- Submissions

Full Text

Research & Development in Material Science

Optimizing Material of Construction for Agitators in High-Temperature, High-Pressure Leach Reactors Handling Abrasive Mineral Slurries

Vipin Kumar Sharma1,2*

1Department of Chemical Engineering, Indian Institute of Technology, Tirupati, India

2Uranium Corporation of India Limited, Tummalapalle, India

*Corresponding author:Vipin Kumar Sharma, Department of Chemical Engineering, Indian Institute of Technology, Tirupati, Pin Code - 517619, Andhra Pradesh, India

Submission: May 13, 2025;Published: May 27, 2025

ISSN: 2576-8840 Volume 21 Issue 5

Abstract

This paper investigates the Research and Development (R&D) in Material of Construction (MOC) for agitators deployed in high-temperature, high-pressure reactors handling highly abrasive leach slurries from mineral ore processing. The operational environment poses significant challenges, including extreme thermal stress, chemical corrosion, and abrasive wear. Conventional materials such as SS316 and Hastelloy often suffer premature failure under such conditions. This study explores advancements in wear-resistant alloys, ceramic-coated composites, and duplex/super-duplex steels. It analyzes their mechanical integrity, corrosion resistance, and long-term durability through laboratory simulations and field trials. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) optimize blade geometry and material performance under dynamic slurry conditions. The paper concludes with a proposed material-performance matrix for agitator selection, aimed at reducing downtime and enhancing operational efficiency in metallurgical leaching reactors.

Keywords:Agitator design; Material of Construction (MOC); High-pressure reactors; Abrasive leach slurry; Corrosion resistance; Mineral ore processing

Introduction

High-pressure and high-temperature reactors used in hydrometallurgical processes often face operational challenges due to highly abrasive and chemically aggressive leach slurries derived from mineral ores. The agitators used in these systems play a crucial role in maintaining slurry homogeneity and enhancing leaching efficiency. However, they are prone to rapid wear and failure due to mechanical abrasion and chemical corrosion.

Material challenges in agitator applications

Agitators operate under extreme conditions, encountering:

a) Temperatures >200 °C

b) Pressures >20 bar

c) Slurry solids content >30%

d) Highly acidic/alkaline or oxidative chemical environments

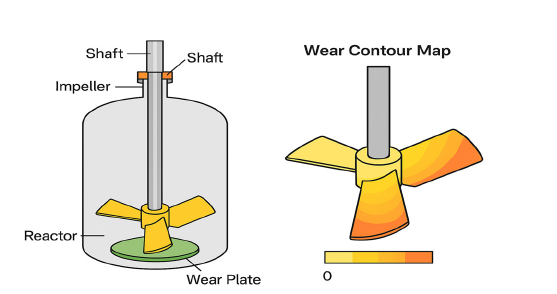

This demands MOC selections that balance abrasion resistance, corrosion resistance, and mechanical strength. A recent study emphasized the failure of conventional rubber linings in leaching circuits due to slurry abrasion and thermal degradation [1]. Figure 1 represents custom figures (agitator cross-sections and wear contour maps):

Figure 1:Custom figures (agitator cross-sections and wear contour maps).

Advances in MOC for agitators Metallurgical solutions:

a) Super Duplex Stainless Steels (e.g., SAF 2507): Enhanced

corrosion resistance with moderate wear strength

b) Nickel Alloys (e.g., Inconel 625, Hastelloy C276): Excellent

corrosion properties but limited wear resistance

c) High Chromium White Cast Irons: Used as claddings for

their hardness (>600HV)

Coating and composite solutions:

a) Ceramic-Polymer Composites: Applied as protective

overlays; e.g., alumina or silicon carbide-based coatings

b) Thermal Spray Coatings (HVOF): Provide surface hardness

>1000HV with corrosion stability

c) Chao’an [2] explored the use of abrasion-resistant linings

for agitators in hydrochloric acid leaching circuits, reporting a

40% increase in service life.

Design optimization

Agitator design also contributes to durability:

a) Blade profile affects slurry turbulence and wear zones

b) CFD simulations show that hydrodynamically optimized

impellers reduce wear concentrations near blade tips.

A CFD-based redesign trial [3] resulted in a 25% lower maintenance frequency in polymetallic nodule reactors.

Case studies and field data

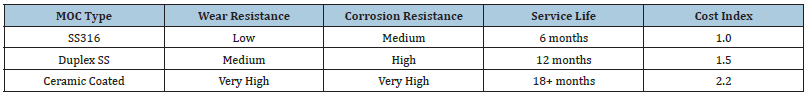

Table 1

Table 1:Comparative performance of agitator MOC in pilot trials.

Recommendations

a) For leach slurries with >30% solids and pH <2, use

ceramic-reinforced duplex or Inconel-blended coatings.

b) Use CFD-optimized blade geometry to limit erosion zones.

c) Schedule Non-Destructive Testing (NDT) intervals to

predict failure [4-6].

Conclusion

Advancements in MOC especially hybrid and coated materials show promise in extending agitator lifespan in harsh mineral leaching conditions. However, material choice must be coupled with design optimization and operational strategy for best performance outcomes.

References

- Akan AKM (2005) Abrasion failure of lining rubber on agitator blades in the leaching circuit of mineral processing industries. Doctoral dissertation, CQ University.

- Chao’an D (2024) Concentrator design. In: Kuangdi X (Ed.), The ECPH encyclopedia of mining and metallurgy. Springer, Singapore.

- Mittal NK, Sen PK (2003) India's first medium-scale demonstration plant for treating poly-metallic nodules. Minerals Engineering 16(9): 865-868.

- Nazari G, Lamotte J, Ries M, Agin J, Tizon E, et al. (2018) Development of a metallurgical process for Eramet’s Mabounié Nb-REE project. Extraction 2018: Proceedings of the First Global Conference on Extractive Metallurgy, pp. 2353-2366. Springer International Publishing.

- Rao LK, Sriharsha P, Sarkar S, Rao MS (2025) Process intensification in precipitation of uranium from post alkali leach liquor using re-dissolution of sodium diuranate slurry: A short review of laboratory and pilot scale test results. Hydrometallurgy 235: 106491.

- Thamida SK, Sharma VK, Reddy BNK (2024) Carbonation and modeling study for process liquor in batch mode using flue gas in the mining and mineral processing industry. Chemical Papers 78(7): 4189-4199.

© 2025 Vipin Kumar Sharma. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)