- Submissions

Full Text

Research & Development in Material Science

Effect of Solidification Direction on Solidification Structures of Single Crystal Superalloy

Yunxing Zhao1,2, Dexin Ma1,2*, Lv Li2, Yangpi Deng2, Bowen Cheng2 and Fuze Xu2

1Powder Metallurgy Research Institute, Central South University, China

2Wedge Central South Research Institute Co. Ltd., Shenzhen, China

*Corresponding author:Dexin Ma, Powder Metallurgy Research Institute, Central South University, Changsha, Hunan, 410083, China

Submission: July 15, 2024;Published: July 19, 2024

ISSN: 2576-8840 Volume 20 Issue 3

Abstract

In the present work, two solidification experiments of a single crystal superalloy were conducted in opposite directions. During conventional upward directional solidification, severe freckle defects and upward accumulation of eutectic structure occurred in the castings. This is attributed to the segregation of alloying elements and density reversal in the mushy zone liquid, leading to an unstable state and then an upward convection of the liquid. While the solidification direction was changed to downward, the lighter residual liquid is located at the upper end of the mushy zone, forming an absolutely stable state of liquid. In this case, the thermal solutal convection, as well as the caused freckle defects and eutectic accumulation could be completely avoided.

Keywords:Single crystal superalloy; Solidification direction; Freckle; Eutectic accumulation

Opinion

Nickel-based superalloys have excellent comprehensive high-temperature properties and have become the preferred materials for manufacturing key components such as turbine blades of aeroengines and gas turbines [1,2]. The Single Crystal (SC) blades produced by the Directional Solidification (DS) process have achieved optimal performance and have been increasingly widely used [3-5]. In the conventional DS process of superalloy castings, the solidification sequence is from bottom to top. Due to the segregation of alloying elements, the liquid density in the mushy zone becomes higher at the top and lower at the bottom. Under the action of gravity, strong tunnel-like convection forms due to the density difference between the upper and lower liquids, causing remelting and breaking of dendrite arms, ultimately resulting in vertical chain-like distribution of freckle grain defects [6-9]. Earlier studies believed that the occurrence of freckles is mainly affected by the solidification conditions. Low temperature gradients can lead to longer solidification time and wider mushy zones, thereby causing convection and freckle formation in the mushy zone. With the development of high-generation SC superalloys, more and more refractory elements are added, which aggravates the element segregation and density reversal in the mushy zone. How to effectively reduce or even eliminate freckle defects has become a challenge in manufacturing SC blades of high-generation superalloys.

The as-cast structure of single crystal superalloys mainly consists of γ phase dendrites and γ/γ’ eutectic structures. The γ/γ’ eutectic is formed from the residual liquid between γ dendrites during the late stage of solidification. With the development of high-generation SC superalloys, the segregation of alloying elements during solidification becomes more severe, and the fraction of γ/γ’ eutectics in the as-cast structure increase continuously. The coarse eutectic structures in the as-cast microstructure can seriously affect the properties of the castings and must be eliminated through solution heat treatment. In previous studies, researchers mainly focused on the morphology, size and volume fraction of eutectic structures with solidification conditions [10,11]. The nucleation and growth processes of eutectic structures in interdendritic liquids were also studied [12-15]. Recently a phenomenon of upward eutectic accumulation was found in the superalloy castings [16], revealing a significant nonuniform distribution of eutectic structure.

In response to the above problems in the production and solidification research of SC superalloy castings, this work conducted experiments on the preparation of superalloy SC castings using traditional pull-down method and a newly developed pullup method. By changing the direction of directional solidification, a new approach was proposed to solve the problems of freckle defects and eutectic accumulation during DS of superalloys.

In this work, a third generation SC superalloy WZ30 (Table 1) was used for DS experiments. The casting shape is a 5mm thick plate with outward protruding platforms, which is geometrically similar to simplified turbine blade.

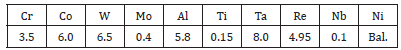

Table 1:Nominal composition of a third-generation SC Nibased superalloy (wt.%).

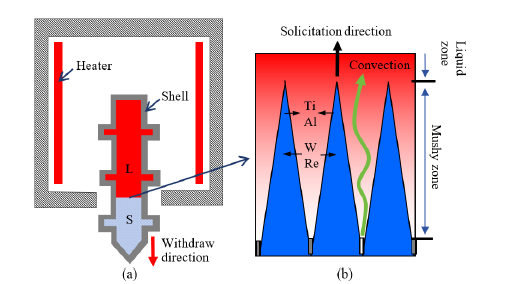

In the first experiment, the conventional Upward Solidification (UWS) method was applied. By pulling down the shell mold filled with overheated alloy melt out of the hot furnace cavity (Figure 1a), the interface between the liquid (L) and solid (S) phases moved from bottom to top, enabling also a upward dendrite growth in the mushy zone (Figure 1b).

Figure 1:Schematic of upward solidification (UWS) process (a) and dendrite growth in mushy zone (b).

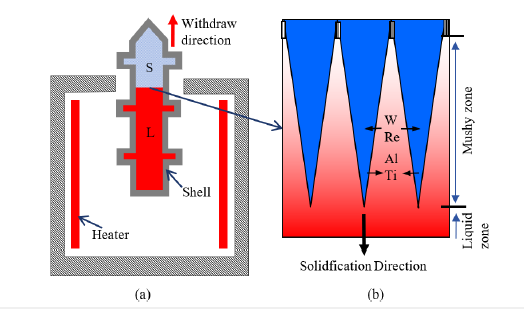

In the second experiment, SC plate castings of the same alloy and the same shape were prepared using a Downward Solidification (DWS) process. By pulling up the shell mold from the furnace top (Figure 2a), a downward dendritic solidification was achieved (Figure 2b). The heater temperature in both experiments was set at 1550 °C, and the pulling rates were both 3.0mm/min. After the solidification process, the plate castings were knocked out of the ceramic mold and sandblasted. The castings were etched to reveal the freckle defects on the surface. The γ/γ’ eutectic was investigated beneath the up- and bottom-surface of the platforms both at as-cast and at heat treated states.

Figure 2:Schematic of downward solidification (DWS) process (a) and dendrite growth in mushy zone (b).

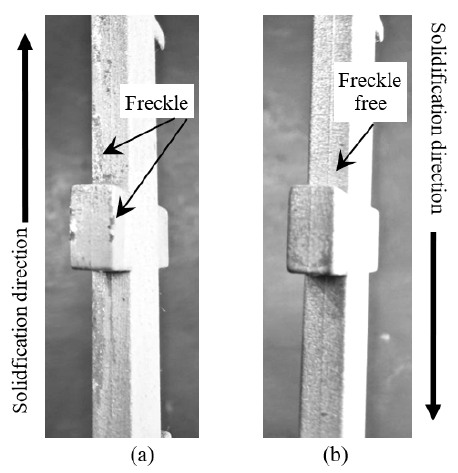

Figure 3a is a photo showing etched surface of plate casting prepared in the conventional UWS (Upward Solidification) process. Severe freckle defects appear on the casting surface as can be seen in the SC castings of superalloys produced under industrial conditions. Because of the enrichment of light elements Al+Ti and the depletion of heavy elements W+Re, the interdendritic liquid density in the mushy zone became significantly lighter than that in the above liquid zone (Figure 1b). Driven by the density inversion under the gravity, upward convection was generated preferentially along the smooth inner wall of the shell mold. As a result, freckle defects were formed as broken dendrite arms distributed vertically in chain-like patterns (Figure 3a).

Figure 3:Surface photos of plate castings prepared in the UWS (a) and DWS (b) process , revealing freckle and freckle free structure, respectively.

Figure 3b shows a casting prepared in the DWS process, revealing a freckle free casting surface. The reason is that when the dendrites grew downward (Figure 2b), the mushy zone and the lighter interdendritic liquid was located above the liquid zone with original density. As a result of a stable state without any convection, the generation of freckle defects can be fundamentally eliminated, as observed in the experiment (Figure 3b). That means the knotty freckle problem in SC superalloy castings could be simply solved by only changing the solidification direction from upward to downward, although the other conditions remain the same.

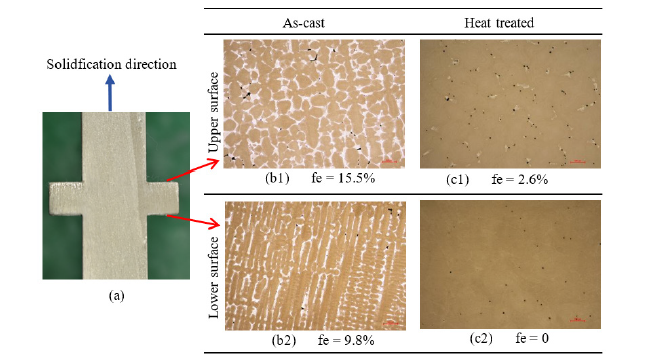

Figure 4a shows a platform of a plate casting solidified in the conventional UWS process. Upon the examination of as-cast microstructure, a large number of white bright γ/γ’-eutectic clusters were observed on the cross-section beneath the upper platform surface (Figure 4(b1)), whose area fraction was measured to be fe = 15.5%. In comparison, the as-cast γ/γ’-eutectic on the lower surface of the same platform (Figure 4(b2)) comprises only a fraction of fe = 9.8%. This observation indicates an upward accumulation of eutectic from bottom to the top of the platform, revealing a nonuniform distribution of the as-cast structure. The reason for this upward eutectic accumulation is the upward convection of the interdendritic liquid enriched with γ′ forming elements Al+Ti+Ta. As the dendrite growth reaches the top, a large number of coarse γ′ phase precipitate in the form of γ/γ′-eutectic, resulting in the phenomenon of eutectic accumulation in the top region of the platform. After the standard solution heat treatment, the eutectics on the lower surface of the platform (Figure 4(c2)) were completely dissolved (fe = 0). In comparison, the residual eutectic fraction on the upper surface (Figure 4(c1)) still reaches fe = 2.6%, exceeding the technical requirement of fe <1.5% for SC superalloy castings.

Figure 4:Platform of a plate casting prepared by UWS method (a), as-cast microstructure (b1, b2) and heat treated one (c1, c2) on the upper and lower platform surfaces respectively.

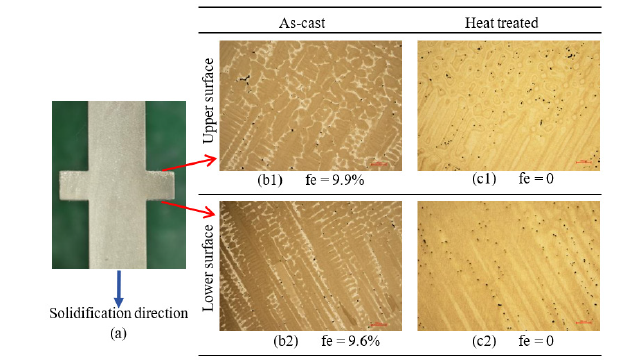

The same plate castings with platforms were also prepared by DWS method (Figure 5a) in which the solidification direction was downward (Figure 2). Figure 5(b1) and (b2) show the ascast microstructures on the cross-sections of the upper and lower surfaces of the platform, respectively. The eutectic fractions measured on the upper and lower platform surfaces are fe = 9.9% and fe = 9.6%, respectively, revealing no significant difference. This is because in the DWS process (Figure 2), the castings were directionally solidified from top to bottom. Due to the segregation of alloying elements, the density of residual liquid in the above mushy zone becomes lower than that of the under liquid zone (Figure 2b), resulting in an absolutely stable state under top-lighter and below-heavier condition. Due to the absence of convection, the liquid enriched with γ’ forming elements Al+Ti+Ta, cannot move long-distance, thus achieving a uniform distribution of eutectic structures. Without accumulation, all eutectics including that on the upper and lower surfaces of the platform, have been completely dissolved during standard solution heat treatment, as shown in Figure 5(c1) and (c2). In this case, the optimal microstructure without any residual eutectic (fe = 0) could be achieved for the SC superalloy castings.

Figure 5:Platform of a plate casting prepared by DWS method (a), as-cast microstructure (b1, b2) and heat treated one (c1, c2) on the upper and lower platform surfaces respectively.

In summary, freckle defects and γ/γ’ eutectic accumulation were observed in the SC superalloy castings manufactured in the conventional UWS experiment. This is attributed to the unstable state of the bottom-lighter and top-heavier liquid between the under mushy zone and the above liquid zone, leading to thermal solutal convection. The consequence was the freckle formation consisting of broken dendrite arms and the upward enrichment of γ’ forming elements, resulting finally in the γ/γ’ eutectic accumulation. In comparison, the freckle defects and eutectic accumulation phenomenon were completely eliminated by the newly developed DWS method. This is because during the downward solidification process, the mushy zone with reduced liquid density was above the liquid zone, forming an absolutely stable state. In this case, the gravitational effect was transformed from a destabilizing factor to a stabilizing one. Due to the absence of convection, the freckle defects and eutectic accumulation could be completely avoided.

Acknowledgement

This research was funded by the Shenzhen Science and Technology Program (JSGG20220831092800001).

References

- Donachie MJ, Donachie SJ (2002) Superalloys: a technical guide. ASM international.

- Reed RC (2008) The superalloys: fundamentals and applications. Cambridge University Press, UK.

- Versnyder FI, Shank ME (1970) The development of columnar grain and single crystal high temperature materials through directional solidification. Materials Science and Engineering 6(4): 213-47.

- Pratt DC (1986) Industrial casting of superalloys. Materials Science and Technology 2(5): 426-35.

- Quested PN, Osgerby S (1986) Mechanical properties of conventionally cast, directionally solidified, and single-crystal superalloys. Materials Science and Technology 2(5): 461-475.

- Giamei AF, Kear B (1970) On the nature of freckles in nickel base superalloys. Metallurgical and Materials Transactions B 1(8): 2185-2192.

- Copley SM, Giamei AF, Johnsons M (1970) The origin of freckles in unidirectionally solidified castings. Metallurgical Transactions 1: 2193-2204.

- Auburtin P, Wang T, Cockcroft SL (2000) Freckle formation and criterion in superalloy casting. Metallurgical and Materials Transactions B 31(4): 801-811.

- Tin S, Pollock TM (2004) Predicting freckle formation in single crystal Ni-base superalloys. Journal of Materials Science 39(24): 7199-7205.

- Seo S, Lee J, Yoo Y (2011) A comparative study of the γ/γ’ eutectic evolution during the solidification of Ni-base superalloys. Metallurgical and Materials Transactions A 42: 3150-3159.

- Souza ND, Dong HB, Ardakani MG (2005) Solidification path in the Ni-base superalloy IN713LC-quantitative correlation of last stage solidification. Scripta Materialia 53(6): 729-733.

- Warnken N, Ma DX, Mathes M (2005) Investigation of eutectic island formation in SX superalloys. Materials Science and Engineering A 413-414: 267-271.

- Souza ND, Dong HB (2007) Solidification path in third-generation Ni-based superalloys with an emphasis on last stage solidification. Scripta Materialia 56(1): 41-44.

- Ma DX, Wang F, Weng XH (2017) Influence of MC carbides on the formation of γ/γ′ eutectics in single crystal superalloy CM247LC. Acta Metallurgica Sinica 53(12): 1603-1610.

- Ma DX, Wang F (2019) Randomly orientated eutectic grains in single crystal castings of superalloys. Foundry 68 (12): 1342-1349.

- Ma DX, Zhao YX (2023) Experimental observation on the upward accumulation of eutectic in superalloy castings. Research & Development in Material Science 18(4) 2118-221.

© 2024 Dexin Ma. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)