- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Electrospinning of Bacterial Cellulose Fibres: Challenges for an Innovative Bioengineered Fibre Production Technique

Subhadeep Paul*, Rashi Gusain, Yunhong Jiang, Paul James and Meng Zhang

Living Construction Group, The Hub for Biotechnology in the Built Environment (HBBE),Applied Sciences Department, Northumbria University, England

*Corresponding author:Subhadeep Paul, Senior Research Assistant, Living Construction Group, The Hub for Biotechnology in the Built Environment (HBBE), Applied Sciences Department, Northumbria University, NE1 8ST, England

Submission: May 27, 2024; Published: June 07, 2024

ISSN 2578-0271 Volume10 Issue1

Abstract

In the last few years, the investigation and findings of alternative and biobased raw material sources has been a focal point of research with respect to reduced impact on the environment. Bacterial cellulose (BC), a biopolymer generated by biosynthesis process, is known for its purity, crystallinity and mechanical properties. Electrospinning of BC has shown potential in various biomedical, packaging and electronic textile-based applications. Ionic liquids (ILs) due to their low vapour pressure and high recyclability have been used in electrospinning of various biopolymers. However, there are few comprehensive studies that investigate the contribution of ILs to electrospinning of BC fibres. This review discusses the potential of using ILs to dissolve BC and its possible effects on the fibre structure, morphology and distribution. It also summarizes the research gaps and challenges available for electrospinning of BC with ILs. Understanding of material properties of BC, the structure of ILs and structure of electro spun fibres is crucial for developing an efficient, eco-friendly and sustainable fibre production process.

Keywords:Tea plant leaves; Bacterial cellulose; Electrospinning; Fibres; Ionic liquids

Abbreviations:Tea plant leaves; DMF: Dimthylformamide; DMSO: Dimethylsulphoxide; DMAc: Dimethylacetamide; LiCl: Lithium Chloride; NMMO N: Methylmorpholine N-oxide; N2O4: Dinitrogen Tetroxide; TFA: Tetrafluoroacetic Acid; BC: Bacterial Cellulose; ILs: Ionic Liquids

Introduction

Over the last decade emphasis has been provided on generating alternative raw material from biobased sources considering the aspects of circularity and upcycling in fibres and polymers sector [1]. Researchers have indulged in investigation and optimization of generation of biopolymer-based products derived from biological sources, waste materials and microbial fermentation [2]. The electrospinning technique for generation of nanofibrous materials is considered highly effective for spinning fibres from biobased renewable sources like cellulose, chitosan, polylactic acid (PLA), alginate etc. [3,4]. Electrospinning technology is known for minimal waste generation, recyclability of solvents and relatively low energy consumption (compared to other fibre production techniques) [5]. This method can be tailored to specific sustainability requirements, making it crucial for developing bioengineered fibres that contribute to a cradle-to-cradle approach in supply chain management within a circular economy. Cellulose is the most naturally abundant organic polymer on earth and primarily obtained from sources like wood and plants and more recently from bacteria and algae. Cellulose due to its availability, hydrophilicity, biocompatibility, biodegradability and desirable mechanical properties is considered as the major source for polymers for environmentally friendly applications [6]. Traditional plant cellulose is a semi-crystalline material where the degree of crystallinity ranges from 40-60% depending on the type of source, method of extraction and pretreatment [7]. BC synthesized from bacteria is a biosynthesis process, where the cellulose chains are produced and extruded by individual cells via enzyme complex. The environment for generation of BC often involves high moisture content and reduced stress condition therefore leads to a highly crystalline structure (80-100%) [8].

BC can be produced by a wide range of bacterial species including Acetobacter, Pseudomonas, Aerobacter and Azobacter etc. [9]. Unlike plant cellulose, which is in the form of Cellulose I (parallel chain arrangements), BC consists of the more stable Cellulose II form (anti parallel chain arrangements) [10], which leads to higher chemical purity, degree of polymerization, water retention and wet strength as compared to its counterpart from plants. BC has found extensive applications in biomedical fields specifically in therapy of wounds, burns and ulcers [11]. Additionally, it is used in tissue engineering, drug delivery systems, packaging, and sensors in the form of electrospun fibres, hydrogel, and biofilms [12]. Moreover, BC can be used for development of filament fibres, knitted structures and nonwoven fabrics which are beneficial for creating fabrics with high mechanical strength and water sorption properties [13].

Electrospinning of cellulose has been challenging due to the presence of strong inter and intra molecular hydrogen bonding within the structure which restricts its solubility in common volatile solvents. However, the advancement of potential ILs has facilitated the dissolution of cellulose. ILs offer advantages such as high thermal and chemical stability, low vapor pressure and recyclability. This article highlights the challenges involved in producing electrospun BC fibres, particularly focusing on the dissolution of BC in ILs, fibre structure, fibre morphology. It also addresses research gaps in the study of functionalized BC-based polymers for electrospinning. To enable the use of electrospun BC fibres in technical textile applications, further investigation into fibre optimization using ILs is required.

Dissolution of bacterial cellulose in ionic liquids

Cellulose in its original form is a linear homopolymer with high molecular weight, thus difficult to dissolve in common solvents. Further the inter and intra molecular interactions between the hydroxyl groups among the chains of polymer makes it more difficult to dissolve. Conventional solvents like sulphuric acid, carbon disulphide, sodium hydroxide was used to disrupt the interchain interactions and modify the structure of the cellulose for its dissolution (viscose fibre manufacturing) [14,15]. The environmental impact of such hazardous chemicals was high at the same time there was a significant decrease in degree of polymerisation of cellulose. To resolve this issue new solvent system like Dimethylacetamide (DMAc)/ Lithium Chloride (LiCl), N-Methylmorpholine N-oxide (NMMO), Trifluoroacetic acid (TFA), N,N-Dimethylformamide (DMF)/ (Dinitrogen tetraoxide) N2O4 etc. were used, and mostly they were associated with drawbacks like low dissolving capability, instability, lesser rate of solvent recovery and harsh processing conditions. This led to the use of ILs which are organic salts with melting temperature less than 100 °C and have added advantage in terms of high chemical stability, recyclability and structural tunability [14]. The initial research involving dissolution of cellulose in ILs was investigated thoroughly by Swatloski et al. [16] which showed that 1-butyl-3-methylimidazolium chloride (BmimCl) has solubility of 10wt% (at 100 °C) and 25wt% (microwave heating) [16]. After that intensive research has been conducted on dissolution of cellulose using imidazolium based ILs and the mechanism of dissolution is also well established where they are known to dissolve the long chain cellulose polymer at high viscosity assisted by temperature and concentration of the ILs. Now dissolution of BC in ILs can be challenging due to its highly ordered and crystalline structure. Thus, co-solvents like DMF, (Dimethyl sulfoxide) DMSO or DMAc are used for lowering the viscosity of the spinning solution. For electrospinning the selection of ILs and co-solvents requires consideration for factors such as conductivity, high volatility, minimal intermolecular interaction between the polymeric chain. However, systematic studies related to effects of concentration and temperature and co-solvent ratio on dissolution of BC are seldom reported in the literature. The dissolution of BC can also be affected by the process variables during synthesis of BC such as nutrient composition of growth media (glucose, fructose, peptone etc.), type of bacterial strain, culture conditions (agitation, pH and aeration).

Structure of bacterial cellulose electrospun fibre

Electrospun fibre from acetylated BC has already been obtained using solvent systems such as DMAc/LiCl, chloroform/acetone [17]. However, the involvement of ILs alongside other co-solvents and its further investigation on the fibre morphology, diameter distribution and fibre alignment are still scarce. This study requires thorough investigation of polymer flow rate, electrospinning voltage, collector and syringe distance (process parameter of electrospinning). BC also tends to form agglomeration during electrospinning which can lead to non-uniform fibre distribution and reduction in mechanical properties. Though BC is known for its mechanical properties but due to agglomeration during electrospinning process causes the lower mechanical properties of generated electrospun fibres. This could be affected by the processing conditions like temperature and RH% of spinning, interaction of co-solvent with ILs, structure of ILs, fibre alignment and distribution. There are few literatures which investigate the structure property understanding of BC electrospun fibres, these include optimization of the diameter distribution of the fibres. Electrospun nanofibres are associated with high surfaceto- volume ratio which enhances the application properties. Thus, for BC a better distribution and diameter range of the fibre can result in uniform fibre structure, high porosity and water sorption capabilities.

Structure of ionic liquids

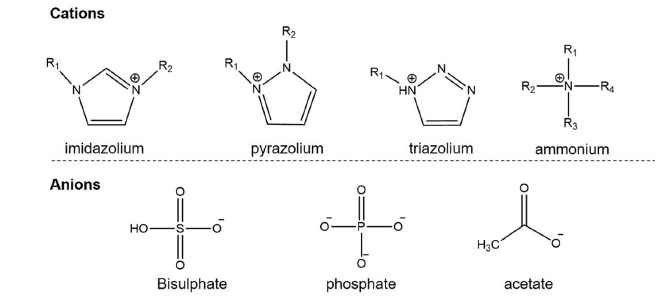

A significant amount of work has been done in dissolution of cellulose with ILs of varying cationic and anionic groups [18]. Dissolution of cellulose has been related to the concentration and functional groups of anions near the polymeric chain, whereas cations are meant to be small enough to enter between the polymeric chain and disrupt the hydrogen bond formation. The high mechanical characteristics of BC can be reduced during formation of the electrospun fibres as presence of co-solvents in ILs can decrease the molecular weight distribution or cause degradation of the polymer. Thus, BC has been used as composite fibre with other polymers or nanomaterials to improve its mechanical properties [19]. The effect of change in type of anion (such as phosphate, acetate, bisulphate (Figure 1)) and cation (such as pyrazolium, triazolium, ammonium (Figure 1)) could affect the solubility of BC at a lower concentration and temperature, potentially resulting in higher mechanical strength of the electrospun nanofibres. In addition, commercialized ILs used for dissolution of cellulose are mostly based on imidazole-based cations (Figure 1) and halogenbased anions, which results in high viscosity during dissolution of cellulose, thus selection of a completely new ionic liquid for dissolution of BC must be considered with respect to its solubility, toxicity, type of structure, biocompatibility, and cost effectiveness.

Figure 1:Structure of cations and anions for ILs.

Functionalisation of bacterial cellulose

BC can be functionalized using proteins within a single growth step during the microbial fermentation stage. BslA is a characterized hydrophobin which is known to form a hydrophobic layer on the Bacillus biofilm and is partitioned on the extracellular matrix of BC biofilm [20]. ILs can be tailored to dissolve the surface hydrophobic layer, but it will be interesting to investigate if the same ionic liquid will be able to dissolve the BC structure alongside. ILs which do not swell BC can also be used as a reaction media for functionalisation of BC [21]. Modification of the hydroxyl groups of cellulose can be associated with grafting of polymers, reaction with anhydrides and silicon-based chemistry to make the surface hydrophobic and such materials can be utilized in water repellent textiles, medical textiles, geotextiles etc. There are few studies which report the involvement of ILs for hydrophobisation of BC and further its dissolution to produce a functionalised BC electrospun fibre.

Conclusion

BC can be considered a futuristic biopolymer to produce sustainable and ecofriendly fibres. Biopolymers like chitosan, alginate, chitin, PLA, casein etc. can be incorporated into the structure of BC to produce electrospun composite fibres resulting in exceptional mechanical strength, specific functionalities (antibacterial, conductive, shape memory effect, piezo electricity) and biocompatibility. ILs due to its versatility of design and high solvation properties can be used as an efficient and ecofriendly solvent for the electrospinning of BC. The optimisation of the dissolution process does possess challenges in terms of rheology of the polymeric system and the effect of structure of ILs and selection of co-solvents expresses a promising area for researchers to investigate and correlate against the fibre morphology, cellulose structure, fibre orientation and distribution within the electrospun BC nanofibres. The involvement of BC and its functionalised fibres can lead towards designing the production of technical textiles using bioengineered fibres and reducing the environmental impact of textile supply chains.

Acknowledgement

The authors would like to thank Prof. Martyn Dade-Robertson, Dr. Katie Gilmour and Dr. Jane Scott for their valuable conversations. We would also like to thank the ‘Fibre Fusion: Circular Manufacturing of Water Repelling Bacterial Cellulose Through a Biological Approach’ project funded by BBSRC (BB/X011402/1).

References

- Ita-Nagy D, Vázquez-Rowe I, Kahhat R, Chinga-Carrasco G, Quispe I (2020) Reviewing environmental life cycle impacts of biobased polymers: current trends and methodological challenges. The International Journal of Life Cycle Assessment 25(11): 2169-2189.

- Salazar Sandoval S, Amenábar A, Toledo I, Silva N, Contreras P (2024) Advances in the sustainable development of biobased materials using plant and animal waste as raw materials: A review. Sustainability 16(3): 1-37.

- Kriegel C, Arecchi A, Kit K, McClements DJ, Weiss J (2008) Fabrication, functionalization, and application of electrospun biopolymer nanofibers. Critical Reviews in Food Science and Nutrition 48(8): 775-797.

- Gómez-Pachón EY, Vera-Graziano R, Campos RM (2014) Structure of poly(lactic-acid) PLA nanofibers scaffolds prepared by electrospinning. IOP Conference Series: Materials Science and Engineering 59(1): 012003.

- Bhardwaj N, Kundu SC (2010) Electrospinning: A fascinating fiber fabrication technique. Biotechnology Advances 28(3): 325-347.

- Manoukian OS (2019) Biomaterials for tissue engineering and regenerative medicine. In: Narayan R (Ed.), Encyclopedia of Biomedical Engineering, Elsevier, Oxford, England, pp. 462-482.

- Avolio R, Bonadies I, Capitani D, Errico ME, Gentile G, et al. (2012) A multitechnique approach to assess the effect of ball milling on cellulose. Carbohydrate Polymers 87(1): 265-273.

- Müller A, Zink M, Hessler N, Wesarg F, Muller FA, et al. (2014) Bacterial nanocellulose with a shape-memory effect as potential drug delivery system. RSC Advances 4(100): 57173-57184.

- Shahruzzaman M, Hossain S, Ahmed T, Kabir SF, Islam M, et al. (2022) Biological macromolecules as antimicrobial agents. In: Nayak AK, Dhara AK, Pal D (Eds.), Biological Macromolecules, pp. 165-202.

- Okiyama A, Motoki M, Yamanaka S (1992) Bacterial cellulose II. Processing of the gelatinous cellulose for food materials. Food Hydrocolloids 6(5): 479-487.

- Ahmed J, Gultekinoglu M, Edirisinghe M (2020) Bacterial cellulose micro-nano fibres for wound healing applications. Biotechnology Advances 41: 107549.

- Lv P, Zhou H, Mensah A, Feng Q, Wang D, et al. (2018) A highly flexible self-powered biosensor for glucose detection by epitaxial deposition of gold nanoparticles on conductive bacterial cellulose. Chemical Engineering Journal 351: 177-188.

- Morrow R, Ribul M, Eastmond H, Lanot A, Baurley S (2023) Bio-producing bacterial cellulose filaments through co-designing with biological characteristics. Materials 16(14): 4893.

- Zhang J, Wu J, Yu J, Zhang X, He J, et al. (2017) Application of ionic liquids for dissolving cellulose and fabricating cellulose-based materials: state of the art and future trends. Materials Chemistry Frontiers 1(7): 1273-1290.

- Sayyed AJ, Deshmukh NA, Pinjari DV (2019) A critical review of manufacturing processes used in regenerated cellulosic fibres: viscose, cellulose acetate, cuprammonium, LiCl/DMAc, ionic liquids, and NMMO based lyocell. Cellulose 26(5): 2913-2940.

- Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellose with Ionic Liquids. Journal of the American Chemical Society 124(18): 4974-4975.

- Maria Manzine Costa L, Molina de Olyveira G, Basmaji P, Filho LX (2012) Nanopores structure in electrospun bacterial cellulose. Journal of Biomaterials and Nanobiotechnology 03(01): 92-96.

- Isik M, Sardon H, Mecerreyes D (2014) Ionic liquids and cellulose: dissolution, chemical modification and preparation of new cellulosic materials. Int J Mol Sci 15(7): 11922-11940.

- Naeem MA, Lv P, Zhou H, Naveed T, Wei Q (2018) A novel in situ self-assembling fabrication method for bacterial cellulose-electrospun nanofiber hybrid structures. Polymers 10(7): 712.

- Gilmour KA, Aljannat M, Markwell C, James P, Scott J, et al. (2023) Biofilm inspired fabrication of functional bacterial cellulose through ex-situ and in-situ Carbohydr Polym 304: 120482.

- Tomé LC, Freire MG, Rebelo LPN, Silvestre AJD, Neto CP, et al. (2011) Surface hydrophobization of bacterial and vegetable cellulose fibers using ionic liquids as solvent media and catalysts. Green Chemistry 13(9): 2464-2470.

© 2024 Subhadeep Paul. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)