- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Encapsulation - Innovative Functionalization of Textiles

Saminathan R*

Associate Professor, Department of Textile Technology, Kumaraguru College of Technology, Coimbatore India

*Corresponding author:Saminathan R, Associate Professor, Department of Textile Technology, Kumaraguru College of Technology, Coimbatore India

Submission: June 11, 2025;Published: June 30, 2025

ISSN 2578-0271 Volume10 Issue4

Abstract

Encapsulation has emerged as a pioneering approach to diversely functionalize textiles possessing both controlled release and enhanced durability characteristics. This paper presents an overview of encapsulation techniques employed in textiles, some key application areas such as healthcare, cosmetics, and protective clothing. It highlights encapsulation-based advancements in smart and sustainable textiles.

Keywords:Functional textiles, encapsulation, sheath materials, core materials, protection

Introduction

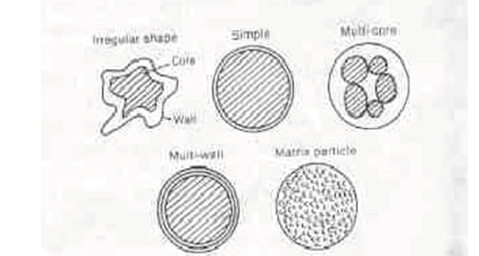

The textile industry has undergone a remarkable transformation from merely providing clothing for modesty and aesthetics to developing advanced materials with diverse functionalities. A pivotal innovation driving this evolution is encapsulation, a sophisticated technique that involves entrapping active substances within a protective shell material. Figure 1 schematically represents some common shapes of microcapsules. The shells, attached to the fabric surface break in response to stimuli and release the active ingredient. This process allows for the controlled release or long-term preservation of the functionality, bestowing textiles with novel and enhanced properties. From cosmetics and pharmaceuticals to temperature regulation and antimicrobial protection, encapsulation offers a versatile pathway to intelligent textiles that respond to user needs and environmental stimuli, pushing the boundaries of traditional fabric capabilities. This innovation has broadened the valuechain for the textile sector [1].

Figure 1:Variety of microcapsule shapes.

Encapsulation for textiles

Encapsulation for textiles yields micro- or nanometre-sized

particles, where active ingredients are enclosed in polymeric

or other suitable shell materials. These capsules are then

integrated into textile structures through methods such as coating,

impregnation, exhaustion, or even direct spinning into fibres. The

choice of shell material and encapsulation technique depends on

the active substance, the desired release profile, and the proposed

end use. Common active ingredients include:

A. Phase Change Materials (PCMs): These absorb and

release heat to maintain comfort and generally employed in

extreme weather conditions.

B. Fragrances: For extended scent release in automobile

and home furnishing textiles.

C. Antimicrobial agents: These kill or inhibit bacterial and

fungal growth, improving safety in hospitals and enhancing

hygiene product performance.

D. Insect repellents: Providing protection against pests

especially to defence forces and agricultural workers.

E. Cosmetic and pharmaceutical agents: Such as

moisturizers, vitamins, insect bite and pain relief, offering

“wearable care.” They may include liposomes, dendrimers, and

nanospheres.

F. Flame retardants: Providing light-weight protection to

fire fighters and personnel employed in high-risk environments.

G. Healing agents: For self-healing textiles that repair

minor damages.

The choice of shell material (e.g., melamine-formaldehyde, polyurethane, cyclodextrins) varies in order to satisfy critical functions, such as protecting the active core from degradation (e.g., oxidation, evaporation), preventing premature release, and ensuring controlled or triggered release mechanisms. These mechanisms can be various external stimuli, such as friction, temperature changes, pH variations, or enzymatic action, allowing the textile to perform its function precisely when needed [2,3].

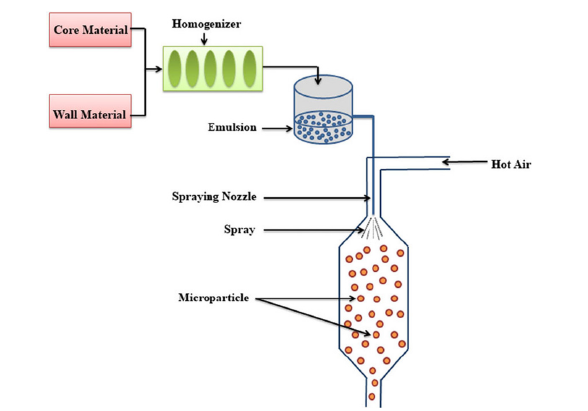

Encapsulation techniques include:

A. Coacervation: Ideal for thermosensitive materials.

B. Interfacial polymerization: Common in producing

durable capsules.

C. Spray drying: Economical and scalable for textile finishes,

schematically shown in Figure 2.

Figure 2:Spray drying technique of micro-encapsulation.

Recent advances

Self-healing textiles: Encapsulating healing agents (e.g., monomers, resins) within textile fibres can enable self-repair of minor damages like tears or punctures. When damage occurs, the capsules break, releasing the agents which then polymerize to mend the structure, significantly extending product lifespan and reducing waste.

Smart delivery systems: Encapsulation can be designed for on-demand release of substances. For example, a medical textile could release a drug only when a specific biomarker is detected, or a chemical protective suit could release a neutralizing agent upon contact with a hazardous substance.

Bioactive textiles: Beyond cosmetics and antimicrobials, encapsulation allows for the integration of enzymes, probiotics, or even diagnostic reagents into textiles, opening doors for advanced wound dressings, health monitoring apparel, and environmental sensors [4-6].

Sustainable encapsulations use biopolymers like chitosan and alginate for the wall material. The integration of “stimuli-responsive capsules” has led to the development of intelligent textiles that react to body heat, sweat, or UV light. Moreover, plasma-treatment and sol-gel processes enhance the binding of capsules to textile substrates, improving wash fastness and durability [7,8].

Challenges and future prospects

Despite its potential, encapsulation in textiles faces limitations

such as:

A. Safety and environmental impact: Ensuring that the

encapsulated substances and shell materials are non-toxic,

hypoallergenic, and environmentally friendly throughout their

lifecycle.

B. Regulatory frameworks: Developing clear guidelines for

novel functionalized textiles, especially those with biomedical

applications.

C. High production cost and uneven distribution during

application.

Future prospects include:

A. Green encapsulation methods.

B. Wearable medical textiles with smart drug delivery.

C. AI-driven design for performance prediction and

optimization.

Conclusion

The future of encapsulated textiles is bright, with ongoing research focusing on novel shell materials (biodegradable polymers, natural waxes), advanced release mechanisms (pHresponsive, light-triggered), and multifunctionality (combining several encapsulated agents). As nanotechnology advances, the precise control over capsule size, structure, and content will further unlock the potential for truly “smart” and interactive textile materials, playing a significant role in wearable technology, healthcare, environmental protection, and everyday comfort.

References

- Gulrajani ML (2010) Textile finishing. Woodhead Publishing, India.

- Gharsallaoui A, Roudaut G, Chambin O, Voilley A, Saurel R (2007) Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Research International 40(9): 1107-1121.

- Montazer M, Harifi T (2015) Nanofinishing of Textile Materials. Woodhead Publishing, India.

- Holme I (2008) Innovative technologies for high performance textiles. Coloration Technology 123(2): 59-73.

- Patel M, Patel R (2022) Recent trends in encapsulation techniques for textiles. Journal of Engineered Fibers and Fabrics 17: 1-15.

- Sharma S, Kaur I (2020) Microencapsulation in textile finishing: A review. Journal of Textile and Apparel Technology and Management 12(1): 1-22.

- Das D, Yadav R (2022) Microencapsulation: Techniques and applications in functional textiles. Journal of Functional Textiles 3(1): 1-15.

- Qiu Y, Chen H (2018) Advanced Textile Functionalization with Microencapsulation Technology: A Review. Textile Research Journal 88(12): 1438-1456.

© 2025 Saminathan R. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)