- Submissions

Full Text

Polymer Science: Peer Review Journal

A Critical Review on Structural Battery Composites: Current State, Challenges, and Future Prospects

Harsha Medicharla and Sanjeev Rao*

Department of Aerospace Engineering, Khalifa University of Science and Technology, UAE

*Corresponding author:Sanjeev Rao, Department of Aerospace Engineering, Khalifa University of Science and Technology, P O Box 127788, Abu Dhabi, UAE

Submission: August 01, 2024;Published: August 28, 2024

ISSN: 2770-6613 Volume5 Issue 5

Abstract

The emergence of Structural Battery Composites (SBCs) presents a transformative potential in energy storage and structural functionality across the transportation sector, encompassing road, air, and space applications. SBCs integrate energy storage directly into structural components, offering significant weight reductions and enhanced efficiency. This review critically examines the state-of-the-art advancements in SBC technology, focusing on the development, integration, and potential benefits of these multifunctional materials. It explores the Technology Readiness Levels (TRL) of SBCs, addressing key technological challenges and scaling concerns. The analysis highlights the economic and structural benefits alongside the technical complexities of implementing SBC technology in practical applications. While SBCs promise substantial improvements in vehicle range and payload capacity, the integration faces hurdles related to material costs, manufacturing processes, and compliance with stringent safety standards. This review underscores the necessity for continued research, standardization, and collaboration between industry and academia to harness the full potential of SBCs for sustainable and efficient energy storage solutions. The conclusion discusses the economic implications, breakeven points, and consumer acceptance of SBC technology, weighing its viability against current market demands and sustainability goals.

Keywords:Structural battery composites; Battery technology; ABC costing; Multifunctional materials; Energy storage; Technology readiness levels (TRL); Transportation sector; Electric vehicles (EVs)

Abbreviations:SBCs: Structural Battery Composites; EVs: Electric Vehicles; LSBs: Laminated Structural Batteries; TRL: Technology Readiness Level; MRL: Manufacturing Readiness Levels; UAVs: Unmanned Aerial Vehicles; UAM: Urban Air Mobility

Introduction

In the current age of environmental awareness, legislation is being passed by governments around the world to reduce emissions in pursuit of fulfilling net-zero commitments [1-4]. In view of those commitments, several governments have provided incentives to domestic industry sectors to switch from conventional fossil fuel-based energy sources to those of renewable ones. Although several of those sectors have responded positively to the initiatives provided, they have tabled several infrastructure and storage limitations that need to be addressed in order to switch successfully from conventional fuels to renewable ones [5,6]. The urgency of limitations such as such storage devices has been outlined in several global initiatives, such as COP-28, Battery 2030+, and the Fit for 55 roadmap, emphasizing the need to adopt technologies that may indeed reduce the global carbon footprint. In recent times, the transportation sector has made strides in developing energy storage devices and their management systems, thereby allowing for the storage of energy generated by renewables [7]. However, their acceptance in the wider market has been somewhat conflicting because of the limitations of their ability to match up with internal combustion counterparts. One prominent limitation is the limited travel range (colloquially termed as range anxiety) before recharge; some others are the time taken to charge the battery completely, availability of charging stations and the nature of the primary source of energy, which in current times is still fossil fuel based. Therefore, the wide adoption of fully electric vehicles in the land transportation segment has received some hesitations, while the intermediate hybrid versions are gaining immense popularity. Similarly, in the Urban Air Mobility (UAM) segment of the aviation industry, the range and payload capacity have played a prominent role in their acceptance, as the supply side is never able to keep up with the demand side. Moreover, with the progression in technology and consumer requirements, there is an ever-growing necessity to increase the capacity of energy storage devices [8-12].

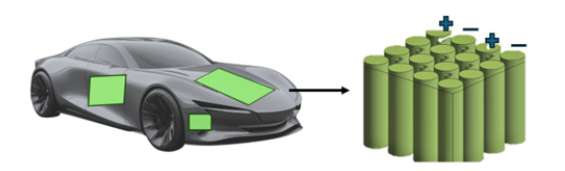

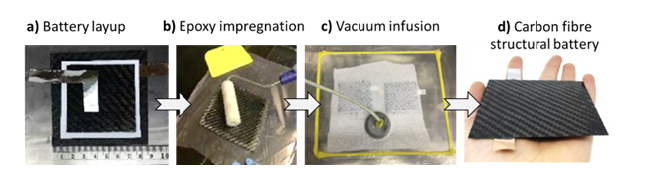

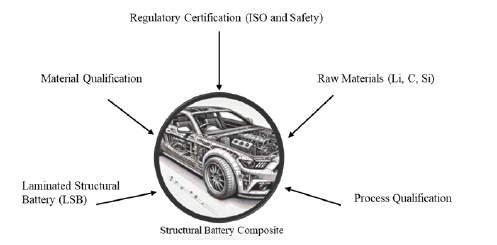

Increased pressures applied by these climate change accords have forced several nations to streamline their approach to lower CO2 emissions into the atmosphere by the year 2030 and achieve net-zero emissions by the year 2050 [13,14]. In view of addressing several challenges faced in electrification, governments have initiated infrastructure changes and new projects to support the technology. Industry in tandem have focused on advancing battery technologies to improve their range and modern technologies such as the Structural Battery Composites (SBCs) have gained some importance. The SBC is a battery-integrated structure which is actually an integral part of the system, as shown in Figure 1, [15-17]. The ideation of SBCs originated from the commonality between modern batteries and lightweight carbon fibre reinforcement in composite materials. This progression led to technologies that harness the ion transfer characteristics of carbon fibre reinforcements while maintaining structural integrity, giving rise to multifunctional composite materials [18]. Additionally, the recent push in the renewables sector has made SBC technology an attractive, lightweight solution to the existing hefty battery technologies [19-21].

Figure 1:Carbon composite vehicles with distributed structural batteries.

SBC technology has the highest potential to address critical issues, such as range anxiety and associated energy consumption in traditional EVs [11], by lightening the overall vehicle structure by incorporating energy storage capabilities directly within them. Tertiary loadbearing structures such as door panels, roofing panels, luggage compartment panels, fuel hatch, etc., are ideal candidates for implementing SBC technology [22,23]. This multifunctional approach not only enhances the driving range but also improves the energy efficiency of transport vehicles, and this concept of ‘mass-less’ energy storage [24,25] is poised to redefine efficiency in future vehicle designs, providing a path towards greener, more sustainable mobility.

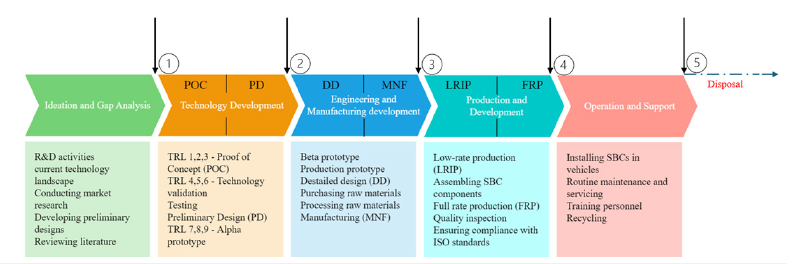

The technology in its current state is still in its nascent (TRL- 3 or under) stages, with critical evaluations underway to make progress. Asp & Co-Workers [26] have been at the forefront of this preliminary development with several other researchers [27,28] following pursuit. The key to progressing the technology is in the cost-benefit it provides when compared to its existing competitors in relevant sectors. The key to progressing the technology is in the cost-benefit it provides when compared to its existing competitors in relevant sectors. The main factors determining the cost of implementing a new technology are the expenses incurred in purchasing capital equipment (both fixed and variable) and the operational costs associated with running the facility. Additional incidental expenses encompass production expenses, maintenance costs, and issues related to scalability. To become profitable and counterbalance these expenses, the market must reach a state of maturity accompanied by a significant level of demand. This need must be driven by technological improvements, competitive pricing tactics, regulatory frameworks, and broad consumer adoption. If the technology does not gain considerable popularity in the market, it may encounter difficulties in obtaining the essential cost efficiency and general acceptance needed for long-term growth and financial sustainability.

There are two primary manufacturing methodologies for SBCs: traditional laminated battery and the 3D-fibre battery approach. The traditional laminated battery utilises established composite manufacturing techniques, infusing a structural battery electrolyte into an assembly of polymer separators sandwiched between electrodes. The 3D-fibre battery approach involves coating carbon fibres with electrode material and assembling them with separators to form a battery. While 3D-fibre batteries face challenges concerning sample size and geometry, Laminated Structural Batteries (LSBs) show potential for scaling from conceptual demonstrators to functional prototypes [26,29]. LSBs typically comprise copper and aluminium mesh layers, doubling as electrodes, a thin glass separator to prevent short-circuiting and a liquid or gel-like electrolyte facilitating ion migration-a recent prototype for a CubeSat by Moyer et al. [30] validates LSBs applicability in realworld settings [31]. However, in order to fulfil the substantial energy requirements of automotive and aerospace applications, it is crucial to carefully assess the electro-mechanical characteristics and safety consequences of scaling these technologies. This is particularly important because the entire structure may need to be composed entirely of LSBs. The 3D-fibre battery technique utilises carbon fibres that are coated with electrode material and coupled with separators to build the battery. This technology is envisioned as a novel innovation that enables the integration of battery functions directly into the physical structure of components. Although there are difficulties related to the dimensions and form of the samples, 3D-fibre batteries offer tailored adaptability and the possibility of being integrated into complex structures, hence improving the scalability of LSBs. Both technologies are advancing to meet the substantial energy requirements of automotive and aerospace applications [32,33], necessitating a comprehensive analysis of electro-mechanical properties and safety issues.

This transition from lab-based technology demonstrators to Full-Rate Production (FRP) is a critical area that the industry must address along with technology developers. To effectively include these sophisticated materials in the production process, it is necessary to address challenges related to scalability, maintaining consistent manufacturing practices, and ensuring that the composites fulfil stringent industry standards for safety and performance [34]. The industry is focused on navigating the complexities of merging energy storage with structural reliability for mass production, a task requiring both innovative engineering and strategic investment [35]. Assessing their maturity through Technology Readiness Level (TRL), proposed by NASA, and Manufacturing Readiness Levels (MRL) is crucial for their adoption into the manufacturing process, ensuring that these structural battery technologies are ready to meet the market demands and can be seamlessly integrated into the manufacturing chain [36-38].

This paper focuses exclusively on reviewing published research on the development of structural batteries and how their specific energy storage capability and structural performance are improved. The applications of such battery structures are also reviewed in the transport industry, where both weight and energy storage are crucial parameters in the design and performance of EVs. The stateof- the-art review presents the development of structural batteries in chronological order. The use of structural batteries in EVs, CubeSats (miniaturised satellites for space research) and Unmanned Aerial Vehicles (UAVs) are also explored with the objective of moving towards greener, safer and affordable land and space transport systems. The status of the Technology Readiness Level (TRL) and the Manufacturing Readiness Level (MRL) of structural batteries, the prevailing gaps in the technology as well as the measures for upscale manufacturing of these batteries for their adoption as an integral part of commercial EVs are discussed in this study.

This review article distinctively focuses on the Technology Readiness Levels (TRL), Activity Based Cost analysis (ABC), and the challenges in manufacturing SBCs, elements not extensively delved into in the current body of literature. For example, Zhao & Tianwei Jin [27] Contribute substantial insights into structural batteries development and multifunctional potential, predominantly concentrating on structural batteries and not exclusively on SBC. Leif E Asp [26] and Federico Danzi [28] enhance our understanding of SBC, including integrating structural power composites and carbon fibre. However, these research studies do not thoroughly examine the TRL to indicate the technological progression and the timeline for these advancements to be integrated into the products pipeline. Our research evaluates the industry readiness and scalability of SBCs. Our approach is notable for its detailed assessment of how these cutting-edge technologies can be pragmatically incorporated into existing manufacturing processes, thereby addressing a vital gap in the discourse surrounding the practical, commercial application of SBCs. In view of advancing technological advancements, research progress with respect to sector-wise research progress is presented chronologically.

Despite the ground-breaking potential of structural batteries to enhance energy storage with reduced mass and multifunctionality, they face significant technological and environmental challenges [11,39,40]. Optimising the connection between energy storage components and structural integrity continues to be a challenging technical obstacle, alongside considerations for the end-of-life recyclability of materials [40, 41]. Innovative solutions, such as the development of multifunctional composites and structural power composites, have been proposed to address these challenges, aiming to utilise up to 80% of the remaining capacity in End-of- Life (EOL) batteries [20,21,42,43]. These advancements align with global efforts to reduce CO2 emissions and improve energy efficiency across various sectors, including road transportation, aviation, and space [5,6]. However, integrating these advanced materials into industrial manufacturing poses its own challenges, emphasising the need for continued research and adaptation to meet commercial viability.

Energy Storage in the Transportation Sector

The transportation sector, pivotal in modern society, is undergoing a significant shift with advancements in energy storage technologies. This section explores how these technologies are being implemented across various domains, such as road, air, and space transportation. In road transportation, we will examine the evolving landscape of Electric Vehicles (EVs), from personal cars to electric buses and trucks; the evolution of EVs signifies a leap in energy storage efficacy and environmental consciousness. The air transportation section will delve into the world of Unmanned Aerial Vehicles (UAVs) and aircraft, where energy storage is essential for operational efficacy and range. Lastly, in the space transportation segment, we will explore CubeSats, where compact and efficient energy storage is vital due to the unique challenges of space exploration. This section also discusses compliance with vehicle safety when implementing the SBCs into the manufacturing pipeline.

Road transportation

As the landscape of Electric Vehicles (EVs) changes globally, the industry will have to keep abreast with the associated technological advancement. Eleksuria, a southeast-based car manufacturer, ventured into electric vehicles as early as 1997, setting a stage for global prayers in the EV space. China, in particular, has taken the lead in the EV sector and has put up big numbers in EV sales and is continuing to do so by creating newer startups and supporting this sector. As of 2023, Tesla’s Model Y leads global EV sales with 772,364 units sold from January to August 2023, followed by Tesla’s Model 3 and several models from Chinese manufacturers such as BYD. Notably, China continues to dominate the EV market, accounting for around 60% of global electric car sales as of 2023 and has more than half of the world’s electric car stock as of the end of 2019 [7]. The global electric car industry’s market share reached approximately 18% in 2023.

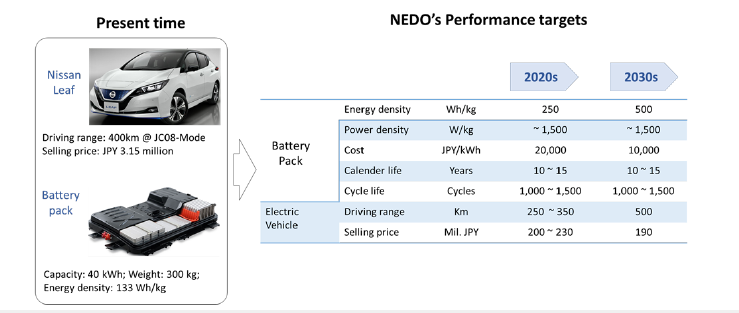

Electric Vehicle (EV) battery technology is advancing rapidly, primarily driven by innovations in Lithium-ion (Li-ion) batteries, which offer higher energy storage and longer life cycles [44- 46]. Recent developments highlight the emergence of solid-state batteries, anticipated to provide longer ranges and faster charging times, with companies like Quantum scape aiming to commercialise this technology by 2025 [44]. Additionally, sodium-ion batteries are gaining attention as a cost-effective alternative due to cheaper and more abundant materials. Policy initiatives, particularly in the US, support further advancements and production capacity through funding and incentives like the Inflation Reduction Act. The future also looks promising for battery recycling, with companies like Redwood Materials and Li-Cycle building facilities to repurpose critical metals [44]. These innovations are vital for achieving more efficient, sustainable, and cost-effective electric mobility solutions. Pursuing lighter Electric Vehicles (EVs) has led to innovative approaches in battery design. Experts are exploring the concept of integrating the battery structure within the vehicle’s frame, significantly reducing the overall weight of the energy storage system [11]. This approach envisions a virtually weightless energy storage unit. The use of multi-functional composite materials is a crucial aspect of this strategy, offering a path to construct lightweight energy storage devices such as batteries and capacitors [47]. This multi-functionalization is seen as a strategic advancement, potentially revolutionising the EV market, including electric, by enabling the production of more competitive models [48].

An electric motor has replaced the conventional Internal Combustion (IC) engine in electric cars. The electric motor, along with the auxiliary power components, are powered by rechargeable onboard energy storage devices such as batteries and capacitors. Modern EVs are highly efficient and perform well. Nevertheless, the currently available technologies for electrical energy storage are expensive and require time-consuming recharging processes. In addition, batteries are heavy and increase the vehicle′ weight significantly. As a result, the TRL of the energy storage system of EVs is recognised as a hindrance to the growth and market penetration of EVs [49]. The key design objectives for energy storage systems in automotive applications include high energy and power densities, safety, and reliability. To date, various energy storage technologies have been developed and considered for electric and hybrid vehicles, including fuel cells, supercapacitors, and batteries. Li-ion Batteries (LIB) are advanced EVs most widely used battery type. There are currently a variety of LIBs available in the market, each containing different active materials and work based on different chemistries: Lithium Cobalt Oxide (LCO), Lithium Manganese Oxide (LMO), Lithium Iron Phosphate (LFP), Lithium Nickel-Manganese- Cobalt Oxide (NMC) are the types used in today’s EVs [50].

Batteries are generally compared based on power density, energy density, shelf-life, cycle life, and cost/kWh, along with other parameters such as safety, volume, energy efficiency, and self-discharge to a lesser extent. In general, the batteries for EVs are selected based on the energy requirement for attaining a specific travelling range. It should be noted that there is no linear relationship between the battery capacity and the vehicle range since additional battery weight in bigger batteries can reduce the efficiency of the vehicle. Therefore, energy and power densities should be used to compare batteries instead of the range [49]. Energy density is defined as the amount of energy that can be stored per battery unit, whereas power density is defined as the maximum amount of energy that can be discharged per battery unit [51,52]. The specific energy and specific power densities for different battery technologies differ widely from one to another. For any given technology, additional trade-off between energy and power could be achieved through battery design.

SBCs offer distinct benefits and face unique challenges across diverse types of carriers, including public, private, and goods carriers. For public carriers like buses and taxis, SBCs promise improved energy efficiency and reduced vehicle weight, which is essential in urban settings. However, their integration requires adherence to stringent safety standards, such as compliance with specific ISO passenger safety regulations. Private carriers, encompassing personal and fleet vehicles, stand to benefit from SBCs in extending the driving range and reducing charging times. These segments may encounter fewer regulatory barriers, facilitating smoother SBC adoption. In contrast, goods carriers like trucks and delivery vans could gain from the weight reduction SBCs offer, yet must meet rigorous safety and durability standards, a necessity when transporting hazardous materials. Private carriers appear suitable for SBC integration due to fewer regulatory complexities and increasing interest in electric personal vehicles. Public and goods transportation sectors may face more significant integration challenges due to more stringent safety requirements and the need for extensive modifications. As SBC technology advances and aligns with ISO and vehicle protocols, its integration is expected to become more streamlined across all road transportation areas, heralding a new era of efficient and sustainable mobility solutions.

While the potential of structural batteries in road transportation is noteworthy, their integration faces significant challenges in adhering to safety standards. For instance, compliance with the Federal Motor Vehicle Safety Standard (FMVSS) No. 227 [53] is essential to ensure resilience in high-impact scenarios for vehicles equipped with structural batteries. This standard, along with other specific certifications like ISO 16750 [54] for environmental conditions and durability and ISO 12405 [55] for electric vehicle battery testing, sets rigorous benchmarks for safety and performance. Comprehensive assessments encompassing Structural Strength and Distortion Tests as outlined in standards such as ISO 16232 [56] for cleanliness and contamination control, Static and Dynamic Tow, Jacking, Hoisting, and Accelerated Durability Tests, as well as Fire Safety evaluations, which could include adherence to ISO 26262 [57]. For functional safety, it is indispensable to ascertain the robustness and safety of these systems. For instance, manufacturers must navigate many tests and certifications to commercialise an electric car. These include Federal Motor Vehicle Safety Standards (FMVSS) for vehicle safety and crashworthiness, New Car Assessment Program (NCAP) crash tests for safety ratings, various ISO standards for electric vehicle and battery safety ISO 6469 [58], ISO 12405 [55], battery safety standards like UL 2580 [59], and rigorous structural integrity and fire safety testing. Each test plays a critical role in validating the safety and efficacy of the vehicle, ensuring that it is fully prepared to meet the demands of the road and protect its occupants in diverse scenarios.

Each test, adhering to its respective ISO or FMVSS standards, is crucial in validating the safety and effectiveness of structural batteries in road vehicles. Yet, the journey to ensure these innovative batteries meet every requirement is complex and demanding. Most SBC systems are still in the laboratory or prototype stages and have yet to prove their ability to pass these safety tests (structural tests and material tests). Transitioning these technologies from research prototypes to commercially viable products satisfying all mandatory safety standards is a significant challenge. It demands technological breakthroughs and thorough testing and validation processes in scaling the lab-grown technology to an FRP. The following section will delve deeper into these technologies, examining their TRL and discussing the steps necessary to bridge the gap and scale the cutting-edge research to market-ready solutions.

Air transportation

To address the aviation industry’s commitment to environmental sustainability, there has been an increased focus on electric propulsion systems and the development of lightweight electric aircraft and drones. Historical data from NASA in 1985 highlighted the potential benefits of electrical technologies in aviation, noting that their integration could lead to a 10% reduction in aircraft weight, 13% less engine thrust required, and a 9% decrease in fuel consumption for a standard 200-seater aircraft. These improvements could lead to substantial environmental and economic benefits, underscoring the significance of continued innovation in this field [60,61]. However, compared to electric cars, which are already in use nowadays, the electrification of aircraft and Unmanned Aerial Vehicles (UAVs) is much less established. and the manufacturing of all-electric regional planes appears to be extremely challenging even by the year 2050 [62]. This can be mainly attributed to the relatively low specific energy density of available battery technologies, which could drastically increase the aircraft’s weight so that flight would be impossible. While an hour flight in a classic 100-passenger aircraft requires approximately 30kg of fuel per passenger, an electric one would need approximately 1000kg of batteries. Even with the concept of structural batteries for reducing the battery weight, it should be beard in mind that, as in many engineering applications, the general idea of multifunctional composite structures is a multidisciplinary and holistic approach to optimising a system in terms of the main design drivers such as weight and efficiency. In large commercial aircraft such as Boeing 747, using multifunctional power structures could reduce weight by reducing the wiring and connections where copper wiring weighs about 2000kg. Nevertheless, it is estimated that for a small all-electric aircraft, the minimum required specific energy of structural batteries is 51.8Wh/kg. It is speculated that unless there are notable breakthroughs in battery technology, all-electric aircraft operations would probably remain limited to intra-continental traffic due to the limited energy supply available onboard [63].

An Unmanned Aerial Vehicle (UAV) is a low-cost flying robot with high mobility, which can operate autonomously or controlled telemetrically to carry out specific tasks. Recent advancements in propulsion systems, high-capacity microprocessors, artificial intelligence, and energy storage technologies have enabled smart UAVs to be employed in a myriad of applications in both military and civil domains, including minesweeping, monitoring and mapping, delivery, wireless coverage, mining and agriculture uses, etc. Electric UAVs have the ability to perform complex or dangerous tasks with high mobility and safety and lower costs [64,65]. The configurations and features of UAVs vary widely with the mission requirements. UAVs are generally classified based on different parameters. The North Atlantic Treaty Organization (NATO) classifies UAVs into three categories based on the Maximum Take-Off Weight (MTOW), and each category is further divided into subcategories depending on altitude and mission radius [66]. Different UAVs are powered by various technologies, most notably batteries, fuel cells, and solar cells. Batteries convert chemical energy to electrical energy, and their major constituent components include two electrodes, an anode and cathode, and an electrolyte. In fuel cells, energy is produced through an electrochemical reaction, where a fuel (often hydrogen) is combined with an oxidising agent (frequently oxygen) into electricity through a pair of redox reactions. Fuel cells based on hydrogen and oxygen have water vapour as their emission. In solar cells, solar radiation is transformed into electrical energy. Batteries are generally cheaper, more reliable, and weigh less than solar and fuel cells. Unlike batteries, fuel cell systems also require a hydrogen tank that could change the position of the centre of gravity of the aircraft [67].

Quadrotors and other small UAVs are powered by lithiumpolymer batteries, which are their principal component. Less noise during operation, higher safety, precise power management, and control are some of the merits of using electric propulsion systems in UAVs. Battery-based powertrains also have zero emissions in contrast to water vapour emissions in fuel cell-powered UAVs. Most UAVs these days use electric propulsion and are powered by lithium-polymer batteries as they are mass-produced and readily available on the market [65]. However, limited energy and power density limit the use of batteries in heavier aircraft. Also, these batteries capacity and lifetime are affected by multiple factors, such as operating temperature and discharge/recharge currents [68,69]. Battery-powered UAVs have short endurance due to the constraints of the battery-pack weight and can fly only for short periods of time. Extending UAVs’ endurance requires additional batteries and balancing the extra battery weight and the UAVs performance. Adding more batteries to increase the autonomy of UAVs results in increased weight and cost. Also, heavier batteries would limit the type of space missions that could be performed since batteries are typically 30% of the mass of a space power system. Thus, reducing the battery-pack weight percentage of the UAVs would enable lower launch mass, leading to potential savings in launch vehicle cost and more mass allowances for payloads or other essential vehicle functions [70].

Electric UAV delivery systems, cargo, and passenger drones are increasingly seen as the most environmentally sustainable methods for future transportation. Central to this transformative shift in the transport sector is the crucial enhancement of UAV mileage and the advancement of battery technology. Particularly, commercial adoption of high-payload UAVs, including those used for military operations, civilian unmanned aviation, and commercial deliveries, hinges on overcoming the power-weight limitations inherent in current energy storage systems. As such, significant resources are being channelled into improving existing battery technologies and developing alternative energy storage structures to address this energy-weight dilemma. These innovations are aimed not just at enhancing the range and payload capacities of electric UAVs, but also at ensuring their broader application in various fields, including sensitive military operations and increasingly demanding commercial and civil aviation requirements, where efficiency, reliability, and sustainability are paramount [71-73].

The adoption of SBCs in UAVs can revolutionise these sectors by enhancing energy efficiency and reducing overall vehicle weight, thereby potentially extending operational range and payload capacity. In military applications, standards like MIL-STD- 810G ensure SBCs withstand extreme conditions, emphasising durability in diverse environments. Commercial and civilian UAVs, including delivery drones, must adhere to FAA regulations, Advisory Circulars, and EASA Certification Specifications for safety. Key challenges include meeting fire safety standards like DO-311A, which set operational performance benchmarks for lithium battery systems, and environmental compliance as per specific ISO norms. The balance between the high energy density of SBCs and strict safety protocols, such as those in RTCA DO-160 for environmental conditions, is critical, especially given the risks of thermal events in high-energy-density batteries. The integration of SBCs into UAVs demands extensive testing for fire resistance, structural integrity, and environmental sustainability. Meeting these stringent standards and certifications, including MIL-STD for military applications and FAA/EASA guidelines for commercial use, is vital for the successful adoption of SBCs. While SBCs offer advantages like enhanced flight times and payload capacities, transitioning from laboratory prototypes to commercially viable SBC-equipped UAVs is a significant challenge. It requires not only technological advancements but also compliance with a range of safety and performance standards, marking a crucial step in harnessing SBCs full potential in the UAV sector [74].

Space transportation

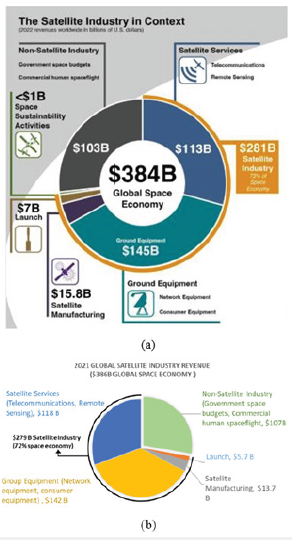

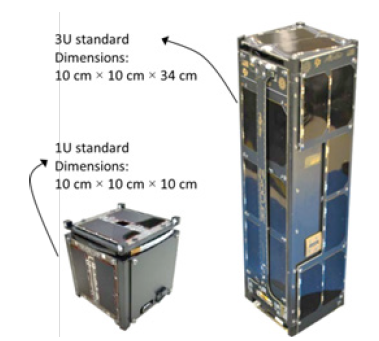

Satellites, integral to various contemporary technologies like GPS, communication networks, and television broadcasting, serve billions globally daily. Presently, there are over two thousand satellites in orbit, playing a crucial role in gathering and relaying data continuously to meet current demands. Figure 2 presents the 2019 revenue on satellite services and satellite manufacturing, which is expected to grow in the coming years and the present space trend supports commercialisation of space and promotes cheaper and faster solutions. CubeSats and other small satellites are becoming popular as they facilitate a cheaper, faster and swift way for satellite applications [75]. CubeSats are a class of miniaturised spacecraft called nanosatellites and consist of standardised 10cm×10cm×10cm cubes, where each cube is described as 1U (Figure 3). CubeSats typically weigh 1-10kg compared to conventional satellites, which are usually the size of a car and weigh 1000kg. CubeSats are cheaper and have smaller size, weight, and power (SWaP) envelopes with a specific mission capability. Providing global connectivity, aircraft signal acquisition, weather forecasting, ionosphere monitoring, earthquake monitoring, low radiation analysis, bandwidth communication test, attitude control test, and high-speed broadband services are only some of the CubeSat applications [76].

Figure 2:Satellite services revenue 2021 [74].

Figure 3:1U CubeSat (left) and 3U CubeSat (right) [76].

CubeSats and other small satellites are becoming popular as they facilitate a cheaper, faster and swift way for satellite applications [75]. CubeSats are a class of miniaturised spacecraft called nanosatellites and consist of standardised 10cm×10cm×10cm cubes, where each cube is described as 1U (Figure 3). CubeSats typically weigh 1-10kg compared to conventional satellites, which are usually the size of a car and weigh 1000kg. CubeSats are cheaper and have smaller size, weight, and power (SWaP) envelopes with a specific mission capability. Providing global connectivity, aircraft signal acquisition, weather forecasting, ionosphere monitoring, earthquake monitoring, low radiation analysis, bandwidth communication test, attitude control test, and high-speed broadband services are only some of the CubeSat applications [76]. CubeSats present a cost-effective approach to space exploration, due to their standardised size and shape, which allows for the use of uniform launch mechanisms. Additionally, CubeSats design accommodates pre-developed components that ensure compatibility and accessibility in the broader market. A key cost-saving strategy in CubeSat deployment involves utilising Commercial Off-The-Shelf (COTS) components, which are significantly more affordable than specialised, custom-built alternatives [77]. In addition, CubeSats, unlike traditional satellites, are affordable, and this allows even companies, public institutions, and universities to construct, operate and explore the technology as it serves as a platform for technological development in which new ideas, concepts and equipment could be tested, qualified and optimised [78]. These spacecrafts are completely self-contained and can operate in space, usually in low-earth orbit. A CubeSat consists of platform systems and a payload, where the platform systems would support the operation of the payload and all the necessary functions of the spacecraft, including power generation and storage, communications, an onboard computer and certain forms of attitude control. The bulk of the mass and volume of a CubeSat is dedicated to the platform systems, leaving only a small amount for payload. Typically, in CubeSats, solar panels generate power, and the energy is stored in secondary batteries. The power that can be produced by the solar cell depends on the incident sunlight, the temperature and the current voltage. To carry out sophisticated missions or when it is necessary to add sub-systems such as cooling that demands higher power, larger solar arrays need to be added, leading to a substantial reduction in payload mass and volume, or it would require a larger platform, which would increase the costs [79]. Thus, batteries are critical components in CubeSats, and it is crucial to ensure their reliable operation in space and an adequate lifetime.

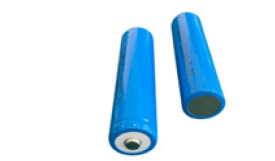

Various parameters such as peak-power requirements, operating temperature, satellite mission life, energy requirement during the worst-case scenario, etc., are the determining selection criteria for a CubeSat′s battery. A typical 1U CubeSat has the maximum and minimum energy requirements of 4.5Wh in a typical technology demonstration mode and 2.2Wh in the safe-hold mode, respectively. A report on the summary of CubeSat battery requirements and comparison of commercially available Li-Po battery technologies points out the necessity of integrating the batteries with the structural components in building the CubeSats to reduce the overall mass [65,80]. Li-ion batteries are more commonly used in small satellites at a percentage of 66%, followed by N-Cd at 16%, Li-Po (12%) and Li-Cl (4%), with the remaining 2% consisting of other battery types. Li-ion cylindrical 18650 COTS cells with dimensions of 1.8cm diameter and 6.5cm height, seen in Figure 4, are extensively used in CubeSats, due to their appropriate size and suitable tolerance for the space environment. Li-S batteries with a gravimetric energy density of six times higher than that of Li-ion batteries could hypothetically offer smaller and lighter energy storage systems, which in aerospace applications would mean significant cost savings, but these batteries suffer from high self-discharge at high state-of-charge levels, fast degradation with limited power capabilities. A survey on the Energy Storage Systems (ESS) available for CubeSats points out that in spite of the COTS Lithium-ion battery cells used for standard applications as shown in Figure 4, it could only be the development of advanced ESS that would potentially enable deep space missions of CubeSats with higher payloads [81].

Figure 4:Typical rechargeable Li-ion cylindrical 18650 COTS.

Structural Battery Composites (SBC)

Functionalising structural composites for storying energy is seen as an opportunity to realise competitive energy-saving as an alternative to traditional batteries in the transportation sectorfrom road to air and space-SBCs present a transformative solution. The ultimate idea of this approach is to improve the specific energy capacity of the system considerably by integrating energy storing capacity into the structural parts and thus converting them into multifunctional components [22]. They are poised to significantly augment vehicle range and payload capacity while concurrently minimising additional weight, which is essential for both energy efficiency and performance optimisation. Electric UAVs, passenger vehicles, and spacecraft can all benefit from the enhanced operational range provided by SBCs without incurring the weight penalties typical of conventional batteries. However, integrating SBCs into these various transportation modes entails not only rethinking battery architecture but also meeting rigorous safety and performance standards specific to each application.

There are two main approaches under investigation in developing multi-functional structural composites. The first one focuses on adding functionalities to structures by embedding offthe- shelf thin batteries into composite laminates or sandwich panels. This approach mostly emerged from the necessity of optimising the volume, rather than the weight, of a composite structure by embedding electrical power elements without compromising their mechanical performance. Nevertheless, this process does not result in a remarkable overall improvement since the embedded battery elements bear no load. Hence, their mass does not contribute to the structural performance of the final product.

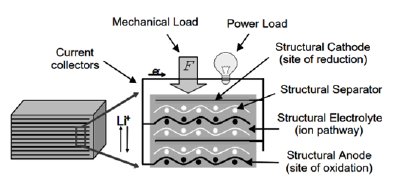

On the other hand, in the second approach, the aim is to develop multifunctional composite materials where the reinforcement elements act as the electrodes while the polymeric matrix works as the electrolyte and as a structural binder for the fibre. The concept of monolithic multifunctional materials comes from the consideration that high-performance composites and modern lithium-ion batteries have several features in common. First, carbon Fibres, commonly used in high-performance composites, exhibit remarkable electrochemical properties such as good electrical conductivity and high lithium-ion intercalation in the case of the graphite carbon allotrope. Also, the layered configuration that characterises both high-performance composites and stateof- the-art lithium-ion batteries could be exploited for a synergistic design. Furthermore, the well-developed various composite processing techniques allow great freedom in the design of innovative configurations for the structural batteries. Considering the significant potential of the latter SBC in solving both mass and energy storage challenges, the present review study focuses on this topic. First, the working structure of batteries is explained briefly, and then the current state of research and Technology Readiness Level (TRL) of structural batteries is reviewed.

Working of structural battery composites

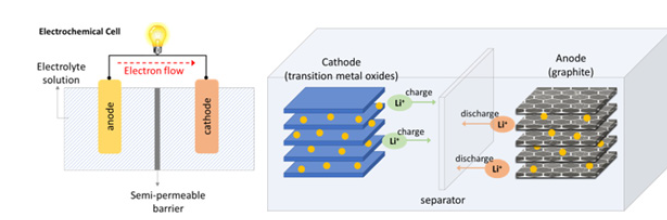

Understanding the operational dynamics of a conventional battery is pivotal when examining the innovative structure of SBCs. A traditional battery transforms chemical energy into direct current power through an electrochemical process involving two electrodes: the anode (negative) and the cathode (positive). In lithium-ion (Li-ion) batteries, widely utilised for their rechargeability, lithium ions shuttle between the anode and cathode during discharge and recharge cycles. These cells utilise materials like graphite for the anode and transition metal oxides for the cathode, with the ions travelling through an electrolyte, typically a lithium salt [82,83] as shown in Figure 5. The process is facilitated by a microporous film separator that prevents electrical contact between the electrodes while allowing ionic flow.

Figure 5:Schematic illustration of a Li battery working mechanism [82].

Figure 6:Fabricating embedded battery composite: a) making a rectangular cut-out space in carbon fabric equal to the size of the battery, b) placing the battery into the fabric cut-out, and c) applying the top plies and passing electrical wires between the carbon fibres yarns [88].

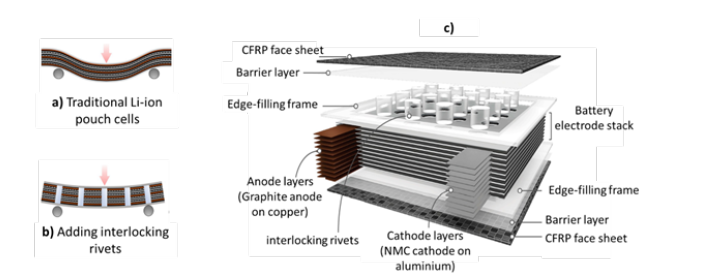

In contrast, SBCs reimagine this structure to provide both energy storage and mechanical strength. Researchers have pursued two approaches: creating multifunctional materials where battery components such as the carbon fibre anode and cathode, reinforced with carbon fibres, are embedded in a solid electrolyte matrix and developing multifunctional structures where conventional Li-ion cells are incorporated directly into composite materials. The latter approach yields a Multi-Functional Energy Storage Composite (MESC), offering space savings and integration into the structural design. For example, studies reveal that embedding batteries directly into composite structures can impact mechanical properties, with the effect varying depending on battery orientation and loading conditions (as demonstrated in Figure 6) [84-86]. The design challenge is to balance energy storage with structural integrity, as embedding conventional Li-ion batteries often degrades mechanical performance. Galos et al.’s [85,86] work further investigates this compromise between energy density and structural integrity [85,86].

Addressing these concerns, Ladpli et al. [87] proposed a novel design for MESCs that introduces polymer rivets through the thickness of stacked lithium-ion battery electrodes, establishing a mechanical linkage and allowing the battery to participate in load bearing (Figure 7). This design retains the chemical properties of the battery while enhancing structural functionality, illustrating a key advantage of SBCs: their dual role as both energy suppliers and structural elements within a vehicle or device. SBCs represent a significant leap forward, enabling technologies like electric UAVs to push boundaries in mileage and payload without the weight penalties of conventional batteries. However, transitioning from conventional batteries to SBCs involves meticulous engineering to maintain safety standards and performance, a task that becomes increasingly complex as the demands on these dual-purpose batteries grow.

Figure 7:Mechanical comparison between MESC and typical Li-ion pouch cell. A) Pouch cells consist of loosely laminated, thin electrode layers that provide minimal resistance to mechanical loading, and b) the addition of structural face sheets and interlocking rivets as separate solutions; c) the 3D schematic illustration of MESC. An array of through-thickness rivets is used to interlock a stack of typical Li-ion battery electrodes three-dimensionally [87].

Multifunctional energy storage structural composites – materials

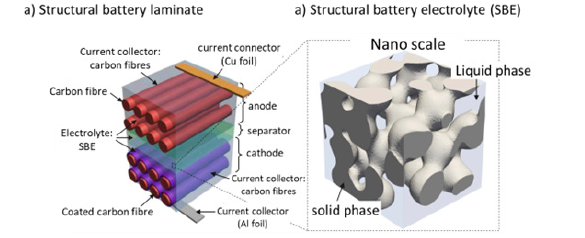

Figure 8:a) Schematic demonstration of a laminated structural battery; b) numerically created porous nanostructure, representing an idealised fine-scale geometry of the structural battery electrolyte that is made of a solid phase (polymer) saturated with a liquid electrolyte [52].

SBC has been explored to provide a massless electrical energy storage system where the composites were prepared from Carbon Fibres (CFs) in an electrolyte matrix where neat CFs, owing to their excellent mechanical properties along with high lithium insertion capacity and electrical conductivity, acted as negative electrodes. Positive electrodes were made of LiFePO4-coated CFs, where LiFePO4 is electrochemically active. The structural battery electrolyte conducts Li-ion and transfers mechanical loads between fibres. Figure 8(a) schematically illustrates a laminated structural battery. Here, the negative (anode) and positive (cathode) electrodes are made from carbon fibres and coated carbon fibres, respectively, and they are embedded in a two-phase Structural Battery Electrolyte (SBE) matrix. The SBE is a bi-continuous bi-phasic composite that consists of a nano-porous polymer with open pores, saturated with the liquid electrolyte seen in Figure 8(b). The solid phase of SBE makes it possible to distribute mechanical loads, while the liquid phase allows the ion transport between the electrodes [52]. Various components of the structural batteries such as the battery elements (anode, cathode, electrolyte, separator), structural material, fabrication techniques (laminated and 3D architectures), Other processes (mechanical, electrochemical and thermal processes) as well as testing techniques have been researched over the recent years. The complex process of structural battery electrode manufacturing has highlighted the importance of the process leading to coating structure and its effect on the chemical, mechanical and electrochemical properties identifying the process structure-property relations [88,89].

Following the methodology developed by Ashby and his coworkers on multi-functional materials from early 90s [90], Thomas et al. [69] have carried out significant research in developing and demonstrating multi-functional structural battery systems. Their structural battery laminate comprised of electrodes made from active particles of Li-ion, bonded by a polymer matrix of Polyvinyl Difluoride (PVDF) and Hexafluoropropylene (HFP), expanded metal mesh embedded in the active layers as current collectors and a thin layer of micro-porous polyolefin as separators. They reported to have obtained specific energy of 95.2Wh/Kg from 0.36cm thick carbon-epoxy reinforced structural batteries. Lyman et al. [91] studied system level implications of adopting structural energy storage for NASA and reported their work to be at TRL 3. Their structural battery panel comprised a two-sided cathode sandwiched between two anodes that were fabricated from carbon fabric. Part of the carbon fabric was saturated with resin to yield high strength, and the rest was exposed to liquid electrolyte to intercalate Li-ions and exhibited a nominal capacity of 1.25Ah. South et al. [92] fabricated a multi-functional structural battery for U.S. Army applications, consisting of a metal mesh cathode coated with lithium-ion donor material, glass fabric separator, structural polymer electrolyte doped with Li salt and Polyethene Glycol (PEG) resin. These structural battery prototypes were designed and fabricated, and their ion conductivity and compressive stiffness were measured. Acrylate and methacrylate monomers electrolyte systems to identify the suitable electrolyte material having both conductive and structural properties. The study identified structural electrolytes with high ionic conductivity as a major requirement for structural batteries. Also, it concluded that the general conception, design and implementation of the structural battery system requires interdisciplinary coordination and cooperation.

In 2007, Snyder & team [93] from the U.S. Army Research laboratory published their work on exploring the possibilities of designing the structural properties directly into electrolytes to achieve significant improvement in the performance of structural batteries. Vinyl ester derivatives of Polyethylene Glycol (PEG) that could dissolve Li ions were utilised to form the first structural battery electrolyte. The U.S. Army Research laboratory further explored the fabrication and performance of structural batteries for a low-cost scalable method, and their battery structure consisted of carbon fibre fabric acting as an anode, fibreglass separator layer, metal mesh coated with cathode material (LiCoO2, LiFePO4), and structural solid polymer electrolyte binding the components together (Figure 9). However, the mechanical and electrical properties were not quantified in this work [94]. Since then, more studies have been carried out by other researchers to enhance the utilisation of carbon Fibre in structural batteries. Carbon fibres are considered among the top materials for lightweight structural electrodes since they have high specific tensile stiffness and ultimate tensile strength, and high lithium-ion intercalation capability. The electrical properties of Carbon Fibre Reinforced Polymer (CFRP) composites, already known for their excellent strength-to-weight ratio, has attracted attention as being a suitable option for structural batteries owing to their potential to store electrical energy.

Figure 9:Concept of a structural battery [94].

In a study by Carlson et al. [95], structural capacitors made from carbon fibre epoxy composites with three different polymer film dielectric separators (PA, PET & PC) were found to have the potential for high multi-functional efficiency and high capacitances compared to other studies while providing increased mechanical strength. The team also studied the effect of plasma surface treatment of the dielectric films on the structural performance of these capacitors and reported that depending on the film thickness and surface plasma treatment, significantly improved multifunctional designs with overall weight savings could be achieved. In another study, Ekstedt et al. [96] worked on structural Li-ion battery prototypes based on CFs as anode with a copper collector, glass fibre separator, LiFePO4 as cathode coated onto aluminium fibre wave as a collector, and solid polymer and polymer gel as electrolytes were studied to confirm the concept of using carbon fibres as the anode in addition to providing load-bearing functionality. The electrical properties of this structural battery were reported as 3.3V open-circuit potential and 268.2Wh/kg of specific energy.

Using carbon fibre as the anode in structural batteries is identified as a crucial requirement for efficient structural energy storage composites. In one study, a team of researchers [97] focus on the surface area of chemically Activated Carbon Fibre (ACF) increased to 32.8m2/g, significantly larger than that of the as-received carbon fibre (0.33m2/g). The increased surface area of the ACF provides more sites for the polymer electrolyte ions to get adsorbed during the charging, resulting in improved electrochemical performance. In addition, a slight improvement in the tensile strength has also been observed for the ACFs. Qian et al. [98] activated the carbon fibres with KOH solution, observing a significant increase in the fibres surface area and porosity and consequently, the specific capacitance of carbon fabric significantly improved after the activation, from 0.06 to 2.63F/g. The activated Fibres were then modified with Carbon Nanotubes (CNT) and exhibited further improvement in electrochemical activity upon CNT-sizing and CNT-grafting, suitable for structural energy storage composites. Mistry et al. [99] developed an SBC as a technology demonstrator, investigating the potential of replacing the boot lid of Volvo S80 with a CFRP-based multifunctional material to serve as the electrical power source for lighting the boot space while acting as a structural part. The team used a twill weave carbon fabric as the electrodes, and the resin was prepared using polyethylene glycol diglycidylether (PEGDGE), Triethylenetetramine (TETA) and 1- ethyl-3-methylimidazolium bis (trifluoromethanesulfonyl) imide. TETA acted as the cross-linker for the PEGDGE, the ionic liquid provided ionic conductivity through the electrolyte, and glass fibre was used as the separator. The structural and electrical performance of the demonstrator was studied using finite element analysis, and it was reported that the structural composite could enable energy storage and weight savings while maintaining its mechanical properties in comparison to the original boot lid made of steel. Additionally, on the effect of machining (drilling) on the SBC laminate, it was concluded that capacitance or the multifunctional capability was not negatively affected. Even though the actual part was not fabricated, the study has shown the possibilities of powering through structural batteries directly, while replacing a car component.

Greenhalgh et al. [100], in their study targeting to replace the existing structural materials and energy storage devices in automotive applications with structural batteries, have detailed the structural battery concept design, structural composite manufacturing, mechanical and electrical properties characterisations, crashworthiness and impact tests, power management, modelling and analysis of costs and benefits along with development and testing of a technology demonstrator. Their small-scale structural battery technology demonstrator had: i) PAN-based CF as anode, ii) woven glass fabric as a separator, iii) CF cathode produced by aluminium foil inclusion, iv) co-polymerized polyethene glycol - PEG for the solid polymer electrolyte, v) carbon fabrics impregnated with CNTs and coated with carbon aerogel for improved electrical conductivity and enhanced surface area, and vi) epoxy resin with ionic liquid and Li-salt forming the matrix. Upon demonstrating an overall weight saving in comparison to the existing structural materials and energy storage devices, the work focused on the production methodology of actual SBC.

Solid Polymer Electrolytes (SPE) in structural batteries transfer the mechanical load to the reinforcing fibres and enable the Lithium-ion transfer between the electrodes. An interesting work was carried out by Leijonmarck et al. [101] in the solid polymer electrolytes field. The team developed and reported a method to deposit a thin SPE coating around individual carbon fibres as a novel concept in structural battery designs. Using electro-coating, they coated methacrylate-based solid polymer electrolytes onto carbon fibres, a dense uniform, apparently pinhole-free, poly (Methoxy Polyethene Glycol (350) Mon Methacrylate) coating with an average coating thickness of 470nm was achieved. Li-triflate used as a supporting electrolyte, remained in the coating after the coating process. The Li-ion content in the solid polymer coating was found to be sufficiently high for battery applications. The team also built a battery device, employing the SPE-coated carbon fibres as the negative electrode, where the battery demonstrated a reversible specific capacity of 260mA h/g at low currents (C/10). This performance suggests that these coated carbon fibres can be employed in future structural composite batteries. In addition to the SPE coating and testing techniques, material and fibre preparation using raw material bought from commercial suppliers, the coating process, experimental characterisation, assembly of battery cells and electric cycling of carbon fibre batteries with LiFePO4 cathode for structural capacitors were detailed by Carlson [102]. Gasco & Feraboli [103] studied nanostructured Thin Film Battery (TFB) technology for multi-functional structural batteries and reported that the curing temperature was a crucial factor limiting the battery survivability during the manufacturing process.

In order to fully exploit the load-bearing and electrical properties of CFs in structural batteries, they need to be combined with a suitable electrolyte matrix which exhibits both load-transferring capacity and good Li-ion conduction. Liquid electrolytes were traditionally used to meet the demand of high Liion mobility. However, the drawback with these electrolytes is that they do not transfer load and also an additional casing is required for containment and protection. Gel Polymer Electrolytes (GPEs) or Solid Polymer Electrolytes (SPEs) are suitable alternatives since they provide enhanced shape retention and, unlike liquids, have fewer leakage problems. SPEs made of thermoset polymers with Polyethene Glycol (PEG) are primarily used in the structure for improved Li ion conductivity. The Structural Battery Electrolytes (SBEs) prepared by reaction-induced phase-separation have significantly improved both elastic modulus and ionic conductivity compared to the non-phase-separated electrolytes. The cycling behaviour of a lamina of a half-cell prepared with this SBE was as good as that of carbon fibre cycled with the traditionally used liquid electrolytes [104].

Gonzalez & Colleagues [105] have prepared a comprehensive report on the novel strategies available in fibre-reinforced polymer matrix composite manufacturing at the industrial level, along with various simulation and mechanical properties testing techniques available to predict defects during the manufacturing of composite laminates. From this work and upon comparing the mechanical and electrical properties of CFs, CNT fibre and its composites, as shown in Table 1, the authors concluded the incorporation of nanocarbons to be a potential strategy to enhance the electrical properties of CFRP composites for structural batteries. This claim is in alignment with the results published from a study on enhancing electrochemical properties of the CFRP composite through carbon fibre activation and grafting [106]. Additionally, the outcome of another study also supported the idea of using CNT and carbon fabric combination for structural battery applications [107].

Table 1:Comparison of mechanical and electrical properties of carbon fibres, CNT fibres and their composites [105].

The significant role of microstructure and crystal size on the multifunctional performance of carbon fibre, such as tensile strength, electrochemical properties and Li-ion intercalation mechanism, were demonstrated, and it was concluded that the structural and flexible electrodes for batteries can be designed where stiffness has to be traded for electrochemical capacity and mechanical strength, and vice versa [108]. In a similar study, the carbon fibre unidirectional lamina produced was electrochemically cycled against lithium for 10 cycles and reported a capacity exceeding 200mAh/g. The longitudinal modulus was measured to be 52GPa, which is relatively low due to the low volume fraction of fibres of 18%. However, the study concluded that by increasing the fibre volume fraction in the lamina, both the longitude modulus and electrochemical properties of the structural battery would improve [109]. In another study on structural batteries, positive electrodes were manufactured with LiFePO4 coating, Polyvinylidene Fluoride (PVDF) and carbon black onto CFs and showed a reasonable capacity of 60-110mAh/g, good rate performance of 0.7 retention at 2C compared to 0.1C and the coating was unaffected by continuous cycling. The mechanical tests revealed that the adhesion of the coating would be sufficient to use it as a load-bearing structural material. Manufacturing a full structural battery with positive electrodes coated with this technique, pristine CF negative electrodes in an SBE matrix was proposed as the next step towards the goal of realising the full potential of structural batteries [110].

A similar study on dip-coating positive electrode carbon Fibre with LiFePO4 (LFP) followed by a layer-by-layer assembly of LiFePO4 particles and carbonizing the coating reported the specific capacity approaching a value of 100mAh/g. Carbonizing the coated CF under Argon for one hour was aimed at turning the insulting cellulose nanofibrils gel electrolyte into electrically conductive material, thus allowing an unrestricted current flow. These coatings could transfer mechanical loads and also possess good electrochemical properties. However, the performance of these coated CF-positive electrodes in the SBE matrix was not reported [111]. A study on two Structural Battery Electrolyte (SBE) matrices, consisting of a twophase system of a polymer phase with an interpenetrating network of liquid electrolytes, characterized the adhesive properties between SBEs and the CFs [112]. It was confirmed that the liquid phase of the SBE was in contact with the carbon fibres. Their results also showed that the mechanical adhesion of the fibre-matrix interface was lower than that of a commercial non-ion conducting polymer matrix but sufficient for structural battery applications. Thermal curing was also identified as an appropriate technique for the upscale manufacturing of structural batteries consisting of multiple CF layers. Schutzeichel et al. [113] worked on structural batteries and developed a new coating material for carbon fibre for Polymer-electrolyte-coated carbon fibres. They reported improved mechanical, electrical and thermo-mechanical properties of 3D-structural energy storage systems compared to classical CFRP laminates.

In a study on electrode design [114], it was demonstrated that coating a thin film of electroconductive Polyacrylonitrile (PAN) onto the surface of the negative and positive electrodes, which consisted of carbon fibres coated with active battery materials, drastically improved the adhesion and multifunctional structural energy storage performance. With this electrode design, a laminate SBC containing lithium iron phosphate (LFP) cathodes and graphite anodes was developed, which exhibited a maximum energy density of 58Wh/kg. These full-cell structural batteries also showed capacity retention of more than 80%, exceeding one hundred cycles, with an average energy density of 52Wh/kg. It was also reported that during battery operation and mechanical loading, the PAN coating could help reduce or eliminate the interfacial delamination and provide a compact and adherent fibre-matrix interphase, enabling significant system-level volume or cost savings.

In a paper by Yang et al. [115], research progress on the application of carbon fibres and their hybrid materials in many novel battery technologies has been discussed. The synthesis procedures, the chemical properties, and the pros and cons of the carbon-Fibre-based materials are discussed along with the charging and discharging principles of various equipment. The authors have summarised the characteristics of different structures of carbon fibre used in Li-ion batteries, such as current density, capacity retention, reversible capacity, cycle number, and the type of electrolyte. The relationship between the architecture of the material and its electrochemical performance is also analysed in this article (Table 2).

Table 2:Compilation of electrical properties of CF-based Li-ion batteries [62].

Apart from the studies focused on the construction methods and development of individual elements, there have been other studies investigating the various testing techniques and analytical models for understanding the mechanical and load bearing of structural batteries. An analytical model developed by Thomas & Qidwai [69] for three different structural battery configurations revealed the yielding of packaging material as the dominant failure mode. It was also noted that the failure shifted from the packaging to carbon-epoxy when the thickness of the latter exceeded a certain value. The surface area and tensile strength of chemically activated carbon fibres, along with their influence on electrical properties, ionic conductivity, and compressive properties of polymer electrolytes, were reported by Bismarck et al. [97]. In a study by Jacques et al. [116], the relationship between the amount of intercalated lithium and its effect on the tensile stiffness and the Ultimate Tensile Strength (UTS) of carbon fibre composite was investigated and it was suggested that: i) the drop in the UTS might depend on the degree of lithiation on the defective areas of the CFs and, ii) further exploration on the impact of intercalated Li on the CF microstructure was needed. In their work on structural supercapacitors, which carry mechanical load while storing/ delivering electrical energy, Greenhalgh et al. [117], also investigated some critical mechanical properties of multi-functional materials to shed light on the relationships between the microstructures and fracture mechanisms. It reported a conflicting requirement of the microstructure of multifunctional structural composite that needs be rigid and solid for mechanical performance whilst porous and non-tortuous for ionic conductivity.

Dionisi et al. [118] reported a method for analysing the global deformations and interlaminar stresses in a structural battery laminate which arise from large volume changes in carbon fibres when intercalated with Li-ions. To model the volume expansions in laminated structural batteries, caused by caused by lithiumion intercalation in carbon fibre electrodes, they developed an analytical model which was validated by finite element method. This model allows the study of the magnitude of interlaminar stresses and therefore the risk of delamination damage due to the electrochemically induced expansions. Global laminate deformations can also be studied using the developed model. Such capabilities enable selection of favourable lay-ups and fibre orientations for minimizing deformations and delamination. Jiang et al. [119] describes the process of creating carbon Fibre reinforced anodes and cathodes that are decorated with active materials like lithium titanate and LiNi0.3Mn0.3Co0.3O2 (NMC111), embedded in a polymer gel electrolyte. In addition, focuses on the innovations around polymer gel electrolytes which consist of PVDF particles dispersed in an ionic liquid containing a lithium salt, explaining their structural and ionic properties which are crucial for the multifunctionality of the composites.

To investigate the effects of State of Charge (SOC) on the elastic properties of SBC, an analytical model based on micromechanical models was developed, enabling estimation of the effective elastic properties of SBC at different SOC [120]. The research team performed a parametric study to identify how different design parameters, such as volume fraction of active materials, stiffness of constituents, type of positive electrode material, etc., affect the moduli of the composite lamina at extremes of SOC. The study observed that the transverse elastic properties E2 and G23, as well as the in-plane shear modulus G12, were strongly affected by the SOC while the longitudinal stiffness E1 was not. The authors identified the fibre volume fraction and the properties of the coating, such as stiffness and Poisson’s ratio, to be critical parameters having a significant impact on the effect of SOC on the effective elastic properties of the composite lamina. The study demonstrated the importance of considering the effects of SOC on elastic properties when designing SBC components.

Structural performance (mass saving potential) – mass less batteries

Considering that the primary objective of building SBC is to eliminate/reduce the mass that conventional batteries add to electrical aircraft, UAVs and cars, it is essential to verify whether the SBC can outperform the structural composite+battery system in terms of mass, as a trade-off between the mechanical properties and electrical performance. Snyder et al. [121] and O’Brien et al. [122] reported a performance metric for structural power composites. While their work was focused on structural supercapacitors, it could be applied to structural batteries as well. The developed metric can be employed to validate multifunctional performance and is applied to manufactured structural capacitors. However, these studies do not present a parametric model for predicting such supercapacitors. In another study, Johannisson et al. [123] developed an analytical model with a bottom-up approach, which considers the two fields of electrochemical and solid mechanics in the analysis, to evaluate the actual mass-savings of the SBC compared to the structural composite + battery systems. In this model, the structural battery has the same mechanical stiffness for a given load case as the structural composite and stores the same amount of electrical energy as the standard Li-ion battery. Considering that there is often an inverse relationship between the mechanical and electrochemical properties of multifunctional materials, the authors performed a sensitivity analysis on variables for the structural battery to understand these relationships. The analytical model investigated a standard laminar CFRP with a Liion structural battery, calculating the mechanical properties and electrochemical energy storage potential. The model estimated the mass of the structural battery and compared this value with the combined mass of a structural composite plate plus a standard Li-ion battery. This model has also underlined the essential parameters required to design structural batteries, such as the volume fraction of carbon fibre electrodes, the thickness of the separator, ionic conductivity and the elastic modulus of SBE, etc., for outperforming the individual monofunctional elements (structural composite+standard battery system). Also, case studies were performed on the use of structural batteries in the roof of an electric car, an interior panel of an aircraft, the hull of an electric ferry and the top and bottom covers of a laptop. The results showed that it is possible to save mass compared to monofunctional elements but that it would depend strongly on the structure it is compared with [123].

In an interesting work by Carlstedt & Asp [124], a modelling framework was introduced, allowing the evaluation of the systemlevel performance of electric vehicles with SBC. Using the framework, a comparative study was performed for the Tesla Model S and BMW i3 with rated ranges of 500km (85kWh battery pack) and 300km (33kWh battery pack) for the NEDC velocity cycle, respectively [124]. A general breakdown pf the two vehicles is provided in Table 3, with the parts having the potential to be replaced by SBCs highlighted in bold. The comparative study demonstrated a compelling weight-saving potential while maintaining the drive range performance. It was also concluded that if the vehicle weight were to be maintained the same while introducing the structural batteries, this would increase the driving range of the EVs by 70%.

Table 3:Estimated breakdown of vehicle weights with potential parts for SBC replacement in bold [124].

The comparative study between Tesla S and BMW i3 consisted of three case studies: case 1) the existing batteries were removed and replaced by 270kg (in Tesla S) and 170Kg (in BMW i3) of structural batteries, corresponding to about 70% of the mass of interior and exterior panels being made of SBC; case 2) included the SBCs from case 1 plus replacing 60% of space frame/life module in Tesla and BMW i3 with SBCs, respectively, resulting in the total mass of SBC in Tesla and BMW i3 to be 490 and 260, respectively. Lastly, case 3 corresponds to Case 2, where the mass of the SBC is doubled, and the additional mass is added to the total weight of the vehicle. This can e.g. be done by doubling the thicknesses of the components made of SBCs. In case 3, the SBCs were 980kg and 520kg in Tesla and BMW i3, respectively. The potential benefits of using the SBCs in each case study are summarised in Table 4, [124].

Table 4:Potential benefits of using SBC in two types of EVs [124].

Meanwhile, Chan et al. [125] focused on the aviation design aspects, Graphene Oxide (GO) films as dielectric layers for structural dielectric capacitors, aiming to harness their high dielectric constants and breakdown strength to store energy efficiently. The incorporation of GO films was found to slightly reduce the tensile modulus and strength of Carbon Fibre Reinforced Polymers (CFRP), suggesting that the mechanical properties of SDCs are finely balanced with energy storage performance. This work contributes to the fundamental understanding of the interplay between mechanical integrity and energy storage efficiency in structural energy storage composites. A team of researchers [126] have showcased substantial strides in developing carbon fibre lithium-ion structural batteries. These batteries uniquely integrate structural functions with energy storage, potentially revolutionising electric vehicle design by reducing overall mass and enhancing efficiency. Furthermore, this team has placed considerable emphasis on structural supercapacitors, which are now nearing industrial application readiness. The architecture of these supercapacitors includes electrodes made of carbon fibre fabric, enhanced with added active materials to increase charge capacity. This design not only prevents electrical shorting but also maintains a structural integrity essential for vehicular use.

Di Mauro et al. [127] worked on optimising the configuration of structural batteries for different transportation applications is a challenging goal. When designing new products, it is important to carefully address the emission of pollutants and the specific procedure of battery recycling and recovery. The objective is to decrease the mass. Considering that conventional battery packs do not enhance structural performance; it is important to highlight that the use of structural batteries can improve mechanical qualities by integrating them into the primary structure. The research examines the behaviour of a composite structural battery model when it is subjected to low-velocity impact testing. The manufacturing process of the structural battery model is explained, and the experimental activities are conducted using a customised drop tower. These activities are then duplicated numerically using explicit code to improve the understanding of the structural dynamics. The differences between a carbon fibre laminate and the subject of comparison are emphasised in terms of the force exerted upon impact and the displacement of the dart while maintaining equal amounts of energy.

Jacob Eaton et al., [128] delves into the multifunctional efficiency of SBCs through extensive thermo-electro-chemical simulations. This study assesses how various thermal boundary conditions affect the specific power and multifunctional efficiency of SBCs, particularly focusing on their application in environments with significant temperature fluctuations. It explores the impact of thermal boundary conditions on the battery’s power capabilities using simulations that incorporate one-dimensional heat transfer equations, equivalent circuit modelling for resistivity-induced losses, and finite difference methods for analysis. The findings underscore the importance of insulation and environmental conditions in influencing the performance and efficiency of SBCs, presenting a detailed exploration of temperature-dependent power characteristics and the potential of SBCs to reduce mass while retaining or enhancing energy storage capacity.

TRL assessment

Despite all the above studies, structural batteries have not entered the market as a mature and fully adopted technology yet. The next section explores the TRL and MRL of structural batteries. Significant improvement in the overall capacity of the energy storage system would require the exploration of new ideas and concepts, engineering design and interfaces, materials development and manufacturability with value-added functionalities. Capacitywise scalability is deemed impossible with the more mature battery technology such as Na-S and Li-ion battery types (Table 5). If battery storage capacity in the magnitude of GW or at least more than 100MW per module or system is needed for the energy transition, no battery type reaches TRL above 6 [129].

Table 5:TRL assessment table.