibit a darker appearance.

Laundering procedure

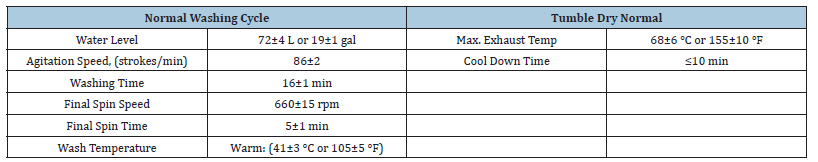

The AATCC LP1-2018e: Laboratory Procedure for Home Laundering: Machine Washing [19] was followed to wash the specimens. Vortex M6D washing machine and dryer were used in the study. They were designed specially for laboratory use and engineered to match the parameters for AATCC home laundering test methods. The lightweight and midweight test fabrics were washed in separate laundering loads. The normal washing cycle in warm water was selected as the washing machine setting, and the normal drying cycle was selected as the tumble dryer setting. The specific washing machine and dryer parameters are listed in Table 1.

Table 1:Washing machine and dryer parameters.

The AATCC Standard Reference Powder Detergent without brightener was used. After the addition of 66±1g of detergent, the fabric specimens were added to the washing machine with ballast (i.e., cotton woven pieces) to make a 1.8±0.1kg or 4.00±0.13lb wash load. Immediately after the final spin cycle, the washed load (i.e., the fabric specimens and ballast) was placed in the dryer. The dryer was operated for 30 minutes or until the total washed load was completely dried, and then the load was removed from the dryer.

Color tests

The colors at three locations of each specimen were measured at the end of 0, 1, 5, 10, 20, 30, 40, and 50 laundry cycles by a X-Rite Ci60 sphere spectrophotometer and reported as L* (lightness), +a* (redness), and +b* (yellowness) values. The formula, ΔE=((ΔL*)2+(Δa*)2+(Δb*)2)1/2, was used to calculate the color difference before and after laundering. The changes of color at three locations of each specimen were also visually evaluated by three assessors using the AATCC Gray Scale for Color Change and the AATCC EP1-2020 Evaluation Procedure for Gray Scale for Color Change [20]. The subjective evaluations of color change were performed in the Macbeth spectra light chamber under the daylight setting. Option A in the AATCC EP9- 2017e Evaluation Procedure for Visual Assessment [21] was used for viewing conditions. The illumination source is horizontal, the specimen plane is at a 45±5° angle to horizontal, and the assessor views the specimen at a 90° angle. The AATCC Gray Scale rates color change from 5 (no change) to 1 (severe change). The assessors compared the perceived visual difference between an original and a tested specimen with the difference represented by a Gray Scale pair to determine the rating.

Result

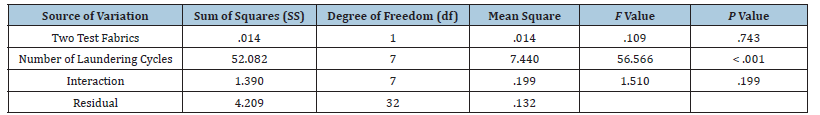

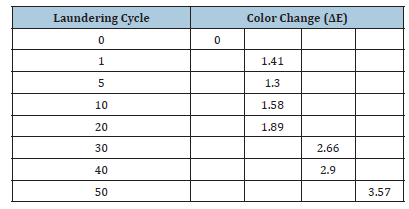

The IBM SPSS statistical software package was used to analyze the data. The two-way ANOVA (analysis of variance) results show that the change in color with the number of laundry cycles is significant (F(7)=56.566, p < .001; Table 2). However, there is no significant difference between the two naturally colored cotton fabrics (F(1)=.109, p=.743) and no significant interaction between the two naturally colored cotton fabrics and the number of laundry cycles (F(7) = 1.510, p = .199), indicating that the two naturally colored cotton fabrics perform similarly in change of color due to laundering, despite the difference in yarn size and fabric weight. The R Squared is .927, indicating that the two independent variables (Two test fabrics and number of laundering cycles) explain a large portion (92.7%) of variance in the dependent variable (color change). For both fabrics, the results of the Tukey HSD (Honestly Significant Difference) test show that the degree of change in color increases as the number of laundry cycles increases. Specifically, the color changes significantly between 0 and 1-20 cycles, between 1-20 and 30-40 cycles, and between 30-40 and 50 cycles (p< .05; Table 3).

Table 2:Results of two-way ANOVA for color change (ΔE).

Table 3:Results of Tukey HSD test for color change (ΔE) with number of laundry cycles.

Note: Data in different columns of the table differ significantly at the .05 level.

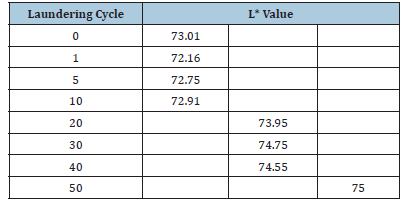

To understand the degree of change in color in terms of color lightness and intensity, we examined the change in L*, a*, and b* values with the number of laundry cycles. The change in L* value with the number of laundry cycles is significant (F(7) = 23.657, p < .001). The L* values after 1-10 cycles become smaller, indicating that the color becomes darker, but the changes after 1, 5, and 10 cycles are not statistically significant (Table 4). The L* value after 20 cycles become larger, indicating that the color becomes lighter and is significantly lighter than the color of original unwashed fabric (p < .05). After 50 laundry cycles, the color becomes even lighter than the color after 20-40 cycles.

Table 4:Results of Tukey HSD test for change in L* value with number of laundry cycles.

Note:An L* value of 100 denotes white, while a value of 0 corresponds to black. Data in different columns of the table differ significantly at the .05 level.

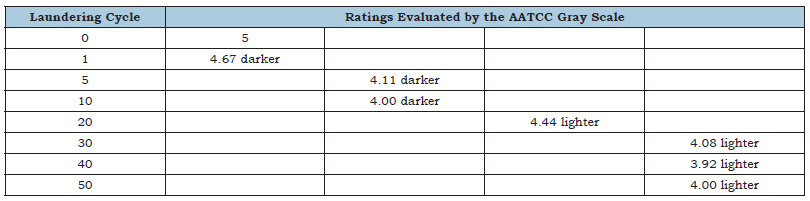

The color change after selected laundry cycles was also assessed by using the AATCC Gray Scale, in which lower ratings indicate a greater degree of color change. This scale primarily assesses perceived changes in lightness, not intensity, across different ratings [22]. The L* values after 1, 5, and 10 cycles show that the color becomes darker, but the changes are not statistically significant (Table 4). However, the Tukey HSD test results of the evaluations by the AATCC Gray Scale show that the human eye can detect the color getting darker after 5 laundry cycles (mean = 4.11 darker, p < .05, Table 5). Consistent with the L* value, the evaluation by the AATCC Gray Scale shows that the color turns lighter after 20 laundry cycles (mean = 4.44 lighter). The color gets even lighter after 30 cycles (mean = 4.08 lighter), and then does not change significantly between 30, 40, and 50 cycles (means = 4.08, 3.92, and 4.00 lighter).

Table 5:Results of Tukey HSD test for change in AATCC Gray Scale rating with number of laundry cycles.

Note:The AATCC Gray Scale rates color change from 5 (no change) to 1 (severe change). Data in different columns of the table differ significantly at the .05 level.

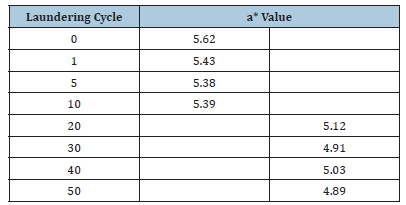

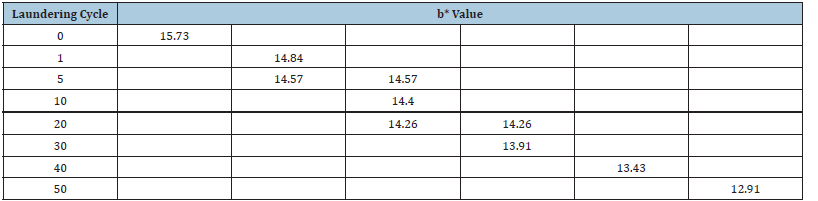

Positive a* and b* values indicate the intensity of red and yellow hues, and a comparison of the values after selected laundry cycles reveals changes in color strength. The changes in both a* and b* values with the number of laundry cycles are significant (F(7) = 20.49, p < .001; F(7) = 64.61, p < .001). The Tukey HSD test results show a significant difference in a* value between 0-10 and 20-50 cycles, indicating that the redness turns weaker after 20 laundry cycles (p < .05, Table 6). For the b* value, the Tukey HSD test results show that the yellowness also gets weaker as the number of laundry cycles increases (p < .05, Table 7); specifically, the intensity of yellowness becomes significantly lower after 1, 10, 30, 40, and 50 laundry cycles.

Table 6:Results of Tukey HSD test for change in a* value with number of laundry cycles.

Note:A positive a* value denotes redness, with values ranging from 0 to 60. Higher values correspond to a greater intensity of red. Data in different columns of the table differ significantly at the .05 level.

Table 7:Results of Tukey HSD test for change in b* value with number of laundry cycles.

Note:A positive b* value denotes yellowness, with values ranging from 0 to 60. Higher values correspond to a greater intensity of yellow. Data in different columns of the table differ significantly at the .05 level.

Discussion

In this study, the two naturally colored cotton fabrics for apparel products perform similarly in change of color after laundering, regardless of the difference in yarn size or fabric weight. Consistent with the study of Zhou [10], our study also found that more laundry cycles lead to greater color changes. Specifically, the color significantly changes after 1, 30, and 50 laundry cycles. According to these findings, H1 is accepted. The color of naturally colored cotton fabrics changes with the number of laundry cycles.

The statistical results reveal that the color lightness of naturally colored cotton fabrics changes with the number of laundry cycles, and thus H1a is accepted. However, the changes of lightness are not linear. The fabrics become darker after 1 to10 laundry cycles, then turn lighter after 20 cycles, and continue to get lighter as the number of laundry cycles increases further. In other words, the color gets darker before it gets lighter.

A possible reason for the initial darkening of fabric color is the alkalinity of the detergent. As Essen [23] notes, detergents are typically mildly alkaline, and this alkalinity interacts with the pigments in naturally colored cotton, leading to a deepening of color after washing. The AATCC standard detergent used in this study has a pH of 10 [24]. Being alkaline, it darkens naturally colored cotton fabrics. However, after repeated washing, if the lightening effect caused by pigment loss outweighs the darkening effect induced by alkalinity, the fabric color becomes lighter.

Another potential explanation for the initial darkening of fabrics is fabric shrinkage, which may result from the relaxation of tensions introduced during the manufacturing process as well as the progressive shrinkage caused by the heat, moisture, and agitation during the washing and drying. As the fabric shrinks and densifies, it absorbs more light and reflects less, thus appearing darker. A linear regression analysis was conducted to investigate this potential explanation. The findings confirmed that fabric shrinkage is a significant predictor of the L* value (F(1) = 17.721, p < .001) as well as the assessments derived from the AATCC Gray Scale (F(1) = 7.528, p = .009). The Tukey HSD test results indicated significant shrinkage after 1 and 10 laundry cycles, but not after 20 (p < .05), supporting that initial darkening is likely due to fabric shrinkage. After 20 laundry cycles, the effect of pigment loss overtakes that of shrinkage, causing the fabric color to lighten.

Our findings show that the color intensity of naturally colored cotton fabrics changes with the number of laundry cycles, supporting H1b. The redness (a* value) decreases after 20 laundry cycles, while the yellowness (b* value) decreases immediately after the first wash and continues to decrease with additional washes, showing an overall desaturation of brown hue. As Aliei [6] note, the removal of waxes, oil, and pigments from natural colored cotton during washing likely causes the reduction in color intensity.

Although the color becomes darker after 1 to 10 cycles and then turns lighter after 20 cycles, the color changes even after 50 laundry cycles are close to Class 4 of the AATCC Gray Scale, meeting the requirements of the ASTM Standard Performance Specifications for various clothing items [12-17]. The AATCC Gray Scale is used for visual assessment of color change, reflecting how consumers perceive color differences in products. These results are particularly relevant in the textile and apparel industries, where the subjective perception of color by humans plays a critical role in product acceptance.

This study addresses a research gap by testing the spectrum of color in naturally colored cotton fabrics after up to 50 washes. The results confirm that naturally colored cotton is a great choice for apparel products because of its ability to retain original color after repeated laundering up to 50 cycles. These results expand the understanding of naturally colored cotton, provide educational information for consumers who prioritize environmental responsibility, and support naturally colored cotton market potential in the fashion industry. With environmental pollution becoming a critical global issue, naturally colored cotton offers a sustainable and eco-friendly option for textile production.

Nevertheless, apparel marketers must assess the cost impact of using naturally colored cotton in textile production. While naturally colored cotton eliminates the need for chemical dyes and reduces water and energy consumption in dyeing processes, the lower yields of naturally colored cotton [25] and potential challenges in ensuring a consistent and reliable supply [26] can increase costs. Although 28% of consumers are willing to pay a premium of up to 15% for naturally colored cotton clothing [27], price sensitivity remains crucial for the wider acceptance of sustainable products [28]. In addition, naturally colored cotton is limited to shades of brown, green, and reddish-brown, thereby providing a narrower range of color options than artificially dyed cotton. Naturally colored cotton mainly appeals to niche markets prioritizing sustainability and health benefits. Retailers can boost growth by using clear, factual messaging in marketing campaigns to promote the merits of naturally colored cotton apparel and adding QR codes on product packaging, tags, retail displays, or signage to provide detailed information about naturally colored cotton.

Conclusion

This study investigates the impact of repeated laundering up to 50 cycles on the color spectrum of naturally colored cotton fabrics for apparel. The study aims to understand how laundering affects color lightness and intensity, filling a gap in prior studies that tested limited laundry cycles and lacked detailed color metrics. This study establishes a benchmark of 50 laundry cycles to more accurately represent the typical lifespan of apparel during normal use. The study also assesses whether color changes meet ASTM standard requirements for acceptable color retention in clothing.

Two naturally colored cotton jersey knit fabrics in the same light brown (Vicuña) shade but different weights-lightweight (105g/ m²) and midweight (209g/m²)-were tested. AATCC standard test methods were followed. Color was measured at multiple intervals (0, 1, 5, 10, 20, 30, 40, 50 cycles) using a spectrophotometer for L* (lightness), a* (redness), and b* (yellowness) values. Color difference (ΔE) was calculated, and visual assessments were conducted by three assessors using the AATCC Gray Scale under controlled lighting. This study quantifies the color changes using statistical analysis and human perception scales.

Our results show that color change becomes more pronounced as the number of laundry cycles increases, and there was no significant difference in color change between the two fabrics despite different fabric weights. Initially, the fabrics darken after 1 to 10 laundry cycles, then become lighter after 20 cycles, with further lightening after 50 cycles. Using the AATCC Gray Scale, the assessors detected significant darkening after 5 and 10 laundry cycles and further lightening after 20 cycles, with no significant changes beyond 30 cycles. Both redness (a* value) and yellowness (b* value) significantly weaken with increasing number of laundry cycles, particularly after 20 cycles for redness and progressively across multiple cycles for yellowness.

This study assessed two light brown jersey knit fabrics from Naturtex, Peru, using “Normal” wash and dry settings. Further research should examine various cotton colors, cotton regions, fabrics structures, and laundering methods to better understand how repeated washing affects color retention in naturally colored cotton.

References

- Statista (2024) Distribution of textile fibers production worldwide in 2023, by type.

- United Nations News (2021) Cotton sustains more than 100 million families worldwide.

- Knowing Fabric (2023) How cotton fabric production affects the environment.

- Günaydin GK, Avinc O, Palamutcu S, Yavas A, Soydan AS (2018) Naturally colored organic cotton and naturally colored cotton fiber production. In: Organic Cotton: Is it a Sustainable Solution? Springer Singapore, Singapore, pp: 81-99.

- Madhu A (2024) Naturally colored cotton: A sustainable innovation. In: Gürsoy S, Akın S (Eds.), Best crop management and processing practices for sustainable cotton production. BoD-Books on Demand.

- Aliei H, Carrera-Gallissa E, Cayuela D (2024) Evaluating the impact of washing conditions on the color changes of naturally colored cotton fabrics: A focus on detergents, water types, and temperature. Materials 17(23): 5777.

- Parmar MS, Chakraborty M (2001) Thermal and burning behavior of naturally colored cotton. Textile Research Journal 71(12): 1099-1102.

- Chen-Yu JH, Wong SW (2017) Effects of repeated treatments of perspiration, weathering, and laundering on the ultraviolet protection of a naturally colored lightweight cotton fabric. Clothing and Textiles Research Journal 35(2): 128-140.

- Williams BL, Horridge P (1996) Effects of selected laundering and drycleaning pretreatments on the colors of naturally colored cotton. Family and Consumer Sciences Research Journal 25(2): 137-158.

- Zhou XL, Shi ZQ, Tang ZR, Zhou WL (2012) Effect of laundering temperature on the color of brown naturally colored cotton. Advanced Materials Research 535: 1577-1581.

- Drycleaning & Laundry Institute International (2019) The long and the shirt of shirts.

- ASTM International (2024) Standard performance specification for men's and boys' woven dress suit fabrics and woven sportswear jacket, slack, and trouser fabrics (ASTM Standard No. D3780-22). American Society for Testing and Materials.

- ASTM International (2024) Standard performance specification for women's and girls' woven sportswear, shorts, slacks, and suiting fabrics. (ASTM Standard No. D4155-22). American Society for Testing and Materials.

- ASTM International (2024) Standard performance specification for woven career apparel fabrics: Dress and vocational (ASTM Standard No. D4232-23). American Society for Testing and Materials.

- ASTM International (2024) Standard performance specification for men's and boys' knitted and woven beachwear and sports shirt fabrics. American Society for Testing and Materials. (ASTM Standard No. D4754-22). American Society for Testing and Materials.

- ASTM International (2024) Standard performance specification for brassiere, slip, lingerie and underwear fabrics (ASTM Standard No. D7019-20). American Society for Testing and Materials.

- ASTM International (2024) Standard performance specification for woven blouse, dress, dress shirt & sport shirt fabrics (ASTM Standard No. D7020-22). American Society for Testing and Materials.

- Akgun M, Becerir B, Alpay HR (2014) Effect of fabric layers on the relationship between fabric constructional parameters and percentage reflectance values of polyester fabrics. Journal of Textiles 2014(1): 267530.

- American Association of Textile Chemists and Colorists (2021) Laboratory Procedure for Home Laundering: Machine Washing (AATCC LP1-2018e). AATCC.

- American Association of Textile Chemists and Colorists (2021) Evaluation Procedure for Gray Scale for Color Change (AATCC EP1-2020). AATCC.

- American Association of Textile Chemists and Colorists (2021) Evaluation Procedure for Visual Assessment (AATCC EP9-2017e). AATCC.

- HunterLab (2019) Gray change and gray stain scales.

- Essen D (2023) Colored cottons-Without dye!

- American Association of Textile Chemists and Colorists (2021) AATCC Standard Reference Detergents and Laundry Detergents in General (AATCC M1-2017e). AATCC.

- Katz D, Boone N, Vreeland JJ (1997) Organically grown and naturally colored cotton: A global overview. Proceedings of Beltwide Cotton Conferences 1: 293-297.

- Madhu A (2024) Naturally Colored Cotton: A Sustainable Innovation. In: Gürsoy S, Akın S (Eds.), Best Crop Management and Processing Practices for Sustainable Cotton Production (pp. 59-68). IntechOpen.

- Dishoja AS, Bharti N, Malik S (2024) Is naturally colored cotton a sustainable substitute for cotton textile? World Review of Entrepreneurship, Management and Sustainable Development 20(3): 338-354.

- Mabuza LL, Sonnenberg NC, Marx-Pienaar NJ (2023) Natural versus synthetic dyes: Consumers’ understanding of apparel coloration and their willingness to adopt sustainable alternatives. Resources, Conservation & Recycling Advances 18: 1-8.

© 2025 Jessie H Chen-Yu. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)