- Submissions

Full Text

Research & Development in Material Science

Performance of Corncob Ash and Anthill Soil in Ternary Concrete Mixes

John Kamau1, Ash Ahmed1* and Joseph Kangwa2

1Civil Engineering Group, Leeds Beckett University, UK

2School of the Built Environment and Architecture, London South Bank University, UK

*Corresponding author: Ash Ahmed, Civil Engineering Group, Leeds Beckett University, UK

Submission: December 12, 2017; Published: March 23, 2018

Volume 4 Issue 4 March 2018

Abstract

This work investigated the performance of ternary Corncob Ash (CCA) and Anthill Soil (AHS) in concrete mixes. CCA and AHS were replaced in concrete using equal proportions at replacements of 0%, 5%, 7.5%, 10%, 15%, 20%, 25%, and 30%. Investigations covered workability, density, compressive and tensile strengths and gain in strength over time of concrete, as these were found to be the major characteristics of Supplementary Cementitious Materials (SCMs). Results showed that the two materials could be used with an advantage over individual binary concretes in these areas.

Keywords: Corncob ash; Anthill soil; Ternary concrete

Introduction

It is well documented in literature that cement is a major contributor to global anthropogenic CO2 [1,2]. Among the constituents of concrete, it is the main and most important ingredient as it acts as the binder, and its global consumption only seconds that of water [2]. It has been claimed that the production of cement accounts for up to 7% of the total global carbon dioxide (CO2) emissions, which are considerably high compared with 2% that are attributed to aviation [1,3]. It has also been argued in literature that the production of one tonne of cement accounts to approximately an equivalent tonne of CO2 [4]. It has been further posited that the cement production processes make it an energyintensive material, only seconding steel and aluminium [4]. A further argument has been raised that cement is the most expensive constituent of concrete, its prices bearing an astronomical increase annually, and is therefore a constraint in the delivery of affordable housing and other essential development [5]. However, energy and cost efficiency can be achieved through the use of Supplementary Cementitious Materials (SCMs) which are sourced locally, require less process heating and emit lower levels of CO2 [5,6]. Such materials include Pulverised Fuel Ash (PFA), Ground Granulated Blast Furnace Slag (GGBS), Rice Husk Ash (RHA) and Corncob Ash (CCA) among others [7]. As most of the SCMs are either industrial or agricultural wastes, their use in concrete not only mitigates on environmental nuisance that otherwise results from their dumping in landfill, but also helps to reduce the cost of concrete, while at the same time improving on the properties of both fresh and hardened concrete [7].

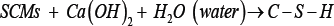

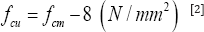

SCMs are defined as materials that are used in concrete alongside cement, and can exhibit pozzolanic properties due to high contents of silicone dioxide (SiO2) and by not gaining strength when they are mixed with water, for example Silica Fume (SF) and class F Pulverised Fuel Ash (PFA), cementitious properties due to a high calcium oxide (CaO) content and by gaining strength when they are mixed with water, for example Ground Granulated Blast Furnace Slag (GGBS) or both pozzolanic and cementitious properties, with a CaO content of between 10% and 30% by mass, for example class C PFA [8]. For pozzolans, the American Society for Testing and Materials (2012) requires a 70% by mass, the combination of Silicon dioxide (SiO2), aluminium oxide (Al2O3) and iron oxide (Fe2O3).

SCMs do not contain enough calcium to form cementitious materials, and need to combine with calcium hydroxide [Ca(OH)2], the hydration product of cement, to form further strength giving Calcium Silicate Hydrate (C-S-H) [7]. As a result, SCMs have been characterised with a delayed strength development, as they only act as fillers before Ca(OH)2 becomes available, but have been reported to gain strengths that are close to or above those of 100% cement at a latter age [7].

The reaction between CaO and SiO2, also referred to as the pozzolanic reaction is shown in (1) [7].

The C-S-H from (1) is less dense and less permeable, and consequently enhances the durability of concrete [9]. SCMs have been reported to improve the mechanical properties of concrete and workability [1,7]. Corncob ash was defined as the remnant of incinerated corn cobs, the hard central core of corn which bears the grain [7]. The suitability of CCA as a SCM was reported in the publication of Kamau et al. [10]. Although no direct comparison of CO2 generation between CCA and cement has been carried out, the authors believe that the less process heating that is associated with the preparation of CCA compared with that of the production of cement is an indication that using CCA to replace cement could mitigate on CO2 emissions to the atmosphere.

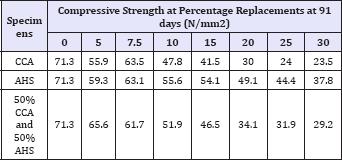

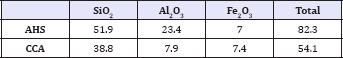

Table 1: Chemical composition of CCA and AHS Kamau et al. [10,12].

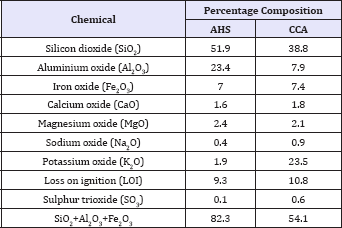

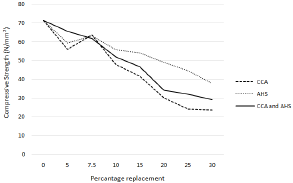

Table 2: Mean compressive strengths of CCA and AHS-replaced specimens at 91 days of curing Kamau et al. [10,12].

Anthill soils on the other hand are made up of very cohesive soil grains that are coated with sticky rapidly hardening secretions from the recta of ants [11], and their suitability as SCMs was investigated by the unpublished work of Kamau et al. [12]. Table 1 & 2 show the chemical composition and the compressive strengths achieved for CCA and AHS respectively. From the chemical analysis, CCA did not satisfy any of the requirements for SCMs, even though a requirement by the British Standards Institution [8] of at least 25% SiO2 was satisfied. However, chemical analysis by Adesanya & Raheem [13] showed that CCA had achieved the requirement of the American Society for Testing and Materials [14] for pozzolans, which is a total of 70% by mass, the combination of SiO2, Al2O3 and iron Fe2O3. Kamau et al. [10] attributed the inferiority in chemical composition of their CCA sample to the procedure that was adopted in incinerating the corncobs. Grinding corncobs to 4mm or less before incineration like Adesanya & Raheem [13] had done, and/or incinerating them under controlled conditions could have improved the chemical composition of the resultant CCA [7].

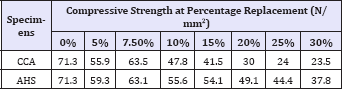

AHS, on the other hand achieved the chemical requirements of the American Society for Testing and Materials [14] for pozzolans, which is a total of 70% by mass, the combination of SiO2, Al1O3 and iron Fe2O3. The mean compressive strengths [when converted to characteristic strengths using (2), after the European Ready Mixed Concrete Organisation [15], of CCA-replaced specimens for replacements of up to 15% by Kamau et al. [10] were among classes that are listed by the British Standards Institution [16] as being durable and suitable for structural applications, whereas AHS-replaced specimens achieved these acceptable compressive strengths for all replacements tested by Kamau et al. [12]. SCM concretes are normally allowed to cure beyond 28 days, since as was mentioned earlier, the SiO2 that is present in them has to wait for the hydration products of cement, such as calcium hydroxide, with which they react to form further strength giving compounds such as Calcium Silicate Hydrate (C-S-H) as is shown in (3).

Where fcu is characteristic compressive strength and fcm is mean compressive strength

SCMs + Ca(OH)2 + H2O (water)→Calcium-Silicate-Hydrate (C-S-H) [3]

Research Significance

SCMs can be used either independently or combined with others to form either binary or ternary mixes, in which case they have been reported to complement each other in areas where they fall short [7,17]. Sathawane et al. [18] and Nehdi et al. [19] reported a complementary effect of SCMs on workability and strength.

Also, the availability of AHS may be limited, and as such using it alongside CCA could be a viable way of utilising its pozzolanic properties in concrete. Moreover, no work was found on the use of combined CCA and AHS in concrete.

Methods

Apart from the chemical composition, tests on workability, density, compressive and tensile strengths were also carried out to investigate the performance of CCA and AHS in Ternary Concrete Mixes. Gain in strength over time was also investigated. These, as defined by Bapat [7] and discussed above, are major characteristics of SCMs.

Combined ternary 50% CCA and 50% AHS were introduced in concrete alongside cement at the point of need at steps of 0%, 5%, 7.5%, 10%, 15%, 20%, 25%, and 30%. Performances were referenced to the 0% replacement, which is also referred to as the control in this work [13]. Performances of the ternary mix were also compared with those of the binary mixes from Kamau et al. [10,12].

The concrete mixing process conformed to the American Society for Testing and Materials [20], at a mix proportion of 1: 2: 3. The concrete mixer was run for a total of eight minutes, with a three- minute rest in between the mixing, after cement, aggregates and water at a Water Cement Ratio (WCR) of 0.5 had been introduced. WCR was informed by Abram's law, which states that the strength of a concrete mix is determined by the WCR, with lower WCRs spelling higher strengths and vice-versa [21]. For a good balance of workability and strength, Singh et al. [22] reported 0.5 as the minimum WCR to make cement mortar workable.

It is also possible to target the slump of a mix based on the weight of cement and total aggregate proportions from the specifications in the British Standards Institution [23] and free water specifications in the British Standards Institution [24]. However, this method was not used as the study aimed to test the effect of CCA and AHS on the workability of concrete.

The process used to test for workability is detailed in the British Standards Institution [25]. The apparatus were the slump cone mould, tamping rod and a steel floater. The slump cone mould was filled with concrete in three layers. Each layer was compacted using 25 uniform vertical strokes of the tamping rod, evenly distributed across each surface. The steel floater was used to level the top of the mould, after which the mould was carefully removed. Workability was determined by measuring the difference between the highest point of the slumped concrete and the top of the mould.

Cubes for compressive strength were made using cube moulds with internal measurements of 100mmx100mmx100mm, whereas cylinder moulds used to make cylindrical specimens for splitting tensile strengths were of internal diameter 150mm and 300mm in height. These measurements conformed to the dimensional guidelines of British Standards Institution [26].

Conforming to the British Standards Institution [27], cube and cylinder moulds were sprayed with a release agent. The cubes were then filled with concrete and secured firmly on to a mechanical vibrating table for compaction. Cylinders were filled using three uniform layers, and compaction was with 25 vertical stokes of the tamping rod distributed evenly across each layer. The specimens were stripped from the moulds after 24 hours, and marked before being submerged into a curing water tank at temperatures of 200C and pH of 7.

The total curing time was 91 days, since as was discussed earlier, pozzolanic reactions are characterised by delayed strength, as they cannot take place without Ca(OH)2, which is the hydration product of cement in the early age [7].

To work out density, (4) was used after the cubes were weighed in both air and water [28].

D= (Weight in air)/(Weight in air-weight in water) [4]

Compressive strength tests conformed to British Standards Institution [29]. The cubes were applied perpendicularly in the direction of the casting. An initial load of 0.6N/mm2.s (Newtons per square millimetres per second) was applied on cubes after they had been placed perpendicularly in the direction of the casting. After this initial application of load, further constant load was applied at a rate of ±10% until no further load could be sustained. Compressive tests were carried out at 7,28,56, and 91 days. Compressive test results were expressed in Newtons per square millimetres (N/ mm2). To ensure repeatability, results were taken as an average of three tests [29].

Tensile strength tests conformed to the British Standards Institution [30]. The specimens were centred in the machine and the packing strips were positioned with the upper and lower platens parallel to each other. Initial load was applied at a constant rate of stress of 0.04N/mm2.s, followed by further constant load at a rate of ±10% until no further load could be sustained. The splitting tensile strength was calculated using (5) to the British Standards Institution [30].

fct=( 2 x F)/(πx L x d) [5]

Where fct is the splitting tensile strength (N/mm2), F is the maximum load (N), L is the length of the line of contact of the specimen (mm) and d is the designated cross-sectional diameter (mm).

Results and Discussion

Workability

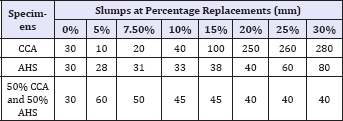

Table 3: Slumps of binary and ternary CCA and AHS-replaced mixes (mm).

Figure 1: Slumps of binary and ternary CCA and AHS- replaced mixes against percentage replacements (mm).

Table 3 and Figure 1 show the workability of binary and ternary CCA and AHS-replaced mixes. The slumps of the ternary CCA and AHS decreased with further replacement, and were higher than both the binary mixes of CCA and AHS at replacements of below 10%, but at higher replacements, they reduced below those of the individual binary mixes. CCA seemed to improve the workability of AHS at the 10% and 15% replacements.

The good workability above that of the control mix can be attributed to the lower densities of SCMs, which result in an increased volume of mixes, prevent block formation of cement particles, and by the filler effect reduce friction between particles, thereby facilitating a better flow of concrete [7,31]. The good workability above that of the control mix spells the possibility of CCA and AHS being used together in ternary mixes with an advantage of optimising on strength in line with Abram's law of WCR [21].

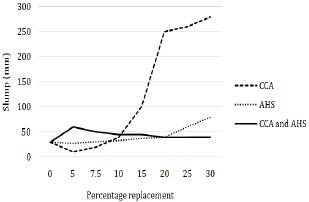

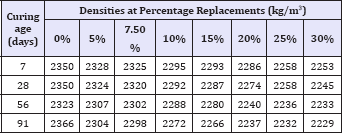

Densities

Table 4: Densities of ternary CCA and AHS-replaced specimens (kg/m3).

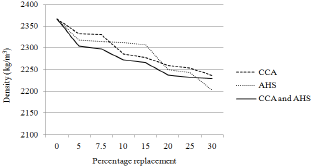

Figure 2: Densities of ternary CCA and AHS-replaced specimens against curing age (kg/m3).

Table 4 and Figure 2 show the densities of ternary 50% CCA and 50% AHS replaced specimens over 91 days of curing. Consistent with literature that as a result of a lower particle specific gravity compared with cement, SCMs provide an advantage by increasing the volume of mixes and reducing the mass of concrete, densities of CCA and AHS specimens were below those of the control [7]. Densities decreased with curing time and with further replacement, also consistent with literature that density decreases at latter ages due to the consumption of Ca(OH)2 during secondary hydration to form C-S-H, which is less dense than the cement components from which it is generated [7,32].

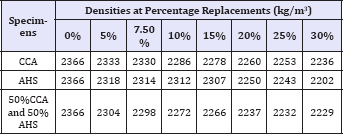

Table 5: Densities of binary and ternary CCA and AHS-replaced specimens at 91 days (kg/m3).

Figure 3: Densities of binary and ternary CCA and AHS-replaced specimens at 91 days against percentage replacements (kg/m3).

Table 5 and Figure 3 show the densities of the binary and ternary CCA and AHS specimens at 91 days, whereby the densities of the ternary specimens are seen to fall below those of individual binary specimens. The reduction in density with time and with further replacement has been reported as being a characteristic of SCMs due to the consumption of Ca(OH)2 during secondary hydration to form the less dense C-S-H [7,32]. These results indicate a possibility of using ternary CCA and AHS in concrete with an advantage of increasing the volume of concrete per unit mass over binary CCA and AHS.

Compressive strength

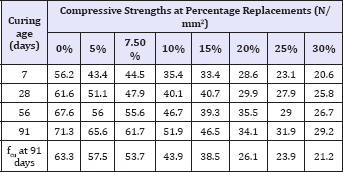

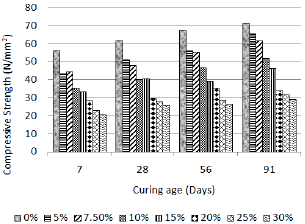

Table 6: Compressive strength of ternary CCA and AHS-replaced specimens over 91 days of curing (N/mm2).

Figure 4: Mean compressive strengths of ternary CCA and AHS-replaced specimens over 91 days of curing (N/mm2).

Table 6 and Figure 4 show the mean compressive strengths of ternary 50% CCA and 50% AHS- specimens over 91 days of curing. Compressive strengths at replacements of up to 20%, when converted to characteristic strengths (f) using (2) achieved the strength of class C20/25, which is among the strength classes that are listed by the British Standards Institution [16] as being durable and suitable for structural applications.

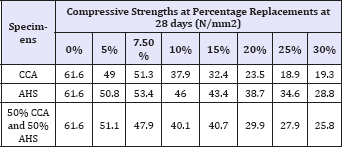

Table 7: Mean compressive strengths of binary and ternary CCA and AHS-replaced specimens at 28 days (N/mm2).

Table 8: Mean compressive strengths of binary and ternary CCA and AHS-replaced specimens at 91 days (N/mm2).

Figure 5: Mean compressive strengths of binary and ternary CCA and AHS-replaced specimens at 28 days against percentage replacements (N/mm2).

Table 7 & 8 and Figure 5 & 6 shows the compressive strengths of the binary and ternary specimens of CCA and AHS-replaced specimens at 28 and 91 days respectively. The compressive strengths achieved by the ternary specimens were higher than those of the binary specimens of CCA but lower than the AHS specimens at both 28 and 91 days. Table 9 shows that the chemical composition (SiO2+Al2O3+Fe2O3) of AHS, from Table 1 exceeded the 70% recommended by the American Society for Testing and Materials [14], whereas it was below this value for CCA. It can be concluded from this information that AHS might have improved the properties of CCA in the ternary mixes, possibly due to its higher pozzolanic activity compared with that of CCA, making it possible for the two materials to be used together in ternary mixes with an advantage. As was discussed earlier, their combined use in concrete could be a practical option because the availability of AHS could be potentially limited. These results are consistent with literature that SCMs used together in concrete complement each other in areas where they fall short, since CCA was also observed to improve the workability of AHS at the 10% and 15% replacement levels [18,19].

Figure 6: Mean compressive strengths of binary and ternary specimens of CCA and AHS-replaced specimens at 91 days against percentage replacements (N/mm2).

Table 9: Percentage chemical composition of AHS and CCA against the requirements of the American Society for Testing and Materials [14].

Generally, compressive strengths of the ternary CCA and AHS at 91 days decreased with further replacement, even though from Table 2, those of the binary AHS and CCA specimens increased between the 5 and 7.5% replacements, and decreased with further replacement.

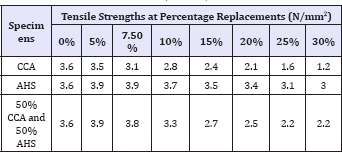

Tensile strength

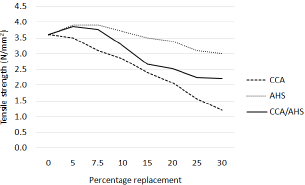

Table 10: Tensile strengths of binary and ternary CCA and AHS- replaced specimens at 91 days (N/mm2).

Table 10 and Figure 7 show the tensile strengths of binary and ternary CCA and AHS-replaced specimens. As was the case with compressive strengths, AHS seemed to improve the tensile strength of CCA, further reinforcing the complementary effect argument of SCMs [18,19]. It can therefore be concluded that ternary CCA and AHS could be used in concrete with an advantage over CCA binary concrete on tensile strength.

Figure 7: Tensile strengths of binary and ternary CCA and AHS-replaced specimens at 91 days against percentage replacements (N/mm2).

Gain in compressive strength over time

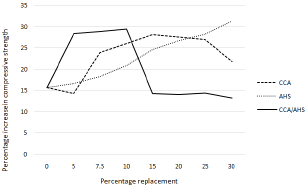

Table 11: Percentage increase in compressive strengths of binary and ternary CCA and AHS-replaced specimens between 28 and 91 days.

Figure 8: Percentage increase in compressive strengths of binary and ternary CCA and AHS-replaced specimens between 28 and 91 days against percentage replacements.

Table 11 and Figure 8 show the percentage increase in compressive strengths of the binary and ternary specimens of CCA and AHS specimens between 28 and 91 days. The ternary mix showed a higher strength development than individual binary specimens between the 5% and 10% replacements. The rate of strength gain however slowed down and fell below those of the control and binary specimens with further replacement. From the results, it can be concluded that the ternary concrete of CCA and AHS could be used with an advantage of higher strength gains over time at lower replacements. Caution should however be exercised at higher replacements as this trend was reversed even below that of the control specimens.

Conclusion

This work investigated the performance of Corncob Ash (CCA) and Anthill Soil (AHS) in ternary concrete mixes. From the evidence that was gathered, the following conclusions were arrived at:-

A. CCA improved the workability of AHS. The slumps of the ternary CCA and AHS decreased with further replacement.

B. The densities of the ternary concrete were lower than those of individual binary concretes, signifying an advantage on increasing the volume of concrete per unit mass over binary CCA and AHS.

C. AHS improved the compressive and tensile strengths of CCA, signifying that the two materials could be used together in concrete with this advantage.

D. Generally, compressive strengths of the ternary CCA and AHS decreased with further replacement, even though those of the binary CCA and AHS specimens increased between the 5 and 7.5% replacements, after which they decreased with further replacement.

E. The ternary concrete of CCA and AHS showed higher strength gains for replacements of up to 10%, after which the gain in strength fell below that of both the binary and control specimens with further replacements.

References

- Jagannadha RK, Mujeeb MA, Sastri MVSS (2014) Behavior of ternary blended concrete with fly ash and silica fume. IUP Journal of Structural Engineering 7(2): 25-34.

- Al-Salami AE, Salem A (2010) Effects of mix composition on the sulfate resistance of blended cements. International Journal of Civil & Environmental Engineering 10(6): 37-41.

- Johnson, Mary E, Gonzalez A (2013) Estimating cost savings for aviation fuel and CO2 emission reductions strategies. Collegiate Aviation Review 31(2).

- O'Brien, Eugene J, Dixon AS, Sheils E (2012) Reinforced and prestressed concrete design to EC2: the complete process: Spon Press, UK.

- Olafusi, OS, Olutoge FA (2012) Strength properties of corn cob ash concrete. Journal of Emerging Trends in Engineering and Applied Sciences 3(2): 297-301.

- Gambhir, Murari L (2009) Concrete Technology 4e. Tata McGraw-Hill Education, USA, ISBN 0070583749.

- Bapat, Jayant D (2012) Mineral admixtures in cement and concrete: CRC Press, USA.

- British Standards Institution (2000) BS EN 197-1:2000. Part 1. Cement composition, specifications and conformity criteria for common cements. British Standards Institution (BSI), London, UK.

- Richardson IG (2000) The nature of the hydration products in hardened cement pastes. Cement and concrete composites 22(2): 97-113.

- Kamau J, Ahmed A, Hirst P, Kangwa J (2016) Suitability of corncob ash as a supplementary cementitious material. International Journal of Materials Science and Engineering 4(4): 215-228.

- Nene AS, Parihar YD (2016) Natural Stabilization of soils with special reference to entomological considerations.

- Kamau J, Ahmed A, Hirst P, Kangwa J (2017) Suitability of anthil soil as a supplementary cementitious material.

- Adesanya DA, Raheem AA (2008) Development of corn cob ash blended cement. Construction and Building Materials 23(1): 347-352.

- American Society for Testing and Materials (2012) ASTM C618 Standard specification for coal fly ash and raw or calcined naturalpozzolan for use in concrete. ASTM International, West Conshohocken, PA, USA, DOI: 10.1520/C0618-12.

- European Ready Mixed Concrete Organisation (2006) Guidance to the engineering properties of concrete.

- British Standards Institution (2015) BS 8500-1:2015 Concrete- complementary british standard to BS EN 206. Part 1: method of specifying and guidance for the specifier, BSI, London, UK.

- Mohammed, Haider O, Hamid RB, Taha MR (2012) A review of sustainable supplementary cementitious materials as an alternative to all-portland cement mortar and concrete. Australian Journal of Basic & Applied Sciences 6(9): 287-303.

- Sathawane, Satish H, Vairagade VS, Kene KS (2013) Combine effect of rice husk ash and fly ash on concrete by 30% cement replacement. Procedia Engineering 51: 35-44.

- Nehdi M, Pardhan M, Koshowski S (2004) Durability of self-consolidating concrete incorporating high-volume replacement composite cements. Cement and Concrete Research 34(11): 2103-2112.

- American Society for Testing and Materials (2016) ASTM C192/C192M standard practice for making and curing concrete test specimens in the laboratory. 16a, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA, USA.

- Oluokun, Francis A (1994) Fly ash concrete mix design and the water- cement ratio law. Materials Journal 91(4): 362-371.

- Singh SB, Munjal P, Thammishetti N (2015) Role of water/cement ratio on strength development of cement mortar. Journal of Building Engineering 4: 94-100.

- British Standards Institution (1990a) BS 5328: 1990 Part 2: 1990. Concrete. Part 2. Methods for specifying concrete mixes. BSI, London, UK.

- British Standards Institution (1990b) BS 5328: Part 1: 1990. Concrete. Part 1 Guide to specifying concrete. BSI, London, UK.

- British Standards Institution (2009a) BS EN 12350-2:2002. Testing fresh concrete Part 2: Slump-test. BSI, London, UK.

- British Standards Institution (2012) BS EN 12390-1:2012. Testing hardened concrete. Part 1: Shape, dimensions and other requirements for specimens and moulds. BSI, London, UK.

- British Standards Institution (2009b) BS EN 12390-2:2009. Making and curing specimens for strength tests. BSI, London, UK.

- British Standards Institution (1999) BS 3762-4.2:1986 ISO 697:1981. Analysis of formulated detergents-Part 4: Physical test methods-Section 4.2 Method for determination of apparent bulk density. BSI, London, UK.

- British Standards Institution (2011) BS EN 12390-3:2009. Testing of Hardened Concrete, Part 3: Compressive strength of test specimens. BSI, London, UK.

- British Standards Institution (2010) BS EN 12390-6:2009. Testing hardened concrete Part 6: Tensile splitting strength of test specimens. BSI, London, UK.

- Zhou, Ming X, Slater JR, Wavell SE, Oladiran O (2012) Effects of PFA and GGBS on Early-Ages engineering properties of portland cement systems. Journal of Advanced Concrete Technology 10(2): 74-85.

- Song, Won H, Pack SW, Nam SH, Jang JC, et al. (2010) Estimation of the permeability of silica fume cement concrete. Construction and Building Materials 24(3): 315-321.

© 2018 John Kamau, et al. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)