- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Photoreactive Wearable: A Computer Generated Garment with Embedded Material Knowledge

Efilena Baseta1, Aldo Sollazzo1*, Laura Civetti1, Dolores Velasco2 and Jaume Garcia Amoros2

1Noumena Design Research Education SL, University of Barcelona, Spain

2Grup de Materials Organics, University of Barcelona, Spain

*Corresponding author: Aldo Sollazzo, Noumena Design Research Education SL, University of Barcelona, Spain

Submission: February 08, 2018; Published: March 12, 2018

ISSN: 2578-0271 Volume1 Issue5

Abstract

Driven by technology, this multidisciplinary research focuses on the implementation of a photomechanical material into a reactive wearable that aims to protect the body from the ultraviolet radiation deriving from the sun. In this framework, the wearable becomes an active, supplemental skin that not only protects the human body but also augments its functions, such as movement and respiration. The embedded knowledge enables the smart material to sense and exchange data with the environment in order to passively actuate a system that regulates the relation between the body and its surroundings in an attempt to maintain equilibrium. The design strategy is defined by 4 sequential steps: a) The definition of the technical problem, b) the analysis of the human body, c) the design of the reactive material system, as well as d) the digital simulations and the digital fabrication of the system. The aforementioned design strategies allow for accuracy as well as high performance optimization and predictability in such complex design tasks, enabling the creation of customized products, designed for individuals.

Keywords: Smart materials; Wearable technology; Data driven design; Reactive garment; Digital fabrication; Performance simulations

Introduction

The advancement in the nanotechnology has led to big inventions in the fields of biology, medicine, and material science. In the information era, technology emerges rapidly providing scientists with more accurate tools to hack existing materials or to create new ones with tailored properties. Therefore, the applications of such materials has started to expand towards the design field.

Driven by technology, this multidisciplinary research focuses on the implementation of a photomechanical material into a reactive wearable that aims to protect the body from the ultraviolet radiation deriving from the sun. In this framework, the wearable becomes an active, supplemental skin that not only protects the human body but also augments its functions, such as movement and respiration. The embedded knowledge enables the smart material to sense and exchange data with the environment in order to passively actuate a system that regulates the relation between the body and its surroundings in an attempt to maintain equilibrium. Unlike most recent projects of wearable technology [1,2], this research is based on the elimination of electronics, which leads to reactive system with zero energy consumption, low maintenance and low rate of failure. Similar projects, embedding smart materials in apparel, have been conducted from other researchers, aiming for optimized thermal regulation of the body [3] or clothes reactive to sunlight [1].

This research, discusses the creation of a reactive to weather conditions garment that also allows for optimized thermal regulation of the body, eliminating hazards from UV radiation. Its design strategy is defined by 4 sequential steps: a) The definition of the technical problem, b) the analysis of the human body, c) the design of the reactive material system, as well as d) the digital simulations and the digital fabrication of the system. The aforementioned design strategies allow for accuracy as well as high performance optimization and predictability in such complex design tasks, enabling the creation of customized products, designed for individuals.

Technical problem and design solution

Harmful effects of UV radiation on human skin

Ultraviolet (UV) irradiation present in sunlight is an environmental human hazard. Divided into three sections, UVA, UVB and UVC, each one has distinct biological effects. UVC is electively blocked from reaching the Earth's surface by the tratospheric ozone layer. UVA and UVB radiation both reach the Earth's surface in amounts sufficient to have important biological consequences to the skin. UVB rays are absorbed into the skin, producing erythema, burns, and eventually skin cancer, whereas UVA is supposed to be weakly carcinogenic, cause aging and wrinkling of the skin [4].

Based on data from satellites, scientists from NASA declared that the decrease of ozone amounts in the upper atmosphere above antarctica has caused an increase in the amount of ultraviolet radiation striking the earth [2]. This fact makes skin protection from UV radiation an urgent problematic.

Photo protection

Our body has its own strong mechanism against the UV radiation which relies on the presence of melanin, a protein that is produced in the lowest level of our epidermis [5]. Epidemiological data strongly support the photo protective role of melanin as there exists an inverse correlation between skin pigmentation and the incidence of sun induced skin cancers [6]. However, melanin can also have toxic properties, especially after exposure to UVR [7]. Moreover, commercially available sun protections like sunscreen have been proven harmful for our bodies [8]. Recent research from the University of Copenhagen also states the harmful effect of the sunscreen on men, decreasing their fertility [3].

Design solution

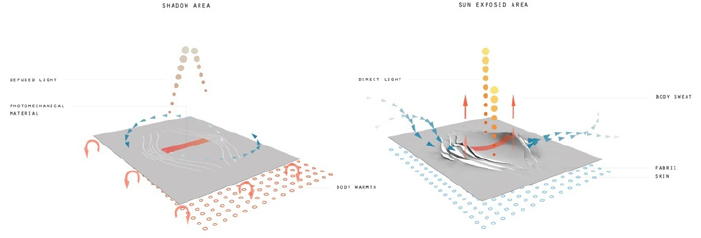

Taking into consideration the aforementioned studies, this research investigates alternative, non harmful ways of photo protection, through are active wearable that fluctuates its permeability according to the presence of direct sunlight, using smart materials. In contrast to photo protection with conventional clothes, this research discusses an optimized to thermal comfort garment, which increases its porosity at the parts exposed to direct sunlight, allowing the less exposed parts to remain less porous, increasing the breathability of the body at its warmer parts, keeping the colder parts warmer (Figure 1). The potential users for such a wearable are people exposed to direct sunlight in daily basis due to their profession or hobby such as farmers, fishermen and construction workers.

Material System

Photomechanical material

By identifying the discussed problematic (UV radiation) as the stimuli for the smart material embedded in the wearable, a less complex and more efficient dynamic system is achieved. Therefore, light has been proven the optimum stimuli for a photo protective wearable. Furthermore, light is a clean energy that can be rapidly, precisely and remotely controlled, as well as its efficient use is necessary for establishing a sustainable society [9].

Regarding the actuators of the system, materials with photomechanical properties which transform photon energy into kinetic energy have been selected. In the nano scale of such materials, molecules that directly absorb the photon and convert its energy into a chemical reaction are ideal transducers of light into motion because the chemical change is usually accompanied by a geometrical rearrangement. In many cases, photochemical reactions can be reversed, so that the process can be repeated. Ordered media, such as liquid crystals, can align the molecular scale motions to produce motion, like bending or twisting, on much larger, micron to millimeter, length scales [10]. Other researches show that the mechanical properties of the photo reactive liquid crystals can be defined by changing the contained photo reactive azobenzene cross linker, in an attempt to control the photo mechanical effect [11]. This could lead to a gradient of geometrical deformations of the system under direct sunlight according to the needs of the body.

Figure 1: Behavior of adaptive materia! system.

Left: Reactive component under shadow. The heat of the body is kept inside the garment in order to warm the body up.

Right: Reactive component under direct sunlight. The sweat of the body is evaporating through the openings as the air passes through the fabric coo!ing down the body.

Finally, researchers from China report a novel strategy for the preparation of rapid and reversible photo-driven actuators consisting of an active linear azobenzene polymer layer and a passive silk fibroin substrate, avoiding the need for oriented azobenzene liquid crystalline elastomers, just through depositing linear azobenzene polymer on the top of silk fibroin film [12]. This logic, of using bilayer actuators, is known for years and has been applied in both adaptive architecture [13] and wearables [3], due to the resulted big deformations; therefore it has been selected for the synthesis of the photomechanical material of the discussed garment.

Reactive component

Embedding the smart material in a flexible geometrical system made of fabric, variation of the system's porosity according to the amount of bending of the photomechanical part can be achieved, allowing for adaptive skin thermal comfort and photo protection.? The control of the photomechanical reaction by the manipulation of the illumination conditions such as light intensity enables diverse air and light permeability along the wearable (Figure 2). More specifically, the reactive components that are located on the parts of the body which are exposed to direct sunlight remain open in order to allow for maximum breathing of the skin but also protect the skin from the UV radiation since the opening are oriented in such a way that perpendicular light does not passes through. On the contrary, the components located in the parts of the body that are in shade, remain closed in order to keep the warmth of the body (Figure 1). Similar behavior can be found in nature in blooming plants, which open during the daylight and close during its absence. Studies on biomimetic photoresponsive polymer springs have proven that shape shift under irradiation with UV light and can be preprogrammed to either wind or unwind, as encoded in their geometry [14], allowing custom deformations and design solutions (Figure 3).

Figure 2: Simulation of reactive component deformations with fluctuating UV intensity.

Figure 3: Data for human body analysis.

Left: The muscular anatomy indicates the stiff and stretching areas while the sweat rate map indicates the highly sweating areas of the body.

Middle: The Kraissl’s lines indicate the less flexible orientation of the skin while the exposure map indicates the mostly exposed to the direct sunlight areas of the body.

Right: The map of the aforementioned overlapping data in a gray scale gradient indicates, with white colour, the parts that are more appropriate to host the reactive components as well as the shape of the resulted patches of the garment.

Human body analysis and results

Optimization of thermal comfort

As mentioned above, what distinguishes the discussed wearable from conventional clothes in terms of photo protection is the fact that it simultaneously protects the skin from UV radiation by covering it as well as allows it to breath. To optimize this function, the design has been the outcome of a digital juxtaposition of various data, such as body thermal maps, sun exposure and sweat maps. Thermo graphic images, from recent research [15], indicating the time evolution of skin temperature during exercise, have been used to defined the parts of the body which need more cooling. Simultaneously, empirical data from body exposure to sun has been considered to defined the most prominent to sunburn parts, consequently the parts that are exposed to direct sun rays. Finally, data of regional sweat rates across the body of women athletes [16] has been taken into consideration for the purpose of this research. The results show that the part of posterior torso and the lower back as well as the area between and under the breast have the highest sweat rates after exercise (Figure 3).

Figure 4: Garment design and material zones.

Top: Zone 1 with dark grey, Zone 2 with light grey and Zone 3 with grey colour.

Bottom: The 14 different patches of the garment in 3D aspect as well as in 2D unrolled laser cut pattern.

Optimization of movement

In addition to thermal comfort, the proposed photo protective wearable has been designed to augment and not disrupt the movement of the body. Analog, two dimensional images of muscular geometries that show the direction of their fibers as well as the less contacted parts where inputs for the design. Furthermore, Kraissl's lines have been an additional input of the design process. The aforementioned lines, being perpendicular to the underlying muscle fibers, [17] correspond to the alignment of collagen fibers within the dermis and defined the direction within the human skin along which the skin has the least flexibility (Figure 3 & 4).

Material zones of the wearable

Based on the aforementioned data, body analysis of the upper part of a woman body has been achieved. The conclusion is depicted into an optimized to movement and thermal comfort garment, which consists of 14 different patches categorized into three zones (Figure 4). Zone 1 consists of the highly sweating parts, which are located at less stretchable parts of the body and are mostly exposed to the direct sun radiation. Zone 2 consists of the highly sweating parts, which are located at more stretchable parts of the body and are less exposed to the direct sun radiation. Finally, zone 3 consists of the least sweating parts, which are the most stretchable parts. Consequently, zone 1 has been characterized more appropriate to place the reactive components, since a) it lacks thermal comfort, b) its parts are the less stretchable, so as the reactive kinetic behaviour of the system will not be affected by the body movement and c) the system can be activated more efficient by the direct UV radiation. Zone 2 includes the rest of the highly sweating parts and is characterized by its need for thermal comfort and zone 3 is characterized by its ability to be stretched. Based on the aforementioned assumptions three different fabrics have been chosen for the three zones (Figure 4).

Fabric

In the framework of creating a garment for users that do laborious works under high temperatures, fabrics which are a) light colored, so as they reflect as much as possible the UV radiation, b) breathable, so as the thermal comfort can be maximized and c) comfortable have to be used. Previous research on fabrics states that among the two quantitative common comfort parameters are tactile and thermal comfort. Tactile comfort mainly depends upon mechanical properties such as stretching, bending, shearing and compression at low stress levels. On the other hand, thermal comfort is related to the fabric's transmission behaviors, namely thermal resistance, water vapor transmission and air permeability [18] . Therefore, 100% cotton and 100% linen has been selected as comfortable fabrics made of natural fibers that have high air permeability. Accordingly to the same research, testing the air permeability between cotton and linen, it shows that linen fabrics permit more air to pass through, as compared to 100% cot- ton fabrics of similar areal density. The reason for the higher permeability in the case of linen and linen- blended fabrics can be attributed to the lower hairiness of these yarns, due to their longer fibers length as compared to cotton (Figure 5).

From the above, it is concluded that 100% linen will be used for zone 1 and zone 2, as they need higher air-permeability, and 100% cotton will be used for zone 3, as it has higher stretch ability.

Geometrical configuration of reactive component

The photomechanical material is placed on the selected patches and its position and orientation has been based on the Kraissl's lines, at the specifically part of the body. As mentioned before, Kraissl's lines follow the less stretchable direction of the skin therefore the photomechanical material, considered as a rectangular un stretchable strip, has been oriented parallel to them. In order to increase the breathability of the garment, cuts on the fabric have been placed at the sides of the photo reactive strip, in such a way that when it bends, due to UV radiation, the cuts open and let the air pass through the garment and cool down the body, without letting direct sun pass through them (Figure 1).

Digital simulations and fabrication techniques

Design of wearable

The design of the wearable has not followed conventional patterns of sartorial techniques but is designed digitally. It has been based on a mesh of a 3D female body with standard proportions. Lines, representing the seams of the garment have been designed on top of the mesh, separating the upper part of the body in 14 different patches, as explained before, creating a T-shirt. By inputting the 3D scanned body of a specifically individual, as well as its body analysis data such as thermal map, taken from infrared pictures or sweat rate data, the design can be customized.

Figure 5: Front and back of the 2D drawing of the wearable including the distorted, cut and engrave lines of the active patches. These lines derive from their relation with the underlying Kraissl’s lines as well as the location of the photomechanical material.

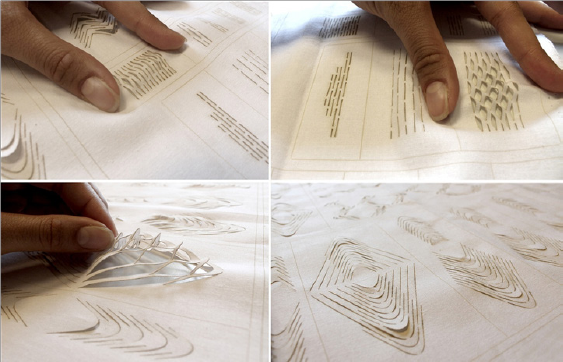

Further computational processes have taken place on the reactive patches which host the photomechanical strip as well as the aforementioned cuts. A process of computational design has been followed in order to embed the cuts into a holistic design pattern. Lines, vertical to the Kraissl's have been designed and distorted through algorithms, so as they create circular cavities, where the photomechanical strip is placed (Figure 5 & 6).

Figure 6: Physical test of cut pattern flexibility.

Top: Longer linear cuts show more flexibility than short linear cuts. Linear cuts deformations induce creases to the fabric.

Bottom: Triangular cuts in opened and closed configuration showing that its deformation does not induce creases to the fabric.

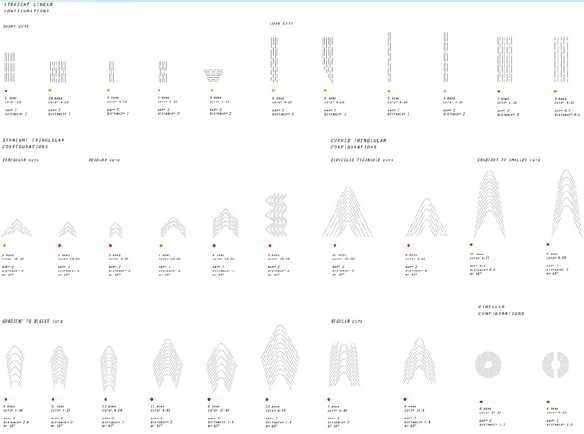

Flexible cut patterns

Kirigami is a well know technique of cutting paper in order to create pop up designs that has also inspired scientists to create expandable electronics [4]. The aforementioned cuts that have been designed in order to increase the breathability of the discussed wearable have been inspired by this technique, allowing the creation of 3D configuration from simple planar sheets. Several physical tests (Figure 7) and digital simulations have been conducted in order to find the most flexible patterns of cuts. During the first trials, linear configuration of cuts have been tested. The samples with the cuts shifted after every second line, showed significant flexibility while the samples with repetitive cuts were static. The distance between the rows of the cuts, the distance between the cuts of the same row as well as the lengths of the cuts appeared to be the key parameters to defined the flexibility of the cut pattern. Consequently, the shortest the distance between the rows and the one between the cuts the more the flexibility. Moreover, the longer the cuts, the less force is required to open them. Although most of the resulted cut patterns were flexible enough, crease were induced to their fabric by their opening, which did not cohere with the objectives of the system (Figure 6).

Therefore, further tests of cutting patterns have been conducted, keeping stable the optimal parameters of the previous tests. This time, samples with triangular and circular configuration of cuts were tested and showed more flexibility than the parallel cuts. Furthermore, no increase of the fabric outline was induced, which makes these cut patterns more appropriate for the system (Figure 6).

Based on these results, circular cuts longer than 10mm, shifted every second row have been placed along the aforementioned distorted pattern of the active patches. The distance between the cuts is 2mm and the distance between consecutive cuts has been kept down to 2mm (Figure 5).

Digital simulations

Digital simulations of the kinetic behavior of the system have been conducted using the Physics engine of Grasshopper 3D, Kangaroo. The fabric is represented by a mesh with high stiffness, so as to better represent the mechanical properties of the fabric. Linear forces, pointing at the positive z direction, represent the forces caused by the bending of the photomechanical material (Figure 1).

The result of the simulation depicts the approximate deformation of the system, although due to the lack of embedding material properties to the algorithm, as well as geometric constraints of the mesh the deformation is not accurate. Therefore the digital simulations precede the physical test, in order to save time and material and when satisfactory results are obtained, physical experiments follow.

The 3-dimensional representations of the reactive component have been created in order to show the shape shifting of the garment according to various sun intensity scenarios (Figure 2). This allows the elimination of design errors, and verifies the performance of the final system by collecting and analysing the resulted data (Figure 6).

Fabrication of wearable

Figure 7: Technical drawing that depicts the tested cut patterns indicating the flexibility of each one (green dot: more flexible, orange dot: less flexible, red dot: not flexible).

In order to fabricate the T-shirt, a digital 2D pattern has been generated by unrolling the 3D geometry of every patch (Figure 7). This process has been conducted with the use of Kangaroo, applying gravitational forces to the oriented parallel to the floormesh patches. In the unrolled patches, a small difference of max 1% between the area enclosed in their outline and the area of the original 3D mesh has been observed. Nevertheless, these small differences will be covered by the elasticity of the fabric.

Subsequently, the digital fabrication of the active patches has been done using laser cutting technique by engraving the pattern of the distorted lines and cutting through the cotton fabric in order to create the actual cuts for the breathing (Figure 8). A thin film of thermo adhesive has been placed close to the cuts so as they do not fray. After having laser cut all the patches, stitching by a sewing machine will take place in order to create the complete garment.

Figure 8: Photograph of laser cut active patches representing their deformed configuration.White fabric of 0,5mm thickness with embedded adhesive film has been used.

Synthesis of photomechanical strip

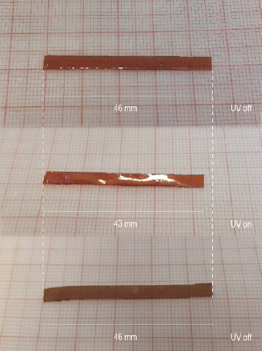

Figure 9: Photograph of photomechanical strip contraction test.

Top: Initial configuration (46mm).

Middle: Contraction of 7% with the presence of white light in 2 min (43mm).

Regarding the synthesis of the photomechanical strips, the first tests have been conducted in collaboration with the Institute of Nanoscience and Nanotechnology of the University of Barcelona. Nematic liquid single crystal elastomers with the ago compound acting as a cross linker [11] of 46mm length have been produced and showed 7% (43mm) contraction after irradiation with white- light, recovering to their initial shape when the light turnedoff (Figure 9). Further tests need to be done in order to introduce the bending behavior by applying the bilayer logic. Moreover, improvements to the synthesis need to be made in order to enhance the contraction of the photomechanical strip induced by sunlight, which is currently 1% as well as reduce the time of reaction which is currently 2 minutes. When the photomechanical elements will be finalized and synthesized they will be cut into strips of 30mm and embedded into the fabric in order to complete the dynamic system [19].

Conclusion

This research aims to expand humans' capabilities in their everyday life through an informative, tactile environment that can sense and respond, placed on human skin. The embodiment of responsive materials, such as photomechanical polymers, in a garment, allows the emergence of reactive photo protective wearables, eliminating the need of electronics.

At the current state the development and verification of the digital design strategies have been accomplished and part of the fabrication ofthe garment has been completed. The photomechanical material synthesis is programmed to be optimised in the following months [20-23]. Subsequently, material tests and design probes of the dynamic system will be conducted and documented in order to verify the digital simulations by a multidisciplinary team, involving private companies and public institutions. The final aim is to create a functional demonstrator, a photo reactive wearable that remains in tune with the user and its environment.

Acknowledgements

This work is part of Noumena Design Research Education S.L (noumena.io) research line on smart materials and their applications in the design field. The synthesis of the photomechanical material is collaboration with the Group of Organic Materials, Institute of Nanoscience and Nanotechnology, IN2UB department of Organic Chemistry of the University of Barcelona and Teresa Gea and Javier Moral Vico from the department of Chemical, Biological and Environmental Engineering of the Universitat Autonoma de Barcelona, Spain. Financial support from the Ministerio de Economiay Competitividad (CTQ2015-65770- PMINECO/FEDER) is gratefully acknowledged.

References

- Farahi B, Huang N, Fox M (2013) Alloplastic architecture: the design of an interactive tensegrity structure. International Conference on Adaptive Architecture: ACADIA 2013, Cambridge, Canada, pp. 129-136.

- Farahi B (2016) Caress of the gaze: A gaze actuated 3d printed body architecture. Proceedings of Acadia 2016, Michigan, USA, pp. 352-361.

- Yao L, Ou J, Cheng C, Steiner H, Wang W, et al. (2015) Biologic: Natto cells as nano actuators for shape changing interfaces. Non-Rigid Interaction Surfaces, Seoul, Korea, pp. 1-10.

- Matsumura Y, Ananthaswamy H (2004) Toxic effects of ultraviolet radiation on the skin. Toxicol Appl Pharmacol 195(3): 298-308.

- Brenner M, Hearing V (2008) The protective role of melanin against UV damage in human skin. Photochem photobiol 84(3): 539-549.

- Gilchrest B, Eller M, Geller A, Yaar M (1999) The pathogenesis of melanoma induced by ultraviolet radiation. N Engl J Med 340(17): 13411348.

- Kvam E, Dahle J (2004) Melanin synthesis may sensitize melanocytes to oxidative DNA damage by ultraviolet A radiation and protect melanocytes from direct DNA damage by ultraviolet B radiation. Pigment Cell Res 17(5): 549-550.

- Salinaro A, Caib L, Serpone N, Horikoshi S, Hidaka H, et al. (1997) Chemical oxidation and DNA damage catalysed by inorganic sunscreen ingredients. FEBS Letters 418(1-2): 87-90.

- Mamiya J (2012) Photo mechanical energy conversion based on cross linked liquid crystalline polymers. Polymer 45: 239-246.

- Kim T, Zhu L, AlKaysi R, Bardeen C (2014) Organic photomechanical materials. ChemPhysChem 15(3): 400-414.

- Garcia Amoros J, Finkelmann H, Velasco D (2011) Influence of the photoactive azo cross linker spacer on the opto mechanics of polysiloxane elastomer actuators. Materials Chemistry 21(4): 1094-1101.

- Hongying W, Weidong Z, Yuyan W, Zhijun H (2014) Photomechanical bending of linear azobenzene polymer. Royal Society of Chemistry 4(23): 11776-11781.

- Ruggeberg M, Burgert I (2015) Bio Inspired wooden actuators for large scale applications. PLoS ONE 10(3): 1-16.

- Iamsaard S, Villemin E, Lancia F, Aphoff S, Fletcher S et al. (2016) Preparation of biomimetic photoresponsive polymer springs. Nat Protoc11(10): 1788-1797.

- Tanda G (2015) The use of infrared thermography to detect the skin temperature response to physical activity. 33rd UIT (Italian Union of Thermo-fluid-dynamics) 2015 Heat Transfer Conference, Aquila, Italy

- Smith CJ, Havenith G (2011) Body mapping of sweating patterns in male athletes in mild exercise- induced hyperthermia. Eur J Appl Physiol 111(7): 1391-1404.

- Lemperle G, Tenenhaus M, Knapp D, Lemperle SM (2015) The direction of optimal skin incisions derived from striae distensae. plast Reconstr surg 134(6): 1424-1434.

- Behera BK (2007) Comfort and handle behaviour of linen blended fabrics. AUTEX Research 7(1): 33-47.

- Jung W, Kim W, Kim HY (2014) Self burial mechanics of hygroscopically responsive awns. Integrative and Comparative Biology 54(6): 10341042.

- (2017) MIT programmable material adapts to temperature just like human skin

- https://www.nasa.gov/vision/earth/lookingateart h/25TOMSAGU. html

- Meera S (2016) Evidence mounts that sunscreen could weaken sperm.

- Katherine M (2015) Kirigami art could enable stretchable plasma screens, University of Michigan, USA.

© 2018 Efilena Baseta, et al. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)