- Submissions

Full Text

Research in Medical & Engineering Sciences

Novel Z-Nanofiber Sheet Mask of High Particle Collection Efficiency, Easy Breathing and Resistant To Water Vapor

Akihiko Tanioka*1, Mitsuhiro Takahashi2 and Tsuneo Hanada3

1Professor, Emeritus, Tokyo Institute of Technology, Tokyo, Japan

2President, Zetta Ltd, Osaki Factory, Zetta Lab, Japan

3Technical Consultant, Zetta Ltd, Japan

*Corresponding author: Akihiko Tanioka, Professor, Emeritus, Tokyo Institute of Technology, Tokyo, Japan

Submission: September 01, 2021Published: September 24, 2021

ISSN: 2576-8816Volume9 Issue3

Opinion

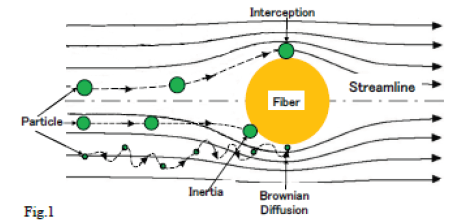

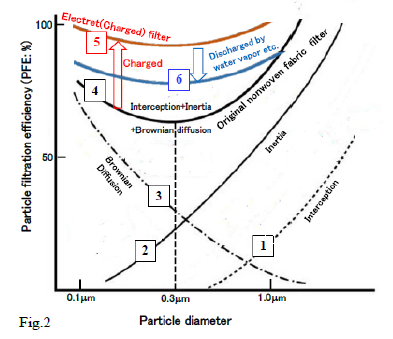

Nonwoven fabric sheet is usually used as mask due to the comparatively high particles removal performance and ease of breathing. The diameter of the SARS-CoV-2 (COVID-19 virus), including various mutants, is considered to be about 50nm to 150nm which is a size that can be removed by the nonwoven fabric sheet mask according to the particle collection Air Filter Mechanism Theory (AFMT) as shown in Figure 1. The most disturbing problems are that large amounts of aerosols of various sizes, including many viruses, are released from the mouth by coughing, and those around the diameter of 300nm slip through the mask according to the AFMT. In order to solve the problem, the electric charge is usually given to the mask. Such modification, however, loses the effectiveness in the presence of water molecules in the breathing. Those are explained in Figure 2.

Figure 1:

Figure 2:

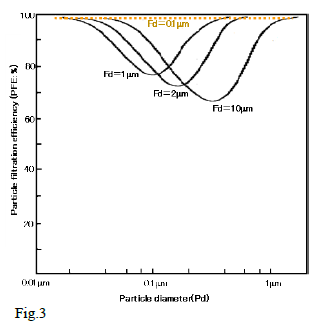

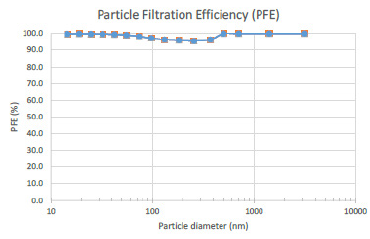

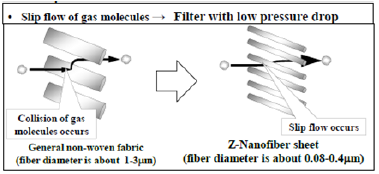

In general, the mask performance is represented by the Particle Filtration Efficiency (PFE) and Pressure Drop (PD) similar to an air filter. PFE corresponds to a measure of virus protection and PD to ease of breathing. Therefore, better performing masks have higher PFE and lower PD. Z-nanofiber sheet mask developed by using Z-melt spinning method [1,2] of PolyPropylene (PP) could solve the problems in charged masks, because the nanofiber can detect the aerosol around 300nm diameter without giving electric charge as shown in Figure 3 because of thin fiber diameter according to the AFMT.

Figure 3:

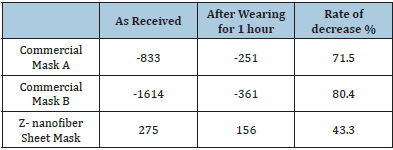

First of all, the electrostatic capacities of three types of masks were measured for the samples before and after masking, respectively, and shown with charge decrease rates in Table 1. Two commercial masks of A and B are charged negatively and Z-nanofiber sheet mask positively in the as-received condition. After wearing them for one hour those electrostatic capacities are decreased more than 40% by water molecules in the breathing. The PFE of commercial masks are reduced more than 70%, which can be explained that Line 4 increases to Line 5 by giving electric charge and Line 5 decreases to Line 6 by discharging with water vapor as shown in Figure 2. On the other hand, PFE of Z-nanofiber sheet mask can keep constant in spite of the reduction of charge capacity by water molecules in breathing. It has already been reported in the previous paper [3] that the PFE of the Z-nanofiber sheet mask is not affected by water molecules. Effects of washing and autoclave processing on PFE are shown for medical, athletic and Z-nanofiber sheet masks in Table 2. “Medical Mask A” is the commercial mask with characteristics close to N95, and “Athletic Mask A” is also the one which was used in Tokyo 2020. The PFE of “Athletic Mask A” is the lowest of three, only 86.2%. “Medical Mask A” reduces the PFE of about 40% after washing and about 53% after autoclave treatment, “Athletic Mask A” increases 2.2% and reduces 4.4%, and “Z-Nanofiber Sheet Mask” increases 1.1% and 4.9%, respectively. The PFE of “Z-nanofiber Sheet Mask” after autoclave treatment shows the highest of three, 99%.

Table 1

Table 2

Figure 4:

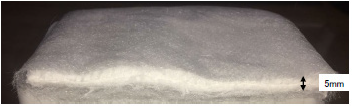

The relationship between PFE and particle diameter of Z-nanofiber sheet mask is shown in Figure3. As the fiber diameters are distributed mainly less than 400nm, the PEF line corresponds to the line of Fd=0.1μm(=100nm) in Figure 4. In this case the PD is 75Pa so that breathing is very easy. In Figure 5 microscopic image of Z-nanofiber sheet is shown, and the sheet thickness is about 5mm. If the air and particles pass through the Z-nanofiber sheet, the particle is captured by nanofiber with van der Waals force [4,5] according to the mechanism shown in Figure 1 and air is passing with slip flow. On the other hand, the normal filters such as commercial medical masks have collision of gas molecules in the air. Those are explained in Figure 6 as slip flow effect.

Figure 5:

Representative characteristics of the Z-nanofiber sheet mask are shown and compared with the commercial medical mask made of general nonwoven fabric sheet. The thickness of the medical mask is about 0.1mm and Z-mask about 5mm. The sheet fiber volume of the Z-mask is about 460 times that of the medical mask. Air passes only in the vertical direction for medical one. On the other hand, due to the low fiber density, air passes both vertically and horizontally, so air from the mouth is also released to the cheek and chin areas and vice versa for Z-one The horizontal air flow also causes slip flow. The distance of air flows becomes longer and the collision number of particles with fibers increases when it flows horizontally, which contributes to the increase of PFC. The long horizontal pass increases the apparent PD in vertical direction of air flow. Those facts suggest that the Z-nanofiber sheet has an anisotropic structure. All masks cover not only mouth and nose parts but also cheek and chin areas. Aerosols are released from the mouth by coughing. Usually, aerosol and air can penetrate though only mouth and nose parts because of very thin thickness for normal commercial mask including medical mask. On the contrary they can also penetrate through cheek and chin areas for Z-mask cited above. Those are explained precisely in Figure 7.

Figure 6:

Figure 7:

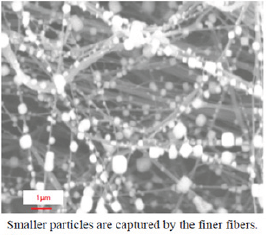

Figure 8 shows the SEM image of NaCl particles of the same size as a virus or aerosol captured on the Z-nanofibers. The important thing is that the particles are not captured on the thick fibers of about 1μm. The thick fiber plays another role that strengthen the mechanical properties Z-nanofiber sheet. Finally, it is suggested that the Z-nanofiber sheet mask shows the best performance to the protection of SARS-CoV-2.

Figure 8:

References

- Akihiko T, Mitsuhiro T (2016) Highly productive systems of nanofibers for novel applications. Ind Eng Chem Res 55: 3759-3764.

- Akihiko T, Mitsuhiro T (2016) Nanofibers in high-performance and specialty fibers. The Society of Fiber Science and Technology, Springer, Japan.

- Akihiko T, Mitsuhiro T, Tsuneo H (2021) protection of very small particles such as viruses and bacteria by washable and wearable z-nanofiber sheet mask. Res Med Eng Sci 9(2): 988-990.

- Ogushi Y, Sasaki N, Imashiro Y, Minagawa M, Matsumoto H et la. (2009) Antimicrobial activity of ultra-fine fiber nonwoven fabrics produced by electrospinning. Seikei Kakou 21: 287-290.

- Hidetoshi M, Akihiko T (2011) Functionality in electrospun nanofibrous membranes based on fiber’s size, surface area, and molecular orientation. Membranes 1(3): 249-264.

© 2021 Akihiko Tanioka. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)