- Submissions

Full Text

Trends in Textile Engineering & Fashion Technology

Bursting Strength and Extension for Jersey, Interlock and Pique Knits

Usha Chowdhary1*, Mohammed Maruf Adnan1 and Chin-I Cheng2

1Central Michigan University, USA

2Department of Mathematics, Central Michigan University, USA

*Corresponding author: Usha Chowdhary, Professor, Human Environmental Studies, Central Michigan University, Mount Pleasant, MI 48859, USA

Submission: January 06, 2018; Published: February 07, 2018

ISSN: 2578-0271 Volume1 Issue2

Abstract

Comfort and durability are important to consumer. Existing literature does not report much on knitted fabrics except for dimensional stability. Knits are reported to lessen fitting problem due to their ability to stretch more than woven fabrics [1]. Some scholars reported that compact and ring-spun yarns perform differently for bursting strength [2,3]. However, none of the reviewed work compared bursting strength for different types of knit fabrics. Extension is negatively associated with strength. Additionally, ASTM D6797-2015 is newly introduced test. Its use and outcome are not published in the existing literature. Therefore, the reported study compared bursting strength and extension of seventeen knitted fabrics (jersey, interlock and pique) in several fiber contents. Because of lack of research in the area of inquiry, thirteen hypotheses were developed for jersey, interlock and pique knits. Oneway Analysis of Variance (ANOVA), correlation coefficient, regression analysis and t-tests were executed using IBM SPSS program to test the hypotheses at 95% confidence level. Eleven of the thirteen hypotheses were rejected. Several significant differences were found by knit structure and fiber content. The study provided empirical data on bursting strength and extension for knitted fabrics and filled void using the newest standard. The findings for which some previous research was available showed different results. Several possibilities for extending this exploratory research are identified.

Keywords: Bursting strength; Extension; Fabric count; Fabric thickness; Fabric weight; Knits; Knit types

Introduction

Knits offer comfort to consumer because of built-in stretch, and are preferred by consumers worldwide. All knits have stretch that alleviates several fitting problems more so than the woven fabrics. Nassif examined relationship between fabrics made from ring and compact yarns [1]. Ring spun yarns are created by the conventional method. In the conventional ring spinning the fibers are twisted with the help of a ring. The distance between the nip of the delivery rollers and twisted end of the yarn is called spinning triangle. In this zone, the fibers contain no twist and the outer fibers are outspread form the yarn structure. This leads to weak yarn strength and problem of yarn hairiness. In contrast, compact spinning is a modified version of ring spinning. In this spinning process, fibers form the drafting system that is guided through perforated drums. To condense the fibers, sideways air pressure is applied. This condensing almost eliminates the spinning triangle. Consequently, the later method creates stronger yarns because fibers are exposed to same amount oftension. Two studies reported that compact yarns perform better than the ring-spun yarns on several performance attributes including the bursting strength [2,3].

Several researchers examined relationship between stitch length and bursting strength [4,5]. Uyanik et al. [4] reported that increase in stitch length resulted in a decrease in the bursting strength [4]. Collier and Epps reported likelihood of higher breaking strength for fabrics with higher than lower fabric count [6]. Fabric count refers to the number of wales and courses per inch for knitted fabrics. However, they did not report on bursting strength specifically. Breaking strength is generally associated with woven fabrics and bursting strength with the knitted fabrics. Couple of scholars mentioned inverse relationship between breaking strength and elongation [7,8].

Degirmenci, Celik, Ghaziantep & Cukurova examined bursting strength and extension of bamboo and modal and cotton "denim viewed knitted fabrics". They did not find any relationship between bursting strength and extension [9]. However, their study revealed that bamboo and modal had higher bursting strength than cotton. Emirhanova and Kavusturan reported that knit structure could impact bursting strength [10]. Existing information shows conflicting results and used different test for bursting strength. Additionally, none of the previous work used commercially available fabrics to examine bursting strength of fabrics along with extension that could impact the comfort level for the wearer. The test used for the reported study is fairly new and has not yet been tested extensively. Therefore, the reported study examined bursting strength and extension of interlock, jersey and pique knits.

Literature review

In general, knitted fabrics have higher elongation than woven fabrics. However, differences could exist between different knit types, such as jersey, interlock and pique. Strength contributes toward durability and elongation toward comfort. Merkel [11] reported that >35% of elongation and 15-20 pounds per square inch breaking strength are required for sewn seams [1]. Collier and Epps mentioned that higher fabric counts yield higher breaking strength and lower tearing strength [6].The authors asserted that strength of knitted and non-woven fabrics should be determined by bursting strength test that applies multidimensional rather than linear force. Epps examined knitted swimwear made from nylon/spandex blend for colorfastness and tensile strength against light, seawater and chloride [12]. Findings revealed that light colored swimsuit had the highest loss in tensile strength. Hsu and Cheek compared ramie, cotton and rayon knits for their dimensional stability and found ramie to be more stable than the other two fiber contents [13]. Both cotton and rayon were reported to have progressive shrinkage for wales and growth for courses. Chowdhary and Kadolphstated that extension and strength are inversely related to each other [7,8]. Increase in strength results in decrease in elongation. The author also reported that the Annual Book of ASTM Standards (2007 vol.2, and 2008, vol.1) provides minimum passing standards for various end uses. For example, 20psi for lingerie; 15 psi for sheer clothing; and 25 psi for beachwear, men's dress shirts, linings, and underwear [14,15]. Higher values were recommended for bed sheets, career and vocational apparel.

Degirmenci et al. [9] examined the extension and bursting strength of "denim viewed knitted fabrics" [9]. They reported bursting strength and elongation as important parameters of textile structure. Bamboo and modal fabrics had lower bursting strength than "cotton30" (p. 105). Researchers did not find any relationship between bursting strength and elongation. Ciobanu et al [16] compared bursting strength of knitted sandwich fabrics [16]. The intent was to determine if high performance yarns could replace the natural yarns. The scholars found that adding linen rather than Kevlar to the sandwich material can reduce the production cost. They drew three main conclusions regarding the bursting strength: 1) stitch density impacted bursting strength, 2) increased in velocity resulted in reduced strength, and 3) in-lay yarns enhanced the bursting strength. Emirhanova, Kavusturan examined the impact of knit structures on abrasion resistance, air permeability, bending rigidity, bursting strength, dimensional stability and pilling resistance [10]. The study yielded significant results for air permeability, bending rigidity and bursting strength. Knit structure impacted the bursting strength the most particularly in the washed fabrics. Several scholars reported that longer stitches have lower bursting strength than the shorter stitches [4,5].

Uyanik et al [4] also found that location of tuck stitches had greater impact than the stitch length [4]. Yesmin et al [5] examined single jersey, Lacoste and double pique knit in relation to their bursting strength [5]. Their findings revealed that bursting strength was highest for 'single Lacoste' and lowest for double pique knit. The team did not study interlock knits. The tested fabrics were manufactured with 100% cotton and five different stitch lengths. Another team of scholars reported that jersey, rib and interlock knits made from compact yarns had higher bursting strength, elongation and pilling resistance than those made from ring spun yarns [3]. Akaydin also found that compact yarns had higher bursting strength and lower pilling [2]. Two other studies reported that increase in Lycra amount enhanced the bursting strength [17,18]. Eryuruk & Kalaoglu [18] also reported relationships of bursting strength with fabric weight and fabric thickness; and elongations with elastane content [18]. The main purpose of the reported study was to determine bursting strength and extension of various types of knits individually and in comparison with each other for different types of knits.

None of the previous research examined the proposed relationships in the reviewed literature. Therefore, the following thirteen hypotheses were developed to examine relationship between seventeen different knitted fabrics for bursting strength and extension. This seminal research will allow better understanding of the bursting strength and extension using newest test method approved in 2015 and can serve as a basis to compare results for highly controlled textile materials for the intrinsic changes induced during the manufacturing process.

Knit type by bursting strength and extension

Hypothesis 1: No difference will exist among interlock knits for bursting strength from different fiber contents.

Hypothesis 2: No difference will exist among interlock knits for extension from different fiber contents.

Hypothesis 3: No difference will exist among jersey knits for bursting strength from different fiber contents.

Hypothesis 4: No difference will exist among jersey knits for extension from different fiber contents.

Hypothesis 5: No difference will exist among pique knits for bursting strength from different fiber contents.

Hypothesis 6: No difference will exist among pique knits for extension from different fiber contents.

Knit type by fiber content

Hypothesis 7: No difference will exist among three knit structures (interlock, jersey, pique) with similar fabric count for 100% cotton for bursting strength.

Hypothesis 8: No difference will exist among three knit structures (interlock, jersey, pique) of similar fabric count for 100% cotton for extension.

Hypothesis 9: No difference will exist between interlock and pique knit with similar fabric count in 100% polyester for bursting strength.

Hypothesis 10: No difference will exist between interlock and pique knit with similar fabric count in 100% polyester for extension.

Structural attributes by bursting strength and extension

Hypothesis 11: Fabric count, fabric thickness and fabric weight will impact bursting strength irrespective of the knit type.

Hypothesis 12: Fabric count, fabric thickness and fabric weight will impact extension irrespective of the knit type.

Relationship between bursting strength and extension

Hypothesis 13: Bursting strength will be inversely related to extension.

Methodology

The study used appropriate test standards for selected structural and performance attributes for the reported study. All specimens were conditioned before testing using ASTM D-1776 specifications. ASTM D-3887-2008 was used for fabric count, ASTM D-1777-2011 for fabric thickness, ASTM D-3776-2013 was used for fabric weight, and ASTM D-6797-2015 was used for bursting strength and extension [14,15]. Fabric count, thickness and weight are important structural attributes that are used to determine quality of both woven and knitted fabrics [19]. It is well-established fact that higher the count, better the quality [7]. Various terms are defined below based on (ASTM D-123-2013a) [14]. Fabric count refers to numbers of wales and courses per inch. Fabric thickness refers to the difference between two planes (top and bottom) of the fabric. Fabric weight refers to mass per unit area and can be denoted as ounces per square yard or grams per square meter. Bursting strength refers to the force required to break the fabric. When force or pressure is vertically applied on fabric it is called bursting. The force needed to rupture the fabric (when applied perpendicularly) is called bursting strength [16]. Extension refers to change in length due to stretching.

Bursting strength is a new test that was approved by ASTM in 2015. Therefore, it has limited history of use and was not reported in the literature reviewed for the study. Therefore, testing it for various types of knits will be valuable contribution to the field. The apparatus included ball burst attachment to a CRE (Constant Rate of Extension) machine. Sample size for these tests is "5x5" and it requires testing of five specimens. The machine was operated at 12+0.5 inches/minute. For the reported study, INSTRON 5544 was used. The printout included both bursting strength and extension ratings. Therefore, both were tested for each of the seventeen fabrics. IBM SPSS program was used for testing. One-Way analysis of variance was performed to test hypotheses for various types of knits (interlock, jersey, pique) and fiber contents individually. Comparisons were also made among and between various types of knits with similar fabric counts to determine if knit structure impacted the bursting strength and/or extension. Tukey's tests were used for post-hoc comparisons if F values from one-way ANOVA were significant at .0f level of significance. This test controls for Type 1 error. T-tests were executed for two variable comparisons between interlock and pique knit. Regression analysis was used to examine impact of structural attributes such as fabric count, thickness and weight on bursting strength and extension. Pearson correlation coefficients were used to determine relationship between bursting strength and extension in general and exclusively for each knit type.

Results and Discussion

Table 1: Mean (M) and Standard Deviation (SD) for Fabric Count, Thickness and weight of the Knit fabrics. (n=5)

Seventeen fabrics used for the study represented three types of knits: Interlock, jersey, and pique. Both 100% as well as blends of fiber content were represented in all types of knits. All fabrics were purchased from an online retailer except 100% cotton jersey that was purchased from the local fabric store. Details about the type of knit, fiber content, fabric count and fabric thickness are provided in Table 1. For fabric count, only combined count is reported to avoid burdensome reading of the table. Inferential statistics for various hypotheses is provided below.

Knit type by bursting strength and extension

Hypothesis 1: No difference will exist among interlock knits for bursting strength from different fiber contents.

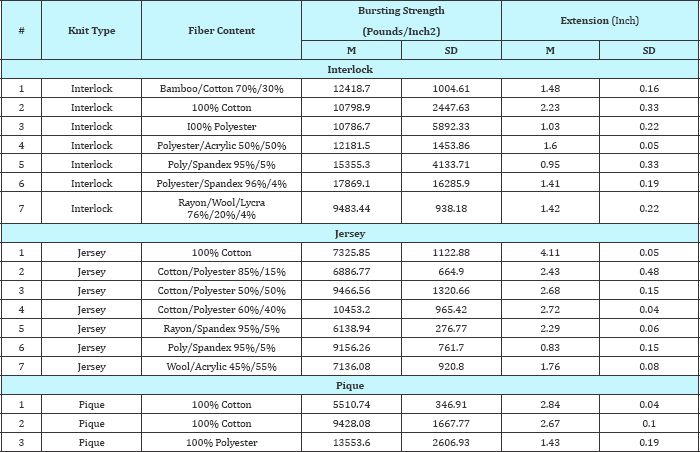

Table 2: Mean (M) and Standard Deviation (SD) of Extension and Bursting Strength.

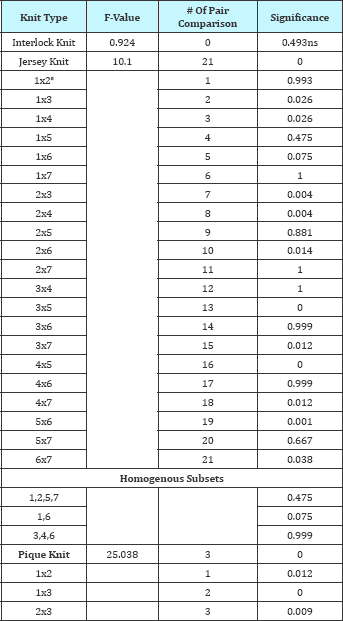

Results from one-way ANOVA (Table 2 & 3) revealed that interlock knits did not differ significantly for bursting strength. F (6,28)= .924, p = .493).There was insufficient evidence to reject the hypothesis. This finding is conceptually different from Degirmenci et al. who reported that bursting strength differed for bamboo and cotton in their study [9]. They looked at denim fabrics and did not identify it as interlock, jersey or pique knit.

Hypothesis 2: No difference will exist among interlock knits for extension from different fiber contents.

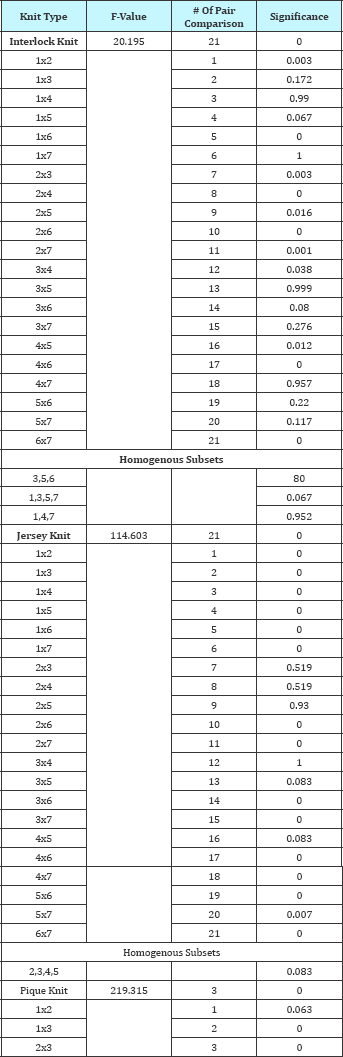

Findings from one-way ANOVA (Table 2 & 4) revealed that interlock knits differed significantly for elongation. F(6,28)= 20.195, p = .000. There was sufficient evidence to reject the hypothesis. Post hoc comparisons using Tukey's test indicated that 11/21 possible comparisons were significantly different for interlock knits. Bamboo/cotton blend differed significantly from cotton and poly/spandex (96/4); 100% cotton from all other interlock knits; 100% polyester from 100% cotton and polyester/ spandex (95/5) blend; and polyester/spandex (95/5) from 100% polyester, poly/acrylic (50/50) blend and 96/4 polyester/spandex blends. Polyester/Spandex (96/4) differed significantly from Rayon/Wool/Lycra blend (76/20/4) It was interesting to observe that addition of spandex to polyester increased strength but did not increase extension. From homogenous subsets' standpoint, three fabric groups were formed. The first subset represented polyester and two poly/spandex blends. The second subset represented bamboo/cotton, polyester, poly spandex (95/5), and rayon/wool/ Lycra (76/20/4). The third subset included bamboo/spandex/ poly/acrylic (50/50), and rayon/wool/Lycra (76/20/4).

Hypothesis 3: No difference will exist among jersey knits for bursting strength from different fiber contents. Bursting strength of jersey knits (Table 3) differed significantly for bursting strength. F (6, 28)= 10.1, p =.000. There was sufficient evidence to reject the hypothesis. For jersey knit, 11 of the 21 comparisons were significantly different from each other. Based on Tukey’s post-hoc test, 100% cotton differed significantly from 50/50 and 60/40 blend of cotton; cotton/polyester (85/15) from cotton/polyester (50/50), cotton/polyester (60/40), and poly/spandex (96/4); cotton/polyester (50/50) from rayon/spandex (95/5) and wool/ acrylic (45/55). Wool/acrylic blend had higher bursting strength than the rayon/spandex blend. Increase in polyester content did not always result in increased bursting strength. Based on the homogenous subsets, 100% cotton, cotton/poly (85/15), rayon spandex (95/5), and Wool/Acrylic (45/55) grouped together. Likewise, 100% cotton and poly/spandex (95/5) formed second group and cotton/poly (50/50, cotton/poly (60/40), and poly/ spandex (95/5) formed the third group.

Table 3: One-Way ANOVA results and the post hoc Tukey’s test for significant F value and Homogenous subsets for bursting strength.

Hypothesis 4: No difference will exist among jersey knits for extension from different fiber contents.

Table 4: One-Way ANOVA results and the post hoc Tukey’s test for significant F value and homogenous sets for Extension.

Results from one-way ANOVA (Table 4) revealed that jersey knits differed significantly for extension F(6,28)= 114.603, p = .000. There was sufficient evidence to reject the hypothesis. For jersey knit, 15/21 comparisons were significant. 100% cotton differed from all other fiber contents. Cotton/polyester (85/15) was similar to other cotton/poly blends and pol/spandex (95/5) blend. However, it was different from poly/spandex (95/5) and wool/acrylic (45/55). Cotton/poly with 50/50 representation differed only from 100% cotton, poly/spandex (95/5) and wool/ acrylic blends. All of the remaining fibers differed significantly from each other except cotton/poly (60/40) and rayon/spandex (95/5). Homogenous subsets revealed that cotton/poly (85/15), cotton/ poly (50/50), cotton/poly (60/5) and rayon/spandex (95/5) were similar for extension.

Hypothesis 5: No difference will exist among pique knits for bursting strength from different fiber contents. Pique knits tested in the reported study differed significantly for bursting strength. F(2,12)= 25.038, p= .000. Hypothesis 5 was rejected. The post hoc analysis revealed that all three possible comparisons were significantly different from each other. Fabrics with highest fabric count and lowest fabric weight (Table 1) had highest bursting strength. Additionally, polyester was stronger than cotton. This finding is consistent with common knowledge that staple fibers have less strength than filaments. From the homogenous subsets perspective, both cottons were similar to each other (Table 3).

Hypothesis 6: No difference will exist among pique knits for extension from different fiber contents.

Findings from ANOVA (Table 4) revealed that pique knits differed significantly for extension F(2,12)=219.315, p = .000. Hypothesis 6 was rejected. For pique knits, 2/3 possible comparisons were significant. Two cottons did not differ from each other. However, cotton and polyester did. Conceptually, staple fibers like cotton are believed to have higher extension than filaments. This finding is consistent with previous literature for pique knits. Cotton had significantly higher extension than polyester. Previous research lacked emphasis on extension. Therefore, results could not be compared with the previous research.

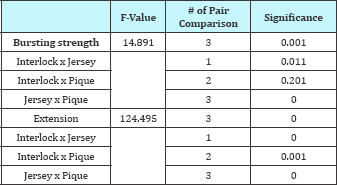

Knit type x fiber content

Hypothesis 7: No difference will exist among three knit structures (interlock, jersey, pique) with similar fabric count for 100% cotton for bursting strength. One-way ANOVA results demonstrated significant differences for bursting strength of100% cotton in three types of knits. F (2, 12)= 14.891, p = .001 (Table 5). Tukey's post-hoc comparisons revealed that bursting strength of 100% cotton differed significantly for interlock (# 2, Table 1) and jersey knit (# 5, Table 1), and pique (# 2,Table 1) and jersey knit. However, inter lock and pique knits did not differ from each other. Hypothesis 7 was rejected. None of their viewed literature commented on the comparison of three types of knits in same fiber content for bursting strength.

Table 5: Results from One-Way ANOVA and Tukey’s post-hoc comparison for Significant F value of Interlock, Jersey and Pique Knits for bursting Strength and extension in 100% cotton.

Hypothesis 8: No difference will exist among three knit structures (interlock, jersey, pique) with similar fabric count for 100% cotton for extension. Findings from one-way ANOVA revealed that three types of knit differed significantly for extension in 100% cotton, F (2, 12)= 124.495, p = .000. Hypothesis 8was rejected. Extension was the highest for the jersey knit followed by pique and interlock knits. Tukey's post hoc comparisons revealed that all three knits differed significantly from each other. No comparison data were available. Further research is needed to repeat research by controlling for other structural variables.

Hypothesis 9: No difference will exist between interlock and pique knit with similar fabric count in 100% polyester for bursting strength. There was insufficient evidence to reject the hypothesis because p value for this relationship was 0.362.This finding is inconsistent with results from the study of Emirhanova and Kavusutran who found that knit structure impacts bursting strength [10]. Results were also in conflict with Yesmin et al. [5] who reported that single Lacoste had higher bursting strength than double pique knit [5].

Hypothesis 10: No difference will exist between interlock (# 5, Table 1) and pique knit (# 3, Table 1) with similar fabric count in 100% polyester for extension. Findings from one-way ANOVA revealed that two groups differed significantly F (1, 9) =13.453, p=.006.). Hypothesis 10 was rejected. It was obvious that knit structure in this case did make a difference. Pique knit had higher extension than the interlock knit. No comparison information was available from reviewed literature.

Structural attributes by bursting strength and extension

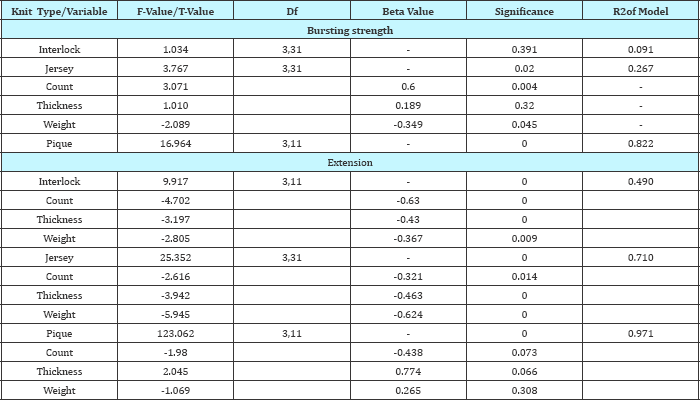

Hypothesis 11:Fabric count, fabric thickness and fabric weight will impact bursting strength irrespective of the knit type. Regression analysis results revealed that associations were significant for jersey and pique knits but not significant for interlock knits based on their F-Value (Table 6). However, t values revealed that associations were significant only for weight and count for the jersey knits and not for the pique knits. For jersey knit, fabrics with lighter weight had higher bursting strength than those with heavier weight. However, higher fabric count resulted in stronger fabric than lower count. This finding is consistent with previous research [7,8]. There was insufficient evidence to accept the hypothesis.

Table 6: Regression analysis of bursting strength and extension for fabric count, thickness and weight for interlock, jersey and pique knitsa.

aOnly significant results are reported

Hypothesis 12:Fabric count, fabric thickness and fabric weight will impact extension irrespective of the knit type. Regression analysis results revealed that fabrics with higher count, thickness and weight extended less than those with lower count, thickness and weight for interlock and jersey knits.

Relationship between bursting strength and extension

Table 7: Pearson’s correlation coefficient between bursting strength and extension.

Hypothesis 13:Bursting strength will be inversely related to extension. Even though the proposed relationship was confirmed for all knits combined (r =-.349, p=.001 in Table 7), the correlation was significant only for pique knit. Further research with stricter controls is needed to resolve this conflict.

Summary and Conclusion

The exploratory study examined seventeen knitted fabrics for their bursting strength and extension. ASTM D-6797 2015 standard was used to measure both attributes using INSTRON 5544 machine. The knit structure represented interlock, jersey and pique. For bursting strength, top three fabrics were polyester/spandex (96/4), poly/spandex, 95/5), and bamboo/cotton for interlock knit; cotton/poly (60/40), cotton/poly (50/50) and poly/spandex (95/5) for jersey knit; and polyester, heavy-weight and light-weight cottons for pique knit. It will be worth comparing the exclusive impact of fabric weight and fabric count on different fiber contents [20].

In the reported study for all three knit types, extension was highest for 100% cotton. For interlock knit, it was followed by poly/acrylic (50/50), Bamboo/Cotton (70/30), rayon/wool/ Lycra (76/20/4), poly/spandex (96/4), 100% polyester, and poly/ spandex (95/5). For jersey knit, extension was highest for 100% cotton followed by cotton/polyester (60/40), cotton/polyester (50/50), cotton/polyester (85/15), rayon/spandex (95/5), wool/ acrylic (50/50) and poly/spandex (95/5). It is worth mentioning that fabric count was highest for poly/spandex but extension was the lowest. One hundred percent cotton had second lowest fabric count; whereas, wool/acrylic (50/50) had lowest fabric count and second lowest extension. There is need to investigate relationship between fabrics count and fabric weight with extension under more controlled conditions than used in the reported study. For pique knit, light weight cotton had the highest extension and was followed by heavier weight cotton and 100% polyester. Light-weight cotton had higher extension that the heavier weight cotton. Polyester had the least amount of extension. Filament yarns are stronger and have lower extension. Staple fibers have relatively lower strength and higher extension.

The reported study has two unique strengths. First, it is the first study that examined bursting strength for knitted fabrics using the latest test. Second, the study tested sever different knit types and fiber contents and can serve as a platform for future studies with tighter controls for within fiber-content comparisons. Examining relationship between fiber content and extension with fabrics manufactured through controlled requirements can offer additional insights as well. The current study reaffirmed some of the existing conceptual understanding of relationship between structural and performance attributes. Additional work is needed to compare new and old methods for optimizing the knowledge base further.

Implications for future research

Future research can also examine the impact of structural attributes on bursting strength and extension exclusively for several structural attributes such as fabric count, yarn size, fabric thickness and fabric weights under more controlled conditions of variability that are hard to control in commercially purchased fabrics. Using same fabric with different thread counts, fabric thickness and fabric weight will further enrich the understanding of relationship between structural attributes, bursting and extension. Former imparts strength and durability and later offers comfort. Consumer values both these attributes in any textile. Findings from this seminal work can serve as a foundation to further refine the understanding of knitted materials that are all pervasive in today's apparel industry. The study added new information and filled the gap in existing literature for understanding bursting strength and extension for various knit types and fiber contents. The reported study was an exploratory research that only scratched the surface. Much needs to be done to further refine the design and make it more controlled than was possible in the current study.

It will be imperative to answer the following questions for understanding durability and comfort in knits. Do finishes influence bursting strength? Does yarn size have an impact on bursting strength and elongation? Which structural attributes enhance the bursting strength property of knits? Will findings differ for CRT (Constant Rate of Traverse) using ASTM D 3787-07 and CRE (Constant Rate of Extension) using ASTM D 6797-2015? Will laundering have an impact on the bursting strength? What is the relationship between pilling resistance and bursting strength?

References

- Nassif GA A (2014) A comparative study between physical properties of compact and ring yarn fabrics produced from medium and coarser yarn counts. Journal of Textiles 2014: 1-6.

- Akaydin M (2009) Characteristics of fabrics knitted with basic knit structures from combed ring and compact yarns. Indian Journal of Fiber and Textile Research 34: 26-30.

- Kretzschmar SD, Özguney AT, Özfelik G, Özerdem A (2007) The comparison of cotton knitted fabric properties made of compact and conventional ring yarns before and after the dyeing process. Text Research Journal 77(4): 233-241.

- Uyanik S, Degirmenci Z, Topalbekiroglu M, Geyik F (2016) Examine the relation between the number and location of tuck stitches and bursting strength in circular knitted fabrics. Fibres & Textiles in Eastern Europe 1(115): 114-119.

- Yesmin S, Hasan M, Miah MS, Momotaz F, Idrish MA, et al. (2014) Effect of stitch length and fabric constructions on dimensional and mechanical properties of knitted fabrics. World Applied Sciences Journal 32(9): 1991-1995.

- Collier BJ, Epps HH (1999) Textile analysis and testing. Upper Saddle River, Merrill, NJ, USA.

- Chowdhary U (2009) Textile analysis, quality control and innovative uses. Deer Park, LINUS, NY, USA.

- Kadolph SJ (1998) Quality assurance for textiles and apparel. New York, Fairchild, NY, USA.

- Degirmenci Z, Celik N (2016) Relation between extension and bursting strength properties of the denim viewed knitted fabrics produced by cellulosic fibers. Fibres & Textiles in Eastern Europe 24: 101-106.

- Emirhanova N, Kavusturan Y (2008) Effect of knit structure on the dimensional and physical properties of winter outerwear knitted fabrics. Fibres & Textiles in Eastern Europe 6(2): 69-74.

- Merkel RS (1991) Textile product serviceability. Macmillan, New York, USA.

- Epps HH (1987) Degradation of swimwear fabrics: Effects of light, sea water and chloride. Clothing and Textiles Research Journal 5(2): 28-32.

- Hsu LH, Cheek L (1989) Dimensional stability of ramie, cotton and rayon knit fabrics. Clothing and Textiles Research Journal 7(2): 32-36.

- Annual Book of ASTM Standards, West Conshohocken, PA: ASTM International, 2007, 2008, 2011, 2013, 7(01).

- (2015) Annual Book of ASTM Standards, West Conshohocken, PA: ASTM International, 7(02).

- Ciobanu AR, Ciobanu L, Dumitras C, Sarghie B (2016) Comparative analysis of the bursting strength of knitted sandwich fabrics. Fibres & Textiles in Eastern Europe 24: 95-101.

- Sadek R, El-Hossini AM, Eldeeb AS, Yassen AA (2012) Effect of Lycra extension percent on single jersey knitted fabric properties. Journal of Engineered Fibers and Fabrics 7(2): 11-16.

- Eryuruk SH, Kalaoglu F (2016) Analysis of the performance properties of knitted fabrics containing elastane. Journal of Clothing Science and Technology 28(4): 463-469.

- Chowdhary U (2017) Comparing three brands of cotton t-shirts. AATCC J Res 4(3): 22-33.

- Cohen AC, Johnson I (2012) Fabric science. Fairchild, New York, USA.

© 2018 Usha Chowdhary. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)