- Submissions

Full Text

Research & Development in Material Science

Wood Drying Industry in Nigeria: Present Status, Challenges and Prospects of Solar Kiln Drying Technology

Amoo-Onidundu ON* and Areo OS

Department of Forest Products Development and Utilisation, Forestry Research Institute of Nigeria, Nigeria

*Corresponding author:Amoo-Onidundu ON, Department of Forest Products Development and Utilisation, Forestry Research Institute of Nigeria, PMB 5054, Jericho Hill Estate, Ibadan, Nigeria

Submission: December 06, 2023;Published: December 20, 2023

ISSN: 2576-8840 Volume 19 Issue 5

Abstract

Drying of wood is imperative towards improving its utilization potentials and service performance. However, it is no gainsaying that the wood drying industry in Nigeria is an obscure sector of the wood products manufacturing industries. Numerous timber species (indigenous and exotic) are available in Nigeria but utilization of properly seasoned timber for structural and construction application is at its lowest ebb. Out of few wood drying facilities available in Nigeria, a small percentage are operating to their expected capacity. This may be attributed to epileptic power supply, cost of operating and maintaining wood drying facilities, high energy consumption, and poor attitude of wood stockiest (or end users) to wood seasoning. Several local wood products manufacturers (small and medium scale) dry their timber by end racking them under the sun, or air drying. These two timber seasoning procedures undermine wood drying quality and increase susceptibility of wood-based products to deformation, biodeterioration, delamination, disjointing and poor service performance. Apart from the aforementioned timber drying procedures, wood products manufacturers in Nigeria are resorting to production of wood-based items from medium density fibre board (MDF). However, utilization of MDF is undermining the relevance of solid wood in the structural and construction industry. This article focuses on present status, challenges and prospects of Nigerian wood drying industry as it affects timber utilization for wood products manufacturing. Solar kiln technology was recommended as a viable method of addressing the challenges and improving the present status of Nigerian wood-based industry. Solar energy is relatively cheap, sustainable, ecofriendly, and involves the use of a renewable energy resource which is potentially cost effective. Due to its availability, affordability and applicability, harnessing solar kiln technology in wood drying industry will enhance the relevance of solid timber to wood products industry in Nigeria.

Introduction

Timber is a versatile raw material provided by nature and derived from natural or plantation forest [1]. Utilization of timber for various applications has outlived many years, from time immemorial. Wooden products or wood-based items are major end products of timber which are commonly used in homes, recreation centres, markets, churches, mosques, offices, and other social gathering both locally and globally. Wood products used for domestic and industrial applications include desk, table, flower vase, kitchen cabinet, wardrobe, chair, and stool [2,3]. Although wood is known to be among the common raw material for structural and construction materials that ever existed, its utilization is hinged on certain processes which makes it more reliable in terms of service performance. Among the vital timber processing procedures which enhance the utilization potentials, durability and service performance of wood products are timber drying [4].

Drying of timber has various importance in relation to its integrity has an engineering material. Wood seasoning improves the dimensional stability of timber, increases the strength properties, eases transportation and handling of timber, enhances preservation and adhesive application. More so, adequately seasoned timber is less prone to activities of bio deteriorating agents [5,6]. Despite the significance of wood drying to its utilization, its emphases in Nigerian timber processing and wood products manufacturing industry are unimpressive. There is paucity of documented information on commercial timber drying in Nigeria. Over the years, as a result of inability to manage the production demands, some wood drying plants became moribund [3]. Up till recent times, wood drying plants are few and there seems to be no focus on ensuring their revitalization or resuscitation in Nigeria. Due to government policies which do not favour the forestry and wood industries in Nigeria, a lot of challenges is limiting the survival of the wood drying industries in Nigeria [4]. Although several wood-based industries exist in Nigeria, the aspect of ensuring the production of high quality wood products through establishment of a well-organized timber drying industry is missing. Consequently, the reputation of timber has a foremost raw material for structural and construction application is dwindling to its lowest ebb [2,3,7].

Present status of wood drying industry in Nigeria

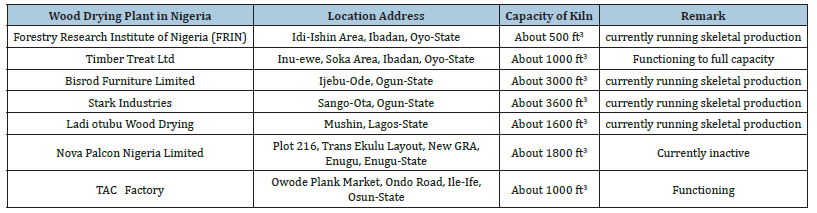

According to Ogunwusi [3] timber processing and wood products manufacturing industries are among the major industrial sectors in Nigeria. However, information relating to conventional timber drying plants in Nigeria has not been adequately documented [4,7]. Field survey (Authors, 2023) revealed that only few wood drying facilities are available in Nigeria at the moment- with just a meagre percentage operating up to expected capacity. Summarized information regarding timber drying plants discovered to be presently functional and productive in Nigeria are presented in Table 1.

Table 1:Timber drying plants discovered to be presently functional and productive in Nigeria.

Source: Authors’ survey, 2023

Challenges of wood drying industry in Nigeria

High energy consumption and capital-intensive nature of wood drying procedures are among the major drawbacks of wood drying industry in Nigeria. Operation of conventional wood drying kilns involves utilization of hydroelectric power or power generating sets (which entails combustion of fossil fuel such as petroleum products). According to Ohagwu [2] and Ashkin [7] epileptic supply of power by electricity distribution companies in Nigeria severely retards operations of conventional dryers; thereby endangering productive capacities of the wood drying industry. Combustion of fossil fuel in wood drying industries is among the major sources of increasing the emission of greenhouse gases (GHGs) in timber processing industries [8]. Hence, it is a potential contributor to global warming and climate change [9]. Raimi et al. [8] recognized atmospheric pollution as one of the major challenges bedeviling Nigeria-based wood processing industries (timber drying plants, inclusive).

Apart from the aforementioned challenges, incessant hike in petroleum products (Premium Motor Spirit, PMS and automotive gas oil, Diesel) has untold negative influences on timber drying plants. According to Eregha et al. [10] and NBS [11], the price (per litre) of PMS rose from ₦97 to ₦617 while AGO rose from ₦115 to 844.28 in 2012 and 2023, respectively. This has considerably increased the cost of seasoning timber [12,13]. Recent findings by author revealed that average price for drying a piece of sawn timber in Nigeria ranges from 800 to ₦1000 and from 1,500 to ₦1,800 for 1’’by 12’’ by 12’ and 2’’ by 12’’ by `` 12’ boards, respectively. Due to relatively high cost of drying timber, the selling price of certain finished wood products becomes seemingly exorbitant and unaffordable. Sometimes, this negatively influences the purchasing decision of wood products consumers. In order to encourage patronage, some wood products manufacturers utilize unseasoned, or improperly seasoned timber for their production [14-16].

Figure 1:End racking of timber for drying.

Other common phenomenon among wood products manufacturers in Nigeria include end racking (Figure 1) of boards, use of outdated timber drying facilities or machines (Figure 2). Unfortunately, finished wood products manufactured under aforementioned procedures become highly prone to distortion, deformation and delamination in service (Figures 3-6). Apart from utilizing unseasoned or improperly seasoned timber for production, indiscriminate use of MDF-without considering its suitability for the desired/intended end use is also a commonplace. This is among practices affecting the reputation of sawn timber for structural and construction purposes [7].

Figure 2:Outdated conventional kiln water boiler.

Figure 3:Warped panel door.

Figure 4:Warped door post.

Figure 5:Warped stool top.

Figure 6:Delaminated table top.

Solar energy in wood drying industry

Solar energy has been discovered as one of the most viable natural and renewable energy resource which has not been adequately harnessed in the timber drying industry. Energy from the sun is readily available, inexhaustible and renewable. Solar kiln drying technology involves utilization of trapped solar radiation for drying [17]. Reports revealed that several designs of solar kiln have be fabricated for timber drying with outstanding results which compared favourably with conventional kiln dryers [18-20].

Solar kiln drying of timber as a veritable option in Nigeria

According to Chris Newsom [21] apart from hydroelectric power, solar energy is the most feasible and practicable renewable energy source in Nigeria when compared to wind, ocean and goethermal energy. Studies carried out in the tropics and subtropics confirmed that solar energy has great potentials for drying technologies [22,23]. Nigeria is located on the equator and receives abundant solar radiation which makes it stands at vantage point regarding possibilities for harnessing opportunities in solar kiln drying technologies [24]. According to Ashkin [7], locally operated solar kilns have the potential of increasing the supply of seasoned lumber, lowering its cost and making wood framing and structural applications feasible in Nigeria, substituting for more expensive conventional kiln drying method. Reports revealed that drying qualities of timber dried in solar kilns compare favourably with that of conventional kiln dryers. According to Pirasteh et al. [17] many benefits could be exploited from solar energy for drying applications. Conventional kiln drying systems involve fossil fuels combustion for their operation while solar dryers take advantage of sun irradiation for drying and dehydration processes [25] such as in wood drying industries [26,27].

Nigeria has a great potential for harnessing the utilization of solar energy in the wood drying industries. Solar energy enables the industries sectors to modify their energy requirement, improve their energy stability, and increase energy sustainability, which lead to improvement in the system efficiency. Significant investment in solar energy technology is a viable alternative in reducing challenges in conventional kiln drying of timber [2,3,7]. Reports revealed that solar dryers produce timber of high drying quality and enhanced efficient environmental condition for timber drying [28,29]. According to Ashkin [7]; Owoyemi et al. [30] and Amoo-Onidundu et al. [29], several research into drying of timber in Nigeria has proven that solar kiln drying method is a relevant and viable timber drying technology with immense potentials of improving the quality of output in wood processing industries and other related wood products manufacturing industries. Ugwu et al. [31] reported final moisture content (FMC) of 12.9% at an average drying rate (DR) of 0.18 while Amoo-Onidundu et al. [29] reported FMC of 10.40% at an average DR of 11.12%/day in solar kiln-drying Prosopis africana. and Gmelina arborea wood, respectively. Based on the FMCs reported by the aforementioned researchers, there is the possibility of solar kiln drying wood specimens to as low as 10.40%. This is an indication that internal environmental condition of solar kiln favours wood seasoning and can enhance timber drying to safe MC levels (10-12%MC) at which wood becomes less prone to dimensional reduction or deformation while in service [32,33].

Conclusion

Having considered present status, challenges and prospects of solar kiln drying technology as a pertinent concept in addressing the state of wood drying industry in Nigeria, this review has been put up as an awareness for sensitization for all stakeholders in the wood processing and wood products manufacturing industries. The relevance of solar kiln drying technology was emphasized with respect to its availability, accessibility and practicability in Nigeria.

The possibility that solar kiln drying of timber may be totally independent on grid-connected electricity makes it a viable means of addressing limitation such as epileptic power supply emanating from electricity (power) Distribution Company in Nigeria. Furthermore, incessant hike in prices of petroleum products which causes lethargic production capacities in Nigerian timber processing industries, especially, where power generating sets are involved for wood drying processes will be reduced with solar kiln technology. The cost of production and prices of finished wood products will relatively be affordable since solar kilns can be locally fabricated at relatively affordable cost. The final moisture content and drying rate of the wood species mentioned revealed that solar kiln chambers have potentials of drying wood to safe moisture content levels.

Recommendation

As recommendations for this review, the following are to be

observed:

1) Adequate awareness on the relevance of wood drying to its

utilization should be projected to all stakeholders in the wood

industry.

2) All concerned should embrace and adopt technologies that

will improve the introduction of a well-organised solar kiln

systems for timber drying on a commercial scale.

3) Government should ensure improvement in supply of power

(national grid electricity) to alleviate the challenges in wood

processing industry.

4) Government should enact policies that will encourage

productive operations in forestry and wood products

manufacturing industry.

References

- Bauer K (2003) Development and optimization of a low-temperature drying schedule for eucalyptus grandis (hill) ex maiden in a solar-assisted timber dryer. Dissertation to obtain the degree of Doctor of Agricultural Sciences (Dr.sc.agr.), submitted to the Faculty of Agricultural Sciences, pp. 1-175.

- Ohagwu CJ, Ugwuishiwu BO (2011) Status of wood processing and storage in Nigeria. Nigerian Journal of Technology 30(2): 94-104.

- Ogunwusi AA (2012) The forest products industry in Nigeria. An International Multidisciplinary Journal, Ethiopia 6(4): 191-205.

- Ibirogba F (2021) Locally made wood drying kilns to mitigate deforestation. The Guardian, pp. 1-20.

- Moya R, Tenorio C, Meyer I (2012) Influence of wood anatomy on moisture content, shrinkage and during defects in Vochysia guatemalensis Donn Sm. Sci For Piracicaba 40(94): 249-258.

- Korkut Süleyman, Nusret AS, Ümit Büyüksarı (2018) Comparison of two kiln-drying schedules for turkish hazel (corylus colurna) lumber of 5-cm thickness. Maderas. ciencia y tecnología 20(1): 129-138.

- Ashkin R (2013) Innovative building technologies- The social housing angle. Housing Africa conference, Abuja, Nigeria, pp. 1-6.

- Raimi MO, Adio ZO, Odipe OE, Timothy KS, Ajayi BS, et al. (2020) Impact of sawmill industry on ambient air quality: A Case study of Ilorin metropolis, kwara state, Nigeria. Energy and Earth Science 3: 1-25.

- Orru K, Tiittanen P, Ung-Lanki S, Orru H, Lanki T (2022) Perception of Risks from Wood Combustion and Traffic Induced Air Pollution: Evidence from Northern Europe. Sustainability 4: 9660.

- Eregha B, Mesagan E, Ayoola O (2015) Petroleum products prices and inflationary dynamics in Nigeria. Munich Personal RePEc Archive, pp. 1-16.

- National Bureau of Statistics-NBS (2023). Automotive Gas Oil (Diesel). Price Watch, pp. 1-9

- Sejdiu R, Bejtja A, Bajraktari A (2015) Calculation of cost during timber kiln drying in Kosovo. International Journal of Ecosystems and Ecology Sciences (IJEES) 5 (1): 115-118.

- Egbewole ZT, Rotowa OJ (2018) Hike in pump price: Major doom to Nigerian forest. Journal of Energy, Environmental & Chemical Engineering 3(2): 19-26.

- Rani P (2014) Factors influencing consumer behavior. International Journal of Current Resources Academic Review 2(9): 52-61.

- Dadzie PK, Afrifah KA, Inkum PB (2015) Some market trends of wood products exports in ghana and their implications for stakeholders: The case of furniture and kiln-dried lumber. International Journal of Business and Economics Research 4(6): 307-314.

- Parajuli R, Tanger Sh, Henderson J (2018) Timber prices: supply, demand and extenuating circumstances. Forest Landowner, pp. 35-38.

- Pirasteh G, Saidur R, Rahman SMA, Rahim NA (2014) A review on development of solar drying applications. Renewable and Sustainable Energy Reviews 31: 133-148.

- Haque MN, Langrish TAG (2006) Performance of an industrial solar kiln for drying timber. Sustainable Energies/Technology 15: 1-15.

- Ali MR, Alam MJ, Rokeya UK, Paul SP (2013) Determination of seasoning schedule of rain tree (Samanea saman) sawn-wood with different thickness using solar kiln. Scholarly Journal of Agricultural Science 3(7): 289-293.

- Pedro LL, Cláudio G, Francisco J, Raquel M, Ricardo JK, et al. (2015) Drying of wood from Mimosa scabrella, Eucalyptus dunnii and Tectona grandis in solar kiln, in South Brazil. Australian Journal of Basic and Applied Sciences 9(5): 445-453.

- Chris Newsom (2013) Renewable energy Potential in Nigeria. The Sun Gas, pp. 1-33.

- Onyinge GO, Oduor AO, Othieno HE (2015) The design and testing of an indirect cabinet solar dryer for thin layer drying of Rastrineobola argentea Fish under the climatic conditions of Maseno, Kenya. African Journal of Food Science 9(1): 1-16.

- Bergel R, Víglaský J, Ježo M (2015) Solar energy exploitation at sawn wood drying process within Slovakia. Wood research 60(6): 963-972.

- Adeola SO, Aro TO, Akinpelu JA (2017) Estimation of Global Solar Radiation in Ibadan, Nigeria using Angstrom -Prescott and Glover - Mcculloch‟s Model. International Journal on Recent and Innovation Trends in Computing and Communication 5(11): 62-67.

- Mekhilef S, Saidur R, Safaria A (2011) A review on solar energy use in industries. Renewable and Sustainable Energy Reviews 15: 1777-1790.

- Bekkioui N, Hakam A, Zoulalian A, Sesbou A, El Kortbi M (2011) Solar drying of Pine Lumber: Verification of a mathematical model. Maderas Ciencia y tecnología 13(1): 29-40.

- Simo-Tagne M, Zoulalian A, Remond R, Rogaume Y, Bonoma B (2017) Modeling and simulation of an industrial indirect solar dryer for Iroko Wood (Chlorophora excelsa) in a tropical environment. Maderas Ciencia y tecnología 19(1): 95-112.

- Bond BH, Espinoza O (2016) A decade of improved lumber drying technology. Curr Forestry Rep 2: 106-118.

- Amoo-Onidundu ON, Ajala Areo OS, Olayiwola YB, Adejoba AL, Ayanniyi D (2023) Influence of weather variability on drying characteristics of air-and solar kiln-seasoned Gmelina arborea Wood.

- Owoyemi JM, Oyebamiji WO, Aladejana JT (2015) Drying characteristics of three selected Nigerian indigenous wood species using solar kiln dryer and air drying shed. American Journal of Science and Technology 2(4): 176-182.

- Ugwu SN, Ugwuishiwu BO, Ekechukwu OV, Njokwu H (2015) Design, Construction, and evaluation of a mixed mode solar kiln with black-painted pebble bed for timber seasoning in a tropical setting. Renewable and Sustainable Energy Reviews 41: 1404-1412.

- EN 14298 (2004) Sawn timber- Assessment of drying quality.

- Eliasson F (2006) Quality hand book joinery kiln drying. Master’s Thesis. Lulea University of Technology. Wood Engineering, Department of Skelleftea Campus, Division of wood Science and Technology, Sweden, pp. 1-66.

© 2023 Amoo-Onidundu ON. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)