- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Potential Usage of Silica Aerogel in Textile Based Insulating Materials

Ramazan Erdem*

Textile Technologies Department, Serik GSS Vocational School, Akdeniz University, Antalya, Turkiye ORCID: 0000-0003-2810-8294

*Corresponding author:Ramazan Erdem, Textile Technologies Department, Serik GSS Vocational School, Akdeniz University, Antalya, Turkiye

Submission: October 04, 2024;Published: November 06, 2024

ISSN 2578-0271 Volume10 Issue3

Abstract

Known for their unique properties such as remarkably less thermal conductivity, great porosity, and minimal dielectric constant, aerogels are gaining attention for various applications, particularly in textiles. Silica aerogels, notable for their outstanding thermal insulation capabilities, offer potential improvements over traditional insulation materials due to their low density and high thermal and acoustic insulation performance. The sol-gel process, involving the hydrolysis and condensation of silicon alkoxides, is used to synthesize silica aerogels, followed by supercritical drying to preserve their porous structure. Recent advancements have explored incorporating silica aerogels into textiles and fibers to enhance their thermal insulation while addressing challenges related to durability and cost. Methods such as wet reaction spinning, coaxial wet-spinning, and electrospinning have been performed to produce aerogel fibers with varying properties. For instance, silica aerogel fibers have been used in composite fabrics to improve flexibility and mechanical strength, while maintaining high insulation performance. Coating textiles with silica aerogel has also been investigated to create lightweight, high-performance thermal insulation for apparel. Additionally, silica aerogel blankets, produced by integrating aerogels into fibrous substrates, provide effective insulation for industrial and aerospace applications. Recent studies further highlight advances in producing silica aerogel-based fabrics with tailored properties for specific applications, such as heat protection and moisture management. Overall, the ongoing research aims to optimize aerogel materials for broader use in textiles and protective clothing, addressing both performance and cost-efficiency challenges.

Keywords:Silica aerogel; Textiles; Sol-gel process; Thermal insulation; Filament; Coating

Introduction

Aerogels are innovative materials that resemble solid smoke. They were first invented by Samuel Stephens Kistler in 1931. They are also nicknamed “blue air” or “frozen smoke” [1]. It contains at least 96% air. The rest of the 4% is a thin matrix of silicon dioxide. As a result, it represents one of the lowest-density solids ever created. Aerogels can be generated using the ‘sol-gel method’ through dispersing silicon alkoxide precursors in water and allowing them to hydrolyze and condense [2,3].

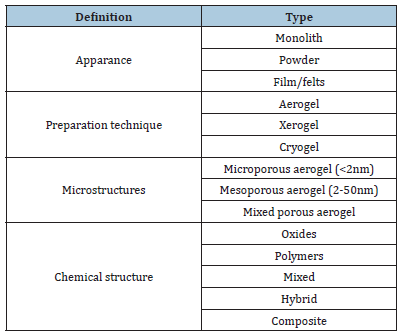

The extraordinarily low permeability of aerogels can be addressed by their pore size, which is ideal for transporting water vapor/gases nonetheless fluid water [4]. General characteristics of aerogels are the followings, extremely low thermal conductivity, exceptionally low dielectric constant, high surface area, ultra-high porosity, hierarchical and fractal microstructure, spontaneously cross-linked network, and non-crystalline structure. Tables 1 & 2 present the classifications of aerogels and where they originated from [5].

Table 1:Types of aerogels [5].

Table 2:Materials from which aerogels are currently produced [5].

Silica aerogel, a unique nanoporous material with excellent thermal insulation characteristics, has received plenty of attention over the last decade due to its potential applications in the textile industry. Unlike standard insulation substances, silica aerogel has a distinct set of properties, notably low density, extensive porosity, and exceptional thermal and acoustic insulation features, rendering it an appealing option for improving the performance of textile goods [6].

Silica aerogel is a desirable alternative to typical textile insulation materials due to its unique combination of characteristics. Yang et al. [7] define aerogel substances as “extremely lowd ensity, huge surface area, and uninterrupted three-dimensional nanoporous network architecture features.” This structure produces extraordinarily low heat conductivity, comparable to that of motionless air [7]. Wang reports that the thermal insulation efficiency of the silica aerogel composite fabric is two times those of the basic fabrics [8]. This renders silica aerogel appropriate for processes requiring minimal heat exchange such as winter outerwear and other thermal protective clothing [9]. Moreover, its lightness enables the development of slimmer and more pleasant insulating outerwear. Although there are still hurdles to putting silica aerogel into textiles, notably in terms of durability and affordability, ongoing investigations are looking into novel strategies for doing so.

Silica aerogel is commonly synthesized via a sol-gel technique, before undergoing a key drying stage. Loy et al. [10] explain the procedure as beginning with the hydrolysis and condensation of a silicon alkoxide precursor, for instance tetraethyl orthosilicate, with the help of a catalyst. This generates a colloidal suspension of silica nanoparticles known as a “sol” [10]. While the sol ages, the nanoparticles fuse together to generate a porous gel architecture that contains solvent. Sui emphasizes that the vital “supercritical drying” stage subsequently eliminates the solvent without crashing the fragile pore structure, which is required to preserve the aerogel’s distinctive features [11]. According to Gao et al. [12] changing each step’s variables, such as pH, temperature, and catalyst preference enables modifying the aerogel’s pore dimensions, surface area, and, eventually, its ultimate qualities [12].

The high thermal insulation capacity of silica aerogel is due to its peculiar microstructure, which efficiently inhibits all three routes of heat transfer: conduction, convection, and radiation. According to Lei et al. [13] the nano-sized pores in silica aerogel (usually <100nm) reduce gas molecule collisions and hence gas conduction, which is the primary mechanism in conventional insulation materials. Plus, the extensive pore network impedes convective heat transfer by restricting air movement within the material [13]. Lei et al. [14] conclude that the amorphous silica form has low solid heat conductivity [14]. Whilst radiative heat transmission may become considerable at greater temperatures, Lei et al. [15] propose that using opacifiers or building composite aerogels may assist minimizing this effect. In general, the combination of these characteristics produces the extraordinarily low heat conductivity that distinguishes silica aerogel [15].

Thermal conduction principle of aerogel

The thermal conductivity (λ) of insulating substances (porous objects) is detailed below.

where ʎgc is thermal conduction through the air, ʎsc is thermal conduction through the solid, ʎc is the heat transfer by convection, and ʎr is the heat transfer by radiation. Thermal conductivity of a gas is defined as the transfer of kinetic energy caused by the collision of molecules from the various gases that constitute the air. The thermal conductivity of a gas is determined by the ‘mean free path’ of its molecules. As the mean free path of gas molecules in a porous material is much bigger than the pore diameter, the gas molecule resides inside the pore. Therefore, gas thermal conductivity, and thus a whole thermal conductivity, decreases dramatically. It is additionally apparent that the heat transmission through thermal conductivity of a porous solid would decrease once its structural framework thins and the solid portion gets smaller. On the other hand, heat transmission by gas convection will be possible whenever the dimension of the pore is sufficiently large for fluid movement to outperform molecular mobility. Moreover, the thermal movement of atoms in an object causes the release of energy in the form of electromagnetic radiation, which will pass through the material if it is transparent to the wavelength(s) of the produced radiation and will be obstructed if it is opaque with these wavelengths [5,16].

Aerogels provide great thermal insulation and consequently nearly eliminate each of the above types of heat transmission. In these substances, heat transfer occurs through lattice vibrations, in which more actively vibrating atoms in a portion of the solid transmit their thermal energy to their lesser energetically vibrating neighboring atoms, an effect aided by collaborative motion in the manner of spreading lattice waves, which at the quantum limit are quantized as phonons. Pores with submicron dimension reduce the gaseous convective thermal transport, whilst radiation is only effective at elevated temperatures. As a result, the aerogel’s poor thermal conductivity implies that it is a desirable thermal insulator [5,16]. At appropriate costs, aerogels might replace glass wool or polyurethane foams in insulation fields, and inexpensive aerogels could also be utilized in thermal insulating sections of apparel for frigid temperatures as well as water container jackets [5].

Silica aerogel as fibers

Silica aerogel, although valued for its thermal insulation capabilities, has limitations because of its intrinsic fragility. To solve this, researchers investigated integrating silica aerogel within synthetic filaments, resulting in composite substances that retain the aerogel’s beneficial features while increasing mechanical strength. Linhares et al. [17] define these composites as having “strongly enhanced flexibility and tensile strength compared to pure silica aerogels,” which makes them appropriate for applications such as textiles and insulation. This strategy makes use of the aerogel’s poor thermal conductivity and the filament’s integrity as a structure. However, issues remain in assuring cost-effective scalability and long-term durability, which require additional research and development [17].

Manufacturing aerogel filaments has the benefit of eliminating the drying stage in the production of aerogel monoliths. The drying stage in fiber production is simple and integral to the fabrication cycle [18]. The earliest proof of the development of aerogel fibers dates back to 2012, when a basic extrusion procedure was utilized to manufacture tidy graphene aerogel fibers with aligned pores (pore diameter ranging from 3.4 to 100nm) [19]. In 2015, this process was broadened to involve the utilization of a twin-screw equipment for the manufacture of cellulose aerogel fibers [20]. After two years, silica and cellulose aerogel fibers were produced using a technology named wet reaction spinning [21]. In 2018, this technology was improved, and an entirely novel category of aerogel fibers called intelligent and multifaceted graphene-based aerogel fibers for sophisticated usage, such as wearable electronics, was presented [22]. In the past few years, a novel approach identified as the wet coaxial spinning process has been employed to fabricate polymer-wrapped aerogel fibers, with significant modifications to existing technologies [23]. In the meantime, extensive studies have shown that by managing the sol-gel procedure, aerogel fibers with adjustable transparency can be created [24]. To conclude, some of the efficient examples of silica aerogel f iber manufacturing technologies are the followings; wet reaction spinning, extrusion/ injection, freeze-spinning, wet coaxial spinning, and electrospinning [18].

The wet-spinning approach has received the majority of attention in research on Kevlar-based aerogel fibers. Tensile strength in the range of 0.6-30MPa has been implied, depending on the Kevlar solution and TBA content. The tensile strain was found to range from 22 to 40 [25]. The twin screw extrusion procedure generated porous cellulose aerogel fibers. The wet gels were washed and coagulated in ethanol before being super critically dried with CO2 to obtain cellulose aerogel fibers. The microstructure is an open porous structure composed of nanofibers with pore dimensions which vary from 10 to 100nm and fiber diameters between 10 and 25nm. The average density of supercritically dehydrated cellulose aerogels ranged from 0.009 to 0.137g/cm3, with BET specific surface areas varying from 120 to 230m2/g. Thermal conductivities in the cellulose aerogel ranged from 0.04 to 0.075 W/m.K, and compression modulus reached to16.2MPa [20]. Sedighi et al. [26] also produced melt spun POY (partially oriented yarn) and DTY (drawn textured yarn) polyester yarns including various amount of silica aerogel fillers (0.4, 1, 2 and 4wt%) by utilizing twin screw extrusion method. The average linear density of the obtained POY yarns was around 251 denier.

The tenacity of the yarns declined from 18,7 to 14,2 CN/Tex and elongation value elevated to 162% while increasing the silica aerogel from 0,4wt% to 2wt%. Microscopic evaluations exhibited that due to the texturing process the silica aerogel is more trapped in the pores and surface of the DTY yarns. Moreover, TGA analyses revealed that the degraded material amount is diminished from 99 to 95% as the filler content increases in the yarns [26]. Song et al. [27] suggested a revolutionary streamlining approach for producing insulative silica-bacterial cellulose composite aerogel fibers that does not require a freeze-dry stage. The procedure for preparing aerogel fibers described here is more straightforward and ecologically responsible. Additionally, the exploratory expenses were lowered. The aerogel fibers possessed significant specific surface area (671.3m2/g), exceptional hydrophobicity (contact angle ~132º), modest density (≤0.154g/cm3), and acceptable mechanical characteristics (tensile strength of 4.5MPa) [27]. Jinde [28] synthesized silica aerogel through the sol-gel ambient drying method and incorporated it into PVDF-HFP nanofiber membranes by two different electrospinning approaches as “exsitu” and “in-situ”. SEM analysis demonstrated that electrical forces efficiently implemented the aerogel particles over the nanofibers and further bonding with the nanofiber nets. The lowest recorded thermal conductivity value among the samples was 0.026W/m.K [28]. Sun et al. [29] proposed a novel technique based on coaxial wet- spinning of polymer-encapsulated aerogel fibers which includes sequential coagulations using an inner aerogel precursor as the initial coagulation bath and an immersion in water as the subsequent coagulation bath. The fibers possessed a pore-like aerogel matrix assembly in the core and porous sheath layers.

Aerogel fibers consisted of cellulose acetate/poly (acrylic acid) (CA/PAA) sheath layers and cellulose nanofiber (CNF) aerogel cores which exhibited the low density of 0.25g cm-3 and a high aerogel core porosity (99.34%). Also, the tensile strength of the fibers was recorded as 5.83MPa whereas the thermal insulation performance was determined as 0.054W/m.K [29].

According to one of the US Patents (US20150259499A1), polyethylene aerogels and aerogel fiber networks feature an exceptionally high level of molecular orientation and interlinked fibers, resulting in outstanding mechanical properties and porosity due to the aerogel fibers’ readily available interconnected 3-D pore structure. The experimental procedure is described as; during the fiber web manufacturing process, before producing fibers, the polymer in solution is transformed into a cross-linked gel having a three- dimensional open pore structure [30].

A group of Chinese researchers have invented an aerogelbased fiber that is suitable for knitting and weaving. The team first examined the polar bear distinctive fur which is recognized for being warm and water-resistant. Then, within the concept of biomimetics, an aerogel fiber with lamellar pores has been developed to capture infrared light and retain heat while preserving mechanical strength [31]. Another company located in Qingdao (China) has developed an aerogel fiber with enhanced porosity and ultra-reduced density. The thermal insulation value of this aerogel fiber has been reported as ≤0.02W/m.K. It has been stated that the density of the fibers can be as low as 0.003g/cm2. Laboratory results revealed that the thermal insulation capacity of aerogel fiber at low temperatures is approximately 2.8 times that of cotton fibers, and its enthalpy value may reach to 162J/g, which can provide thermal insulation performance for an extended period under extreme circumstances of minus 196 ℃ to minus 300 ℃ [32].

Silica aerogel coated fabrics that are used for thermal insulation

Coating fabrics with silica aerogel is a viable approach to create light in weight thermally insulating textiles. Lin et al. claim that these coated textiles can be used for “winter coats” and other thermal safety apparel. This technique takes advantage of silica aerogel’s remarkable thermal insulation characteristics while using the fabric as a reinforcing surface [9]. Sun et al. [33] observe that existing insulating materials frequently depend on rising density and thickness to attain the necessary thermal performance, resulting in bulky and uncomfortable clothes. The nanoporous nature of silica aerogel, on the other hand, enables thinner coatings while maintaining insulating efficiency. Several coating processes, including dip-coating and spray-coating, have been investigated, each with advantages and limits in terms of coating consistency, adherence, and versatility [33].

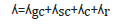

Islam et al. explored the thermal insulation property of nanoporous silica aerogel coated three-layered weft-knitted spacer fabrics with varied thicknesses. Experimental results proved that thermal resistance of 0.09131W/m.K has been reached [34]. Yan et al. [35] examined the morphological characteristics and thermal insulation performance of cotton- and PET- based hybrid knitted fabrics coated with silica aerogel. Fabric samples were immersed in aqueous dispersions with varying silica aerogel concentrations, dried, and piled in 1, 3, and 5 layers. The thermal insulation efficiency of cotton- and PET-based hybrid textiles was vastly enhanced by increasing the silica aerogel proportion to 56wt% [35]. Bhuiyan et al. [36] aimed to investigate level of protection and thermal comfort performance of needle punched viscose nonwoven coated with electrospun PAN-silica aerogel nanofiber (259.1±14.7nm) membrane (Figure 1). Results exhibited that coated nonwoven fabric was able to resist radiative heat and liquid chemical penetration, however, vapor transport performance was remarkable which is important for thermal comfort. The moisture permeability index encounters a hypothetical range of 0 to 1, whereby 0 is entirely impermeable and 1 is a completely permeable garment. The PAN-nonwoven displayed the lowest evaporative cooling index value, 0.557, while the PAN-aerogel fabric with 4.0% aerogel achieved the highest value (0.719) [36]. In another study, Kumar et al. developed silica aerogel integrated Nomex® based thermal liner for heat protection.

Figure 1:Wear comfort properties of viscose nonwoven coated with electrospun PAN-silica aerogel nanofiber membrane [36].

The linear density of the Nomex® fibers was 1.7dtex and during the experiment fiber diameter was reduced to nanoscale (~200nm) by electrospinning. The mass per unit area of the Nomex® and silica aerogel based nonwoven materials was reported as 150g/ m2. To reach the final composite structure, electrospun web coated on the nonwoven surface. Findings revealed that when samples were treated with aerogel, their heat retention ability increased [37]. Wang et al. [38] designed novel heat and metallurgical protective clothing. Polyacrylate coating was used efficiently to yield silica aerogel/potassium hexatitanate whisker composite fabric. Assessments indicated that when the quantity of aerogel particles expanded, the thermal insulation characteristic of the coated textiles initially enhanced and eventually fell. A 3:7 mass ratio of silica aerogel particles to potassium hexatitanate whisker resulted in an optimal thermal insulation feature, with a thermal conductivity of 0.232W/m.K for the composite coated fabric. Furthermore, the coated specimen was exposed to 250g molten splash of aluminum and there was no adhesion or serious damage observed [38].

Silica aerogel blankets

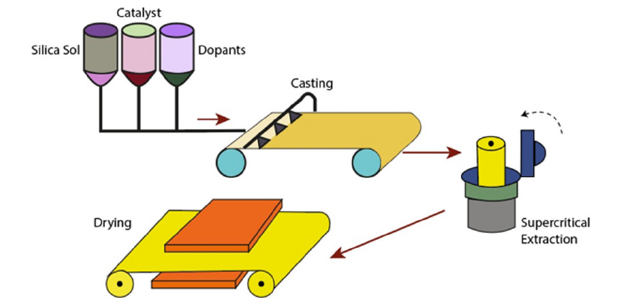

Typically, silica aerogel synthesis consists of three stages: gel preparation, ageing, and drying. The manufacturing cycle is not perpetual. Firstly, the initial components, such as alkoxysilanes, are combined with water in a solvent. Following alkoxysilane hydrolysis, a catalyst is introduced to initiate the condensation reaction, which produces a connected silica matrix in the state of a wet gel. The gel is subsequently aged to make the silica lattice network stronger, and hydrophobicity-enhancing chemicals are employed throughout the ageing phase. The last task is to dry the ‘wet gel’ by attentively eliminating the liquid phase, leaving solely the silica assembly intact and preventing collapse. Nowadays, research about developing an alternative cheaper production of silica aerogel continues [39,40].

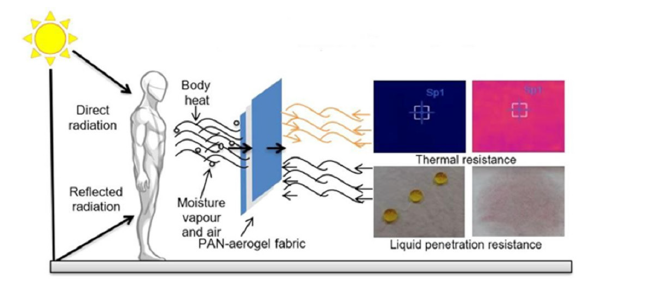

CO2 is utilized by Aspen Aerogel, Inc. to dry gels under supercritical pressure and temperature. This technique produces a dry, hydrophobic, nanoporous solid body with a density of roughly 0.1g/cc yet an architecture which is too fragile to be employed in monolithic format in clothing applications. To yield a material with excellent endurance, the aerogel is infiltrated into fibrous substance, often non-woven textile blankets, leading to a versatile, drapeable aerogel composite (Figure 2). Aspen Systems invented this ‘aerogel blanket’ in 1999, which is used as insulating material in aerospace and various industrial fields [5].

Figure 2:Schematic illustration of aerogel blanket production.

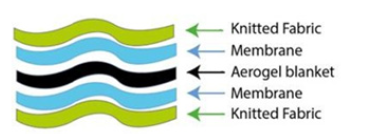

To investigate the potential benefits of laminated aerogel blankets for textile applications, a silica aerogel blanket Spaceloft® 3251 (Aspen Aerogel, USA) was inserted in a polyester microfiber nonwoven. The silica aerogel blankets created dust when handled due to the fragile silica aerogel fragmented. The resulting small particles are highly oleophilic and produce discomfort when in touching the skin of individuals. As a result, whenever aerogel blankets are fashioned into clothes, they need to be guarded from dust invasion. Consequently, the silica aerogel blanket was overlaid with an already prepared laminate of monolithic breathable membrane Platilon® M2234 produced from polyether block amide and a lightweight warp-knitted garment constructed from polyester filament yarns. A hotmelt gravure method with reactive polyurethane dot bonding was used to laminate a silica aerogel blanket on manufacturing machinery at Zvezda SPT Kranj (Slovenia). The aerogel blanket was laminated on its two faces (Figure 3), resulting in a five-layered composite [41].

Figure 3:Multilayered silica aerogel blanket: knitted fabric layer (upper), membrane layers, aerogel blanket with laminated membranes on both sides.

There are recent interesting research studies in the literature regarding designing novel textile-based silica aerogel blankets. Chakraborty et al. [42] synthesized the silica aerogel inside the porous meta-aramid fibrous batting. The wet gel surface was altered through chemical reactions (silylation) with different doses of trimethylchlorosilane in hexane. The fiber- reinforced silica aerogel blanket was then created via atmospheric pressure drying. A three-layer design was created utilizing a composition of woven textile (Nomex 93%, Kevlar 5%, and 2% antistatic fibre) as the outermost part, an aerogel blanket as the middle component, and a modacrylic/cotton fabric (60/40%) as the inner layer to test radiant heat shielding. Authors reported that the hydrophobicity of the aerogel blankets have been improved with an incremental amount of trimethylchlorosilane (silylating agent) in the composition. Furthermore, the bulk density as well as the thermal conductivity of the aerogel blankets declined noticeably with the increase in silylation treatment [42]. Prevolnik et al. [41] investigated the potential usage of laminated silica aerogel blankets in the field of apparel and technical textiles. In the experiments, a breathable membrane (Platilon® M2234) which is based on polyether block amide and warp knitted polyester filaments were used to complete the lamination process of silica aerogel blanket. The thermal conductivity of laminated aerogel blanket was measured as 0.0474W/mK which is twice higher than the silica aerogel blanket itself [41]. Sharma et al. [43] explored the properties of non-supercritical dried silica aerogel-based glass blankets. Assessments revealed that the amount of silica in the aerogel material apparently affected the integration between aerogel and fibers in the blanket. The thermal conductivity of theyielded aerogel blanket was recorded as 0.021W/mK. Also, fireproofing properties of the produced blankets were appropriate with the standard of ISO2685 [43]. Xue et al. [44] proposed a new method for designing thermal insulation clothing constitute of SiO2, polyimide and aramid fibers aerogel composite fabric. Results presented that the prepared aerogel fabric could efficiently hinder heat transfer where the thermal conductivity of was measured as 3.91 (W/cm⋅ °C) × 10-4 [44].

Conclusion

Silica aerogels stand out as exceptional materials due to their unique combination of extremely low density, high porosity, and superior thermal insulation properties. Initially developed in the early 20th century, they have since evolved into a versatile material with promising applications, particularly in textiles and protective clothing. The sol-gel process remains central to their synthesis, with advancements in drying techniques, such as supercritical drying, ensuring the preservation of their distinctive structural characteristics.

Recent innovations have expanded the utility of silica aerogels beyond monolithic forms to include fibers and coated fabrics. Incorporating aerogels into synthetic filaments has enhanced mechanical strength while maintaining thermal insulation efficiency, making them suitable for various textile applications. Coating fabrics with aerogels offers a lightweight solution for high-performance insulation in apparel, overcoming traditional limitations of bulkiness and weight associated with conventional materials.

The development of aerogel blankets further exemplifies their potential in providing high-performance insulation for industrial and aerospace applications. Advances in manufacturing techniques, such as lamination and fiber integration, have improved the durability and practical use of these blankets. Ongoing research continues to explore new methods and materials to enhance the functionality and cost-effectiveness of aerogels, aiming to address challenges related to scalability and longevity.

In summary, silica aerogels represent a significant advancement in materials science, offering exceptional thermal insulation and versatility for a range of applications. Continued innovation in their production and integration into various substrates will likely expand their use in both everyday products and specialized fields, further showcasing their potential as a transformative material in the textile and insulation industries.

References

- Lee KH, Arshad Z, Dahshan A, Alshareef M, Alsulami Q A, et al. (2023) Porous aerogel structures as promising materials for photocatalysis, thermal insulation textiles, and technical applications: A review. Catalysts 13(9): 1498.

- Hrubesh LW (1998) Aerogel applications. Journal of Non-Crystalline Solids 225: 335- 342.

- Schmidt M, Schwertfeger F (1998) Applications for silica aerogel products. Journal of Non-Crystalline Solids 225: 364-368.

- Beckingham G (2001) Aerogels: Their history, structure, and applications.

- Venkataraman M, Mishra R, Kotresh TM, Militky J, Jamshaid H (2016) Aerogels for thermal insulation in high-performance textiles. Textile Progress 48(2): 55-118.

- Manzur ME, Cataldo PG, Iramain MA, Castillo MV, Brandán SA (2023) Theoretical investigation on monomer and dimers of inhibitor of cytochrome p450 enzymes: 1- Aminobenzotriazole. European Journal of Theoretical and Applied Sciences 1(3): 456- 484.

- Yang H, Wang Z, Liu Z, Cheng H, Li C (2019) Continuous, strong, porous silk firoin- based aerogel fibers toward textile thermal insulation. Polymers 11(11): 1899.

- Wang JM (2018) Preparation and properties of SiO2 aerogel and fabric composite based on polyurethane. Integrated Ferroelectrics 189(1): 36-43.

- Lin L, Li Z, Mao H, Li W, Wang C (2021) Optically active polyurethane/silica aerogel coated cotton fabrics for thermal protection. Frontiers in Materials 8: 681678.

- Loy DA, Russick EM, Yamanaka SA, Baugher BM, Shea KJ (1997) Direct formation of aerogels by sol-gel polymerizations of alkoxysilanes in supercritical carbon dioxide. Chemistry of Materials 9(11): 2264- 2268.

- Sui R, Rizkalla AS, Charpentier PA (2004) Synthesis and formation of silica aerogel particles by a novel sol-gel route in supercritical carbon dioxide. Journal of Physical Chemistry B 108(32): 11886-11892.

- Gao B, Lu S, Kalulu M, Oderinde O, Ren L (2017) Synthesis of silica aerogel monoliths with controlled specific surface areas and pore sizes. Materials Research Express 4(7): 075020.

- Lei Y, Chen X, Song H, Hu Z, Cao B (2017) The influence of thermal treatment on the microstructure and thermal insulation performance of silica aerogels. Journal of Non- Crystalline Solids 470: 178-183.

- Lei Y, Chen X, Song H, Hu Z, Cao B (2017) Improvement of thermal insulation performance of silica aerogels by Al2O3 powders doping. Ceramics International 43(14): 10799-10804.

- Lei Y, Chen X, Song H, Hu Z, Cao B (2017) A general strategy for improving the thermal insulation performance of aerogels by multiple impregnation. Scripta Materialia 139: 5-8.

- Bangi U-P K-H (2010) Preparation and characterization of hydrophobic aerogels using inorganic precursor by ambient pressure drying. PhD Thesis, Department of Physic, Shivaji University, Kolhapur, India.

- Teresa L, Pessoa de Amorim MT, Durães L (2019) Silica aerogel composites with embedded fibres: a review on their preparation, properties and applications. Journal of Materials Chemistry A 7: 22768-22802.

- Tafreshi OA, Mosanenzadeh SG, Karamikamkar S, Saadatnia Z, Park CB, et al. (2022) A review on multifunctional aerogel fibers: processing, fabrication, functionalization, and applications. Materials Today Chemistry 23: 100736.

- Xu Z, Zhang Y, Li P, Gao C (2012) Strong, conductive, lightweight, neat graphene aerogel fibers with aligned pores. ACS Nano 6(8): 7103-7113.

- Karadagli I, Schulz B, Schestakow M, Milow B, Gries T, et al. (2015) Production of porous cellulose aerogel fibers by an extrusion process. Journal of Supercritical Fluids 106: 105-114.

- Pico D, Meyer E, Luking A, Milow B, Gries T (2017) SILICA-AERO. Production of lightweight silica aerogel fibers for excellent heat insulating application. Chemical Engineering Transactions 60: 91-96.

- Li G, Hong G, Dong D, Song W, Zhang X (2018) Multiresponsive graphene-aerogel- directed phase-change smart fibers. Advanced Materials 30(30): e1801754.

- Meng S, Zhang J, Chen W, Wang X, Zhu M (2019) Construction of continuous hollow silica aerogel fibers with hierarchical pores and excellent adsorption performance. Microporous and Mesoporous Materials 273: 294-296.

- Du Y, Zhang X, Wang J, Liu Z, Zhang K, et al. (2020) Reaction-spun transparent silica aerogel fibers. ACS Nano 14(9): 11919-11928.

- Liu Z, Lyu J, Fang D, Zhang X (2019) Nanofibrous kevlar aerogel threads for thermal insulation in harsh environments. ACS Nano 13(5): 5703-5711.

- Sedighi S, Khoddami A, Izadan H, Alsharif MA, Naeimirad M (2022) The influence of silica aerogels on physical, mechanical, and morphological properties of melt-spun POY and DTY polyester yarns. Polymer Testing 112: 107628.

- Song Q, Miao C, Sai H, Gu J, Wang M, et al. (2022) Silica- bacterial cellulose composite aerogel fibers with excellent mechanical properties from sodium silicate precursor. Gels 8(1): 17.

- Jinde PD, Gudiyawar MY (2024) Synthesis, characterization, and thermal behavior of silica aerogel-embedded PVDF-HFP nanofibers. Journal of Materials Research 39: 1396-1410.

- Sun H, Mu W, Cui X, Xu Z, Zhang T, Zhao Y (2023) Polymer-encapsulated aerogel fibers prepared via coaxial wet spinning with stepwise coagulation for thermal insulation. ACS Applied Polymer Materials 5(1): 552-559.

- Attia YA (2015) Polymeric aerogel fibers and fiber webs, US Patent (9540495B2).

- Wu M, Shao Z, Zhao N, Zhang R, Yuan G, et al. (2023) Biomimetic, knittable aerogel fiber for thermal insulation textile. Science 382(6677): 1379-1383.

- https://kohantextilejournal.com/aerogel-fiber/

- Sun Y, Wang R, Li B, Fan W (2019) The design and manufacture of a multilayer low-temperature protective composite fabric based on active heating materials and passive insulating materials. Polymers 11(10):1616.

- Islam SR, Yu W, Naveed T (2019) Influence of silica aerogels on fabric structural feature for thermal isolation properties of weft-knitted spacer fabrics. Journal of Engineered Fibers and Fabrics 14.

- Yan J, Choi HY, Hong YK, Jeong YG (2018) Thermal insulation performance of cotton and PET-based hybrid fabrics impregnated with Silica Aerogel via a facile Dip-Dry process. Fibers and Polymers 19: 854-860.

- Bhuiyan MAR, Wang L, Shanks RA, Ara ZA, Saha T (2020) Electrospun polyacrylonitrile-silica aerogel coating on viscose nonwoven fabric for versatile protection and thermal comfort. Cellulose 27: 10501-10517.

- Kumar S, Rathour R, Das A, Alagirusamy R (2024) Development of thermal liner for extreme heat protective clothing using aerogel technology. Journal of the Textile Institute 115(5): 803-812.

- Wang J, Wang M, Zhan L, Wang N (2023) Silica aerogel/potassium hexatitanate whisker composite coated fabric for metallurgical protective clothing. Fibers and Polymers 24: 243-252.

- Wang J, Zhang Y, Wei Y, Zhang X (2015) Fast and one-pot synthesis of silica aerogels via a quasi-solvent-exchange-free ambient pressure drying process. Microporous and Mesoporous Materials 218: 192-198.

- Dong W, Sakamoto JS, Dunn B (2003) Electrochemical properties of vanadium oxide aerogels. Science and Technology of Advanced Materials 4(1): 3-11.

- Prevolnik V, Zrim PK, Rijavec T (2014) Textile technological properties of laminated silica aerogel blanket. Contemporary Materials 5(1): 117-123.

- Chakraborty S, Pisal AA, Kothari VK, Rao AV (2016) Synthesis and characterization of fibre reinforced silica aerogel blankets for thermal protection. Advances in Materials Science and Engineering 2017(1).

- Sharma J, Shukla S, Singh O, Sheikh J, Behera BK (2023) Multi-field and multi-scale characterization of non-supercritical dried silica aerogel-based glass blankets: investigating thermal, mechanical, acoustic, and fire performance. Journal of Sol-Gel Science and Technology108(1): 60-72.

- Xue R, Liu G, Liu F (2023) A simple and efficient method for the preparation of SiO2/PI/AF aerogel composite fabrics and their thermal insulation performance. Ceramics International 49(1): 210-215.

© 2024 Ramazan Erdem. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)