- Submissions

Full Text

Research & Development in Material Science

Study on Design, Fabrication and Properties of Biomedical Porous Titanium

Guangsheng Xu*, Huaixiao Luo, Zhanying Zhang, Liping Song and BingBing Yang

Department of Material Science and Engineering, Shaanxi Polytechnic Institute, China

*Corresponding author: Guangsheng Xu, Department of Material Science and Engineering, Shaanxi Polytechnic Institute, Xianyang, Shaanxi, China, 71200

Submission: January 31, 2018; Published: February 09, 2018

ISSN: 2576-8840Volume3 Issue3

Mini Review

It has been shown that introducing porous structure in titanium and its alloys implant material is an effective way to reduce the "stress shielding" effect [1,2]. Interconnected pores in titanium and its alloys not only can decrease Young's modulus through tailoring porosity but also can enhance bone ingrowth and improve fixation [3,4]. Therefore, design, fabrication, mechanical behavior and biocompatibility of porous titanium and its alloys have become a research focus in this field. Development of fabrication methods, together with studies of mechanical behavior and biocompatibility is beneficial to improve the performance of porous titanium and its alloys for implant applications.

First, effect of pore size, pore shape, pore topology and strut material on mechanical properties of porous titanium and its alloys has been studied by using computer simulation methods. The results show that porosity increases as the pore size increases from 200|im to 500|im, which also leads to the decrease in Young's modulus and yield strength of porous titanium. Porous titanium with square pores has a low Young's modulus and relatively high yield strength compared with the circle and hexagonal pores. Porous titanium has a good match of elastic modulus and high yield strength when pore topology is changed from regular array to staggered array. In addition, yield strength increases as the strut material changed from CP-Ti to Ti-6Al-4V alloy. Therefore, Young's modulus and yield stress of porous titanium and its alloys can be adjusted through designing pore size, pore shape, pore topological arrangement and strut material.

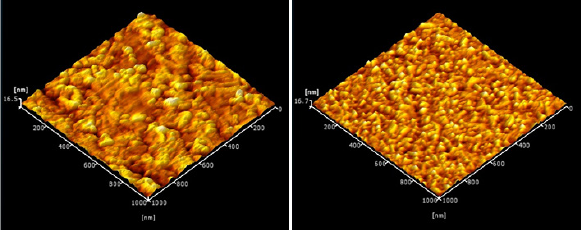

Based on the results of the above simulation, porous titanium is prepared by titanium mesh stacked-forced-sintering method (TMSS) [5]. Structure and mechanical properties of the prepared porous titanium are studied by tailoring pore structure parameters, strut material and process parameters [6,7]. The results show that porous titanium fabricated by TMSS has square pore structure. There are no cracks and inclusions on the strut. Mechanical behavior of porous titanium is anisotropic and sensitive to strain rate. The flow curves are smooth, stable and no obvious serration yield process. The strain for plastic platform region reaches up to 64%. It can obtain a fine match of low elastic modulus and high yield strength by regulating the pore topology at the same porosity [8]. Porous titanium prepared by Ti-6Al-4V alloys owns Young's modulus and tensile strength in the range of 9.5~12.2GPa and 360~505MPa, respectively. Fatigue fracture intensity level is about 40MPa at the testing condition of R =-1, f=10Hz and N=5*106. Heat treatment has much more influence in the tensile stress but minor influence in the Young's modulus [9] (Figure 1).

Figure 1a: Schematic diagram of porous titanium.

1b: Microstructure model of porous titanium,

1c: Mechanical properties of porous titanium, bulk titanium and natural bone.

References

- Long M, Rack HJ (1998) Titanium alloys in total joint replacement--a materials science perspective. Biomaterials 19(18): 1621-1639.

- St-Pierre JP, Gauthier M, Lefebvre LP, Tabrizian M (2005)Three- dimensional growth of differentiating MC3T3-E1 pre-osteoblasts on porous titanium scaffolds. Biomaterials 26(35): 7319-7328.

- Takemoto M, Fujibayashi S, Neo M, Suzuki J, Kokubo T, et al. (2005) Mechanical properties and osteoconductivity of porous bioactive titanium. Biomaterials 26(30): 6014-6023.

- Gepreel MA, Niinomi M (2013) Biocompatibility of Ti-alloys for longterm implantation. Journal of the Mechanical Behavior of Biomedical Materials 20: 407-415.

- Xu GS (2013) The Chinese Journal of Nonferrous Metals 23(S1): 343.

- Xu GS (2014) Rare Metal Materials and Engineering 43(11): 2778.

- Li FP, Li J, Xu G, Liu G, Kou H, et al. Fabrication, pore structure and compressive behavior of anisotropic porous titanium for human trabecular bone implant applications. Journal of the Mechanical Behavior of Biomedical Materials 46: 104-114.

- Xu GS, Kou HC, Liu XH, Li F, Li J, et a l. (2017) Microstructure and mechanical properties of porous titanium based on controlling young's modulus. Rare Metal Materials and Engineering 46(8): 2041-2048.

- Xu GS (2017) Rare Metal Materials and Engineering 46(S1): 478.

© 2018 Guangsheng Xu, et al. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)