- Submissions

Full Text

Progress in Petrochemical Science

Stress-Strain Characteristics of Rubber Vulcanizates: Insights into the Effects of Strain Rate and Cure Time

Ajay C*1, Sohan Kumar Kanrar1, Saikat Das Gupta1, Rabindra Mukhopadhyay1, Dipankar Chattopadhyay2 and Mahuya Das3

1 Hari Shankar Singhania Elastomer and Tyre Research Institute, India

2 Department of Polymer Science and Technology, Calcutta University, India

3 Greater Kolkata College of Engineering and Management, India

*Corresponding author:Ajay C, Hari Shankar Singhania Elastomer and Tyre Research Institute, Mysuru, 570016, India

Submission: August 19, 2025;Published: September 26, 2025

ISSN 2637-8035Volume7 Issue 3

Abstract

Rubber vulcanizates are essential in many industries due to their elasticity, durability and flexibility. Their mechanical properties, especially their stress-strain behavior, depend largely on the vulcanization process, which strengthens rubber by forming cross-links between molecules. Among the key factors in this process, cure time plays a major role in determining the final strength and flexibility of the rubber vulcanizates. While previous research has examined the effects of cure time and strain rate separately, their combined impact is not yet well understood. This study investigates how Natural Rubber (NR) and Styrene Butadiene Rubber (SBR) behave under different strain rates and cure times. The results show that stress at 300% elongation increases with both strain rate and cure time, but at higher strain rates, stress stops increasing, showing a strain-hardening limit. Breaking elongation decreases as cure time increases because the vulcanizate becomes stiffer, while strain rate has a small influence on elongation. Based on these observations, mathematical models were developed to predict stress at 300% elongation and breaking elongation using power-law and nonlinear relationships. These models proved highly accurate, with R² values above 0.94, confirming their reliability in predicting rubber behavior. The study provides useful insights into how strain rate and cure time affect rubber properties, helping to improve material design and performance. The developed models can be used to optimize rubber processing and ensure better mechanical performance in industrial applications.

Keywords:IStress-strain; Crosslink density; Cure time; Fatigue; Universal testing machine

Introduction

Rubber vulcanizates are essential materials in a wide array of industries, including automotive, aerospace, construction, healthcare and consumer products. Their unique combination of mechanical properties, elasticity, flexibility, durability and resistance to wear and aging makes them indispensable in applications like tyres, seals, hoses, gaskets and vibration dampeners. These properties arise from the process of vulcanization [1], where raw rubber undergoes a chemical transformation that imparts strength and stability to the rubber vulcanizates by forming cross-links between the polymer chains. Vulcanization drastically improves the mechanical performance of rubber [2], enabling it to withstand significant mechanical loads, recover after deformation and resist degradation from heat, chemicals and environmental exposure. Stress-strain behavior defines how rubber materials deform under applied loads, influencing key properties such as tensile strength, elongation, stiffness and resilience. These properties are vital in determining the suitability of rubber for high-performance applications, especially in fields where materials are subjected to cyclic loading, dynamic stress and extreme environmental conditions. Despite the widespread use of rubber vulcanizates, a comprehensive understanding of how processing parameters such as vulcanization cure time affect their mechanical behavior under different strain rates is still lacking, even though mechanical properties at higher strains have been investigated earlier [3].

The vulcanization process involves heating rubber with sulfur or other cross-linking agents to form bridges between polymer molecules, increasing the rubber’s vulcanizate’s rigidity and resilience. One of the most critical parameters in this process is the cure time, which dictates the extent of cross-linking. Over-curing can make rubber too stiff and brittle [4], while under-curing can leave it too soft and prone to deformation [5]. The precise optimization of cure time is therefore crucial for tailoring the mechanical properties of rubber to meet specific performance requirements [6]. However, the impact of cure time on the strain rate-dependent stress-strain behavior of rubber is not fully understood, particularly when dealing with different operational environments where rubber materials are subjected to varying rates of deformation. Additionally, the type of rubber matrix used in vulcanization plays a significant role in defining the material’s properties. Natural Rubber is renowned for its excellent elasticity, high tensile strength and fatigue resistance, making it ideal for applications that require superior mechanical flexibility [7]. On the other hand, Styrene Butadiene Rubber is a synthetic elastomer known for its abrasion resistance [8], heat stability and aging performance [9], commonly used in products such as tyres and industrial belts. Blending NR with SBR provides a synergistic combination of properties, balancing the elasticity of NR with the durability and thermal resistance of SBR.

This makes NR-SBR vulcanizates highly relevant for applications requiring both resilience under dynamic loads and resistance to environmental degradation. In this context, it becomes important to investigate how the vulcanization cure time influences the stressstrain behavior of NR and SBR across different strain rates. Strain rate sensitivity is a key factor in many industrial applications where rubber materials are subjected to rapid or slow deformations. For instance, automotive tyres experience high strain rates [10] during acceleration and braking, whereas seals and gaskets may face slower but constant deformation over time. Understanding how cure time affects the strain rate-dependent behavior of rubber vulcanizates is therefore crucial for optimizing material performance in diverse operational environments. This study aims to fill the gap in existing research by systematically examining the relationship between cure time, strain rate and stress-strain behavior in NR and SBR vulcanizates. By characterizing how the rubber vulcanizate responds to varying strain rates under different curing conditions, we seek to identify the optimal cure times that maximize mechanical performance while minimizing undesirable effects such as premature failure. The findings from this research will not only provide insights into the mechanistic interactions between cure time and strain rate in rubber materials but will also offer practical guidelines for enhancing material design and improving processing techniques in industries reliant on vulcanized rubber products.

In addition, the authors attempted to develop empirical models that relate stress at 300% elongation and breaking elongation to strain rate and cure time for both NR and SBR vulcanizates. Models were developed to predict stress-strain behavior by analyzing experimental stress-strain data obtained under varying strain rates and cure times. This approach parallels prior studies on non- Newtonian fluid behavior, in which simple Microsoft Excel Solver tools were utilized for parameter optimization [11]. These models serve as valuable tools for understanding how cure conditions and strain rates influence rubber performance, ultimately supporting improved material selection, process optimization, and product reliability in industrial applications. As industries continue to push the boundaries of material performance, especially in areas like electric vehicles and sustainable manufacturing, a deeper understanding of the cure time-strain rate relationship in rubber vulcanizates will play a pivotal role in driving innovation and enhancing material efficiency.

Experimental

Materials

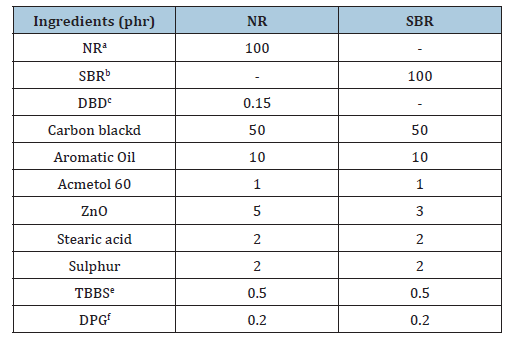

Table 1:Formulation of compounds (in PHR).

Abbreviations: a: Natural Rubber, RMA IV; b: Styrene Butadiene Rubber 1502; c: 2,2′-Dithiobisbenzanilide; d: Carbon Black N134; e: N-Tert-Butyl-Benzothiazole Sulfonamide; f: Diphenyl Guanidine

All the ingredients used for mixing are used as obtained without any further treatment. All ingredients utilized in the presented studies were used in their original form. Natural Rubber (RMA IV) was provided by JK Industries Pvt. Ltd., India and Styrene Butadiene Rubber 1502 was supplied by Zeon India Pvt. Ltd. additional ingredients included 2,2’-Dithiobisbenzanilide (DBD; Acmechem Pvt. Ltd., India), N134 carbon black (Birla Carbon Black India Pvt. Ltd., India), Aromatic grade oil (Raj Petro, Chennai, India), rubber-grade zinc oxide (Zinc-o-India, India), stearic acid (Godrej Industries Ltd., India), Acmetol 60 (Acmechem, India), N-tert-butyl-benzothiazole sulfonamide (TBBS; National Organic Chemicals, India Ltd., India), soluble sulfur (Jain Chemicals Ltd., India) and diphenyl guanidine (DPG; National Organic Chemicals, India Ltd., India) used in compound preparation. The formulations of the compounds studied in this experiment are given in Table 1. The mixing of rubber compounds was carried out in a 1.5L volume Banbury mixer (Stewart Bowling, USA). Masterbatch mixing of rubber compound was carried out by fixing the Temperature Control Unit (TCU) at 90 °C and the speed of the rotor was fixed at 60 Revolutions Per Minute (rpm).

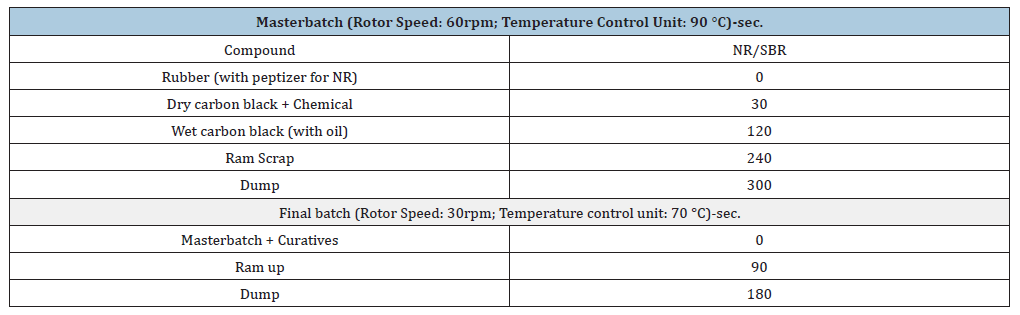

Initially, the rubber (along with a peptizer in case of NR) was added into the mixer and masticated for 30 seconds, followed by the carbon black, plasticizer, zinc oxide and stearic acid into the mixer. The masterbatch was dumped after 300 seconds. The dump temperature (display) of the masterbatch compounds was 140 °C and 142 °C. The final batch mixing of the compound was carried out at a TCU temperature of 70 °C and with a rotor speed maintained at 30rpm. The masterbatch compound with the curative package, such as sulfur, TBBS and DPG, was added into the mixer at 0 seconds and dumped after 180 seconds. The observed dumb temperature of the final batch compound was between 90 °C and 95 °C. The mixing sequence of the masterbatch and final batch is given in Table 2.

Table 2:Mixing sequence (Masterbatch >>>> Final batch).

Characterization

Cure properties were analyzed using a Moving Die Rheometer (Premier MDR, Alpha Technologies, USA) following ASTM D5289. The rheometric test was conducted for NR at 140 °C for 60 minutes and SBR at 160 °C for 60 minutes. Hardness (Shore-A) was measured using a Multi-Unit Hardness Tester (Gibitre Instruments, Italy) following ASTM D2240. Tensile properties at different strain rates were tested using a Universal Testing Machine (Z010 Model, Zwick Roell, Germany) in line with ASTM D412 (Die C). The reported data is the median of 5 readings. Crosslink density studies were conducted on cured vulcanizates using a Dynamic Mechanical Analyzer (DMA+2000, ACOEM, France). Crosslink density was studied at 90 °C with a frequency of 1Hz and 0.2% strain [12].

Results and Discussion

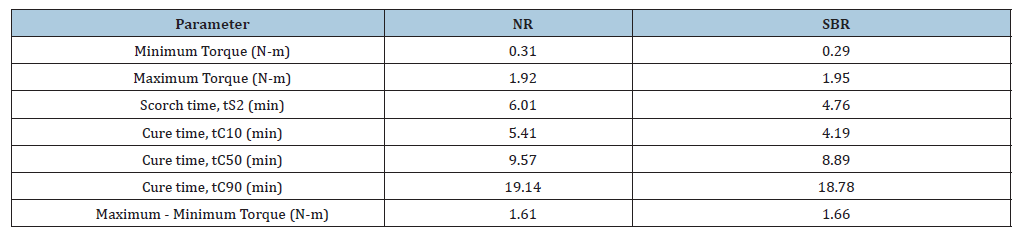

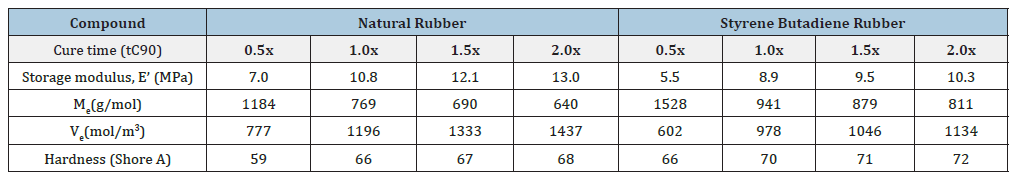

The rheometric properties of NR compounds were studied at 140 °C for 60 minutes, while SBR compounds were analyzed at 160 °C for 60 minutes. Based on the Cure time, (tC90) values, which represent the time required to achieve 90% of the cure, tensile slabs were molded using an 18-inch curing press (manufactured by M/s. Hind Hydraulics) at different multiples of tC90: 0.5 times (0.5x), 1.0 times (1.0x), 1.5 times (1.5x) and 2.0 times (2.0x) respectively. From Table 3, the cure times for NR and SBR compounds were nearly identical due to the use of the same curing package, consisting of the same mixture of vulcanizing agents and accelerators. Additionally, the torque values, which indicate the stiffness of the rubber during curing, were also similar for both NR and SBR compounds. This similarity arises because both formulations use the same filler package, specifically carbon black. By curing the rubber compound at different multiples of tC90 (0.5x, 1.0x, 1.5x and 2.0x), the effects of under-curing, optimal curing and over-curing on the strain rate and stress-strain behavior of the subjected rubber vulcanizates were evaluated. Table 4 presents the crosslink density (Ve), molecular weight between crosslinks (Me), Storage Modulus (E′) and hardness (Shore A) for NR and SBR under varying Cure Times (tC90).

Table 3:Rheometric properties.

Table 4:Crosslink density & Hardness.

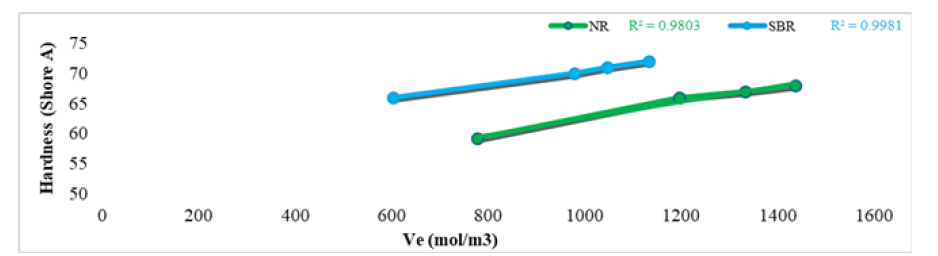

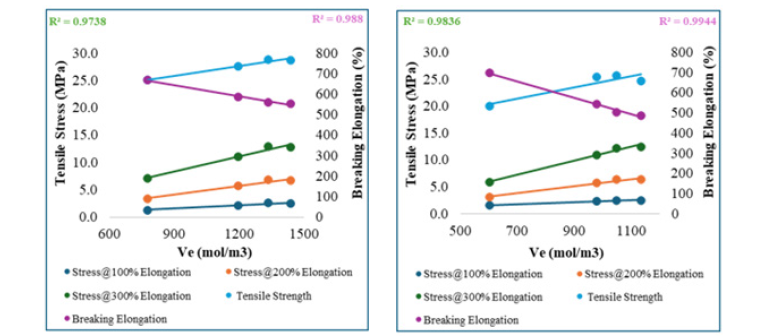

The results show that increasing cure time increases crosslink density [6] and a corresponding decrease in molecular weight between crosslinks. For NR, crosslink density rises from 777mol/m³ (0.5x cure time) to 1437mol/m³ (2.0x cure time), while molecular weight between crosslinks decreases from 1184g/mol to 640g/ mol, indicating that more polymer chains are crosslinked together, leading to higher stiffness. Similarly, for SBR, crosslink density increases from 602mol/m³ to 1134mol/m³, but remains lower than NR at equivalent cure times, suggesting a less crosslinked network. The hardness (Shore A) values for both NR and SBR follow a similar trend, increasing with cure time [13] due to the formation of a denser polymer network. However, SBR exhibits slightly higher hardness at higher cure times compared to NR, likely due to its more rigid polymer backbone. The storage modulus (E′), which represents the stiffness of the rubber vulcanizates, also increases with cure time, confirming that higher crosslink density results in a more rigid structure. Figure 1 illustrates the direct correlation between crosslink density and hardness [14], reinforcing that a more crosslinked structure translates to greater material rigidity. The R² value for the correlation between crosslink density and hardness was found to be above 0.98, indicating a strong linear relationship.

Figure 1:Cross-link density vs hardness.

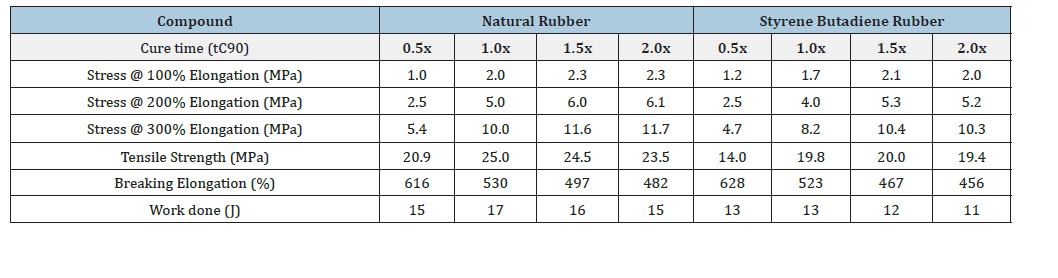

At a strain rate of 5mm/min, as shown in Table 5, the rubber dumbbells undergo quasi-static deformation, which means the applied loading is slow enough for the molecular chains to have sufficient time to rearrange and relax during stretching. This allows the rubber vulcanizates to exhibit a predominantly elastic response, with minimal influence from strain rate-dependent viscous effects. At this low speed, the mechanical response is primarily controlled by the degree of crosslinking, as the time-dependent relaxation mechanisms are active and unimpeded by rapid deformation. For NR, increasing cure time and thereby crosslink density leads to a clear enhancement in stiffness and strength [15]. The stress at 100% elongation increases from 1.0MPa at 0.5x cure time to 2.3MPa at 2.0x. Similarly, stress at 200% elongation rises from 2.5MPa to 6.1MPa and stress at 300% elongation, from 5.4MPa to 11.7MPa. These trends confirm that with higher crosslink density, the molecular network becomes more rigid, restricting polymer chain mobility and thereby increasing resistance to deformation. The tensile strength of NR reaches a maximum of 25.0MPa at 1.0x cure time, after which it slightly declines at higher cure levels. This indicates that over-crosslinking may introduce internal stresses or defects in the network, potentially causing early failure through localized stress concentrations or limited chain extensibility [16].

Table 5:Stress-strain properties at 5mm/min.

In addition, overcuring can reduce strength due to brittleness, chain scission, uneven crosslinking, thermal degradation and poor interfacial adhesion. The breaking elongation decreases significantly from 616% (0.5x) to 482% (2.0x), clearly illustrating that increased crosslink density reduces the material’s flexibility and stretchability [17]. Interestingly, the work done, representing the total energy absorbed before failure, remains nearly constant across cure times for NR at this strain rate. This suggests that although the vulcanizates become stiffer, their total energy absorption capacity is conserved, possibly due to compensation between increased stress and reduced elongation [18]. In SBR, similar trends are observed, although with lower absolute stress values. The stress at 100% elongation increases from 1.2MPa (0.5x) to 2.0MPa (2.0x), at 200% from 2.5MPa to 5.2MPa and at 300% from 4.7MPa to 10.3MPa. Tensile strength peaks at 20.0MPa at 1.5x cure time before slightly decreasing at higher crosslink densities. The breaking elongation drops from 628% to 456% and unlike NR, the work done in SBR declines steadily with cure time, indicating a loss in both flexibility and energy absorption. These observations confirm that at low deformation speeds, crosslink density plays a dominant role in determining mechanical properties.

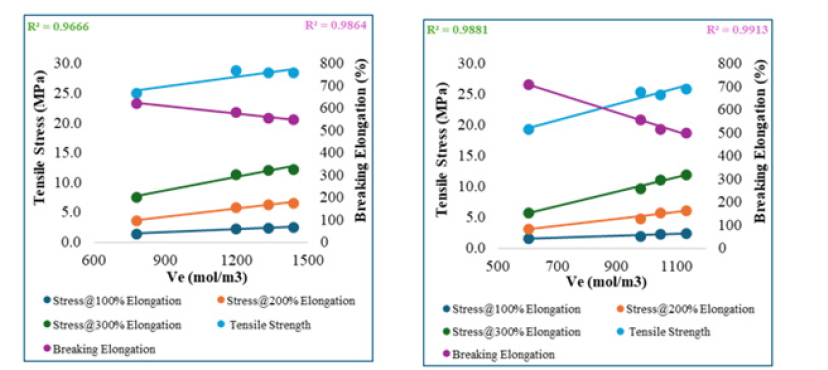

As Cure Time (tC90) increases, more chemical crosslinks form, which enhance initial stiffness and resistance to deformation but limit the ability of polymer chains to extend before failure. This results in higher stress values at all elongations, a peak in tensile strength followed by a decline due to over-crosslinking and a steady decrease in breaking elongation. The behavior at this strain rate further underscores the time-dependent viscoelastic recovery mechanisms active in rubber. At 5mm/min, these mechanisms are fully operative, allowing the rubber vulcanizates to exhibit their maximum elastic potential. However, as crosslink density increases, the viscoelastic character is suppressed, shifting the material response toward a stiffer, less flexible structure with lower elongation and reduced capacity for energy dissipation. Notably, the correlation between crosslink density and mechanical properties such as stress @ 300% elongation and breaking elongation was exceptionally strong at this strain rate, with R² values ranging from 0.94 to 0.99 for both NR and SBR, as shown in Figure 2a & 2b. This high correlation confirms that the mechanical response at this low strain rate is strongly governed by crosslinking, rather than strain rate-dependent phenomena.

Figure 2a & 2b:NR & SBR-Crosslink density vs Stress-strain properties (5mm/min).

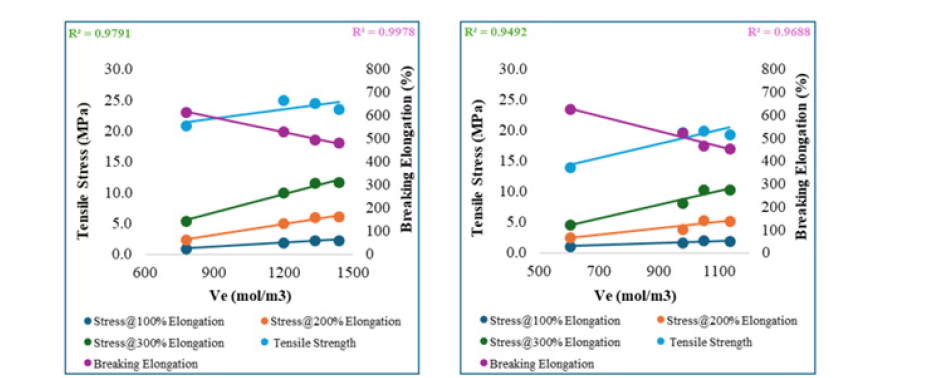

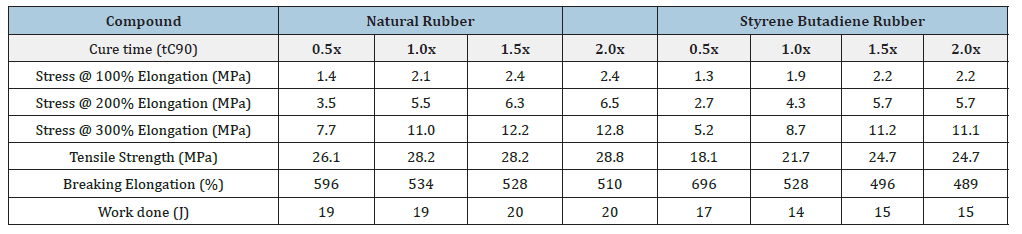

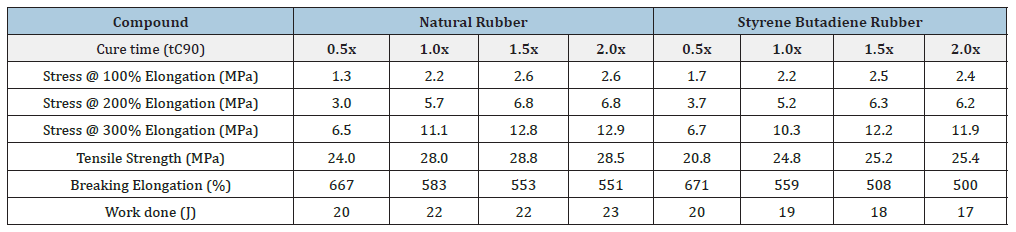

It highlights the effectiveness of vulcanization control in tailoring the mechanical properties of elastomers for applications where rubber vulcanizates are subjected to low-speed or static loading conditions. From Table 6, at a strain rate of 50mm/min, NR exhibits a stronger and more pronounced stress response compared to 5mm/min, due to the reduced time for molecular chain rearrangement during deformation. The stress at 100% elongation increases from 1.4MPa at 0.5x cure time to 2.4MPa at 2.0x. Similarly, stress at 200% elongation rises from 3.5MPa to 6.5MPa and stress at 300% elongation increases from 7.7MPa at 0.5x cure time to 12.8MPa at 2.0x, showing a notable gain in stiffness across all cure levels. This is higher than the corresponding values at 5mm/min and is attributed to the strain rate stiffening effect, wherein polymer chains are deformed faster than they can relax, resulting in higher resistance to elongation. The tensile strength also benefits from this higher strain rate, increasing to 28.8MPa at 2.0x cure time, which surpasses the peak value of 25.0MPa observed at 1.0x cure time under 5mm/min. This indicates that moderate strain rates promote better load distribution and polymer chain alignment, enhancing the rubber vulcanizate’s ability to bear stress, especially in more crosslinked networks. Interestingly, the breaking elongation at 1.0x cure time increases to 534%, compared to 530% at 5mm/min, suggesting a slight compromise in extensibility.

Table 6:Stress-strain properties at 50mm/min.

However, the decline in breaking elongation with increasing cure time remains consistent, dropping to 510% at 2.0x. This continued reduction reflects the increasing rigidity and reduced chain flexibility due to higher crosslink density, but also indicates that the influence of crosslinking becomes more dominant than strain rate at higher cure times. The work done also improves over time, with more energy being absorbed before failure than at 5mm/ min. This enhancement reflects the ability of NR to store more elastic energy and maintain greater durability under moderatespeed deformation. The high R² values (>0.98) shown in Figure 3a across the parameters indicate that the data is predictive, even as strain rate begins to introduce more dynamic complexity to the material’s behavior. At 50mm/min, SBR also demonstrates a more pronounced mechanical response compared to its behavior at 5mm/min, particularly in terms of stress development and energy absorption. The stress at 100% elongation increases from 1.3MPa (0.5x) to 2.2MPa (2.0x), at 200% from 2.7MPa to 5.7MPa, and the stress at 300% elongation rises from 5.2MPa (0.5x) to 11.1MPa (2.0x), which is significantly higher than the range observed at 5mm/min. This improvement is a direct result of the faster strain rate restricting relaxation mechanisms, causing the rubber vulcanizates to resist deformation more forcefully. The tensile strength increases notably to 24.7MPa at 2.0x cure time, exceeding the 19.8MPa peak seen at 1.0x cure time under 5mm/min loading.

Figure 3a & 3b:NR & SBR-Crosslink density vs Stress-strain properties (50mm/min).

This implies that, similar to NR, SBR benefits from strain rateinduced enhancement in internal network alignment, which allows the rubber matrix to more efficiently resist rupture. A particularly interesting behavior is observed in the breaking elongation, which shows a marked increase at low cure time. At 0.5x cure time, the breaking elongation reaches 696%, which is significantly higher than the 628% observed at 5mm/min. This suggests that at moderate speeds, SBR chains have just enough time to align and stretch without premature breaking, especially when the network is less constrained. However, as cure time increases and crosslinking becomes denser, elongation reduces again, down to 489% at 2.0x, confirming the stiffening effect of excessive crosslinking. The work done is also higher at this strain rate compared to 5mm/min, especially at lower cure levels. This indicates that SBR is capable of absorbing more energy during deformation at moderate rates, before failure occurs. The increase in work done reflects enhanced durability, which is advantageous in applications involving dynamic or intermittent loading. R² values remained robust (above 0.93) as shown in Figure 3b, supporting the observation that the material’s behavior remains strongly governed by crosslink density, even as strain rate begins to play a more active role in shaping the stressstrain response. From Table 7, at a strain rate of 250mm/min, NR reaches near-optimal mechanical performance, where the influence of both crosslink density and deformation speed contributes synergistically.

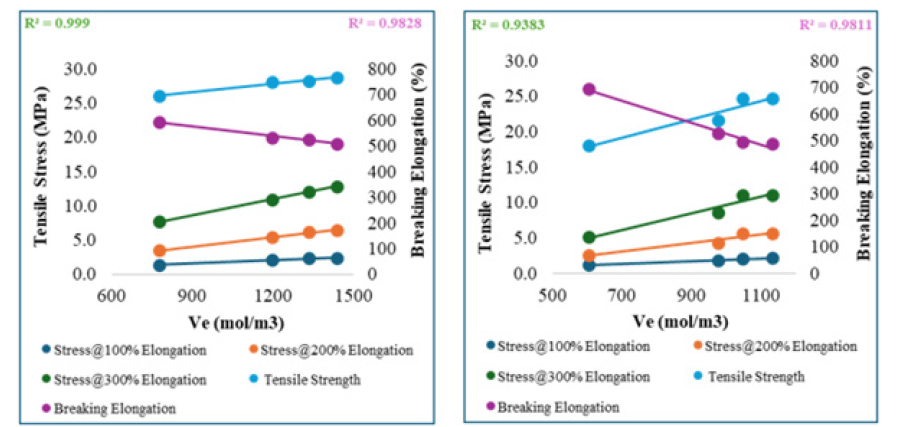

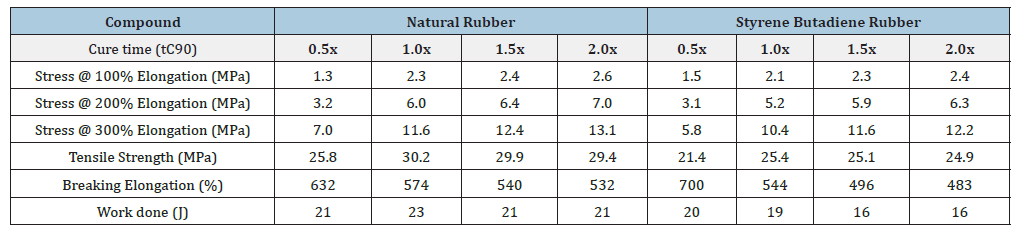

Table 7:Stress-strain properties at 250mm/min.

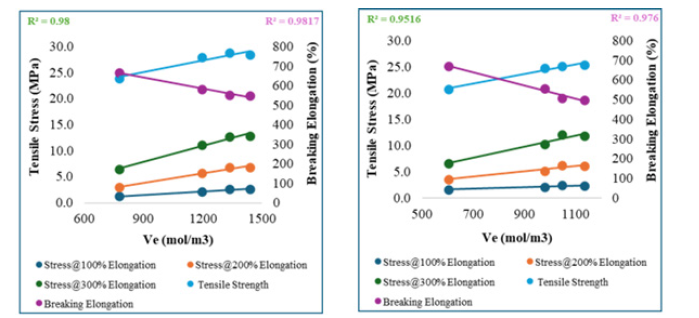

The stress at 100% elongation increases from 1.3MPa at 0.5x cure time to 2.6MPa at 2.0x. Similarly, stress at 200% elongation rises from 3.2MPa to 7.0MPa and stress at 300% elongation increases steadily with cure time, rising from 7.0MPa at 0.5x to a maximum of 13.1MPa at 2.0x, indicating a stronger resistance to deformation than seen at both 5mm/min and 50mm/min. This elevation in stress highlights the increasing strain rate stiffening effect, where faster deformation inhibits polymer chain relaxation, resulting in higher internal resistance and network tension. The tensile strength also achieves its highest recorded value at this strain rate, peaking at 30.2MPa at 1.0x cure time. This improvement over previous strain rates suggests that 250mm/min allows sufficient molecular alignment under load without overly suppressing chain mobility. However, a slight reduction in tensile strength is observed beyond 1.0x cure time, possibly due to over-crosslinking that introduces less flexibility and limits chain extensibility. In terms of breaking elongation, NR maintains substantial flexibility. The values remain relatively high across all cure times, decreasing moderately from 632% at 0.5x to 532% at 2.0x. Compared to the sharper drop seen at lower speeds, this plateauing behavior suggests that at 250mm/ min, the rubber benefits from both enhanced strength and retained flexibility, especially at intermediate crosslink densities. This reflects a well-balanced mechanical regime where both stiffness and stretchability coexist.

The work done also peaks at this strain rate, indicating that NR is capable of withstanding higher energy inputs while maintaining structural integrity. This superior energy absorption compared to 5mm/min and 50mm/min reflects the ideal compromise between chain extensibility and network rigidity. The R² values remain high (above 0.98) as shown in Figure 4a, confirming the accurate prediction of NR’s mechanical response. At 250mm/min, SBR also exhibits a substantial enhancement in mechanical performance, with clear benefits in both stiffness and durability compared to lower strain rates. The stress at 100% elongation increases from 1.5MPa (0.5x) to 2.4MPa (2.0x), at 200% from 3.1MPa to 6.3MPa, and the stress at 300% elongation increases consistently across cure times, ranging from 5.8MPa at 0.5x to 12.2MPa at 2.0x, surpassing values observed at both 5mm/min and 50mm/min. This significant increase reinforces the strain rate stiffening effect, where faster stretching limits molecular relaxation, leading to higher stress buildup across the network. The tensile strength also improves notably, reaching 25.4MPa at 1.0x cure time-a substantial increase over the 19.8MPa and 24.7MPa peaks observed at 5 and 50mm/min, respectively. This suggests that at this strain rate, the molecular chains in SBR achieve optimal orientation and load transfer before being constrained by excessive crosslinking. The breaking elongation for SBR declines from 700% at 0.5x to 483% at 2.0x.

Figure 4a & 4b:NR & SBR-Crosslink density vs Stress-strain properties (250mm/min).

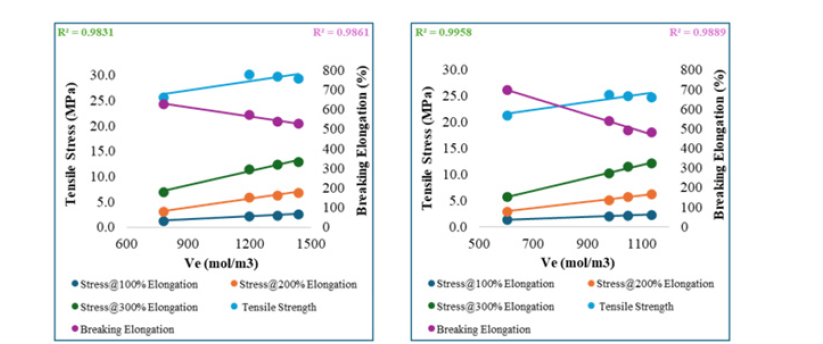

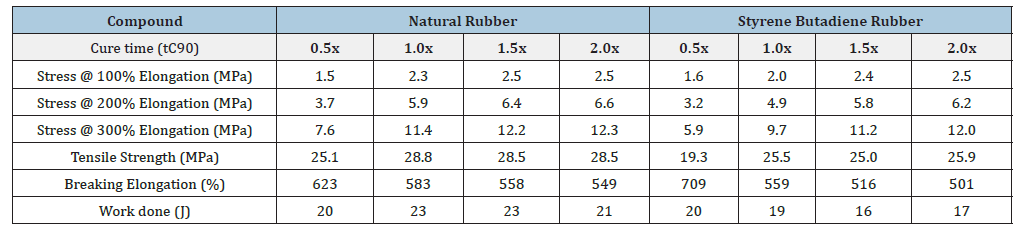

This drop is consistent with the reductions observed at lower speeds, indicating that the faster strain rate may not allow SBR chains to stretch more efficiently under stress, even as crosslink density increases. This is a positive indicator of improved durability, as the material maintains flexibility while gaining strength. Correspondingly, the work done is highest at this strain rate compared to all previous ones, reflecting SBR’s ability to balance stiffness with deformability under moderate-speed loading. The improved work done underscores that 250mm/min may be an optimal strain rate for maximizing durability in SBR, before the onset of saturation effects at higher speeds. R² values exceeding 0.98, as shown in Figure 4b, confirm a strong correlation between stress-strain and crosslink density. From Table 8, at a strain rate of 500mm/min, NR begins to exhibit signs of mechanical saturation, where further increases in strain rate yield diminishing returns in mechanical reinforcement. The stress at 100% elongation increases from 1.5MPa at 0.5x cure time to 2.5MPa at 2.0x. Similarly, stress at 200% elongation rises from 3.7MPa to 6.6MPa, and stress at 300% elongation for NR ranges from 7.6MPa at 0.5x to 12.3MPa at 2.0x cure time. While these values remain higher than those recorded at lower strain rates, particularly 5 and 50mm/min, the incremental gain compared to 250mm/min (where stress reached 13.1MPa) is smaller, indicating that strain rate stiffening begins to plateau [19].

Table 8:Stress-strain properties at 500mm/min.

The tensile strength also stabilizes at this speed, with NR achieving values of 28.8MPa at 1.0x, which is slightly lower than the peak of 30.2MPa at 250 mm/min. This suggests that while NR remains strong, additional increases in strain rate do not significantly enhance load-bearing capacity, likely due to restricted chain relaxation and a limit in chain orientation efficiency under high-speed stretching. The trend in breaking elongation supports this interpretation. NR maintains a moderate decline in flexibility with increasing crosslink density, with values decreasing from 623% at 0.5x to 549% at 2.0x. While this shows continued flexibility, the reduction from earlier strain rates indicates the material is becoming more rigid, particularly as strain rate and crosslink density increase together. The work done also reflects a plateauing behavior. While it remains relatively high, suggesting good durability but it does not surpass the values observed at 250mm/ min. This signals that energy absorption efficiency has reached a near-optimal level, and the rubber is operating near its mechanical capacity under rapid deformation. The R² value of 0.96 and above from Figure 5a confirms that the mechanical response against cure time variation is still acceptable with increased deviations compared to lower strain rates. At 500mm/min, SBR also shows a transition toward mechanical saturation, with stress and energyabsorbing properties stabilizing compared to lower strain rates.

Figure 5a & 5b:NR & SBR-Crosslink density vs Stress-strain properties (500mm/min).

The stress at 100% elongation increases from 1.6MPa (0.5x) to 2.5MPa (2.0x), at 200% from 3.2MPa to 6.2MPa and stress at 300% elongation rises from 5.9MPa at 0.5x to 12.0MPa at 2.0x, indicating continued stiffness gain with crosslink density. However, as with NR, the improvement over 250mm/min (which reached 12.2MPa) is marginal, demonstrating the onset of a limit in strain-induced stiffening. Tensile strength for SBR also levels off, reaching 25.9MPa at 2.0x, just below its previous peak of 25.4MPa at 250mm/min. This suggests that the benefits of enhanced chain alignment and load transfer are no longer increasing significantly with strain rate and the material is approaching its peak performance envelope. The behavior of breaking elongation mirrors that of NR, showing a gradual decline as cure time increases, from 709% at 0.5x to 501% at 2.0x. These values indicate that SBR retains flexibility, but the decrease with increasing cure time and deformation speed points to restricted chain extensibility under high-strain-rate conditions. In terms of work done, SBR demonstrates a stable but non-increasing trend. While energy absorption remains efficient across all cure levels, it does not improve beyond the values observed at 250mm/ min. This plateau indicates that the material has reached a balance between stiffness and energy absorption, and further increases in deformation speed may only contribute to increased rigidity, not flexibility. The R² value of 0.98 and above from Figure 5b confirms a high correlation, with minimal deviation.

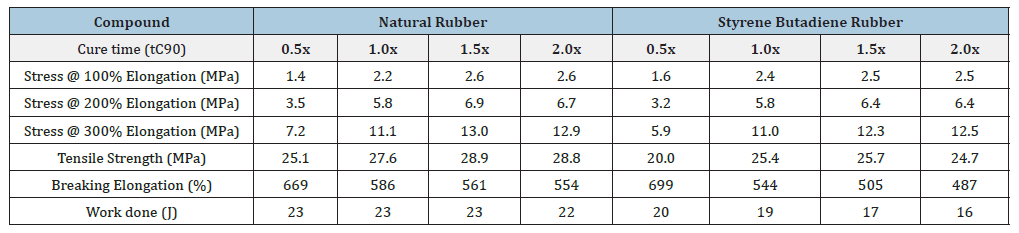

From Table 9, at a strain rate of 750mm/min, NR exhibits clear signs of entering a mechanical saturation zone, where increases in deformation speed no longer yield proportional enhancements in mechanical performance. The stress at 100% elongation increases from 1.3MPa at 0.5x cure time to 2.6MPa at 2.0x. Similarly, stress at 200% elongation rises from 3.0MPa to 6.8MPa and the stress at 300% elongation ranges from 6.5MPa at 0.5x to 12.9MPa at 2.0x, closely aligning with values recorded at 500mm/min. The minor increase compared to earlier strain rates suggests that the polymer chains are no longer able to effectively reorient or stretch, as the relaxation time becomes too limited under rapid loading. The tensile strength also plateaus, stabilizing at around 28.8MPa at 1.5x cure time, nearly identical to the value observed at 500mm/min. This indicates that network reinforcement has reached a structural limit, beyond which additional crosslinking or strain rate increases do not significantly enhance the material’s ability to bear stress. This behavior reinforces the presence of a strain-hardening ceiling under high-speed deformation. Regarding breaking elongation, NR shows a saturation at 1.0x cure time, 583% (500mm/min and 750mm/min). Chain segments become increasingly locked by crosslinks and are less able to uncoil or realign, leading to earlier rupture under load. The work done remains nearly unchanged across cure times, reflecting a plateau in the material’s ability to balance strength with deformability.

Table 9:Stress-strain properties at 750mm/min.

Figure 6a & 6b:NR & SBR-Crosslink density vs Stress-strain properties (750mm/min).

This suggests that NR has reached a point where energy absorption is dictated more by structure than by deformation dynamics. The R² value remains above 0.98 as seen in Figure 6a, confirming that the relationship exists, despite the mechanical saturation. At 750mm/min, SBR similarly enters a regime where mechanical properties begin to plateau, indicating the limits of reinforcement achievable through crosslinking and increased deformation speed. The stress at 100% elongation increases from 1.7MPa (0.5x) to 2.4MPa (2.0x), at 200% from 3.7MPa to 6.2MPa and stress at 300% elongation progresses from 6.7MPa at 0.5x to 11.9MPa at 2.0x, closely matching the stress levels at 500mm/min. This minimal gain shows that strain rate-induced stiffening has reached its functional limit, as molecular mobility becomes highly constrained. The tensile strength of SBR also levels off, reaching approximately 25.4MPa at 2.0x cure time, a marginal change from the 25.9MPa observed at 500mm/min. This reinforces the idea that the maximum load-bearing capacity has been reached and that further increases in crosslink density or strain rate have little additional effect on strength due to restricted chain dynamics. The breaking elongation remains relatively stable across cure times, ranging from 559% at 1.0x to 500% at 2.0x. This steady value, like that at 500mm/min, reflects a situation where chain scission or failure occurs at lower extensions, and the material no longer benefits from delayed rupture due to chain alignment. It indicates that high crosslink density, coupled with fast deformation, significantly limits the rubber’s flexibility.

In terms of work done, SBR maintains a consistent profile with values that neither increase nor decrease meaningfully compared to previous strain rates. This suggests a mechanical plateau, where the energy stored and dissipated during deformation is governed predominantly by the material’s fixed network structure. Despite the limited gains, with R² values above 0.95 in Figure 6b indicate close agreement with experimental results even in this high-speed regime. From Table 10, at the highest experimental strain rate of 1000mm/min, NR reaches a definitive mechanical saturation point, where all key mechanical properties exhibit minimal change despite increases in crosslink density. The stress at 100% elongation increases from 1.4MPa at 0.5x cure time to 2.6MPa at 2.0x. Similarly, stress at 200% elongation rises from 3.5MPa to 6.7MPa and the stress at 300% elongation rises modestly from 7.2MPa at 0.5x to 12.9MPa at 2.0x cure time, which is nearly identical to values recorded from 250mm/min onwards. This indicates that the material’s stiffness has reached its upper threshold, governed more by the static structure of the crosslinked network than by the speed of deformation. Similarly, the tensile strength of NR stabilizes at 28.9MPa, essentially unchanged from 28.8MPa at 750mm/min and 28.5MPa at 500mm/min. This consistent value confirms that additional increases in strain rate no longer improve the material’s ability to bear load, as polymer chains are unable to reorient or distribute stress efficiently under such rapid elongation conditions.

Table 10:Stress-strain properties at 1000mm/min.

Figure 7a & 7b:NR & SBR-Crosslink density vs Stress-strain properties (1000mm/min).

The trend in breaking elongation also reflects saturation, showing 583% to 586% between 500mm/min to 1000mm/min (noting minor experimental fluctuations) at 1.0x. This steady behavior implies that NR’s ability to stretch before rupture becomes independent of strain rate at high speeds and is instead entirely governed by crosslink density and inherent molecular constraints. The work done, representing energy absorption before failure, also shows no meaningful increase compared to earlier strain rates. The energy storage capacity appears capped, indicating a fully engaged network structure that cannot deform further without failure. The R² of 0.97 and above from Figure 7a & 7b shows a good correlation, though minor deviations begin to appear due to the dominance of nonlinear viscoelastic effects at such high loading rates. At this extreme strain rate, SBR likewise exhibits fully saturated mechanical behavior, mirroring NR’s trends. The stress at 100% elongation increases from 1.6MPa (0.5x) to 2.5MPa (2.0x), at 200% from 3.2MPa to 6.4MPa and the stress at 300% elongation increases from 5.9MPa at 0.5x to 12.5MPa at 2.0x, nearly matching the values above 250mm/min. This stagnant progression indicates that the strain rate stiffening effect has completely leveled off, and further increases in deformation speed offer no mechanical advantage. Tensile strength for SBR also plateaus at approximately 25.7MPa, identical to the values observed at the preceding strain rate above 250mm/min.

The material’s internal structure is now maximally engaged and load-bearing capacity becomes insensitive to further increases in strain rate due to the inability of the polymer chains to move or align quickly enough under high-speed stress. Breaking elongation continues its slow and steady decline, decreasing slightly to 487% at 2.0x, from 500% at 750mm/min. This suggests a continued, although small, loss in flexibility, confirming that chain mobility is significantly compromised at this strain rate, particularly in highly crosslinked samples. The work done remains effectively unchanged from 250mm/min, affirming that energy absorption capacity has reached a ceiling. SBR, like NR, is now operating in a regime dominated by structural rigidity rather than dynamic deformation. R² value of above 0.98, though small deviations hint at the onset of rate-dependent nonlinearities, did not affect the relationship with cure time. The proposed models for predicting stress at 300% elongation (𝜎300) and breaking elongation (εb) as functions of strain rate (ϵ˙) and Cure Time (tC90) were developed based on experimental findings to enhance accuracy and correlation with observed data. Stress at 300% elongation increases with strain rate, while higher cure time enhances crosslink density, leading to greater stiffness. However, at very high strain rates (750mm/ min and 1000mm/min), stress values begin to stabilize, indicating a strain-hardening limit beyond which further increases in strain rate do not significantly enhance stress.

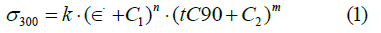

Breaking elongation, on the other hand, decreases with increasing cure time due to restricted polymer chain movement, while strain rate has only a minimal effect, as breaking elongation remains relatively stable across different strain rates rather than decreasing sharply. These observations led to the development of empirical models to describe their behavior. The model for stress at 300% elongation is expressed as

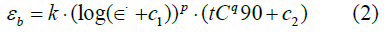

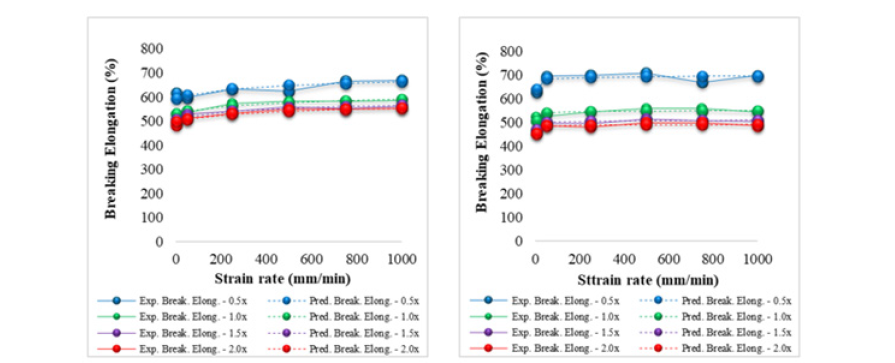

Where, for NR, k=11.96 is a material-dependent constant, n=0.00506 represents the strain rate sensitivity exponent, m=0.1255 denotes the cure time effect exponent, C1=0.01 denotes the strain rate offset, C2=-0.488 represents the cure time offset, and R2 =0.95 shows a strong correlation with experimental data. For SBR, k=8.89, n=0.0413, m=0.1703, C1 =2.83, C2 =-0.479 and R2 =0.97. The model describes how stress increases with strain rate at lower values, but plateaus at higher strain rates, where polymer chains reach their mobility limits, leading to strain rate saturation effects. The strain rate exponent (n) is small, confirming that stress at 300% elongation is more sensitive to cure time than strain rate. The model successfully ensures accuracy across different deformation conditions and enables reliable predictions for rubber processing optimization, material selection and mechanical performance evaluation in industrial applications, as shown in Figure 8a & 8b. For breaking elongation, a nonlinear model was introduced to incorporate logarithmic dependence on strain rate and nonlinear cure time effects. The model is expressed as:

Figure 8a & 8b:NR & SBR-Stress@ 300% Elongation (Exp. & Pred.).

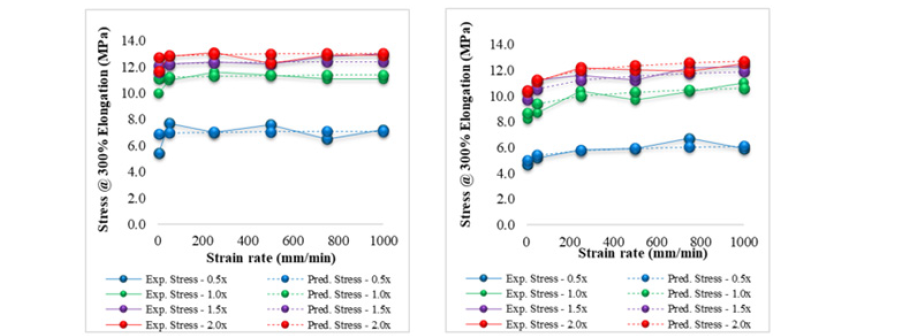

where, For NR, k=46.47 is the material-dependent constant, p=0.2448 represents the strain rate sensitivity exponent, q=−0.979 denotes the cure time effect exponent and offset parameters c1 =81.81 and c2 =6.89 with R2 =0.96 shows a strong correlation with experimental data.

Figure 9a & 9b:NR & SBR-Breaking Elongation (Exp. & Pred.).

For SBR, k=91.84 is the material-dependent constant, p=0.0272 represents the strain rate sensitivity exponent, q=-1.325 denotes the cure time effect exponent, and offset parameters c1 =-3.62 and c2 =4.69 with R2 =0.98. The model captures how, as the strain rate increases, breaking elongation initially improves due to better molecular chain alignment, but eventually chain mobility becomes restricted at higher strain rates, leading to a gradual, not abrupt, reduction in breaking elongation as shown in Figure 9a & 9b. The cure time dependence ensures that the model captures the nonlinear reduction in breaking elongation as crosslink density increases. Despite the strong predictive capabilities of both models, some limitations exist. The stress model assumes a continuous power-law relationship, which may slightly overpredict stress at very high strain rates due to strain rate saturation. The breaking elongation model does not account for certain factors such as viscoelastic relaxation, molecular entanglements, and strain rate history effects, which may influence breaking elongation behavior under extreme conditions. Furthermore, experimental variations, processing conditions, and temperature effects are not explicitly included in either model, which could introduce slight deviations in real-world applications. Nevertheless, these models provide highly accurate and reliable predictions for stress at 300% elongation and breaking elongation, making them valuable tools for rubber processing optimization, material selection and mechanical performance assessment under varying deformation conditions. The developed equations are specifically applicable to the studied recipes; however, a similar modeling approach can be applied to other rubber compounds, provided it is supported by targeted experimental data from limited but well-designed studies.

Conclusion

This study examined the mechanical behavior of Natural Rubber and Styrene Butadiene Rubber by analyzing their stressstrain response under varying strain rates and cure times. The findings confirmed that stress at 300% elongation increases with both strain rate and cure time, but at higher strain rates (500mm/ min and above), stress stabilizes, indicating a strain-hardening limit beyond which further strain rate increases do not significantly improve stress. Breaking elongation decreases with increasing cure time due to restricted polymer chain mobility, while strain rate has a relatively small effect on elongation, as the values increase a little or remain stable across different deformation speeds. To describe these behaviors, empirical models were developed for stress at 300% elongation and breaking elongation, incorporating power-law and nonlinear dependencies on strain rate and cure time. These models demonstrated strong predictive capabilities, with R² values above 0.94, confirming their accuracy and reliability. The results emphasize that cure time has a greater influence than strain rate on both stress and elongation properties, as higher cure times lead to increased stiffness and reduced flexibility. The study provides important insights into how strain rate and cure time together influence rubber performance, enabling material design optimization for improved mechanical properties. The developed models can be effectively used in industrial applications to predict rubber behavior, optimize processing conditions and enhance product performance with the support of experimental data. These findings contribute to a better understanding of the stress-strain relationship in vulcanized rubber, aiding in the development of more durable and high-performance rubber materials for various engineering and industrial uses.

Author Contributions

Ajay C, (https://orcid.org/0000-0002-3855-643X), Writingoriginal

draft, Writing-review and editing, Visualization,

Methodology, formal analysis, Investigation, Data curation,

Conceptualization, Validation, Experimentation.

a) Mr. Sohan Kumar Kanrar: Experimentation.

b) Dr. Saikat Das Gupta: Writing-review and editing, Resources,

Supervision.

c) Dr. Rabindra Mukhopadhyay: Resources, Financial support.

d) Prof. (Dr). Dipankar Chattopadhyay: Writing-review and

editing, Planning and Supervision.

e) Prof. (Dr). Mahuya Das: Writing-review and editing, Planning

and Supervision.

Data Availability Statement

The data supporting the findings of this study can be obtained from the corresponding author upon a reasonable request.

Conflict of Interest

We declare that this manuscript or its content in some other form has not been published elsewhere and is not under consideration by any other journal at the time of submission. All authors have approved the manuscript and agree with the submission. The authors have no conflict of interest to declare.

Acknowledgements

The authors extend their gratitude to the management of Hari Shankar Singhania Elastomer and Tyre Research Institute for generously granting permission to publish this work.

Funding

The authors received no specific funding for this work.

Clinical Trial Number

Not Applicable.

References

- Coran AY (2013) Chapter 7-Vulcanization. In: James EM, Burak E, Michael CR (Eds.), The Science and Technology of Rubber. (4th edn), Academic Press, USA, pp. 337-381.

- Bhowmick AK, Mukhopadhyay R, De SK (1979) High temperature vulcanization of elastomers. Rubber Chemistry and Technology 52(4): 725-734.

- Roland CM (2006) Mechanical behavior of rubber at high strain rates. Rubber Chemistry and Technology 79(3): 429-459.

- Ikeda Y, Miyaji K, Ohashi T, Nakajima T, Junkong P (2002) Vulcanization for reinforcement of rubber. Rubber Chemistry and Technology 95(2): 161-174.

- Muhr AH, Roberts AD (1992) Rubber abrasion and wear. Wear 158(1-2): 213-22.

- Yilmaz E, Dayioglu A, Balaban S (2020) Effect of vulcanization time on crosslink density and aging performance of natural rubber composites. Materials Testing 62(8): 858-862.

- Mohammad AS, Mohammad A, Mohammad L, Hossein R (2025) Improved fatigue resistance of thermoplastic elastomer-filled natural rubber composites. Materials Chemistry and Physics 340: 130824.

- Sung SC, Jong CK (2012) Lifetime prediction and thermal aging behaviors of SBR and NBR composites using crosslink density changes. Journal of Industrial and Engineering Chemistry 18(3): 1166-1170.

- Li Y, Ge D, Ju Z, Lv S, Xue Y, et al. (2022) Study on performance and mechanism of SBR and bio-oil recycled SBS modified asphalt. Polymers 14(23): 5096.

- Pawel B, Jerzy M, Lukasz M (2016) Numerical and experimental testing of vehicle tyre under impulse loading conditions. International Journal of Mechanical Sciences 106: 346-356.

- Roberts GP, Barnes HA, Mackie C (2019) Using the Microsoft excel ‘Solver’ tool to perform non-linear curve fitting, using a range of non-Newtonian flow curves as examples. Applied Rheology 11(5): 271-276.

- Ajay C, Saikat DG, Rabindra M, Dipankar C, Mahuya D (2025) Exploring crosslink density in rubber vulcanisates-a comprehensive analysis using a dynamic mechanical analyser and an insight into mechanical properties. Journal of Rubber Research 28(2): 305-323.

- Kulkarni SD, Manjunatha B, Chandrasekhar U, Siddesh GK, Lenin H, et al. (2023) Effect of curing temperature and time on mechanical properties of vinyl polymer material for sealing applications in industry using machine learning techniques. Advances in Polymer Technology 9964610: 1-10.

- Zhao F, Bi W, Zhao S (2011) Influence of crosslink density on mechanical properties of natural rubber vulcanizates. Journal of Macromolecular Science Part B 50(7): 1460-1469.

- Flory PJ, Rabjohn N, Shaffer MC (1949) Dependence of tensile strength of vulcanized rubber on degree of cross-linking†. J Polym Sci 4(4): 435-455.

- Morrison NJ, Porter M (1984) Temperature effects on the stability of intermediates and crosslinks in sulfur vulcanization. Rubber Chemistry and Technology 57(1): 63-85.

- Nie W, Jack FD, Xia W (2023) Competing effects of molecular additives and cross-link density on the segmental dynamics and mechanical properties of cross-linked polymers. American Chemical Society 3(6): 512-526.

- Stephen HL (1983) Rubber technology and manufacture. In: Blow CM, Hepburn C (Eds.), (2nd edn), J Polym Sci B Polym Lett Ed, Buttenvorths, London 21: 505-505.

- Kitamura Y, Okada K, Masunaga H (2019) Role of strain rate in the Strain-Induced Crystallization (SIC) of natural and synthetic isoprene rubber. Polym J 51: 221-226.

© 2025 Ajay C. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)