- Submissions

Full Text

Peer Review Journal of Solar & Photoenergy Systems

Design, Fabrication and Testing of an Inexpensive Solar Water Heater

Jay N Meegoda*, Jason Jawidzik and Paul Rodriguez

New Jersey Institute of Technology, USA

*Corresponding author: Jay N Meegoda, New Jersey Institute of Technology, USA

Submission: December 17, 2018;Published: February 12, 2019

Volume1 Issue3 February 2019

Abstract

Hot water is essential for industries and households, as well as for smooth running of hospitals. A novel inexpensive flat plate solar water heater was designed using black Plexiglas instead of the conventionally preferred material of copper or metal. This design differs from conventional solar water heaters as black Plexiglas plates are used as energy insulator as well as absorber. Its function as an insulator retains solar energy; the direct thermal contact between the plates and water results in elevated thermal transfer. This design was motivated to reduce the loss due to theft in developing nations by not having metal parts. Based on initial laboratory scale tests and theoretical analysis, a solar water heater with a surface area of 1.67m2 was designed, fabricated and tested. The test results showed that the solar water heater was able to increase the outlet water temperature by 11.7 °C and produced a flow rate of 34L per hour with a thermal efficiency of 68% on sunny days. The efficiency of using this design and material is comparable or better than that of conventional ones, yet the cost of black Plexiglas is much lower than that of copper or metal. The invention is a sustainable water heating system since black Plexiglas can be produced from recycled plastic waste, which has the added benefit of lower fabrication cost of 13.7% when compared to metallic solar collectors. Proposed solar water heater in residences, hospitals and hotels will reduce greenhouse gas emission if the electric water heaters are replaced. A complete package of design drawings is provided for large scale implementation in developing nations.

Keywords: Solar water heater; Efficiency; Temperature; Irradiation; Black plexiglas; Plastic; Thermosiphon

Introduction

Access to abundant and reliable supply of hot water is not only essential for industries and households, but of paramount importance for smooth running of hospitals as well. As its necessary aid for cleaning and sterilization, washing of clothing, and generally for maintaining personal hygiene of patients and health workers among others. The usual source of energy for heating water to obtain hot water for such uses in urban areas are electricity, coal and petroleum base fuels. Similarly, charcoal and firewood are the major sources of energy for the rural areas and hence the most common means of heating water. There is a rising concern about conventional fossil fuels like oil, coal, and natural gas for energy due to limited availability, supply security and environmental pollution with resource exhaustion and emissions from production and use of fossil fuel [1-5]. In 2010, energy from fossil fuel sources amounted to 81% of the worldwide energy expenditure [6]. Current consumption rates projected depletion of the fossil fuel stock in about half a century for petroleum oil and natural gas, and the coal reserve is also projected to last just a century [7-9]. In developing nations this concern is exacerbated by economic issues, limiting their affordability. Therefore, making availability of a cheap and reliable energy supply a major constrain on socio-economic growth of the poorer nations of the world. Globally reduction in carbon emissions and air pollution requires increasing the proportion of energy harnessed from sustainable sources like biofuels, solar, wind, hydropower and geothermal, in addition to development and utilization of energy saving technologies.

The sun’s average power is approximately 1000W/m², which represents 10,000 times the power required for the world’s population [10]. Solar water heaters are one such technologies, as they operate by harnessing and utilizing the free and abundant radiation energy from sun, and therefore have found a wide spread acceptance and application in agriculture, industrial and in household applications. As such, making it one of the most popular means of solar energy utilization because of technological feasibility and economic attraction compared with other kinds of solar energy utilization [11]. Solar water heating technologies are also attracting increasing interest as a solution to saving energy and reducing greenhouse gases, thereby reducing of carbon footprint of conventional fossil fuels [12,13]. Fundamentally, solar water heaters are devices that convert the infrared energy of sunlight into thermal energy using solar thermal collectors to heat water. A water heating solar collector panel works by first collecting the heat from solar radiation onto its absorbing layer(s). Consequently, the said layers heat up the water flowing through the collector, or in some cases heat up water in an attached container. In contrast to photovoltaic cells that convert light to electricity, solar thermal collectors do not convert light to electricity and simply collect the solar radiation from the sun to heat up air, water, or other spaces. A simple example would be setting water in a black metal container out in the sun. The metal would eventually heat up, and, in turn, the water would as well.

Solar water heating systems comprise various techniques that are categorized into two major types, namely; active, which have circulating pumps and controls, and passive (natural circulation), which only employs thermal conversion. In the active or pumpcirculated system the storage tank is ground- or floor-mounted and is below the level of the collectors; a circulating pump moves water or heat transfer fluid between the tank and the collectors, this subsystem is known as Direct Circulation and Indirect Circulation systems respectively.

In the passive or natural circulation, on the other hand requires no pumping and operate using local water pressure and/or solar radiation. Primary there are two types of passive systems, known as: Integral Collector Storage (ICS) and Thermo-syphon systems. The ICS system has their hot water storage tank as the collector and cold water flows progressively through it where it is heated by the sun, the generated hot water is drawn from the top of the collector which is subsequently replaced by cold water which enters at the bottom [14]. For the Thermo-syphon systems; as the cold water gets heated by the solar radiation it becomes less dense, and water flows through the system when warm water rises as cooler water sinks, as such, the hot water naturally rises into the storage tank, which is horizontally mounted immediately above the solar collectors, through thermosiphon flow [15]. The three basic types of solar collectors commonly used for residential applications are Flat-plate collector, Integral collector-storage systems, Evacuatedtube solar collectors [15]. The success of the solar energy applications is closely related to the performance of the collectors [12] in addition the performance also depends upon climatic and operational parameters [16]. It is normal to use water as the heat transfer fluid as it has a relatively good thermal conductivity [17].

Another important component of solar water heater is the absorber, which helps in boosting the water heating by absorbing and transferring the solar radiation energy to the water. As such they are made of material that are good thermal conductors with an irregular surface to reflect possible rays that are not absorbed. One way to achieve this is to paint the surface of the material with a back paint with a good thermal absorption property. The absorption coefficient α depends on the type of materials used for the absorber sheet, but it’s always about 90% - 98% [18].

Of all the different types of solar water heater systems, natural convection system is the most common solar water heater for domestic application. In particular, Gupta and Garg (1968) modeled the thermal performance of domestic solar water heaters, employing thermos-syphon circulation between the collector and the insulated storage tank [19], in addition to systems design and performance [20-24] Investigated the performance of various types of solar collectors [25] Investigated characteristics of horizontal mantle heat exchangers for application in thermos-syphon solar water heaters [26] studied internal vertical heat exchanger with R22 in a liquid-gas phase [27]. Flat plate collector is the simplest type of collector, which were investigated by [28-31]. Flat plate collector performance is influenced by its design variables such as the nature of absorber plate [32-34], type and depth of insulation used [35], surface coating of the absorber [36,37]. Evaluated the effect of absorber plate absorption and thermal emittance on the efficiency [38]. Investigated a two phase closed thermos-syphon flat plate solar water heaters with natural circulation [39,40] studied the thermal performance of thermosiphon flat-plate solar water heater with a mantle heat exchanger [40].

One type of popular solar collector is a copper flat plate collector. A copper flat plate collector utilizes a large black copper plate with thin black copper pipes running length-wise on top of the plate. Water travels through the thin black copper pipes while the solar radiation hits the copper plate and transfers heat generated to water. Copper is ideal for these flat plate collector designs because of its high thermal conductivity, however it is very costly and a solar plate collector utilizing copper is difficult to manufacture. Skilled labor would be required to weld the copper parts together. Utilizing copper or any metal for that matter, in solar collector construction is disadvantageous because it is costly and potentially harmful to the environment. Hence a novel inexpensive flat plate solar water heater was designed using black Plexiglas instead of the conventionally preferred material of copper or metal.

Proposed Design

Material selection, design and fabrication

Black plastic sheet: The black plastic sheet is the solar absorber plate for the proposed design. The top of the plate will absorb solar radiation turning it into thermal energy due to the black color of the plate. Since the plate is made of plastic material, the thermal energy will not transfer through the plate but instead transfer to the more conductive water above the plate. Laboratory scale tests showed that the insulation properties of plastic produced higher thermal transfer rate of solar radiation energy to the water than that from a conductive metal sheet.

Transparent plastic sheet: The transparent plastic sheet serves two purposes. First, it allows the solar radiation to reach the passage. Optimum cost-efficient transparency has been found to be about 92% of the solar radiation passing through the transparent plastic sheet. Second, the transparent plastic sheet provides a greenhouse effect, where the thermal heat is not allowed to pass through the plastic sheet. To increase efficiency, another transparent plastic sheet may be added above the current sheet with a small air filled between the two transparent plastic sheets, in doing so the overall thermal losses are further reduced.

Design: The panel is constructed entirely of plastic components joined with epoxy. It has 2 main sheets. The top one is transparent to allow for the passage of sunlight. The bottom one, which is separated from the top one by a layer of flowing water and spacers, is black, to absorb the sunlight. The sheets remain equidistant from each other at all points. They are roughly 3’ x6’ in area and 1/16” or 1/8” thick. The layer of water and spacers is roughly 1/8” to 1/4”. The spacers are thin strips which run parallel to the direction of water flow. They prevent the sheets from bowing due to water pressure or collapsing prior to installation. The 6’ long sides are sealed with plastic extrusions. At both 3’ ends water enters and exits through headers, made of machined 1”x1” plastic square bar. A complete package of design drawings is provided in Appendix A for large scale implementation in developing nations.

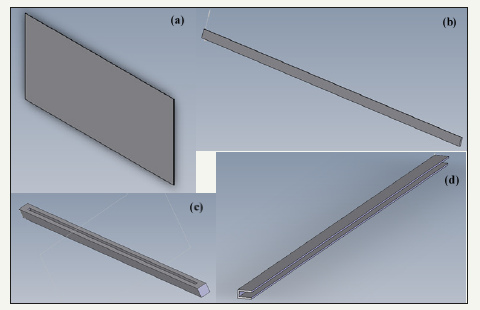

Fabrication: To fabricate the solar collector, the black plastic and the clear plastic sheet were cut to a rectangular shape of 12 inches wide by 23 inches long (Figure 1a). After which, plastic spacers were cut from the plastic strips. Two were cut to 23 inches long, to line the long edges of the panel, and one was cut to 14 inches to provide a center support in the middle of the panel (Figure 1b). Next, the headers were fabricated. For the headers, two pieces of the plastic bar were milled using a CNC milling machine. The length was milled to a value of 14 inches. Then a slot was milled out of the center of one of the faces of the bar, the slot width was ½ an inch and the slot depth was ½ an inch was well. Then a ½ inch diameter hole was drilled from the back face of the block through to the half inch slot, creating a port for the water to pass through (Figure 1c). Once the two headers were made, the next step was to go about making the side braces. The same material that was used for the headers, was used for these braces. To make these side braces, two pieces of the plastic bar were milled to a length of 22 inches. From there a slot was milled completely through the length of the entire piece, with a slot width of ½ inch and a slot depth of ½ and inch (Figure 1d).

Figure 1:a)12”x23” Black/clear plastic sheet, (b)Spacer, (c)Header, (d)Side brace.

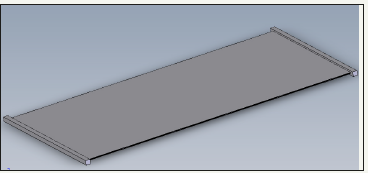

Once all the parts are acquired, solar water heater was assembled using epoxy. First, the black plastic was bonded to the spacer strips, using the epoxy. The orientation of the two long strips bonded along the long edges was used, with the smaller support strip being bonded to the center of the panel. Next, the clear panel was bonded to the spacer strips, creating a three-layer system, with the spacer strips pressed in between the black and the clear panel. After the epoxy had cured, the 22-inch side braces were introduced. These pieces were milled to have a very tight fit, so epoxy was not necessary. These side braces were to run along the 23-inch edges of the panels, with the three layers being pressed into the ½ inch slot of the braces. The braces were also offset ½ of an inch off of the end of the panels, leaving 1.2 of an inch of extension out of each end of each brace. Subsequently, the headers were introduced. Both headers were pressed onto either short end of the panels, with the outlet holes being on opposite sides, this was to induce cross flow of water from left to right. Finally, the tubing was pressed into each hole, one length of tubing was cut to ¼ of the size of the other. After this, a hole was drilled in the bucket and the longer length of tubing was bonded to the bucket, lining up with the hole. Finally, silicone was used to line all seams providing a good, robust, waster tight seal. Figure 2 shows the image of the assembled collector without the tubing or the bucket.

Figure 2:Assembled solar collector.

Theoretical analysis

Figure 3 displays a portion of the solar collector where the solar collector can be analyzed theoretically. The collector consists of a transparent plate on top to allow for the passage of solar radiation and a black plate on the bottom to absorb and transfer the solar radiation. In between these two plates is a layer of flowing water that absorbs the heat from the surface of the black plate through convection. Therefore, the black plate serves as an energy transfer mechanism to absorb the sun’s radiative energy and re-radiate it as thermal energy into the flowing water. The black plastic absorber plate is the key to the novelty of the proposed design.

Figure 3:Basic energy balance on collector plate.

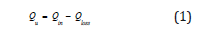

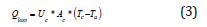

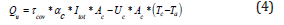

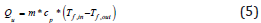

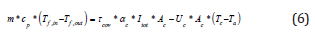

To analyze the thermal performance of certain embodiments of the present “flooded-plate” solar collector, we consider a steady state analysis heat transfer equilibrium. The energy balance depicts the amount of useful energy received from incoming solar radiation. This basic energy balance is shown in Equation 1:

where Qu=Useful Energy=rate of heat transfer from collector plate to the working fluid, W

Qin =rate of heat incident on collector plate, W

Qloss =total rate of heat loss from the collector plate to the surroundings, W Determination of in

where τcov = effective solar transmittance of collector cover (Transparent Plastic)

αc= solar absorbance of the collector plate (Black Plastic)

Q = Energy Incident on Panel= Itot* Ac

Itot = total solar irradiation per unit area. W/m2

Ac = Area of collector plate, m2 Collector Heat-Loss loss

where Uc =the total overall heat loss coefficient = Utop + Ubottom

Utop =losses from the top of the collector.

Ubottom =losses from the bottom of the collector.

Tc =Temperature of Collector

Ta =Temperature of Ambient (outside) Air

The heat losses from the top of the collector can calculated with the empirical equation developed by for other similar systems, however for our design further tests would have to be conducted on the prototype to obtain a more accurate value. The heat losses from the bottom of the collector include losses through the insulation and ambient air.

Determination of useful energy Qu

To determine the useful energy, the rate of heat transfer from the collector plate to the working fluid, we can solve the general energy balance equation by inputting in Qu and Qout into Eq 1. This is shown in Eq 4.

Alternatively, the useful energy gained by the water can be calculated based on the change of inlet and outlet water temperatures, Eq 5.

Where m=mass flow rate through the collector.

cp =average specific heat of water.

Tf,in =Inlet water temperature.

Tf ,out =Outlet water temperature.

Combining these two equations gives us a possibility of finding

Tf ,out , such that:

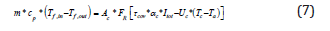

Considering other factors of efficiency and simplifying the equation, one can obtain a full relationship, Eq 7, to describe the amount of heat being absorbed by the water. This is known as the famous Hottel-Whiller-Bliss Equation [41]. R F is the ratio of actual rate of heat transfer to the working fluid to the rate of heat transferred at the inlet fluid temperature?

The test result below gives experimental data related to the proposed design.

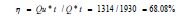

Efficiency of System (η )

The Efficiency of System is defined as:

Test result

Prototype test:

A. Date: Last week of August

B. Exposure Time: 12:37pm EST -1:27pm EST (Daylight Savings Time)

C. Address: 105 Lock Street Newark, NJ, USA

D. Latitude: 40˚44’33”

E. Longitude: 74˚10’54”

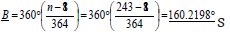

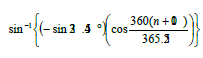

F. Equation of Time Factor (B):

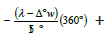

G. Equation of Time (EOT): EOT=9.87sin(2B) -7.53cosB -1.5sinB=-6.2861+7.0857-.5076=.2920 [min]

H. Local Solar time (LST): LST=Standard Time  + EOT

= Standard Time

+ EOT

= Standard Time  + .2920=Standard Time+19.9312

[min]

=> Standard Time ≈ LST–20[min]=LST– (1/3) [hours]

+ .2920=Standard Time+19.9312

[min]

=> Standard Time ≈ LST–20[min]=LST– (1/3) [hours]

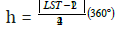

I. Hour Angle (h): h = [degrees] => LST =

[degrees] => LST = [Hours]

[Hours]

J. Sun’s Declination (δ ): δ = = sin −1 (.1403)=8.0624˚

= sin −1 (.1403)=8.0624˚

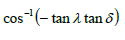

K. Hour Angle at Sunrise/Sunset ( hs ): hs = = cos−1 (− .122) = 97˚

= cos−1 (− .122) = 97˚

L. Local Solar Time at Sunrise/Sunset (LSTs): LSTs = [Hours] = 5.53 at sunrise, 18.47 at sunset [hours]

[Hours] = 5.53 at sunrise, 18.47 at sunset [hours]

M. Standard Time at Sunrise/Sunset (Standard Time s): Standard Time s=LST–1/3=5.2 at sunrise, 18.14 at sunset [hours]

N. Daylight Savings Time (Clock time) at Sunrise/Sunset: 6.2 at sunrise, 19.14 at sunset [hours]

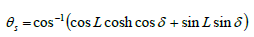

O. Solar Incident Angle on a horizontal surface ( s

θ ):

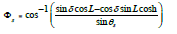

P. Solar Azimuth Angle (ϕ s ):

Q. Difference angle (γ ):

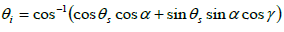

R. Solar Incident Angle on a tilted surface ( i θ

):

S. Solar Irradiation on surface normal to sun (GND): GND =

T. View Factor Between Surface and Sky (FWS): FWS =

U. Diffuse solar irradiation (GdH): GdH = (C)(GND) = .134(GND)

V. Diffuse solar irradiation incident on panel (Gd): Gd = (FWS)(C)(GND) = .128(GND)

W. Total irradiation incident on panel (Gt): Gt = GNDcosθ i + Gd

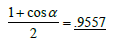

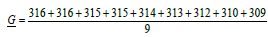

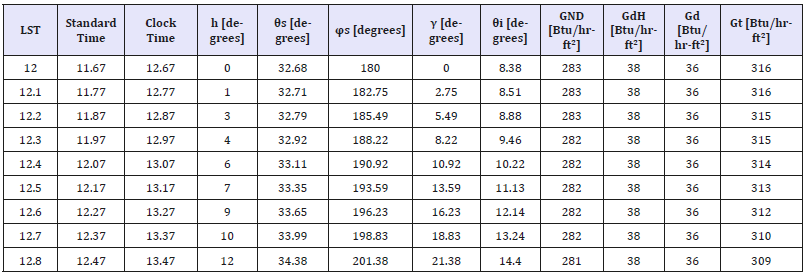

Figure 4 shows variations in irradiation values with the time of day and Table 1 shows the calculated solar data for the demonstration period. Average total irradiation incident on panel during demonstration period (G)

=313 [ Btu/hr-ft²]

=313 [ Btu/hr-ft²]

Figure 4:

Figure 5:

Table 1:Calculated solar data-demonstration period.

Field test results: The collector was placed at an angle, with the front face of the panel angled towards the sun. Next, the bucket was placed with a specific height in mind. It was necessary that the bucket was placed so that the lowest point of the water in the bucket was about 2 inches above the highest point of water in the collector. After the bucket was properly placed, the outlet tube, which would provide the heated water, was placed in the bucket, forming a circuit between the panel and the bucket itself. The thermometer was then placed in the bucket ready to measure bucket water temperature. Finally, the water was introduced to the system, being poured into the bucket. Once the reservoir was filled to 75% of the total volume, the water flowed down one tube, and into the panel. Figure 5 shows set up of the panel prototype.

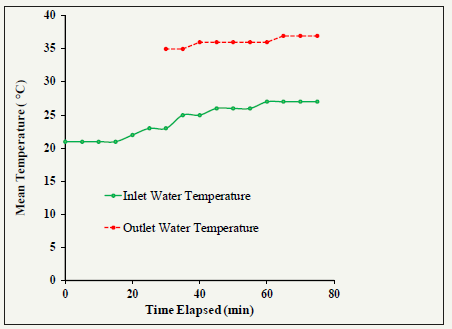

The temperature of the water in the bucket and that of outlet heated water was measured with a digital thermometer (Model# DPT392FC, General Tools & Instruments) and recorded every five minutes. Once the thermal siphon had started, the system was kept operational for about another 45 minutes, to ensure that extended use would not change any results. Figure 6 show the temperature readings. The solar heat produced hot water that was 11.7 °C hotter than the water in the inlet. During the test period of 50 minutes produced approximately 28.4L of hot water.

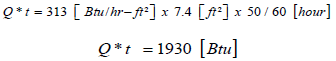

Demonstration Panel Area (A):

A=Exposed black plastic area-center supports area

A=25in x 43in - 3(3.14) in²=1065.6 square inches A=7.4 [ft²]

Total Energy Incident on Panel During Demonstration Period(

Q * t )

Figure 6:Variation of inlet and outlet temperature with time.

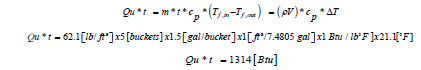

Total Energy Change of System Due to Exposure During Demonstration(Qu* ts ):

Efficiency of System During Demonstration (η ):

Required Panel Size Calculations:

Assumptions Made to Calculate Required Panel Size:

A. Panel is meant to be used in geographic locations with daily solar insolation curves comparable in intensity to the solar insolation curve generated herein.

B. Water entering the panel in the morning is 55 ˚F.

C. Water is to be heated up to 120 ˚F by 5:00pm (Daylight Savings Time or Clock Time) by the panel alone.

D. The volume of water is 80 gallons

E. The heating time is 10.63 hours (6:22am to 5:00pm).

F. Performance of a larger system will be equivalent to or better than system used during demonstration.

Average total irradiation incident on panel during assumed exposure period (Ga):

Ga=Average between 6:22am and 5:00pm=213 [Btu/hr− ft ²]

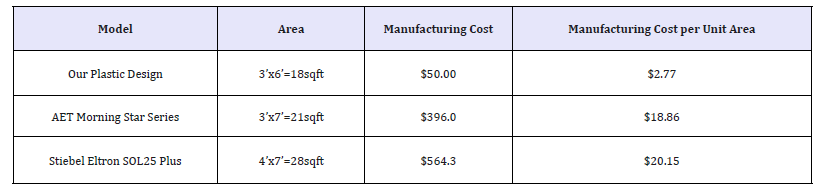

Required Panel Area Based on Assumptions for One Embodiment of the Present Invention (Ap): Ap = s

Results and Discussion

The sun emits radiation in the form of visible light at wavelengths of 0.2-4 micrometers. One aspect of the present invention, a transparent plate, will allow a certain percentage of this light to pass through. The light will then pass through a thin layer of water in the internal space between the transparent plate and the opaque or black plate. As light is absorbed by the surface of the black plate it will heat up and emit long-wavelength infrared heat, 4-100 micrometers. The opaque black plate absorbed the radiation energy from the sun because of the black color. This physical property allowed it to collect a large amount of the incident energy on its surface. Since the opaque plate is made of an insulating material, the heat did not transmit through the material but instead transferred to the more conductive flowing water. The process in which the water absorbed the heat from the black plate is called convection. The transparent plate creates a greenhouse effect in which the short length visible light wavelengths can pass into the collector while a portion of the long wavelength infrared wavelengths (heat) is contained in the sealed collector and transferred to the water.

The most popular solar water heaters in the market are copper flat plate collectors. A flat plate collector consists of a large black copper plate with thin black copper pipes running length-wise on top of the plate. Water travels through the thin black copper pipes. In this copper design, the solar radiation hits the copper plate and due to the high conduction of copper the heat is transferred into the water. Copper is ideal for these flat plate collector designs because of its high thermal conductivity, however, it is very costly and difficult to manufacture. Skilled labor is required to weld the copper parts together.

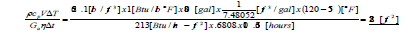

Proposed design is completely made from plastic and glued by epoxy. Plastic has replaced metals in many industries (i.e. automobiles) because it is less costly then metals. Therefore, the main advantages over current systems in the market would be reduced cost and ease of manufacturing. The manufacturing costs of our plastic solar water heater design in comparison to some solar water heaters in the market are displayed in Table 2. The test results showed that the solar water heater was able to increase the outlet water temperature by 11.7 °C and produced a flow rate of 34L per hour. The efficiency (68.03%) of using this design and material is comparable or better than that of conventional ones, yet the cost of black Plexiglas solar water heater is much lower than that of copper (13.7%).

Table 2:Manufacturing cost comparison of solar water heaters*.

*Comparison based on size of plates not the performance. Manufacturing costs are considered to be 100% of the retail value.

Summary and Conclusion

The proposed solar water heater includes a solar collector of surface area of a 1.67m2, with a storage tank capacity is 10.6L and the piping of connections. The solar collector includes a flat plate absorber composed of black plastic sheet. The collector is covered with transparent plastic sheet with a surface area of 1.67m2 and a thickness of 6.35mm. This collector is thermally insulated at the back and on sides by plastic extrusions. The proposed solar water heater produced outlet hot water 11.7 °C hotter than inlet water and produced a flow rate of 34L per hour. The experimental results show an efficiency of 68.03% for sunny days. The cost of black Plexiglas solar water heater is much lower than that of copper (13.7%)

This solar water heater realized will permit reduction in greenhouse gas emission if the electric water heaters for example are replaced by solar water heaters in residential, hospitals and hotels. The reduction in consumption of natural gas due to the use of proposed solar water heater would result in reduction of environmental pollution and our system will also allow reducing the consumption of nonrenewable energy sources. It will help the protection of the environmental and help in curbing poverty in developing nations. A complete package of design drawings is provided for large scale implementation in developing nations.

References

- Xu H, Miao X, Wu Q (2006) High quality biodiesel production from a microalga chlorella protothecoides by heterotrophic growth in fermenters. Journal of Biotechnology 126(4): 499-507.

- Chisti Y (2008) Biodiesel from microalgae beats bioethanol. Trends Biotechnol 26(3): 126-131.

- Bhattacharya SC (2002) Biomass energy in Asia: a review of status, technologies and policies in Asia. Energy for Sustainable Development 6(3): 5-10.

- Antoni D, Zverlov VV, Schwarz WH (2007) Biofuels from microbes. Appl Microbiol Biotechnol 77(1): 23-35.

- Miao X, Wu Q (2006) Biodiesel production from heterotrophic microalgal oil. Bioresource Technology 97(6): 841-846.

- IEA (2012) World Energy Outlook, OECD/IEA.

- Petroleum B (2008) BP statistical review of world energy.

- Shafiee S, Topal E (2009) When will fossil fuel reserves be diminished? Energy Policy 37(1): 181-189.

- Salameh MG (2003) Can renewable and unconventional energy sources bridge the global energy gap in the 21st century? Applied Energy 75(1- 2): 33-42.

- Cariou J, Meisen P (2010) Solar water heater. Global Energy Network Institute.

- Xiaowu W, Ben H (2005) Exergy analysis of domestic-scale solar water heaters. Renewable and Sustainable Energy Reviews 9(6): 638-645.

- Koffi PME, Koua BK, Gbaha P, Touré S (2014) Thermal performance of a solar water heater with internal exchanger using thermosiphon system in Côte d’Ivoire. Energy 64: 187-199.

- Zhai XQ, Wang RZ, Dai YJ, Wu JY, Xu YX, et al. (2007) Solar integrated energy system for a green building. Energy and Buildings 39(8): 985- 993.

- Harrison J, Tiedeman T (1997) Solar water heating options in Florida. Florida Solar Energy Center

- USDOE (2003) Heat your water with the sun. US Department of Energy- US National Renewable Energy Laboratory, Washington DC 20585, USA.

- Nahar NM (2003) Year round performance and potential of a natural circulation type of solar water heater in India. Energy and Buildings 35(3): 239-247.

- Haltiwanger JF, Davidson JH (2009) Discharge of a thermal storage tank using an immersed heat exchanger with an annular baffle. Solar Energy 83(2): 193-201.

- Lucky M, Ochs A, Bertaux X, Weber M, Konold M, et al. (2014) Haiti sustainable energy roadmap-harnessing domestic energy resources to build a reliable, affordable, and climate-compatible electricity system. World watch Institute, Washington DC, USA.

- Gupta CL, Garg HP (1968) System design in solar water heaters with natural circulation. Solar Energy 12(2): 163-182.

- Vaxman M, Sokolov M (1986) Effects of connecting pipes in thermosyphonic solar systems. Solar Energy 37(5): 323-330.

- Morrison G, Tran H (1984) Simulation of the long term performance of thermosyphon solar water heaters. Solar Energy 33(6): 515-526.

- Morrison GL, Sapsford CM (1983) Long term performance of thermosyphon solar water heaters. Solar Energy 30(4): 341-350.

- Ong KS (1974) A finite-difference method to evaluate the thermal performance of a solar water heater. Solar Energy 16(3-4): 137-147.

- Nahar NM, Gupta JP (1987) Performance and testing of improved natural circulation type solar water heater in arid areas. Energy conversion and management 27(1): 29-32.

- Sakhrieh A, Ghandoor AA (2013) Experimental investigation of the performance of five types of solar collectors. Energy Conversion and Management 65: 715-720.

- Morrison GL, Rosengarten G, Behnia M (1999) Mantle heat exchangers for horizontal tank thermosyphon solar water heaters. Solar Energy 67(1-3): 53-64.

- Pluta Z, Pomierny W (1995) The theoretical and experimental investigation of the phase-change solar thermosyphon. Renewable energy 6(3): 317-321.

- Hottel H, Woertz B (1942) Performance of flat-plate solar-heat collectors. Trans. ASME (Am Soc Mech Eng), USA.

- Ward G (1955) Performance of a flat-plate solar heat collector. Proceedings of the Institution of Mechanical Engineers 169(1): 1091- 1112.

- Simon FF (1976) Flat-plate solar-collector performance evaluation with a solar simulator as a basis for collector selection and performance prediction. Solar Energy 18(5): 451-466.

- Francken JC (1984) On the effectiveness of a flat plate collector. Solar Energy 33(3-4): 363-366.

- Kundu B (2002) Performance analysis and optimization of absorber plates of different geometry for a flat-plate solar collector: a comparative study. Applied Thermal Engineering 22(9): 999-1012.

- Zheng W, Li B, Zhang H, You S, Li Y, et al. (2016) Thermal characteristics of a glazed transpired solar collector with perforating corrugated plate in cold regions. Energy 109: 781-790.

- Kumar R, Rosen MA (2010) Thermal performance of integrated collector storage solar water heater with corrugated absorber surface. Applied Thermal Engineering 30(13): 1764-1768.

- Whillier A, Saluja G (1965) Effect of materials and construction details on the thermal performance of solar water heaters. Solar Energy 9: 21- 26.

- Colangelo G, Favale E, Miglietta P, Risi DA (2016) Innovation in flat solar thermal collectors: A review of the last ten years experimental results. Renewable and Sustainable Energy Reviews 57: 1141-1159.

- Nahar N, Garg H (1981) Selective coatings on flat-plate solar collectors. Renewable Energy Rev J 3: 37-51.

- Roberts D, Forbes A (2012) An analytical expression for the instantaneous efficiency of a flat plate solar water heater and the influence of absorber plate absorptance and emittance. Solar Energy 86(5): 1416-1427.

- Hussein HMS (2002) Transient investigation of a two phase closed thermosyphon flat plate solar water heater. Energy Conversion and Management 43(18): 2479-2492.

- Huang J, Pu S, Gao W, Que Y (2010) Experimental investigation on thermal performance of thermosyphon flat-plate solar water heater with a mantle heat exchanger. Energy 35(9): 3563-3568.

- Keith F, Kreider JF (1978) Principles of solar engineering. Hemisphere, Washington DC, USA.

© 2018 Jay N Meegoda. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)