- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Investigation on Mechanical Properties of Single Jersey and Rib Knits after the Chemical Treatments of the Dyeing Process

Usha Chowdhary* and Md Rashedul Islam

Professor, DIFM, Central Michigan University, USA

*Corresponding author:Usha Chowdhary, Professor, DIFM, 216 Wightman Hall, Central Michigan University, Mount Pleasant, MI 48858, USA

Submission: January 15, 2025;Published: February 11, 2025

ISSN 2578-0271 Volume10 Issue4

Abstract

Textile substrates are subjected to various chemical treatments during the dyeing process, which causes severe changes in the physical and mechanical properties of textiles. Nevertheless, the final product must show an adequate level of physical and mechanical properties as per buyers’ requirements. Previously, many scholars investigated fabric strength and appearance loss under the influence of the textile chemical process. However, there is a very limited number of studies that conclusively compared these losses among different dyeing stages. This study investigated some selected mechanical properties which are directly related to the strength, such as bursting strength, breaking strength, elongation, compression, and stretch & recovery at each stage of dyeing. In the meantime, fabric GSM and thickness loss were also examined at different stages. The obtained results were then statistically analyzed using ANOVA to see the impacts of each dyeing stage. The findings revealed that the dyeing stages significantly impacted the mechanical properties of single jersey and rib structures. The study could be useful to understand the range of mechanical loss in single jersey and rib structures at each stage of dyeing.

Keywords:Textile substrates; Dyeing process; Textile chemical process; Fabric GSM

Introduction

The extended life or durability of textile products is a matter of concern for modern-day consumers. The higher durability implies the greater quality of the products [1]. The most recent trend of textile sustainability and consumer behaviour on consumption patterns grabbed the heed of manufacturers and retailers to produce durable products [2]. In previous studies, the durability of textile products evaluated by means of physical and mechanical assessment [3]. The garment products made of textiles are subjected to repeated stress when they are worn, which causes deformation after a certain amount of time. The ability to endure against bursting strength, breaking strength, compression, and stress make the textile durable [4]. On the other hand, fabric GSM (grams per square unit area), thickness, and surface structure are damaged with times due to frequent usage and wet treatment [5].

The coloration process of cotton fabric is composed of three stages: pre-process, dyeing, and post-process. The pre-process activity generally includes scouring and bleaching [6]. The scouring treatment takes out oil, fat, wax, and other impurities from the fabric surface and enhances hand feelings, while the bleaching treatment eliminates natural colours (light yellow/off white) [7]. Several studies reported the tendency of cotton to decline its’ strength due to the bleaching process. Bulut [8] compared high-temperature and low-temperature bleached cotton for enhanced dyeing performance. The test result disclosed a reduction in bursting strength and fabric weight. Abdel-Halim [9] developed a redox bleaching system to reduce the strength loss in cotton using sodium chlorite/potassium permanganate solution. The bleached fabric had a satisfactory whiteness index, including a modest amount of strength loss. Piccoli et al. [10] treated several raw knitted specimens with condensed ozone inside of a closed vessel. Additional wetting agent solution was added to carry out the bleaching process with low water usage. Even though the process was successful for low water usage and optimal whiteness index, the strength loss was significant in bleached cotton.

In the same way, many studies reported the influence of the dyeing process on the physical and mechanical properties of cotton. Hasani [11] compared the effect of the bleaching and dyeing process on knitted cotton. The result exhibited a reduction in tensile strength, compression recovery, weight, and thickness after dyeing - however, the bio-finishing treatment using softener enhanced fabric stiffness, strength property, weight, and thickness. Lam et al. [12] coated cotton fabric with titanium dioxide after plasma treatment. The result found negative impacts on the strength and compression properties in coated materials. Nevertheless, the surface smoothness was improved due to plasma treatment. Senthilkumar [13] analyzed the impacts of the laundering process on the cotton/spandex blended fabric for stretch and recovery. The changes in stretch and recovery at specific extensions were not significant in the experiment. Sun [14] explored the consequences of scouring, bleaching, and dyeing process on cotton fabric. The strength, compression, thickness, and weight had a significant loss after these processes.

The textile materials are subjected to enzymatic treatment during the dyeing process. Sometimes the enzymatic treatment is done at the pre-stage of dyeing. Other times, it is done at the poststage. Hao et al. [15] that the fabric loses its’ thickness and weight during chemical treatments, which causes the creation of damaged fibers on the surface. In later, these damaged fibers produce the pilled surface, which is considered an undesirable trait. The enzymatic treatment helps to eliminate the damaged fibers from the surface and improve the smoothness of fabrics. Several studies showed the enzymatic treatment for the smoothness of textiles. Ali et al. [16] used an amylase enzyme for cotton finishing. After the treatment, the scanning electron microscopy revealed a smooth appearance on the fabric surface. Jevšnik et al. [17] improved the surface smoothness of interlock knits using the Trichoderma Reesei enzyme. Jabasingh [18] reported that the use of aspergillus enzyme in slightly acidic conditions enhances fabric softness property. In later, the study was confirmed by scanning electron.

The current study is essential from the viewpoint of manufacturers and consumers since the physical and mechanical properties of knitted garments should be enough to sustain repeated washing and wearing. Besides, manufacturers are concerned about strength and weight at each stage of dyeing these days because they want to maintain buyers’ recommended strength and GSM in the final products [7]. The purpose of this study was to examine the mechanical properties of single jersey and rib knitted structures at the pre-dyeing stage, dyeing stage, and post-dyeing stage.

Literature Review

Bleaching of cotton

The bleaching chemicals can be classified into two categories;

oxidizing bleaching agent (it gains electrons from others) and

reducing bleaching agent (it donates electron). In this study, we

used a sodium hypochlorite (NaOCl) based oxidizing bleaching

agent since it was available in the traditional marketplace. NaOCl

is a powerful oxidizer and consisted of a (Na+) sodium cation and

a (ClO-) hypochlorite anion. NaOCl reacts in the following way with

water to perform the bleaching action. The formation of HOCl is

important as it provides the nascent oxygen molecule responsible

for bleaching [7,19].

Cl2 + H2O ⇌ HCl +HOCl

2HOCl ⇌ 2HCl + O2

In the acidic medium, NaOCl creates chlorine molecules for

bleaching [20]. In this case, the reaction is very fast, and it can lead

to fiber damaging. The reaction is given below:

NaOCl + HCl → NaCl + HOCl

HOCl + HCl → H2O + Cl2

Reactive dyeing of cotton

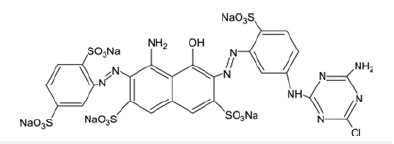

Cotton is a cellulosic fiber that contains -OH group in the structure. This -OH group is responsible for the reaction between cotton and reactive dye. The most common chemical structure of reactive dye consists of the sodium salt of sulphonic acid groups, which is water-soluble, and chlorotriazine reactive group, which causes the reaction with reactive dye in alkaline condition [21] (Figure 1).

Figure 1:Reactive dye [21].

For the sake of dyeing reaction, if cotton is represented as Cell-

OH and reactive dye is represented as Dye-Cl, then the reaction will

be as follows in alkaline medium [6].

Cell-OH + OH- → Cell-O- + H2O

Cell-O- + Dye-Cl → Cell-O-Dye + Cl-

Mechanism of enzyme treatment

Cotton fiber degrades into cellulose in the presence of cellulase enzyme. This study used cellulase enzyme for cotton as the postdyeing process, which works in neutral pH (6 to 7). The cellulase enzyme is divided into two main components in the enzyme bath: endo-cellulases and exo-cellulases. Endo-cellulases randomly attack the cellulose polymer chain of cotton; the preferable place for attacking is the amorphous region in the polymer chain. This causes breakage on the fiber surface, which helps to eliminate protruding fibers. Exo-cellulases mainly attack at the end of the polymer chain. This also causes breakage on the fiber surface. When both components work together, they damage the fabric surface severely [22].

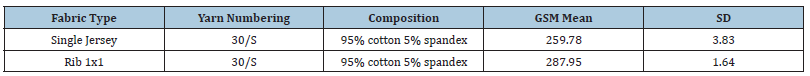

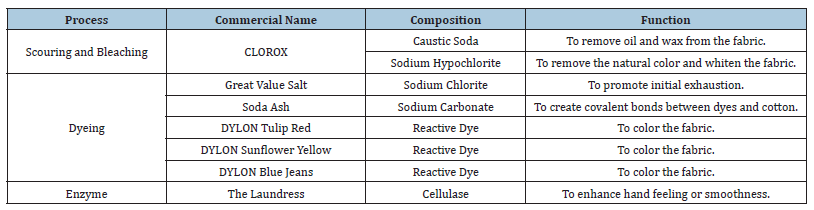

Materials

The study selected single jersey and rib-knit structures for mechanical assessments at each stage of dyeing. The reactive dye has been chosen for the dyeing process as it is the best dyestuff for cotton and creates uniform shades. Table 1 represents fabric structural attributes and composition, and Table 2 contains the list of chemicals used in the experiments.

Table 1:Fabric specification.

Table 2:Lists of chemicals used in dyeing stages.

The fabric specimens were obtained from the local fabric store named JOANN at Mount Pleasant. Fabric structures [23], yarn numbering (ASTM 4898-13), composition, and GSM (ASTM 3776- 02) were tested according to the standards and validated with the supplier-provided information.

Most of the textile industries use hydrogen peroxide as their bleaching chemical since it works most efficiently than other bleaching chemicals [6]. The proposed study selected CLOROX chlorine-based bleaching agent because hydrogen peroxide bleaching (50%) agent was not available in the traditional market. In the same way, the study tried to obtain other chemicals from the traditional marketplace. Sodium chloride and sodium carbonate were used in the dyeing process to facilitate the dyeing reaction between the reactive dye and cotton fiber. Acetic acid neutralizes fabric and prepares the bath for enzyme treatment by reducing the pH level to 6 [24,25].

Methods

The study was carried out in nine different steps; such as

1) test identification,

2) sampling,

3) dyeing,

4) bursting strength assessment,

5) breaking strength assessment,

6) compression and thickness test,

7) stretch and recovery test,

8) GSM, and

9) statistical analysis.

The results obtained from these steps were statically analyzed using ANOVA at a 95% confidence level.

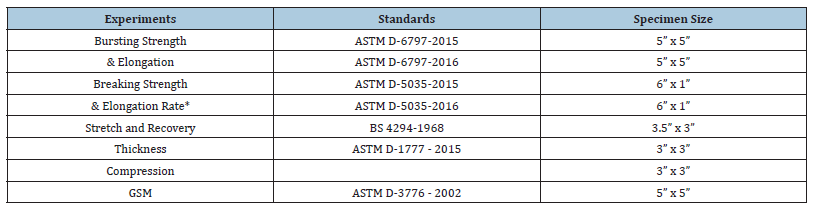

Test identification (Table 3)

Table 3:Lists of experiments.

*The breaking strength test was carried out only in the wale direction because the elongation rate in course direction was so higher that it surpassed the capacity of testing equipment.

Sampling

The study required to create four groups of specimens to carry out all the experiments; (group-A) raw or untreated specimens, (group-B) only bleached specimens, (group-C) bleached + dyed specimens, (group-D) bleached + dyed + enzymed specimens. Each specimen in a group was subjected to all the physical and mechanical tests to analyze the impact of chemical treatments.

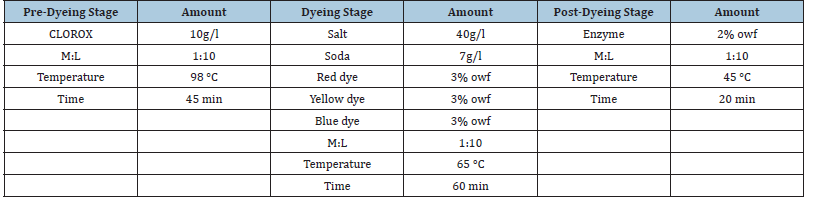

Dyeing process

The overall dyeing process was carried out in three stages: (1) pre-dyeing stage, (2) dyeing stage, and post-dyeing stage. The predyeing stage was composed of combined scouring and bleaching [6], the dyeing stage was composed of coloration and soaping (to remove unfixed dyes) [7], and the post-dyeing stage was composed of enzymatic treatment. The chemical recipe and dyeing parameters are given below (Table 4). The fabric specimens were washed properly before going to the next stage. The term owf indicates on the weight of fabric.

Table 4:Dyeing recipe and parameters.

Bursting strength and downward elongation test

Bursting strength refers to the amount of force or pressure required to rupture a fabric radially. In this case, the force or pressure works at the right angle with the fabric plane. The study used the INSTRON 5544 tester, which measured bursting strength and downward surface extension (elongation) of the fabric specimens concurrently. The data was recorded in lbf. Five specimens were cut into 5”x5” (any direction) and conditioned according to the ASTM D 1776-08 before initiating the experiment. INSTRON tester was arranged for bursting strength using ball burst piece; the stroke length 3 inches, and the downward speed of ball burst mace was 12 inches/min.

Breaking strength and elongation rate test

Breaking strength of textile materials refers to the amount of tensile strength or pulling force required to rupture the textiles. The INSTRON tester was again rearranged by the replacement of the ball burst piece with upper and lower jaws for fabric gripping during the breaking strength test. Five specimens were cut into 6”x1” in the wale direction only. Both ends of the specimen placed inside of the jaws, and then the jaws were closed by pressing on the foot pedal. The data were recorded in the lbf unit with a CRE of 12inches/min. In this case, the elongations were recorded in wales.

Compression and thickness

The test specimens were pressed between two rounded pressure

feet as a sandwich layer to obtain the results for compression and

thickness. Even though many of the previous studies reported

compression testing for 3D fabrics/composites, our literature

review did not find any standard procedure for the compression

study of regular wear. Mark-10 Force and Torque Measurement

ES-30 was used for the compression. The initial thickness and

compression were determined by using an ATLAS fabric thickness

tester. The specimen size was 3’’x3” regardless of any direction.

Let, fabric initial thickness is ti, thickness after compression is tc,

and thickness after relaxation is tr; then the compression (%) and

recovered thickness (%) equations are as follows.

Compression (%) = [(ti-tc)/ti x 100%]

Stretch and recovery

The specimens were subjected to stretch and recovery test

using Fryma Fabric Extensometer. The size of the specimens was

3.5”x3” in both wale and course directions. The Extensometer has

two horizontal jaws for specimen gripping; a rotating wheel and

load of 3Kg were used to facilitate extension in the specimen. After

that, the stretching was recorded, and the specimen was kept in 5

min of relaxation. Then, the recovery was calculated by dividing

the recovered dimension with stretched dimension. For instance,

if S indicates the dimension after stretching, D indicates the

dimension after recovery, and O indicates the original dimension,

then stretched portion, lS = S-O and recovered portion, lr = S-D. The

stretch (%) and recovery (%) equations are as follows.

Stretch (%) = (lS/O x 100) %

Recovery (%) = (lr/lS x 100) %

GSM

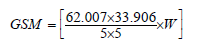

According to the ASTM D-3776 -02, the weight of the fabric is expressed in gram per square meter (GSM) unit. Fabric specimens are cut into 5”x5” small pieces before weight measurement. Suppose the weight of 5”x5” cut specimen is w gm; then the GSM should be as follows [6].

Statistical analysis

After carrying out each stage of the wet process, the mechanical experiments were performed. The results were recorded in SPSS v25. Finally, the statistical analysis was performed to see the nature of changes in mechanical properties of single jersey and rib structure.

Result and Discussion

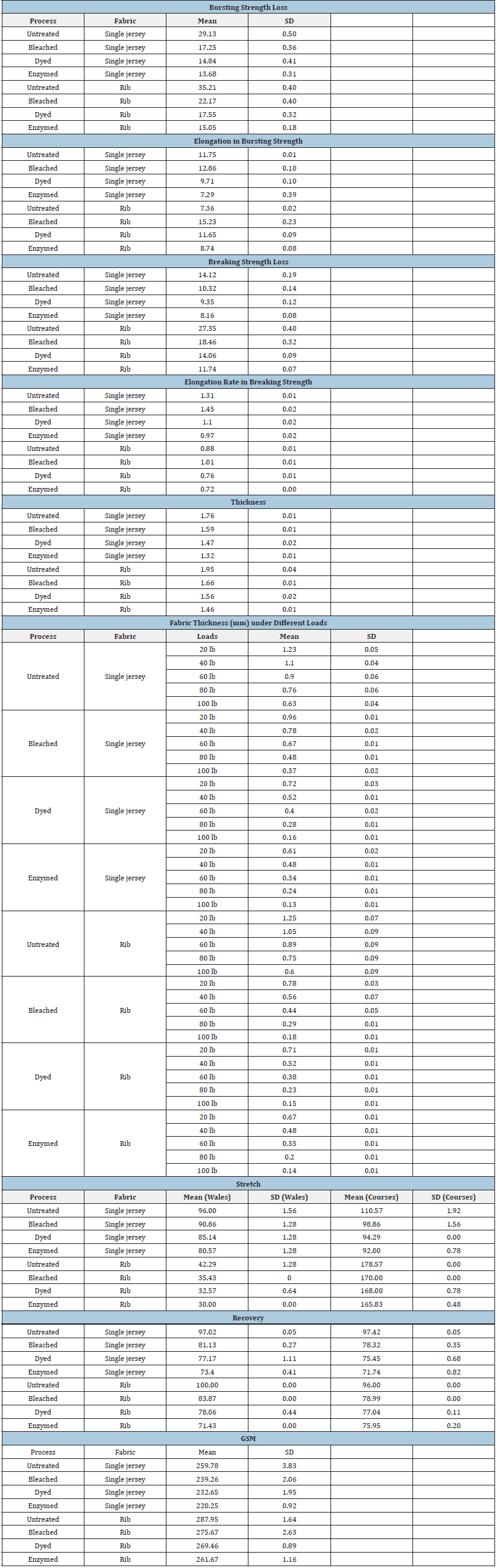

The mean and standard deviation from all the experiments were presented in the Appendix. All the statistical analyses regarding this research were performed using the data from the Appendix. One may use it as his/her reference to better understand the analysis.

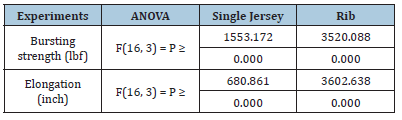

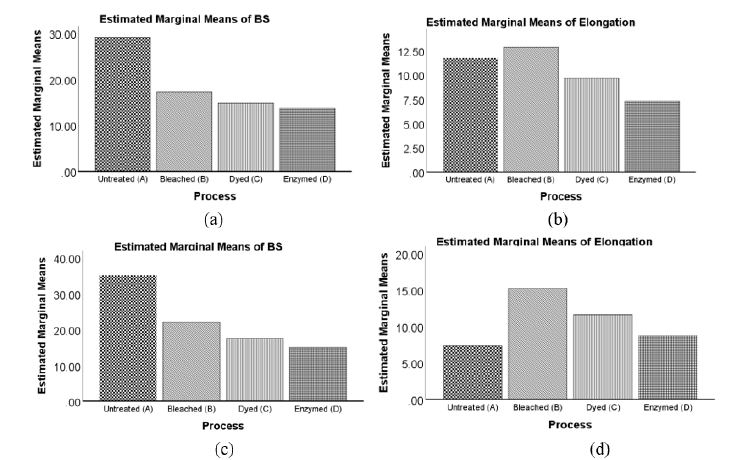

Bursting strength loss and elongation

The statistical analysis (ANOVA) revealed that the bursting strengths and elongations (or the length of downward extensions) varied significantly at each stage of dyeing (Table 5). The bursting strengths decreased gradually in the subsequent dyeing processes, where the strength loss was the highest after bleaching treatment (Figure 2a&c). Previous studies reported that the chemical processes during fabric coloration cause a decline in bursting strength [7,8], but they have never mentioned which process reason for the maximum loss. On the other hand, the downward elongation acted differently at each stage of dyeing. The downward elongation was the highest after bleaching (Figure 2b& d).

Table 5:Statistical Analysis of Bursting Strength and Elongation.

Figure 2:(a) Bursting Strength of SJ in lbf, (b) Downward Elongation in inches of SJ, (c) Bursting Strength of Rib in lbf, and (d) Downward Elongation in inches of Rib.

*The resulted strength loss and elongation happened due to some reasons. Firstly, after the bleaching treatment, single jersey and rib lost their cuticle layers from the fabric surface, which caused a reduction in rigidity. Single jersey and rib lost the maximum amount of bursting strengths due to less rigidity. Also, the elongation was the highest for the same reason. Point to be noted that the specimens had lower elongation after dyeing (C) and enzyme (D) treatments. Because the specimens were already elongated after bleaching treatment, so they had minimal opportunity to extend.

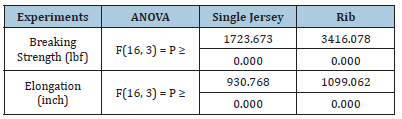

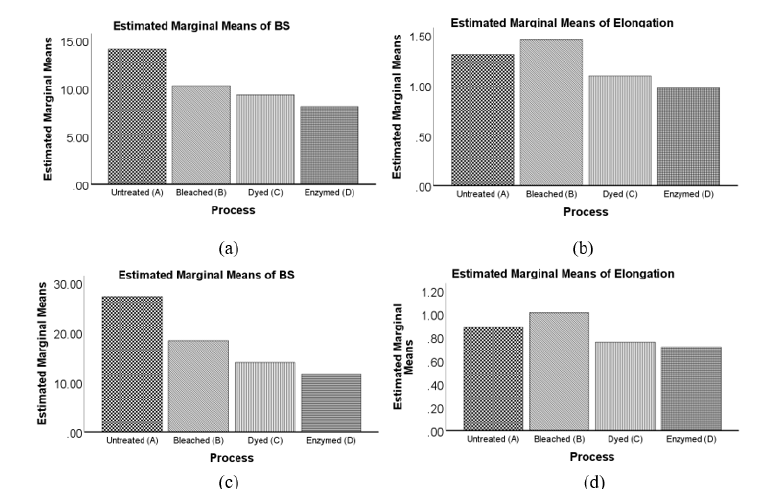

Breaking strength

The statistical analysis (ANOVA) revealed that the breaking strengths and elongation rate (extended length/initial length) varied significantly at each stage of dyeing (Table 6). The breaking strengths declined gradually in the subsequent dyeing processes, where the strength loss was the highest after bleaching treatment (Figure 2a&c). Previous studies reported that the chemical processes during fabric coloration cause a decline in breaking strength [9,10], but they have never mentioned which process reason for the maximum loss. On the other hand, the elongation rate acted differently at each stage of dyeing. The elongation rate was the highest after bleaching (Figure 3b&d). The reasons for yielded breaking strength loss and elongation rate are mentioned in the bursting strength section.*

Table 6:Statistical analysis of breaking strength and elongation rate.

Figure 3:(a) Breaking Strength of SJ in lbf, (b) Elongation Rate in inch/inch of SJ, (c) Breaking Strength of Rib in lbf, and (d) Elongation Rate in inch/inch of Rib.

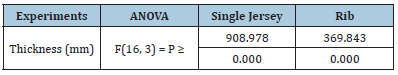

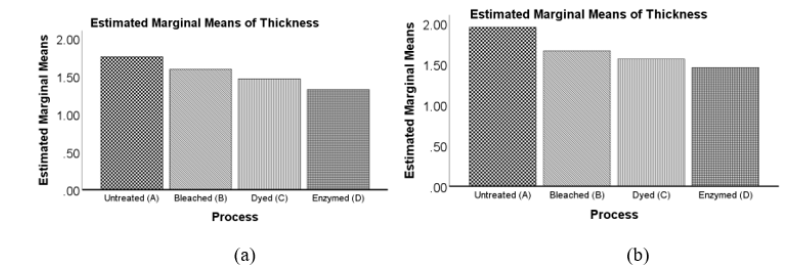

Thickness

One-way analysis of variance disclosed that the thickness of single jersey and rib specimens differed significantly at each stage of dyeing (Table 7). The thickness of specimens decreased gradually after each chemical treatment. According to Figure 4, the thickness rank is Untreated (A) > Bleached (B) > Dyed (C) > Enzyme (D). This phenomenon happened due to the removal of cuticle layers and damaging of fabric surface as it touched chemicals. Besides, the thickness loss percentage was the highest for the bleaching treatment, and it was the lowest for the dyeing process. The enzymatic treatment caused a significant amount of thickness reduction since it removed protruding fibers from the fabric surface and made it smoother. The order of thickness loss percentage was Bleaching (SJ 14%, Rib 15%) > Enzymatic treatment (SJ 11%, Rib 7%) > Dyeing (SJ 8%, Rib 6%). This comparative relation of thickness loss has not been found in previous studies. Please, see the Appendix for reference.

Table 7:Statistical analysis of thickness.

Figure 4:(a) Thickness in mm of SJ, and (b) Thickness in mm of Rib.

Appendix 1:

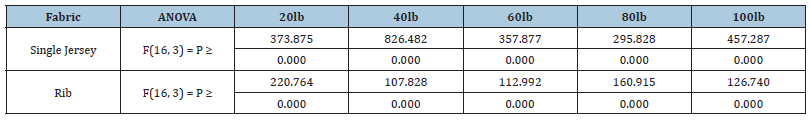

Compression

One-way analysis of variance disclosed that the thickness of single jersey and rib specimens differed significantly under 20 lb, 40 lb, 60 lb, 80 lb, and 100 lb loads at each stage of dyeing (Table 8). Figure 5a&b represent that the compression percentage of the single jersey and rib specimens was the lowest for untreated fabric. The reason for this outcome was the presence of the cuticle layer and unnecessary substance on the fabric surface, which caused a higher resistive force against compression. Additionally, the compression (%) increased at subsequent dyeing stages (Figure 4).

Table 8:Statistical analysis of compression.

Figure 5:(a) Compression Curve of SJ, and (b) Compression Curve of Rib.

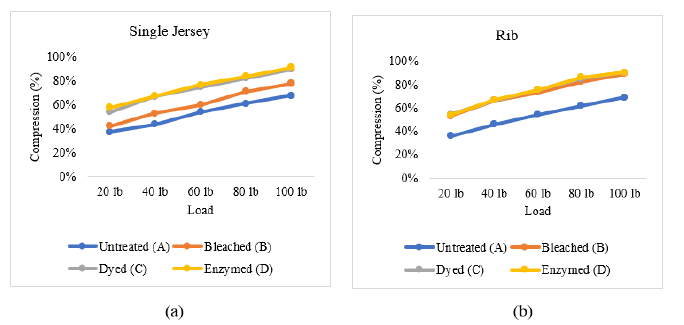

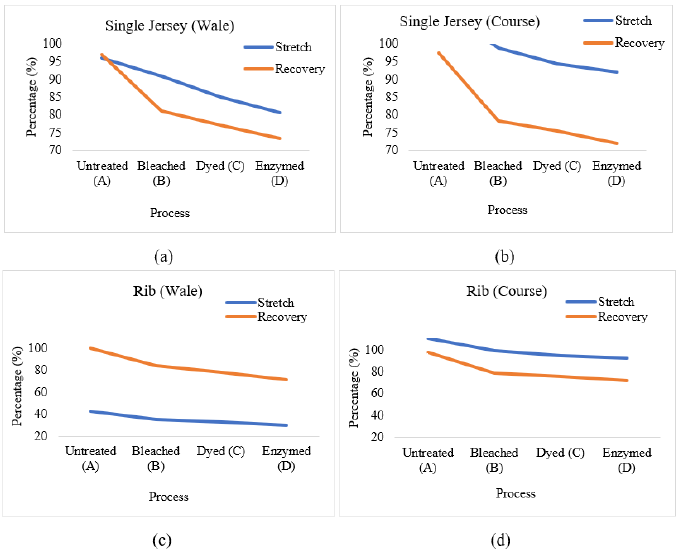

Stretch and recovery

The statistical analysis of stretch and recovery was performed for single jersey and rib in both wale and course direction. The results from the analysis are mentioned in Table 9, which describes that the stretch and recovery percentages differed significantly at each stage of dyeing. The stretch percentages were higher than recovery percentages in most cases except for the rib examined in the wale direction. The stretch was higher in course direction than in wale direction (Figure 6a-d). Moreover, a decline is seen for stretch and recovery with subsequent treatments.

Table 9:Statistical analysis of stretch and recovery.

Figure 6:Stretch & Recovery Percentage of (a) SJ in Wale Direction, (b) SJ in Course Direction, (c) Rib in Wale Direction, and (d) Rib in Course Direction.

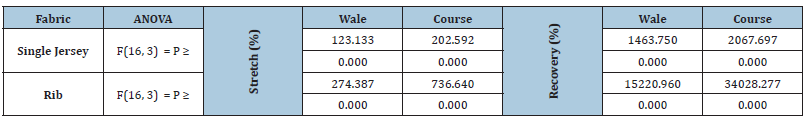

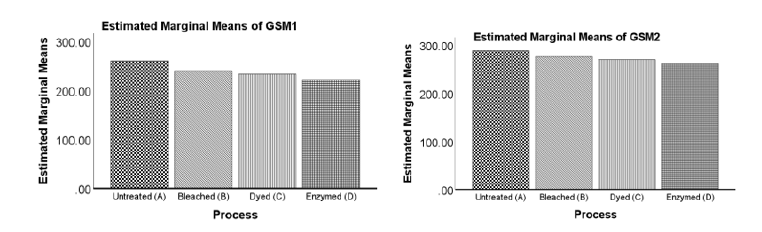

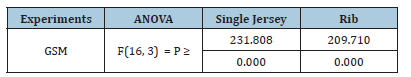

Impact on fabric GSM

Figure 7:(a) GSM of SJ, and (b) GSM of Rib.

One-way analysis of variance disclosed that the GSM of single jersey and rib specimens differed significantly at each stage of dyeing (Table 10). GSM decreased gradually after each chemical treatment. According to Figure 7, the order of GSM is Untreated (A) > Bleached (B) > Dyed (C) > Enzymed (D). This phenomenon happened due to the removal of cuticle layers and damaging of fabric surface as it reacted with chemicals. Besides, the GSM loss percentage was the highest for the bleaching treatment, and it was the lowest for the dyeing process. The enzymatic treatment caused a significant amount of GSM reduction. The order of GSM loss is Bleaching (SJ 8%, Rib 4%) > Enzymatic treatment (SJ 5%, Rib 3%) > Dyeing (SJ 3%, Rib 2%). This comparative relation of GSM loss has not been found in previous studies. Please, see the Appendix for reference.

Table 10:Statistical analysis of GSM.

Conclusion

The key findings of the study are as follows.in wale

direction), thickness, compression, stretch and recovery, and

fabric GSM varied significantly at each stage of dyeing. The

overall results showed the following order, i.e., Untreated

(A) > Bleached (B) > Dyed (C) > Enzymed (D) for selected

mechanical experiments.

B. The downward extension (in bursting strength) and the

elongation rate (in breaking strength) have a different order

than the previous one, which is Bleached (B) > {Untreated (A),

Dyed (C), and Enzyme (D)}.

C. The thickness loss and GSM loss percentage can be ordered as

Bleaching (loss %) > Enzymatic treatment (loss %) > Dyeing

(loss %).

The findings may have implications for the manufacturers as the guideline for the selection of dyeing process. The manufacturers can eliminate any one of the stages of dyeing depending on the strength requirement. The study can be extended to other types of knits and fiber contents. Such information will be useful for the industry as well as academia.

References

- Niinimäki K, Koskinen I (2011) I Love this Dress, It makes me feel beautiful! Empathic knowledge in sustainable design. The Design Journal 14(2): 165-186.

- Fletcher K (2012) Durability, fashion, sustainability: The processes and practices of use. Fashion Practice 4(2): 221-238.

- Nobili A (2016) Durability assessment of impregnated Glass Fabric Reinforced Cementitious Matrix (GFRCM) composites in the alkaline and saline environments. Construction and Building Materials 105: 465-471.

- Bodur MS, Bakkal M, Sonmez HE (2016) The effects of different chemical treatment methods on the mechanical and thermal properties of textile fiber reinforced polymer composites. Journal of Composite Materials 50(27): 3817-3830.

- Fontana GD, Varesano A, Vineis C (2018) Effect of the bleaching on physical and mechanical properties of different fabrics. Fibers and Polymers 19(12): 2590-2596.

- Islam MR, Chowdhary U (2019) Relative color pickup of three different knits and predictive dyeing recipe formulation. SSRG International Journal of Polymer and Textile Engineering 6(3): 1-16.

- Islam MR, Alam MR (2020) Pre-post bleaching behaviors of cotton knits using reductive and oxidative bleaches. SSRG International Journal of Polymer and Textile Engineering 7(1): 42-53.

- Bulut MO (2016) Low temperature bleaching for reactive dyeing and top white knitted cotton fabric. Journal of Cleaner Production 137: 461-474.

- Abdel-Halim E (2012) An effective redox system for bleaching cotton cellulose. Carbohydrate Polymers 90(1): 316-321.

- Piccoli HH, Souza AAUD, Souza SMAGUD (2014) Bleaching of knitted cotton fabric applying ozone. Ozone: Science & Engineering 37(2): 170-177.

- Hasani H (2010) Effect of different processing stages on mechanical and surface properties of cotton knitted fabrics. Indian J Fibre Text Res 35(2).

- Lam YL, Kan CW, Yuen CWM (2014) Objective measurement of hand properties of plasma pre-treated cotton fabrics subjected to flame-retardant finishing catalyzed by zinc oxide. Fibers and Polymers 15(9): 1880-1886.

- Senthilkumar M, Anbumani N (2012) Effect of laundering on dynamic elastic behavior of cotton and cotton/spandex knitted fabrics. Journal of Textile and Apparel Technology and Management 7(4): 10.

- Sun D, Stylios GK (2012) An investigation of continuous finishing and dyeing on the mechanical properties and handle of cotton fabrics. Fibers and Polymers 13(10): 1286-1291.

- Hao L, Wang R, Zhao Y, Fang K, Cai Y (2018) The enzymatic actions of cellulase on periodate oxidized cotton fabrics. Cellulose 25(11): 6759-6769.

- Ali H, Hashem M, Shaker N, Ramadan M, El-Sadek B, et al. (2012) Cellulase enzyme in bio-finishing of cotton-based fabrics: Effects of Process Parameters. Research Journal of Textile and Apparel 16(3): 57-65.

- Jevšnik S, Fakin D, Heikinheimo L, Stjepanovič Z (2012) Changes in a knitted fabric’s surface properties due to enzyme treatments. Fibers and Polymers 13(3): 371-379.

- Jabasingh SA, ValliNachiyar C (2011) Optimization of cellulase production by Aspergillus nidulans: Application in the biosoftening of cotton fibers. World Journal of Microbiology and Biotechnology 27(1): 85-97.

- Fu E, Mccue K, Boesenberg D (2007) Chemical disinfection of hard surfaces - Household, industrial and institutional settings. Handbook for Cleaning/Decontamination of Surfaces pp. 573-592.

- Sandin S, Karlsson RKB, Cornell A (2015) Catalyzed and uncatalyzed decomposition of hypochlorite in dilute solutions. Industrial & Engineering Chemistry Research 54(5): 3767-3774.

- Teli M (2015) Advances in the dyeing and printing of silk. Advances in Silk Science and Technology pp. 55-79.

- Cavaco-Paulo A (1998) Mechanism of cellulase action in textile processes. Carbohydrate Polymers 37(3): 273-277.

- Spencer DJ (2001) Knitting technology: A comprehensive handbook and practical guide. Woodhead Publishing, Sawston, United Kingdom.

- Chowdhary U, Islam MR (2019) Pre-post wash wicking behaviour, moisture transfer, and water repellency of plain, twill, and satin weaves. Journal of Textile Science of Fashion Technology 2(3).

- Hashemi N, Asayesh A, Jeddi AAA, Tehrani MA (2019) The role of geometry on the viscoelastic materials properties: Tensile and stress relaxation of the yarn. The Journal of The Textile Institute 110(12): 1733-1739.

© 2025 Usha Chowdhary. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)