- Submissions

Full Text

Peer Review Journal of Solar & Photoenergy Systems

Effect of Texturing Regimes on the Efficiency of p-Si/Textured-Si/ZnS1-xSeSex Heterojunctions Solar Cells

HM Mammadov, MA Jafarov*, EF Nasirov and EA Chanmammadova

Azerbaijan

*Corresponding author: MA Jafarov, Z Khalilov street 23, Baku, Azerbaijan

Submission: April 18, 2019;Published: May 22, 2019

Volume1 Issue3 May, 2019

Abstract

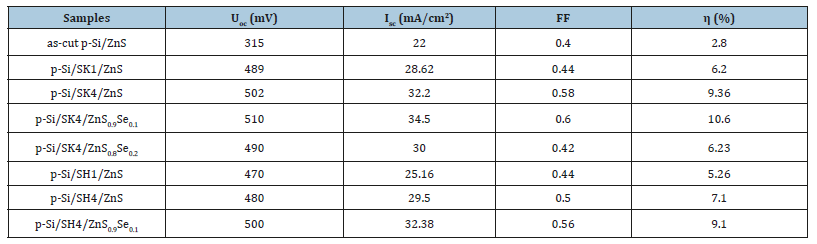

In this paper the p-Si/ textured-Si/ZnS1-xSeSex heterojunctions were fabricated by electrochemical deposition of ZnS1-xSeSex (x=0; 0.1 and 0.2) films onto the crystalline p-Si/SK and p-Si/SH substrates (SK and SH are textured silicon etched in KOH+C3H8O and HF+HNO3, respectively). Photoelectrical properties of heterojunctions were investigated depending on the etching duration, solution temperature and concentration of solids in solutions (KOH and HF (1-5wt%); C3H8O and HNO3 (3-10vol%). It has been established that the efficiency of the p-Si/ textured-Si/ ZnS1-xSeSex solar cells depends on the etching regime. The optimal concentration of solids (KOH-3wt%+ C3H8O-6vol%; HF-5wt%+HNO3-8vol%), solution temperature (80 ˚C) and etching duration (40 min) were determined for maximum efficiency of solar cells: for p-Si/SK4/ZnS-FF=0.58; η=9.36%; for p-Si/SH4/ZnS-FF=0.5; η=7.1%; for p-Si/SK4/ ZnS0.9Se0.1- (Jsc -34mA/cm2, Voc - 0, 620V) FF -0,65; η=10.6% and for p-Si/SH4/ZnS0.9Se0.1- FF=0.56; η=9.1%.

Introduction

Cost distribution of c-Si solar cells is clearly dominated by material costs, especially by the costs of the silicon wafer. But besides low-cost technologies (chemical deposition methods), cell efficiency is the main lever to reduce costs even more. In order to reduce the light loss via reflection, the texturing of front surfaces on crystalline silicon solar cells is mostly performed for improvement of the cell efficiency, by means of its antireflection properties and light trapping [1-6].

Since, application of wide-gap semiconductors of CdS, ZnS, ZnSe and its solid solutions as optical window in silicon-based heterojunctions, to some extent, allows minimizing the free charge losses due to surface recombination. Application of the ternary and even quaternary solutions of above-mentioned semiconductors has succeeded in reducing the lattice mismatch, but it has not been possible to achieve sufficiently value of efficiency due to the large value of silicon refractive index [7-9]. The use of textured silicon allows solving problems with surface reflections related to refractive index of silicon. There are many reports of p-Si/ textured-Si/ ZnS heterojunction solar cells [10-12]. But textured silicon-based heterojunction solar cells with n- ZnS1-xSeSex have seldom been reported. Based on the above, this paper aims to improve the p-Si/ ZnS1-xSeSex solar cell conversion efficiency by developing improved surface texturing.

Experiment

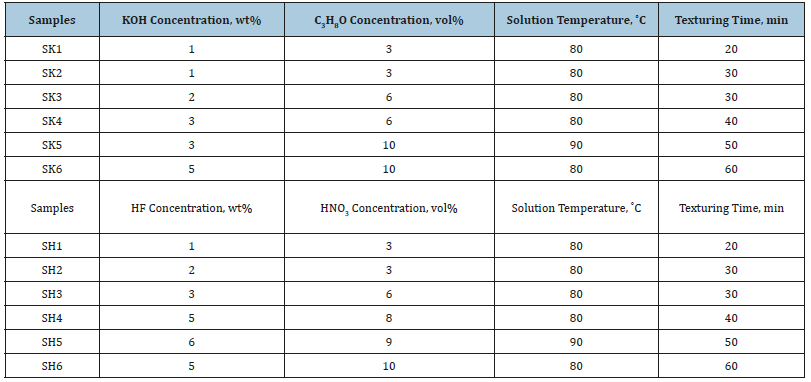

Monocrystalline wafers of p-Si (100) with thicknesses 800μm and resistivity (0.8-1)Ω.cm were used as absorber. Before texturization, the Si wafers were cleaned by acetone, ethanol, and deionized water and dried by N2 gas. The texturing of wafers was carried out in two types of solutions: KOH (1-5 wt%) + C3H8O (3-10vol%) +H2O (100ml) and HF (1-5wt%) + HNO3 (3-10%) + H2O (100ml). The samples with dimension of 2×2cm2 were separated from one wafers of p-Si, and each sample was etched in different solutions, temperature and etching time (Table 1).

After texturing, the p-Si wafers were cleaned by ethanol, deionized water and dried by N2 gas. Samples with 1×1cm2 dimension were separated from each textured Si wafers and used as substrate (as a cathode) for electrochemical deposition of ZnS1-xSeSex films. Electrochemical deposition of the ZnS1-xSeSex (x=0; 0.1; 0.2) films onto the textured p-Si substrates was carried out at temperature of 80 ˚C. The electrodeposition bath system is composed of ZnSO4 as source of cation, SeO2 and Na2S2O3 as source of anions, H2SO4 as pH control, K2SO4 as inert electrolyte and distilled water.

Table 1:

Cyclic voltammetry was used to monitor the electrochemical reactions in solutions of ZnSO4, SeO2 and Na2S2O3, then in their combined solution of the same concentration and pH. The cyclic voltammograms was scanned in the potential range 1.2V to -1.2V versus graphite (or Ag/AgCl) electrodes. Depending on the deposition time, ZnS1-xSeSex films with thickness up to 520, 530nm with different morphology were deposited from a solution. Pure aluminum (Al) was used as the back-electrode contact. The front contact was made by Al, and indium (In) materials in a grid form

Result and Discussion

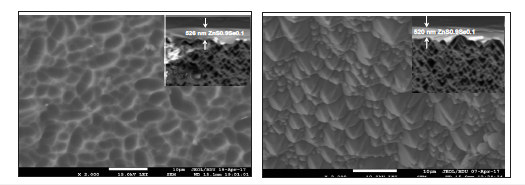

Figure 1:SEM pictures of Textured SH4

Figure 1b: SK4 wafers.

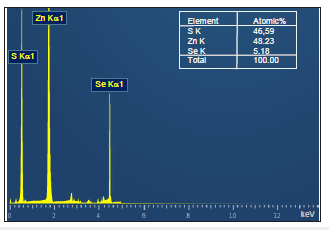

It is established that the etching in HF+HNO3 (SH samples in Table 1) and KOH+ C3H8O (SK samples in Table 1) solutions results to formation of oval shaped pits and pyramids on the silicon surface, respectively, which morphology and size depends on the solution temperature, concentration of contents and etching time (different etching regimes are shown in Table 1). SEM pictures show that the pits and pyramids began to appear after 20-30min etching time (samples SH1, SH2, SH3, SK1, SK2 and SK3). The surface these samples were uneven. It is established that the required distribution of pits and pyramids can be get by controlling the solution concentration. After the etching for 40min the surface of silicon (sample SH4 and SK4) was covered with oval shaped pits and pyramids distributed relatively evenly and Si wafers was flat, which is very important for improving the stability of solar cells (Figure 1a & 1b). There was no change in the surface morphology of Si wafers at future increase of solutions concentration, etching time and temperature (samples SK5, SK6, SH5 and SH6). Figure 1a & 1b shows also the cross-section SEM pictures of textured p-Si/ZnS1- xSex junctions. As seen the ZnS1-xSeSex films are uniformly deposited on the p-Si substrate. Chemical composition analysis of ZnS1-xSeSex films was done by EDS technique. Figure 2 show EDS spectra of ZnS1-xSeSex (x=0.1) films.

Figure 2:EDS spectra of ZnS1-xSeSex (x=0.1) films.

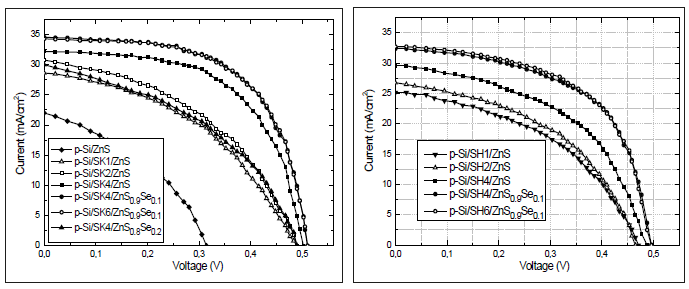

All investigated heterojunctions solar cells based on textured silicon under standard test conditions demonstrated photovoltaic performances under AM1.5 illumination (W=100 mW/cm2), which sign of open circuit photo-voltage (Uoc) does not change in all region of photosensitivity. However, the maximum values of Uoc and Jsc nonmonotonically dependent on the texturization regimes (Table 2). Light J-V characteristics of the p-Si/ textured-Si/ZnS1-xSeSex measured under AM 1.5 standards, depending on the texturization regimes are shown in Figure 3. As seen the highest value of efficiency show the cells textured in KOH+C3H8O solution (SK4 samples), which can be explain by the flatness of the pyramids. A slight addition of selenium (x=0.1) leads to sharp increase in efficiency and further increase in selenium concentration (x=0.2) led to decrease in efficiency, which can be explain by the lattice matching between ZnS1-xSeSex and Si. As seen from Figure 3a & 3b, texturization in high concentration of solutions does not change the efficiency (samples SH5, SK5, SH6 and SH6).

Table 2:

Figure 3:Photovoltaic output characteristics for p-Si/textured-Si/ZnS1-xSeSex solar cells.

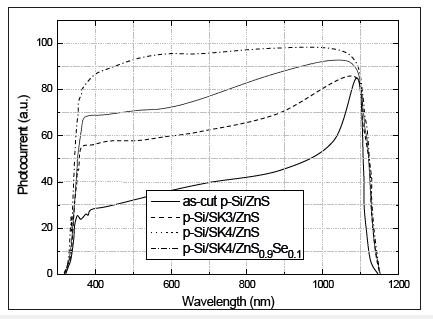

The optimal concentration of solids (KOH-3wt% +C3H8O - 6 vol%; HF-5wt% + HNO3-8 vol%), solution temperature (80 ˚C) and etching duration (40min) is directly reflected in the improved high short-circuit current density (Jsc-34mA/cm2) as well as improved open-circuit voltage (Voc- 0,620V), fill factor (FF-0,65) for p-Si/SK4/ZnS0.9Se0.1. We investigated the spectral distribution of photocurrent depending on the texturization regime (Figure 4). However, long-wavelength peak of spectrum is due to the direct interband transitions in Si. There occurs a reconstruction of the photosensitivity spectrum after texturization, i.e. the spectrum broadens. As the solution concentration increased, photosensitivity in short wavelength region sharply increased. It is clear that this is due to the morphology of the selenium surface, i.e. degree of light absorption, which is determined by the morphology of texturized silicon.

Figure 4:Spectral distributions of photocurrent in p-Si/SK/ZnS1-xSeSex solar cells.

Conclussion

p-Si/textured-Si/ZnS1-xSeSex heterojunctions were fabricated by electrochemical deposition Efficiency of heterojunctions can be regulate by etching duration, solution temperature and concentration of solids in solutions of KOH and HF (1-5wt%); C3H8O and HNO3 (3-10vol%). Solar cells of p-Si/SK4/ZnS0.9Se0.1 show short-circuit current density (Jsc-34mA/cm2) as well open-circuit voltage (Voc-0, 620), best efficiency (10.6%) after the etching in solution of KOH-3wt% +C3H8O - 6 vol%.

References

- Kosyachenko LA (2011) Solar cells-silicon wafer-based technologies. InTech pp. 1-364.

- Fırat ES, Baytemir G, Kulakci M, Turan R (2017) Solar energy materials & solar cells. 160: 269.

- Aziz WJ, Ramizy A, Ibrahim K, Omar K, Hassan Z (2009) Journal of optoelectronics and advanced materials. 11: 1632.

- Altinoluk SH, Ciftpinar HE, Demircioglu O, Baytemir G, Akar O, et al. (2016) Energy procedia. 92: 291.

- Basu PK, Khanna A, Hameiri Z (2015) Renewable energy. 78: 590.

- Zhao J, Wang A, Green MA (1998) Applied physics letters. 73: 1991.

- Mamedov H, Mammadov V, Mammadova V, Ahmedova KH, Tagiyev E, et al. (2018) Journal of optoelectronics and advanced materials. 20: 468.

- Abdinov A, Mamedov H, Amirova S (2006) Thin solid films. 140: 511- 512.

- Mamedov H, Konya Z, Muradov M, Kukovecz A, Kordas K, et al. (2014) Solar energy engineering. 136: 44-503.

- Kaifu Q, Depeng Q, Lun C, Shenghao L, Weiliang W, et al. (2017) Materials letters. 198: 23.

- Kaifu Q, Qi X, Depeng Q, Lun C, Weiliang W, et al. (2018) Solar energy. 165: 35.

- Wen LJ, Jen YH, Tseng IT, Hang TM, Hung CL, et al. (2013) Nanoscale research letters. 8: 470.

© 2018 MA Jafarov. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)