- Submissions

Full Text

Research in Medical & Engineering Sciences

Wastewater Treatment by Electrocoagulation

Mervat A Sadik*

October High Institute for Engineering & Technology, Egypt

*Corresponding author: Mervat A Sadik, October high Institute for engineering & technology, Egypt

Submission: July 01, 2019;Published: July 16, 2019

ISSN: 2576-8816Volume8 Issue1

Abstract

Water shortage is very important issue in the world; especially at the current rates it is being used. Drinking water and water for industrial use demand for freshwater is at an all-time high. Using electrocoagulation method, industrial companies can treat wastewater to a point that it can be reused within their plant, discharged without environmental restriction or for use in irrigation. A review of recent research identifies future opportunities to use the application of electrochemical water treatment systems for many different industrial wastewaters.

Introduction

Water is one of the world’s most spirited resources. It is critical to the survival of every living individual on the world. Health experts stress drinking fluids all over the day the day to remain properly hydrated. However, in many parts of the world, water is hard to obtain. Either there are no sources adjacent to, or there is an incomputable management system that makes it hard for people to obtain water. Water and wastewater treatment have become very important standard in all over the world. Wastewater effluents from homes, buildings, and factories in many countries are also treated via wastewater treatment systems before being discharged back into surface waters. Without environmental damage However, there are two main significances of wastewater treatment, one is defending the environment and the other one is sustaining freshwater resources [1]. With the ever-increasing population and the stringent environmental regulations regarding the wastewater discharge, electrochemical technologies have retrieved their importance worldwide for treatment waste waters.

Conventional Wastewater Treatment

Chemical coagulation, biological methods and advanced oxidation processes, such as ozonation and UV/ H2O2 that cannot treat the effluent. All of earlier methods have some boundaries and problems. Biological treatment by activated sludge is very high efficiencies in COD removal but does not effective in decolorization of the wastewater and have problems such as bulking appear. Chemical oxidation by ozone, or a combination of UV-radiation and ozone and H2O2, has great interest, but the costs are still very high due to the high doses required [2-4], Coagulation-flocculation process has been found to be cost effective, easy to operate and energy saving treatment alternatives, but the coagulation process does not work well for soluble dyes. Electrocoagulation treatment technology method that used electrons only employed agents in ECF being responsible for facilitating wastewater treatment.

Electrocoagulation Process

The (EC) technology includes coagulation and precipitation of contaminants by a direct current electrolytic process followed by the separation of flocculent (settling or flotation) with or without the addition of coagulation-inducing chemicals. A direct electric current is applied to the electrodes to induce the electrochemical reactions needed to achieve the coagulation. In an EC process the coagulated ions a produced in “in situ” and it involves three successive stages [5,6].

- Formation of coagulants by electrolytic oxidation of the sacrificial electrodes.

- Weakening of the contaminants, particulates suspension and breaking of emulsions.

- Collection of the destabilized phase to form flocculent.

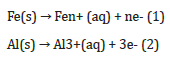

iron or aluminum are Electrodes which produce coagulants into water. Iron and aluminum cations dissolve from the anodes according to Equations 1 and 2.

And at cathode according to Eq. 3

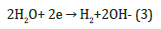

In solution the positively charged ions are attracted with the negatively charged hydroxides to produce ionic hydroxides that have a strong attraction towards dispersed particles as well as counter ions to cause coagulation (Table 1).

Table 1:Examples in recent applications of electrocoagulation in treatment of water and wastewater [1].

Different Modes of Electrode Connections [7]

Monopolar electrodes in serial connections (MP-S): In the monopolar electrodes in serial connection, each pair of sacrificial electrodes is internally connected with each other. The addition of the cell voltages leads to a higher potential difference for a given current. Bipolar electrode in serial connections (BP-S): In this connection mode, the outer electrodes are connected to the power supply and there is the no electrical connection between the inner electrodes. reported that MP-P mode is the most cost effective for both aluminum and iron electrodes (Figure 1).

Figure 1:

Conclusion

Finally, according to findings of this Article, it can be concluded that electrocoagulation process can obtain the highest favorable color removal which can make a recycle for wastewater, but in case of COD removal, I recommend adding a help method to complete treatment which agrees with restricted environment. The author and their colleagues recently proved that treated textile wastewater of activated sludge biomass was investigated and the results indicated that both dye and minerals content have negative effect therefore it is recommended to recycle treated effluent in industrial processes or consider total dissolved solids in the effluent as clearance limits [8].

References

- Sadik MA (2019) A review of promising electrocoagulation technology for the treatment of wastewater. Advances in Chemical Engineering and Science 9: 109-126.

- Slokar YM, Marechal AM (1998) Methods of decoloration of textile wastewater. Dyes Pigments 37(4): 335-356.

- Daneshvar N, Oladegaragoze A, Djafarzadeh N (2005) Decolorization of basic dye solutions by electrocoagulation: an investigation of the effect of operational parameters. Journal of Hazardous Materials 129(1-3): 116-122.

- Edris Bazrafshan, Amir Hossein M, Mohammad Ali Z (2014) Textile wastewater treatment by electrocoagulation process using aluminum electrodes. Iranian Journal of Health Sciences 2(1): 16-29.

- Barrera DCE, Lugo Lugo V, Bilyeu B (2013) A review of chemical, electrochemical and biological methods for aqueous cr (VI) chaturvedi SI electrocoagulation a novel wastewater treatment method. Int J Mod Eng Res 3: 93-100.

- Barrera Díaz CE, Lugo Lugo V, Bilyeu B (2012) A review of chemical, electrochemical and biological methods for aqueous Cr (VI) reduction. J Hazard Mater 223-224: 1-12

- Khandegar V, Saroha AK (2013) Electrocoagulation for the treatment of textile industry effluent. Review Journal of Environmental Management 128: 949-963.

- Kobya M, Ulu F, Gebologlu U, Demirbas E, Oncel MS (2011) Treatment of potable water containing low concentration of arsenic with electrocoagulation: different connection modes and Fe-Al electrodes. Sep Purif Technol 77(3): 283-293.

- Nasr FA, Sadik MA, Shafai SA (2019) Innovative electrochemical treatment of textile dye wastewater. Egypt J Chem 62(11)

© 2019, Mervat A Sadik. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)