- Submissions

Full Text

Research & Development in Material Science

Dielectric Properties of Samarium Doped- Sodium Potassium Niobate Thin Films

Umar Al-Amani Azlan1*, Nurul Azuwa Azmi2, Maziati Akmal Mohd Hatta2, Mohd Warikh Abdul Rashid2 and Mohd Asyadi Azam Mohd Abid2

1Faculty of Engineering Technology, Universiti Teknikal Malaysia Melaka, Malaysia

2Faculty of Manufacturing Engineering, Universiti Teknikal Malaysia Melaka, Malaysia

*Corresponding author: Umar Al-Amani Azlan, Faculty of Engineering Technology, Universiti Teknikal Malaysia Melaka, 76100, Hang Tuah Jaya, Durian Tunggal, Melaka, Malaysia

Submission: November 11, 2017; Published: February 01, 2018

ISSN: 2576-8840Volume3 Issue3

Abstract

This short communication revealed the importance of Samarium, Sm as a dopant in Sodium Potassium Niobate, KNN thin films. It was found that the surface roughness of about 1.583nm was reduced with Sm doping. Furthermore, the microstructure of doping films was more uniform in term of size and shape. This also led to the improvement of dielectric properties.

Keywords: KNN, Sm, Thin films, Doping

Introduction

For the past 10 years, ferroelectric ceramics with a perovskite structure, a tungsten bronze structure, and bismuth layer- structured (BLSF) have been reported to replace the lead-based materials. Recently, more findings with better results has been reported from various perovskite-structured ferroelectrics such as barium titanate (BaTiO3 (BT)), bismuth titanate ((Bi1/2Na1/2) TiO3 (BNT)), bismuth sodium titanate ((Bi1/2 K1/2)TiO3 (BKT)), potassium niobate (KNbO3 (KN)), sodium potassium niobate ((K, Na)NbO3 (KNN)) [1]. Among these, KNN has been nominated as one of the most promising candidates to replace the wide usage of lead- based materials especially the lead zirconate titanate (Pb[ZrTi1-x] O3). KNN is a combination of solid solution ferroelectric KNbO3 and anti-ferroelectric NaNbO3 that has been the most studied lead-free piezoceramics materials due to its relatively high piezoelectric constant (416 pC/N) and high Curie temperature (420 °C) [2-4].

The formation of KNN structure has some lacking due to oxygen vacancies and some intrinsic defects. Therefore, many researches have been done in substituting the vacancies with rare-earth and researchers still trying to find the ideal dopant to be doped into the KNN structure. Different dopants will give different effects to the materials. However, not all dopants are suitable for certain applications. In our current work, samarium (Sm) was introduced into KNN structure in order to overcome the intrinsic defects. Samarium is a member of lanthanide series with an oxidation state of +3, atomic radii of 1.81 A and ionic radii of 0.964 A, was chosen as a doping element due to its stability of perovskite phase, ionic radius and the Curie-Weiss temperature [5].

Research Methodology

The experiment was divided into precursor preparation, deposition and annealing process and followed by analysis. The precursor was started by dissolving CH3COOK and CH3COONa into 2-ME in a beaker with constant stirring at room temperature. Nb2(OC2H5)10 was also prepared with a constant stirring at room temperature in another beaker containing 2-ME with the addition of acetylacetone. Later on, both of the precursors were mixed together for another constant stirring at 60 °C for an hour. The same steps were repeated for the doping precursor, where the samarium with different concentrations was added to the beaker containing CH3COOK and CH3COONa. After that, the deposition process was done by depositing the precursor onto the silicon (Si) substrate for five layers. Spin coater had been used in order to deposit the layers. One minute of pyrolysis was taking place between each of the layers. To end the deposition process, the wet films were annealed at 650 °C for 10 minutes by using the rapid thermal processing (RTP) furnace. The samples were ready to be characterized and analysed.

Result and Discussions

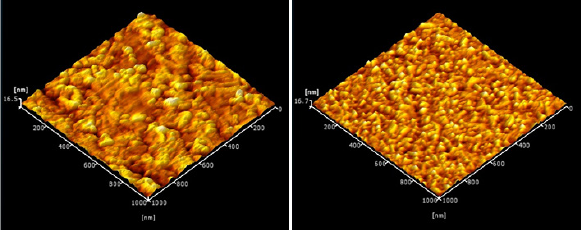

The 3D AFM surface topography micrographs for both samples are shown in Figure1. The scanned area of 1m x 1μm came out with roughness, Rq of 1.658nm for KNN films (Figure 1a) while 1.583m for Sm doping (Figure 1b). The integration of Sm as a dopant into KNN structure helps to minimize the roughness of thin films. Furthermore, the microstructure of KNN with Sm doping is more uniform in term of size and shape as compared to that of KNN.

Figure 1: 3D AFM topography micrographs of:

1a: KNN and

1b: Sm-KNN thin films.

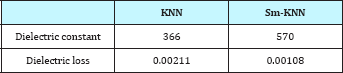

Table 1: Dielectric properties measured at 1kv.

Table 1 shows the dielectric properties of both thin films measured at 1kV. The incorporation of Sm into KNN shows a significant result in term of electrical properties. As seen, the dielectric constant and dielectric loss of Sm-KNN were greatly improved with 36% and 49%, respectively as compared to that of KNN thin films. This improvement is in line with the uniformity of microstructure as shown clearly in Figure 1b. It is well to be said that the incorporation of Sm into KNN might be useful for fabricating this material into microelectronic devices with better dielectric properties. Further studies on the other analyses will be reported in order to have a good conclusion on this research.

Conclusion

Initial study on the comparison of KNN and Sm doped- KNN thin films were successfully carried out in this work. It was clearly seen that the improvement on surface roughness with uniform microstructure shown by the films with Sm doping, thus leading to a significant result on dielectric properties.

Acknowledgment

The author would like to thank MOHE, Universiti Teknikal Malaysia Melaka and Ministry of Higher Education under the FRGS number: FRGS/1/2014/TK04/FTK/02/F00207 for funding this project.

References

- Takenaka T (2013) Lead-free piezoelectric ceramics. Handb Adv Ceram.

- Rödel J, Jo W, Seifert K T P, Anton E M, Granzow T, and Damjanovic D, et al. ( 2009) Perspective on the development of lead-free piezoceramics. Journal of the American Ceramic Society 92(6): 1153-1177.

- Saito Y, Takao H, Tani T, Nonoyama T, Takatori K, et. al ( 2004) Lead-free piezoceramics. Nature 432(7013): 84-87.

- Shrout T R, and Zhang S J (2007) Lead-free piezoelectric ceramics: Alternatives for pzt? Journal of Electroceramics 19(1): 111-124.

- Chon U, Kim KB, Jang HM, Yi GC (2001) Fatigue-free samarium- modified bismuth titanate (Bi4xSmxTi3O12) film capacitors having large spontaneous polarizations. Applied Physics Letters 79(19): 3137-3139.

© 2018 Umar Al-Amani Azlan, et al. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)