- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Optimal Configuration for Jute- Polyester Plain-Weaved Coated Fabric to be Used in Tensile Architecture in Bangladesh

Ar Golam Morsalin Choudhury Rana1* and Dr Khandakar Shabbir Ahmed2

1Doctoral Student, Department of Architecture, Bangladesh University of Engineering & Technology (BUET), Dhaka, Bangladesh

2Professor, Department of Architecture, Bangladesh University of Engineering & Technology (BUET), Dhaka, Bangladesh

*Corresponding author:Ar Golam Morsalin Choudhury Rana, Doctoral Student, Department of Architecture, Bangladesh University of Engineering & Technology (BUET), Dhaka, Bangladesh

Submission: February 06, 2024; Published: February 27, 2024

ISSN 2578-0271 Volume9 Issue4

Abstract

This paper explores the optimal tensile strength for various combination of Jute-Polyester plain-weaved coated fabric to be used tensile membrane architecture in hot-humid climate of Bangladesh. Jute is very beneficial to the environment. Jute has a high tensile strength, is harmless, and biodegradable. Using products based on jute is environmentally friendly, sustainable, and lowers carbon emissions. Since ancient times, jute has been used to make twine, ropes, and bags; Bangladesh is the natural home of the best jute. The world’s top exporter of jute is Bangladesh. Jute is used to make a wide range of items. Engineered textiles, such as Jute Geo Textiles (JGT) derived from Jute, find use in filtration, riverbank erosion management, and road building. In this study Jute yarn is weaved with different pattern and quantity of polyester and cotton yarn to achieve optimum tensile strength and then coated with PVC to make it durable and increase its strength. The Jute fabric yarn was collected from Bangladesh Jute Research Institute (BJRI), weaved with Polyester and Cotton in Bangladesh University of Textiles (BUTEX) lab and tested in Bangladesh University of Engineering & Technology (BUET) lab facilities. A simulation software ixcube Forten was used for simulation. It is found that 2Jute-1Polyester fabric has optimum has optimum tensile strength to be used as Tensile Membrane.

Keywords:Jute; Jute fabric; Tensile membrane structures; Lightweight structures; Environment friendly material

Introduction

Natural fibers like jute have several benefits for the environment. It is a renewable resource with a high biomass production per unit land area. Additionally, products made of jute are biodegradable, meaning that at the end of their life cycle, they break down in the soil. Although synthetic materials are thought to be the cause of numerous issues, natural fiber products have been shown to be completely safe. Bangladesh is the natural home of the best quality Jute in the world. Jute is positioned second after Cotton in terms of production, consumption, and availability worldwide [1]. Study shows that chemical treatment of jute fabric increases its longevity [2]. Jute geo textiles are used for soil erosion protection [3]. Specially treated Jute geo textile has higher durability [4]. Therefore, Jute has the opportunity to be used as a technical textile in the field of Tensile Architecture, but its strength upgradation through fiber mixing and coating are necessary for better sustainability and longevity.

Tensile Architecture is a lightweight structure system with a membrane or fabric held in tension. It can be a permanent, semi-permanent or temporary structure. Tensile architecture is evolved from the concept of Nomadic Tent, which was used for centuries by Arab Bedouins, Mongols. “The Shamiana” tents are introduced in the Indian subcontinent by the Mughals [5]. Tensile Architecture has many uses, from large span structures like airports and stadiums to small structures like shade shelters. The construction fabric market is currently worth 1.47 billion USD and is expected to grow to 2.26 billion USD by 2023 [6].

The global drive for bio-based and sustainable developments guided by Kyoto protocols on greenhouse gas reduction and CO2 neutral production provides a higher perspective on the natural fiber market [7]. As there are fewer alternatives to synthetic fabric, jute fabric can be a good material for Tensile Architecture in hothumid Bangladesh due to its strength, eco-friendliness, availability, and affordability. But jute fabric needs to be improved strength and environmental performance to increase its durability. The combination of Jute fabric, polyester and cotton with coating has been studied for better understanding their performances under tension load.

Objective

This paper investigates the potential strength upgradation of Jute-Polyester woven fabric to be used as an alternative biomaterial in Tensile Architecture in hot-humid climate of Bangladesh. It will enhance the applicability of Jute fabric and lead the way to a sustainable and green future uses as a membrane material.

Methodology

This study is mainly focused on constructing a jute fabric made of through the combination of jute, cotton, and polyester yarn. Based on the literature survey, a target fabric weight is set for construction. Jute reinforced membrane samples were made by combining different amounts of jute, cotton, and polyester yarn. These Test samples are applied surface coating to increase fabric cohesion and bonding. The lab tests are done at BUET and BJRI where following tests are performed the strength of the samples for weight, elongation, and tensile strength for comparative study.

Literature Review

Bangladesh is the natural home of the best quality Jute in the world and it is one the major exporter of raw Jute in the world [8]. Jute is now being used in diversified fields such as technical textiles for civil engineering, automotive application, electrical and leather industries, medical, environmental protection, etc. Jute textiles are now used for making automotive parts, medical textiles for implants, Agro textiles for crop protection and protective clothing for heat and radiation protection for firefighters and metal welders.

Jute fabric and polymer-based Natural Fiber Composite (NFC) corrugated sheet termed as ‘Jutin’ has been invented by Bangladesh Atomic Energy Commission (BAEC) led by Dr. Mubarak Ahmad Khan in 2010. Jute based packaging bag “Sonali bag” has recently been developed by Dr. Mubarak Ahmad Khan and his team in 2018 [9], which is comparable to the common polybag, but it is biodegradable and friendly to the environment. Jute-cotton or other synthetic fiber blended yarn is well studied. Sulphonated Jute-Cotton blended yarn and fabric have almost equivalent properties of 100% Cotton fabric [10]. Jute-Polyester blend is studied by [11] and Jute-Acrylic blend is studied by [12].

Synthetic fabric or technical textiles are used in Tensile Architecture. The most used technical textiles in Tensile Architecture are PVC (Polyvinyl chloride) coated PES (Polyester) or PVDF (polyvinylidene bifluoride) coated PES material, etc. [13]. Unfortunately, these materials are not biodegradable and can increase environmental pollution [14]. So, there is a potential need for natural fabric in this field and jute fabric can fill that role.

Jute and its properties

There are two Jute types of trade: white (Chorchorus capsularis) and Tossa (Chorchorus olitorius). Tossa Jute is softer, silkier, and stronger than white Jute. It is also known as Paat in Bangladesh. Jute fiber is collected from the best or skin of the Jute plant. That’s why Jute fiber falls into the bast fiber category. Jute plants grow in hot humid rainy alluvial lands. Jute plants are photo reactive; they harvest within 120 days. It grows up to six to ten feet high. Matured Jute plants are cut, tied in a bundle, and put into slow flowing water for several weeks for fermentation. Jute fibers are pulled off from the bark, washed carefully and dried in the sun (Figure 1).

Figure 1:Preparation of Jute fibre from jute bark.

Jute is a cellulose-based material. It is stiff and yellowish

because of hemicellulose and lignin. Each Jute fiber is composed of

smaller units known as fibrils. They are arranged in right-handed

spirals and make closely held molecular chains which are known

as micells.

The chemical composition of jute is as follows-

Alpha Cellulose 58-63%

Hemicellulose 21-24%

Lignin 12-14%

Pectin 0.2-0.5%

Fat & Wax 0.8-1.5%

Mineral Materials 0.6-1.1% [14]

Tensile membrane

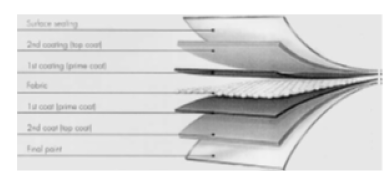

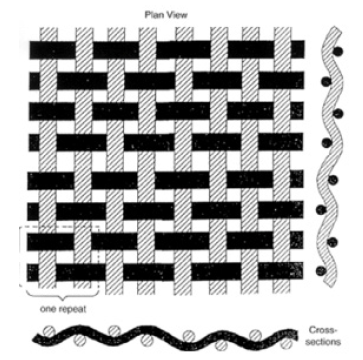

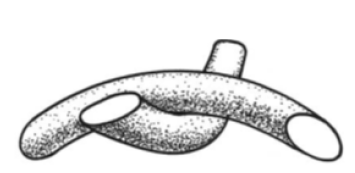

Tensile membrane structures use lightweight fabric or membrane that is loaded only in tension and supported by a primary structure. Tensile membrane structures are lightweight, flexible and more stable than conventional structures. The membrane material used in Tensile Architecture is regarded as construction fabric or technical textiles. Based on material strength five different types of fabric are proposed by Messe Frankfurt [15], where type I fabric has tensile strength of 60kN/m in warp and weft. And type II fabric has tensile strength of 88kN/m. Most commonly used materials are PVC coated Polyester fabric. The PVC compound is added to the fabric directly via floating knife method where a fabric is stretched flat and PVC compound is then even spread over fabric via a knife [16] (Figures 2-4).

Figure 2:Coated Tensile Membrane layers.

Figure 3:Plain weave composition of a tensile membrane fabric.

Figure 4:Yarn overlapping in a plain weave.

Fabric Composition

The proposed Jute membrane aims to achieve Type I membrane

as proposed by the Messe Frankfurt.

Proposed Tensile Membrane Fabric Construction 01

Jute yarn (2 ply) as warp, Yarn Count = 13lb/spydle (Ne

1.32Nec) Available at BJRI

Polyester filament as weft = 600 denier (66.66tex = 8.85Nec)

Warp/inch= 30, Weft/inch=40

Warp (Jute) weigh in gm/m2 = (30×39.37×1.0936×453.6)/

(840×1.32) =528.40gm

Weft (Polyester) weigh in gm/m2 = (40×39.37×1.0936×453.6)/

(840×8.85) =105.08gm

Total Fabric weight (calculated) = (528.40+105.08) = 633.48

gm/m2

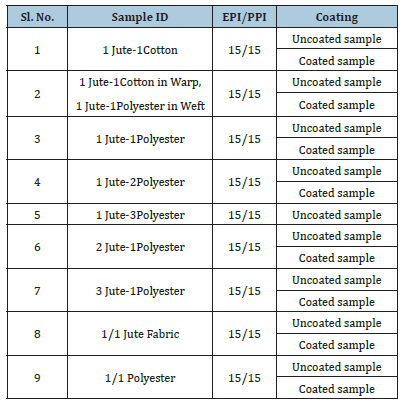

Sample preparation

For testing purposes, seven samples of various compositions have been developed in BUTEX CCI Lab using 13lb/spindle Jute yarn, 600denier Polyester yarn, and Ne 3 Cotton yarn. Sample description given below in the following table (Table 1).

Table 1:Jute/Polyester/Cotton weaved samples.

Sample testing

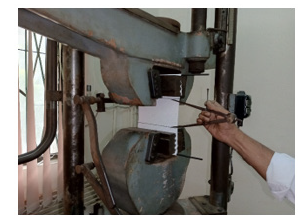

Sample weight, tensile strength, thickness, and elongation are tested in Geotech Lab of Dept. of Civil Engineering, Bangladesh University of Engineering & Technology. Strip tensile strength was done according to ASTM D4595. Coated fabric was done in old Dhaka coating factory through direct application method (Figures 5-8).

Figure 5:Uncoated Jute-Polyester fabric samples.

Figure 6:Sample preparation for testing.

Figure 7:Coated Jute-Polyester fabric on left and coated jute fabric on right.

Figure 8:Strip tensile strength testing at Geotech lab, BUET.

Test Result and Discussion

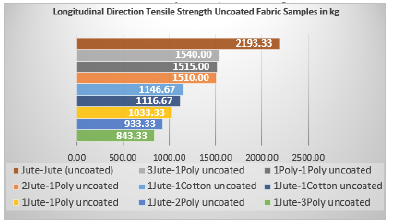

From the strength test we can see that uncoated jute-jute fabric has the highest strength due to its thicker jute yarn which breaks under heavy load early due to its less strain, compared to the polyester yarn (Table 2). However, 1/1 Polyester, 3jute-1Poly, 2Jute-1Poly fabric exhibited similar tensile strength due to their similar fabric weight.

Table 2:Uncoated fabric strip tensile strength.

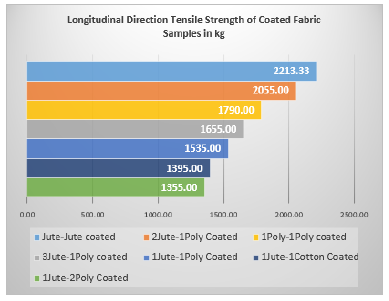

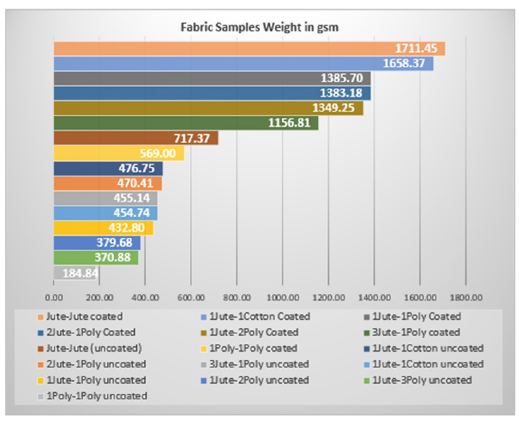

PVC surface coating helps in tensile strength increment. As we can see that there is significant increase of tensile strength in longitudinal or warp direction. However, in case of Jute-Polyester samples, the tensile strength of 2Jute-1Polyester has increased the most (Table 3), it is around 36% increase from 1510kg/m to 2055kg/m. the strength of jute-jute coated fabric has slightly increased from 2193kg/m to 2213.33kg/m though it is the highest strength among other samples. Which indicate that PVC coating has less impact on jute yarn’s strength, compared to polyester yarn. However, the highest tensile strength is gained by 1/1 coated Polyester sample which is around 73% (Table 4). The coated Jute- Cotton combination fabrics have less tensile strength gain than other samples.

Table 3:Coated fabric strip tensile strength.

Table 4:Coated fabric strip tensile strength.

The PVC coating has added extra weight to fabric samples. Jute-jute coated fabric is the heaviest of all, followed by jute-cotton fabric and other samples. If we adjust the gsm of Jute-jute fabric to match with jute-polyester fabrics which is around 1373gsm then we find that jute-jute fabric strength is lower than 2jute-1poly coated fabric.

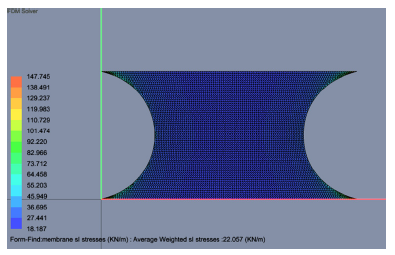

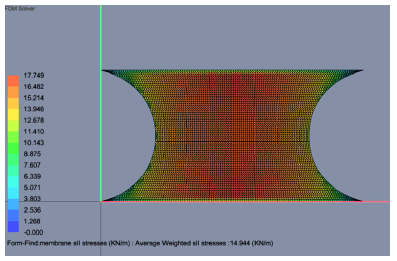

Surface stress simulation

The membrane surface stress simulation was done via ixcube forten tensile membrane software to observe the surface stress of 2Jute-1polyester fabric. It is found that sI stress is about 22.067kN/m (Figure 9) and sII stress is 14.944kN/m (Figure 10) which is ok to withstand seasonal storms in Dhaka [17].

Figure 9:sI stress simulation of 2Jute-1polyester fabric using ixcube forten software.

Figure 10:sI stress simulation of 2Jute-1polyester fabric using ixcube forten software.

Conclusion

Coating enhances the tensile strength of jute fabric, particularly in Jute-Polyester composite fabric. 2Jute-1polyester fabric has better tensile strength among the samples studied. So coated 2Jute-polyester weaved fabric can be used as tensile membrane in small to medium sized projects. As climate of Bangladesh is hot humid coated jute-polyester fabric will improve its longevity and sustainability. Therefore, jute- polyester weaved coated fabric can be used as a tensile membrane project in hot humid climate like Bangladesh. This research has paved the way for future development of jute-based biomaterial for lightweight, costeffective tensile architecture.

References

- Jahan A (2019) The environmental and economic prospects of jute with a connection to social factors for achieving Sustainable Development. Master thesis in Sustainable Development, Department of Earth Sciences, Uppsala University, Sweden.

- Ghosh SK, Ray Gupta K, Bhattacharyya R, Sahu RB, Mandol S (2014) Improvement of life expectancy of jute-based needle punched geotextiles through bitumen treatment. Journal of The Institution of Engineers (India): Series E 95(2): 111-121.

- Islam MS, Khan AJ, Siddique A (2016) Effectiveness of Treated Jute Geo-textiles (JGT) in riverbank protection.

- Saha P, Roy D, Manna S, Adhikari B, Sen R, et al. (2012) Durability of transesterified jute geotextiles. Geotextiles and Geomembranes. 35: 69-75.

- Chowdhury Z (2015) An imperial Mughal tent and mobile sovereignty in eighteenth-century Jodhpur. Art History 38(4): 668-681.

- (2008) Construction Fabrics Market by Type (PVC, PTFE, ETFE), Application (Tensile Architecture, Awnings & Canopies, Facades), and Region (Europe, North America, APAC, Middle East & Africa and South America) - Global Forecast to 2023.

- Jan EG (2009) Environmental benefits of natural fibre production and use. Proceedings of the Symposium on Natural Fibres pp. 3-17.

- Niloy AC (2021) Jute: Solution to global challenges and opportunities of Bangladesh. SEISENSE Business Review 1(2): 59-75.

- Kabir DM, Razzaque DMA, Rabi MRI (2019) Reviving exports of jute products from Bangladesh a study prepared as part of the BEI project on Trade and Investment.

- Salam M, Farouqui F, Mondal MI (1970) A study on sulphonated jute-cotton blended yarn and fabrics and their characteristics. Bangladesh Journal of Scientific and Industrial Research 42(3): 281-286.

- Dip TM, Begum HA, Hossain AA, Uddin M, Faruque O (2018) Analysis of physico-mechanical properties of jute and polyester blended yarn. International Journal of Scientific Research and Management 6(9).

- Sinha AK, Basu G (2001) Studies on physical properties of jute-acrylic blended bulked yarns. Indian Journal of Fibre and Textile Research 26(3): 268-272.

- Berger H (2005) Materials for tensile structures. In: Light Structures - Structures of light (2nd edn).

- Thornton J (2002) Environmental impacts of polyvinyl chloride building materials. A Healthy Building Network Report, Washington DC, USA, p. 110.

- Forster Brian, Mollaert Marijke (2004) The European design guide for tensile surface structures. Tensinet.

- Singha K (2012) A review on coating & lamination in textiles: Processes and applications. American Journal of Polymer Science 2(3): 39-49.

- Rana GMC (2021) Exploring “Golden Fiber” jute as tensile membrane architecture in Dhaka.

© 2024 Ar Golam Morsalin Choudhury Rana. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)