- Submissions

Full Text

Research in Medical & Engineering Sciences

Anti-microbial Finishing of Cotton Fabric Using Neem Leaf Extract for Medical and Healthcare Textiles

Mazharul Islam1, Firoz Ahmed1,2, Nahid Pervez3 and Ibrahim H Mondal1*

1Polymer and Textile Research Lab, Department of Applied Chemistry and Chemical Engineering, Rajshahi University, Rajshahi-6205, Bangladesh

2BCSIR Laboratories RajShahi, Bangladesh Council of Scientific and Industrial Research, Rajshahi, Bangladesh

3Sanitary Environmental Engineering Division (SEED), Department of Civil Engineering, University of Salerno, via Giovanni Paolo II 132, 84084 Fisciano (SA), Italy

*Corresponding author:Ibrahim H Mondal, Polymer and Textile Research Lab, Department of Applied Chemistry and Chemical Engineering, Rajshahi University, Rajshahi-6205, Bangladesh

Submission: March 13, 2023Published: April 21, 2023

ISSN: 2576-8816Volume10 Issue2

Abstract

There are many prospects for the application of new finishes due to the fast rise of technical fabrics and their end uses like medical and healthcare applications. In the present study, an anti-microbial agent is extracted from Neem leaf with methanol to investigate the effect of anti-microbial activity on cotton fabric. Cotton fabrics were treated with 3, 6, 9 and 12% Neem leaf extract and extract with 8% citric acid (CA) separately at a fabric-to-liquor ratio of 1:20 using the dip-dry-cure method. These finished samples were subjected to an antimicrobial activity test. It was found that the treated cotton fabric showed excellent anti-microbial activity at a higher concentration of Neem leaf extract. The treated and non-treated fabrics were characterized by Fourier Transform Infrared spectroscopy (FTIR) and this analysis showed that there were characteristic absorption bands of Neem leaf extract appearing in the spectra of the treated fabric. TGA and SEM were studied to identify the loss of weight of fabric on temperature and the surface morphology of treated and non-treated fabric

Keywords:Keywords: Autism; Telehealth; Behavioral skills training

Introduction

A healthy, contagious-free lifestyle is made possible by clothing, which is sometimes referred to as the “second skin”. The functionality of clothing depends on attributes such as wrinkle resistance, soil release, water repellency, flame retardancy and resistance to microbial invasion [1]. Textile materials are very interesting to everyone as they play a most important role in civilized life. These materials are good carriers of various types of microorganisms and can cause health-related problems to the wearer and besides, and these microorganisms are responsible to deteriorate the textile product’s quality including fabric strength, colour, stains and bad odour [2]. The word “antimicrobial” refers to a wide range of technologies that offer varied degrees of protection for textile fabrics against microbes. Antimicrobials differ greatly in terms of their chemical makeup, mechanism of action, effects on people and the environment, handling characteristics, durability, prices, compliance with regulations, and interactions with microbes [3]. A variety of antimicrobial fabrics now have a fast-expanding market owing to consumer attitudes towards hygiene and an active lifestyle, which has, in turn, encouraged vigorous research and development. This has led to a significant rise in the number of bio-functional textiles with antibacterial activity during the past several years, especially during the COVID-19 pandemic situation [4].

There are two different antimicrobial treatments that are applied to textiles: synthetic antimicrobial finishes (both organic and inorganic), and natural antimicrobial finishes. Synthetic antimicrobial agents used are antimicrobial dyes, quaternary ammonium compounds, triclosan, metals and metal salts such as silver, zinc, and copper and natural agents are those that utilize a variety of components from the plant or animal kingdom [5]. Although synthetic antimicrobial agents are very effective against microbial growth on textiles these are caused by different side effects on consumers’ health and water pollution. Hence, there is a great demand for anti-microbial textiles-based eco-friendly agents which act as an accelerator to reduce the ill effects associated due to microbial growth on healthcare textile material and maintain the statutory requirements of regulating agencies [6,7]. Therefore, bacterial adherence to textile fabrics is an important field of study to prevent the growth and further proliferation of these harmful organisms [8].

Ashraf et al. [5] reported a comparative idea for the application of antimicrobial finishes on bleached cotton fabric using plant leaf extract. Overall, the result indicates the potentiality of these plant extract to be used for anti-microbial textile product [5]. Zaghloul et al. [9] showed the effect of a neem extract concentration of 15g/L on the antibacterial properties of the treated fabric expressed as inhibition zone diameter in presence of silicon microemulsion for gram-positive (S. aureus) and gram-negative (E. coli) bacteria. The finding of antibacterial activity is higher than the other actionized cotton or blank fabric [9].

A variety of natural antimicrobial agents have been found including polysaccharides and their derivatives e.g., chitosan, some plant extracts e.g., Aloe Vera, Tulsi leaf, natural dyes and pigments derived from plants, insects, animals and minerals [8,10]. These agents contribute to controlling a variety of different diseases, infections and allergies. Among all these agents, plant extracts comprise a major segment. Neem plants are one of these and have good microbial growth-inhibiting properties [6,8,10]. In this study, Neem leaf extract was established as a prominent anti-microbial agent that helps to remove adverse side effects and gives ecofriendly anti-microbial cotton fabrics for medical & healthcare applications. Thus, it is intended to produce Neem leaf extracttreated eco-friendly anti-microbial cotton fabric that protects the consumer from microorganism contamination.

The major objectives of this study are:

a) to prepare anti-microbial finishing of cotton fabric with

natural neem leaf extract and with citric acid as a cross-linking

agent for a more effective result and

b) to compare the neem leaf extract and neem leaf extract

with CA treated sample for finding the better result on antimicrobial

properties and

c) to deliver eco-friendly, non-toxic and anti-microbial

cotton fabrics for medical and healthcare textiles.

Material and Methods

Materials

Natural neem leaf extract as an antimicrobial agent was prepared, methanol (Merck, Germany), citric acid 1-hydrate crystal. Extra pure (Merck, India), Nutrient agar (HIMEDIA, India) and Glacial acetic acid (Merck, India) were purchased.

Methods

Preparation of neem leaf extract: The fully expanded fresh Neem leaf was selected from the Neem plant and washed with distilled water. Then leaves were kept in dark condition at room temperature for shadow drying. Shadow-dried Neem leaves were converted into fine powder by grinding. This fine powder was treated with methanol in the material-to-liquor ratio of 1:5. The mixture was shelved for seven days at room temperature in dark conditions to allow the active material to be dissolved in methanol. After seven days, active substances of Neem were achieved as a solution by filtration. This methanolic extract of Neem leaf was used as an antimicrobial agent to finish cotton fabric. Citric Acid (CA) was added as a crosslinking agent to the prepared neem leaf extract and finally, neem leaf extract with an 8% CA sample was achieved.

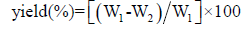

Yield percentage of neem leaf extract: The required amount of shadow-dried Neem leaf powder sample was dissolved in 250ml methanol solution. After 6 days, the solution was filtered and the residue was dried and weighed. The yield percentage was calculated by the following formula:

Where W1 is the weight of dried neem leaf powder (g), and W2 is the weight of dried residue after extraction (g). Then dissolved amount of Neem leaves powder was 6.24 %.

Antimicrobial finish: Extracted neem leaf solution was applied on cotton fabrics using the dip-dry-cure method. The cotton fabrics were immersed in 3, 6, 9 and 12% concentrations of neem leaf extract at room temperature for 2h in the fabric-to-liquor ratio of 1:20. Again separately the cotton fabrics were the treated at same conditions with 8% citric acid as an across-linking agent. Then the fabric samples were dried at 40 °C for 30 minutes. Finally, the neem leaf-treated cotton fabrics were obtained.

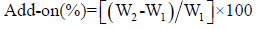

Determination of add-on weight: The amount of extract absorbed by the fabric was determined

by measuring the fabric weight before and after treatment. In this case, the fabric sample was dried at 60 °C. Then add-on percentages were calculated using the following formula [11].

Where W1 is the weight of fabric before treatment (g), and W2 is the weight of fabric after treatment (g).

Moisture absorption study: The moisture absorption study of Neem leaf extract treated fabric sample as well as non-treated fabric samples were performed at 64% humidity level for 24 hours. The treated and non-treated fabrics were dried at 50 °C temperature in the oven until a constant weight was obtained. The percentage of moisture absorption was studied as a function of weight gain and was calculated using the following formula [12].

Percentage of moisture absorption (%)=[(Wf -Wi)/Wi]×100 Where Wi is the weight of the dried sample (g) and Wf is the final weight of the sample taken out from the humidity level (g)

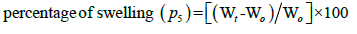

Swelling behavior study:The treated fabric samples’ weight was measured and immersed in 100ml of distilled water for 24 hours. Then samples were taken out and the adhering water was removed using tissue paper. It was then weighed. The percentage of swelling of the treated and non-treated fabrics can be calculated as:

Where Wt is the weight of swelling samples at different times and W0 is the initial weight of samples [13].

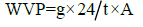

Water vapour permeability study:The water vapour permeability was measured as per ASTM E96, procedure B and standard test methods by the upright cup method [14]. The circulating temperature is set to 23 °C with controlled relative humidity at 50%. The airflow is maintained with a velocity of 2.8m/s. Finally, the water vapour permeability rate was estimated by estimating the weight change g, in a time period of 24h through a test area in m2.

Water vapour permeability was calculated by the following formula:

Where WVP is the water vapour permeability (g/m2/day), G is the weight change (g), t is the time during which g occurred (h) and A is the test area (m2).

Fourier-transform infrared spectroscopy (FTIR) analysis:FTIR is used to identify compounds and investigate sample composition as well as interaction/reaction between functional groups on the different components in polymer blends and composites [15]. The IR spectra of samples were recorded using FTIR (Shimadzu-8900, FTIR Spectrum, Kyoto, Japan) in the spectral region of 4000-650cm-1.

Scanning electron microscopy (SEM) analysis:Scanning electron microscopic (SEM) studies of untreated and treated with neem leaf extract cotton fabrics were carried out on an Electron Microscope Machine (FEI Quanta Inspect, Model: S50).

Thermal Analysis:Thermogravimetric analysis (TGA) and Differential scanning calorimeter (DSC) were completed using a Perkin Elmer simultaneous thermal analyzer (STA 8000, Germany). The tests were conducted between 30-600 °C under a nitrogen atmosphere. The heating rate and the airflow rate were 20 °C /min and 200ml/min respectively.

Anti-microbial activity test:The study of anti-microbial activities was performed by the agar diffusion plate method. The prepared petri plates were incubated at 37 °C for 48h and then the plates were examined for bacterial growth. The presence of a clear zone between the agar and the inhibition zone across the specimen was measured by a ruler. The inhibition zone was calculated using the following expression:

Where H is the Inhibition zone in mm, D is the total diameter of the specimen and inhibition zone in mm, and d is the diameter of the specimen in mm.

Result and Discussion

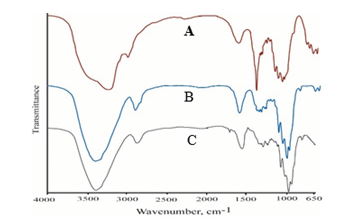

FTIR analysis

Figure 1 represents the FTIR spectra of untreated cotton fabric, neem leaf extract treated cotton fabrics and neem leaf extract with 8% citric acid treated cotton fabrics. The FTIR spectra of untreated and both treated (neem leaf and neem leaf with 8% CA) cotton fabrics were near about the same, except for a few characteristic peaks like 670cm-1, 1162cm-1 and 2123cm-1 that appeared on both treated cottons. These additional peaks confirm the attachment of active ingredients of neem leaf extract on cotton fabric.

Figure 1:FTIR of A. Untreated cotton fabric, B. Neem leaf extract treated cotton fabric and C. Neem leaf extract with 8% citric acid treated cotton fabric.

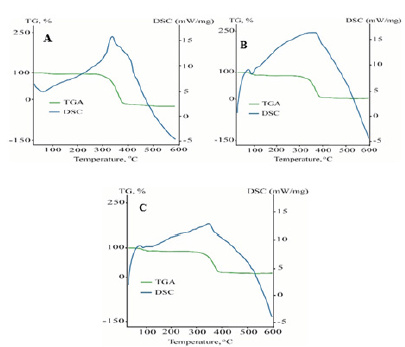

Thermal analysis

In Figure 2A, there are two stages of degradation that occur. The first stage shows a weight loss of about 17% at a temperature range of 30-320 °C due to the formation of volatile disintegrated products and the second stage shows a weight loss of about 80% at 320-380 °C. In Figure 2B&2C the first stage shows a weight loss of about 21% at temp. range 30-310 °C and the second stage show weight loss of about 70% at 310-370 °C. DSC curve of both untreated and treated fabric shows one endothermic peak of the decomposition of the carbon-hydrogen bond. Comparing the thermograms, Neem leaf extract and neem leaf extract with 8% CA treated fabric contains more loosely bound water than untreated fabric. This is clear that the anti-microbial active agent has been attached to the fabric properly.

Figure 2:TGA and DSC curve of A. Untreated cotton fabric, B. Neem leaf extract treated cotton fabric, C. Neem leaf extract with 8% citric acid treated cotton fabric.

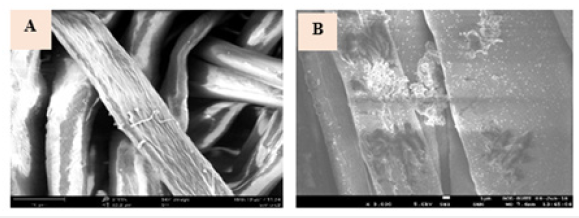

Surface morphology

The surface morphology of untreated and antimicrobial finished cotton fabrics was studied by Scanning Electron Micrographs. Figure 3A shows maximum pore size and poor smooth structure. In Figure 3B, Neem leaf extract produces a large number of small spherical shapes with a fairly uniform size distribution on the cotton surface which in turn confirms the attachment of neem leaf extract on finished cotton fabric.

Figure 3:SEM of A. untreated cotton fabric, and B. Neem leaf extract treated cotton fabric.

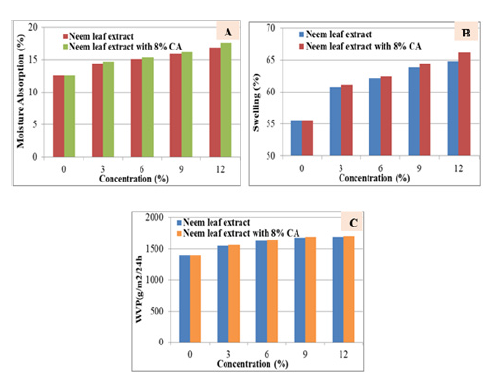

Moisture absorption, swelling behavior and water vapor permeability

Figure 4A shows that the moisture absorption (%) increases with increasing neem extract concentration. The untreated bleached cotton fabric absorbed 12.63% moisture whereas neem leaf-treated fabric absorbed 16.89% and Neem leaf in presence of 8% CA-treated fabric absorbed 17.62% moisture at 12% concentration. The addition of cross-linking-agent confirms more addition of neem extract in cotton fabric. Neem extract certainly would contribute more moisture absorption as they have many functional groups which are hydrophilic in nature. Thus, the presence of various chemical compounds in neem leaf extract would certainly impart hygroscopic characteristics which lead to the improvement in moisture-related properties like wetting, water vapour permeability, swelling etc. in the finished fabrics. From Figure 4B, Untreated bleached cotton fabric swells 55.63% water whereas Neem leaf extract treated fabric swells 64.84% and Neem leaf extract with 8% CA treated fabric swells 66.22% water and it can be explained by the above discussion like Figure 4A.

Figure 4:A. Moisture absorption (%), B. Swelling (%) and C. Water vapor permeability of methanol extract Neem leaf and Neem leaf with 8% CA treated fabrics.

From Figure 4C, increasing in water vapour permeability may be attributed to the polar groups present in neem leaf extract that increased the absorption property of neem enabling the absorption of water vapour and passing this water vapour through the pores in the fabric quickly to the atmosphere.

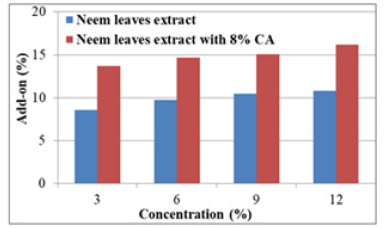

Add-on of neem leaf extract

From Figure 5, it can be seen that the add on % increase with increasing concentration of active neem leave extract and better result found for treatment with 8% CA at 12% concentration. Thus, CA enhanced higher Neem leave extract on to cotton fabric.

Figure 5:Percentage of add-on behavior of Neem leaf extract and Neem leaf extract with 8% CA

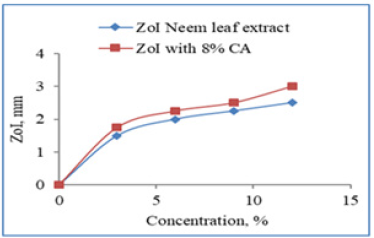

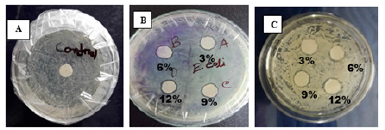

Anti-microbial activity measurement

From Figure 6&7, it is apparent that the antimicrobial activity of neem leaf extract increased with respect to concentration and excellent results were found in neem leaf extract with 8% CA treated samples at 12% concentration. It is attributed that bacterial inhibition is due to the slow release of active substances from the fabric surface.

Figure 6:Antimicrobial finishing behavior of textile fabrics treated with natural Neem leaf extract and with 8% CA as crosslinking agent.

Figure 7:Antimicrobial effect of A. Untreated (control) cotton fabrics, B. Treated with natural Neem leaf extract, and C. Treated with natural Neem leaf extract with 8% CA.

Conclusion

In this study, neem leaf extract and neem leaf extract with citric acid treated cotton fabric were developed to get the anti-microbial properties. FTIR and SEM analysis confirm the attachment of neem leaf extract as an active anti-microbial agent. From the results, it can be concluded that neem leaf extract with citric acid treatment shows better anti-microbial characteristics than neem leave extract. The findings of this study suggested that neem leaf extracttreated finished fabric possessed high antimicrobial activity. These anti-microbial finished fabrics can be used for the preparation of various health and hygiene products like gloves, medical textiles, and even storage of things which are vulnerable to bacterial attack.

References

- Vastrad JV, Byadgi SA (2018) Eco-friendly antimicrobial finishing of cotton fabric using plant extracts. International Journal of Current Microbiology and Applied Sciences 7(2): 284-292.

- Soe AA, Tun O (2016) A study on antimicrobial properties of cotton fabric treated with neem leaf extract. International Journal for Innovative Research in Multidisciplinary Field 5(9): 182-187.

- Shalini G, Anitha D (2016) A review: Antimicrobial property of textiles. International Journal of Science and Research 5(10): 766-768.

- Gouveia IC (2010) Nanobiotechnology: A new strategy to develop non-toxic antimicrobial textiles. Journal of Biotechnology 150(1): 407-414.

- Ashraf, Rahman H, Rahman M (2021) Comparative study on antimicrobial activity of four Bangladeshi medicinal plants used as antimicrobial finishes on cotton fabric. Journal of Textile Science & Fashion Technology 8(3): 6.

- Hein TN, Hnin SS, Htay DH (2013) A study on the effect of the antimicrobial agent from Aloe vera gel on bleached cotton fabric. International Journal of Emerging Technology and Advanced Engineering 4(2): 7-11.

- Ali WS, Purwar R, Joshi M, Rajendran S (2014) Antibacterial properties of Aloe vera gel-finished cotton fabric. Cellulose 21(3): 2063-2072.

- Mishra S, Babel S (2017) Screening of antimicrobial flux fibres treated with leaf extract of Azadirachta indica. International Journal of Current Research 9(2): 45969-45972.

- El Shafei A, El Bisi MK, Zaghloul S, Refai R (2017) Herbal textile finishes-Natural antibacterial finishes for cotton fabric. Egyptian Journal of Chemistry 60(2): 161- 180.

- Yadav S, Rose MN, Devi S, Kumar A (2020) Development of antibacterial finish for cotton with neem leaf extract and assessment of wash durability. Journal of Cotton Research and Development 34(1): 158-166.

- Hooda S, Khambra K, Yadav N, Sikka VK (2013) Effect of laundering on the herbal finish of cotton. International Journal of Textile and Fashion Technology 3(4): 35-42.

- Islam MK, Mondal MIH, Ahmed F, Akter T (2020) Surface modification of cotton fibre with functionalized silane coupling agents. International Journal of Polymer and Textile Engineering 7(1): 63-67.

- Leu P, Zhai M, Li J, Peng J, Wu J (2002) Radiation preparation and swelling behaviour of sodium carboxymethyl cellulose hydrogels. Radiation Physics and Chemistry 63(3-6): 525-528.

- Singh MK (2021) Textiles functionalization-A review of materials, processes, and assessment. In: Kumar B (Ed.), Intechopen.

- Pavia DL, Lampman GM, Kriz, GS, Vyvyan JR (2015) Introduction to spectroscopy: A guide for students of organic chemistry (5th edn), Cengage Learning, USA.

© 2023 Ibrahim H Mondal. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)