- Submissions

Full Text

Progress in Petrochemical Science

Numerical Simulator of Production Forecast for Multi-Lateral Oil Well using MATLAB-based Simulator

Ekrem Alagoz1*, Emre Can Dundar1 and Mouad Al-Krmagi2

1Turkish Petroleum Corporation (TPAO), Turkey

1Texas A&M University, USA

*Corresponding author:Ekrem Alagoz, Turkish Petroleum Corporation (TPAO), Turkey

Submission: October 24, 2024;Published: November 20, 2024

ISSN 2637-8035Volume6 Issue4

Abstract

This paper presents the development and application of a MATLAB-based numerical simulator for forecasting oil production from a multilateral, saturated reservoir. The simulator predicts reservoir pressure depletion, oil production and cumulative oil production over time for two formations, while accounting for physical assumptions such as solution gas drive and no fluid interaction between reservoirs. Using reservoir and well properties, the pressure and production trends of both the upper and lower formations are forecasted over a two-year period. Results indicate a 1000psi pressure drop in the lower formation and a 1157psi drop in the upper formation. Additionally, the simulator was used to investigate the impact of varying wellhead pressures on liquid holdup and oil production during the first 150 days. It was observed that a wellhead pressure of 1800psi minimized liquid holdup, although this did not correspond to the maximum oil production, highlighting the trade-off between reducing holdup and optimizing production. This research provides an adaptable tool for reservoir engineers to optimize production forecasting and holdup analysis under different operational conditions. Suggestions for further refinements and improvements to the simulator are welcomed to enhance its accuracy and application to broader reservoir scenarios.

Keywords:Multilateral oil well; Production forecasting; MATLAB simulator; Reservoir pressure depletion; Liquid hold-up optimization

Introduction

The oil and gas industry are continually seeking innovative methods to enhance production efficiency while minimizing operational challenges. One significant area of focus is the accurate forecasting of oil production from multilateral wells, which are increasingly utilized due to their ability to access multiple reservoir layers from a single drilling location. Accurate production forecasts are crucial for effective reservoir management and decision-making, influencing strategies related to well design, completion and production optimization. This paper presents a MATLAB-based numerical simulator designed to predict oil production from a multilateral saturated reservoir. The simulator employs a comprehensive approach that integrates various physical models and reservoir properties, allowing for a detailed analysis of production dynamics. The primary objectives of this research include forecasting oil production over a specified period and identifying the optimum wellhead pressure to minimize liquid holdup during production. The methodology involves setting an arbitrary wellhead pressure and simulating the resulting reservoir pressure dynamics, utilizing mass balance procedures to assess the impact of varying pressures on oil production rates. Key performance indicators, including reservoir pressure changes, oil production rates, cumulative oil production and liquid holdup, are evaluated to determine the optimal operational parameters.

Through this work, we aim to provide a valuable tool for engineers and researchers in the oil and gas sector, facilitating improved production forecasting and reservoir management. The findings of this study contribute to the broader understanding of multilateral well dynamics, ultimately supporting the industry’s efforts to maximize recovery while addressing economic and environmental considerations. In-depth research has delved into the dynamics of pressure distribution within pore throats, with a focus on elucidating the fundamental mechanisms governing fluid flow in porous media. Alagoz E et al. [1] conducted a sensitivity analysis on bottomhole pressure calculations in two-phase wells, providing valuable insights into the factors influencing pressure dynamics within such systems [1]. Furthermore, Alagoz E et al. [2] have contributed to the field by developing computational tools for analyzing wellbore stability, thereby enhancing our understanding of pressure behavior in complex geological formations [2]. These studies have laid the groundwork for comprehending pressure dynamics in pore throats and have paved the way for further exploration in this area.

Previous Works

Amin RS et al. [3] discuss the rising norm of drilling multi-lateral wells for enhanced reservoir coverage, improved productivity and better financial returns. Their study introduces a multi-parametric optimization approach for designing and placing multi-lateral wells to maximize contact with productive hydrocarbon zones. Utilizing advanced 3D transient numerical models that incorporate dynamic data, the study simulates transient-pressure behaviors of multi-lateral wells accurately. The optimization process considers variables such as the number of laterals, spacing and lateral length based on reservoir characteristics, generating multiple well patterns to identify the most productive configuration. Ahmet et al. emphasize minimizing competition among laterals and maximizing the drainage area, which is crucial for optimizing productivity, especially in permeable and tight reservoirs. They present graphical productivity indices from these simulations to guide the selection of the best well design. Additional sensitivity analyses illustrate the impact of reservoir heterogeneity, lateral length, spacing and the presence of offset producers or injectors. Their workflow has been successfully tested and aids in designing optimal multi-lateral wells for various reservoir conditions.

Alagoz E et al. [4] provides a comprehensive analysis of gas well production forecasting and pressure dynamics within natural gas formations. By focusing on transient flow conditions and assuming Darcy flow with zero skin factors, the authors investigate two key aspects: production forecasting and pressure drop analysis. Their primary objective is to develop a production forecast until the average reservoir pressure declines to 2,000psi. Additionally, the paper delves into the pressure drop along the well, detailing its components such as friction, acceleration and gravitational potential, with depth profiles presented for at least one average reservoir pressure scenario. Moreover, temporal variations in pressure drop are considered, offering insights into the evolution of these dynamics over time. Through rigorous examination and discussion, this study contributes valuable insights for optimizing gas well production strategies and enhancing understanding of pressure behavior in natural gas formations.

Aranguen C et al. [5] explore cutting-edge sequence-based machine learning models, commonly used in language processing, to reproduce a multi-porosity reservoir simulator. Their approach integrates advanced techniques to significantly reduce numerical simulation time and improve decision-making for Huff and Puff (H-n-P) gas injection optimization in shale reservoirs. The method involves three crucial steps: 1) validating simulation results against actual data, 2) training and validating a machine learning model using simulation results from commercial or in-house numerical simulators and 3) exhaustively exploring hyperparameter tuning and selecting machine learning techniques, such as sequence-tosequence (Seq2Seq), Luong attention, and ConvLSTM. The proxy model uses well control parameters-like injection and production periods, number of cycles and gas injection rates-as input variables to estimate results. This multi-porosity proxy reservoir simulation model combines numerical simulation with data-driven techniques [6]. Despite the significant time required for tuning the model, it can speed up simulation time by up to 20,000 times, enabling the generation of hundreds or thousands of scenarios within minutes, albeit with some reduction in accuracy. Notably, with a small training dataset, the proxy model can accurately predict oil production in complex low and ultra-low permeability reservoirs, significantly reducing error relative to the multi-porosity reservoir simulator. The ability to reproduce numerous scenarios quickly allows for the exploration of different well control configurations. The novelty of this proxy multi-porosity reservoir simulator lies in its ability to accelerate numerical simulation time by using techniques that solve sequence learning problems where outputs depend on previous outputs.

Alagoz E et al. [7,8] conducted a comprehensive comparative analysis of gas production forecasts for non-fractured and fractured vertical gas wells. By examining factors such as Darcy flow, zero skin factor assumptions and fracture stimulation techniques, the study highlights the significant impact of fracture stimulation on enhancing gas recovery rates and overall profitability. The findings demonstrate substantial differences in production volumes and economic outcomes across various fracture program models, underscoring the importance of strategic decision-making in optimizing resource utilization and maximizing revenue. This research elucidates the interplay between reservoir characteristics, operational parameters and economic considerations, providing a valuable framework for guiding future research and industry practices. The insights gained are crucial for informing stakeholder decisions and advancing gas production technologies and strategies.

In the realm of unconventional well production forecasting, Laalam A et al. [9] conducted a comprehensive evaluation of empirical correlations and time series models, focusing on the Wolfcamp a Formation. Their study compared the performance of traditional decline curve models with advanced machine learning techniques such as ARIMA, LSTM and GRUs. The research highlighted that no single model consistently excelled across all scenarios, emphasizing the necessity for tailored approaches based on specific reservoir characteristics. Notably, the ARIMA model demonstrated superior accuracy with an R2-score of 93.50%, outperforming the Logistic Growth Model. This underscores the potential of advanced statistical methods and machine learning models in managing the complex data typical of unconventional reservoirs [9].

In a related study, Dehdouh A et al. [10] explored the application of Fishbone Drilling (FbD) technology to enhance recovery efforts in the Bakken formation. Their investigation revealed that FbD, characterized by multiple minor holes branching from the main wellbore, significantly improves hydrocarbon recovery by enhancing reservoir contact and exploiting natural fractures more effectively than traditional methods. The study’s detailed numerical simulations and comparative analyses highlighted the superior performance of FbD over conventional drilling and fracturing methods, suggesting a promising avenue for future exploration and development within unconventional reservoirs [10]. Our study builds upon these findings by implementing a MATLABbased simulator to analyze multilateral saturated reservoirs. This approach involves detailed numerical simulations that calculate critical parameters such as pressure, temperature, flow regime and production rates, providing a robust framework for sensitivity analyses and optimization in reservoir management.

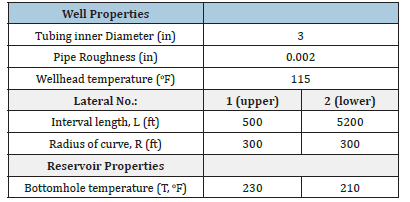

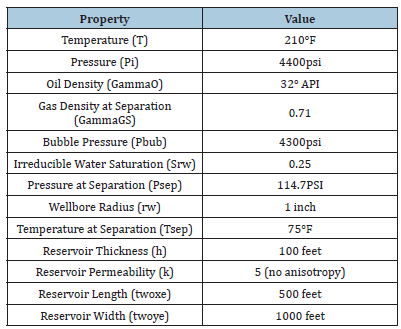

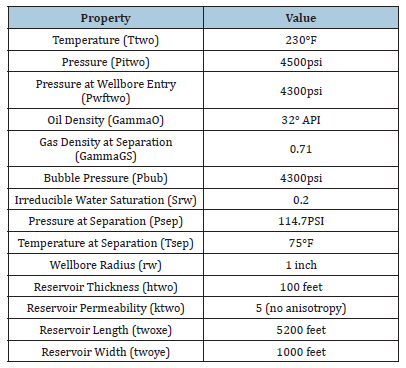

Relevant Dimensions, Properties and Assumptions

In the present study, a comprehensive examination of the properties outlined in the original problem statement is facilitated through tabulation in the accompanying table. It is noted that the productivity indices provided in the problem statement were omitted from integration into the simulator owing to compatibility concerns (Table 1). This decision was made to ensure the robustness and reliability of the simulator’s functionality in addressing the core objectives outlined in the research (Figure 1) (Table 2). These properties serve as fundamental inputs for the numerical simulation and analysis conducted in this research endeavor, contributing to the comprehensive characterization of the multilateral oil well system under investigation (Table 3). These properties are instrumental in the analysis and modeling of Formation 2 within the multilateral oil well system, contributing to a comprehensive evaluation of its behavior and performance. The simulator developed for this well scheme operates on a set of physical assumptions that facilitate the approximation of actual production data. These assumptions are crucial for simplifying complex reservoir dynamics and enabling manageable computational analysis. While these approximations serve a valuable purpose in predicting production performance, it is essential to acknowledge their limitations in accurately reflecting real-world scenarios.

The first assumption, solution gas drive, posits that the primary mechanism driving oil production is the gas that dissolves in the oil under reservoir conditions. This model assumes that as pressure decreases during production, the gas comes out of solution, thereby expanding and pushing oil to the wellbore. This simplification allows for straightforward calculations regarding pressure and production rates but may not account for the complexities introduced by other drive mechanisms, such as water encroachment or gas-cap expansion, which can significantly influence production outcomes in actual reservoir conditions.

Table 1:Well and reservoir properties used as an input for this study.

Figure 1:Schematic of the wells.

Table 2:Properties of upper formation.

Table 3:Properties of lower formation.

The second assumption, no gas cap, further simplifies the simulation by eliminating the presence of a gas cap above the oil column. In reality, many reservoirs exhibit a gas cap that can affect the pressure distribution and oil recovery process. By disregarding this factor, the simulator focuses solely on the oil phase, which may lead to an oversimplified view of the reservoir behavior. However, this assumption allows for a clearer analysis of the primary oil production mechanisms without the added complexity of gas cap interactions.

The third assumption, that of a virgin reservoir, indicates that the model operates under the premise of initial reservoir conditions prior to any production activity. This assumption implies a static environment where the pressure, temperature and saturation conditions have not been altered by previous extraction efforts. In practical applications, however, reservoirs often undergo significant changes due to production, such as pressure depletion and changes in fluid saturation levels. Therefore, while this assumption facilitates initial modeling, it may not adequately capture the evolving dynamics of an actual reservoir over time.

Finally, the assumption of flow in one direction only asserts that fluid movement occurs solely from the reservoir to the wellbore without any cross-flow between different reservoir formations. This directional flow assumption simplifies the modeling process by preventing the complexities associated with multi-directional fluid migration, which can occur in more interconnected reservoir systems. Although this assumption enables the simulation to focus on the primary production flow path, it may overlook significant interactions between adjacent formations that can influence overall production efficiency and reservoir behavior. While the assumptions underpinning the simulator provide a structured framework for analyzing oil production in multilateral wells, they inevitably introduce limitations that should be considered when interpreting the results. Future work may involve refining these assumptions to incorporate more complex reservoir interactions and drive mechanisms, thereby enhancing the accuracy and applicability of the simulator in real-world scenarios.

Solution Approach

General methodology

The methodology employed in developing the simulator begins with the establishment of arbitrary wellhead pressure, which serves as the foundation for subsequent calculations. This initial pressure setting is critical, as it influences the pressure dynamics within the lower reservoir. The simulator subsequently calculates the decrease in pressure of the lower reservoir by predetermined increments, simulating the impact of production activities on reservoir pressure over time. To determine the duration required for this pressure drop, the simulator utilizes the oil reservoir mass balance procedure discussed in the lecture materials. This method involves analyzing the relationship between the produced fluids and the changes in reservoir pressure, allowing for an accurate estimation of production timelines. In addition to forecasting the pressure drop in the lower reservoir, the simulator also examines the appropriate pressure drop in the upper reservoir over the same time period. This dual focus ensures a comprehensive understanding of reservoir dynamics and provides insights into the interactions between the two reservoirs during the production process.

The second part of the problem statement addresses the optimization of wellhead pressure to minimize liquid holdup during production. This optimization is specifically focused on lower reservoir pressures ranging from 4500psi to 4200psi. By utilizing the results from the first part of the analysis, the simulator plots a range of wellhead pressures against liquid holdup and oil production for the two specified lower reservoir pressures. This graphical representation aids in identifying the optimal wellhead pressure that balances production efficiency with liquid management, thus guiding operational decision-making. The simulator integrates the production simulation algorithm developed in the initial project, ensuring continuity and leveraging previously established methodologies. This integration enhances the overall robustness of the simulation and streamlines the process of analyzing production scenarios.

Physical models utilized

In this subsection, we delineate the physical models incorporated into the simulator, emphasizing that they remain consistent with those employed in the initial project. These models are designed to simulate the fundamental processes governing oil production and reservoir behavior, ensuring that the simulator yields reliable and actionable results.

Oil reservoir: The oil reservoir model plays a pivotal role in

calculating the time required for a specific pressure reduction

within the reservoir. This model processes various input parameters

produced by the production simulator from the first project [8],

facilitating a dynamic assessment of reservoir behavior as pressure

changes occur. The core function of this model is encapsulated in

the Time function, which is defined as follows:

function [time,Np,Gp] =

Time(Bo,Bg,Rs,qo,miuo,miug,Srw,twoxe,twoye,h,prst, Npold,

Gpold, BoInitial,RsInitial);

Phin = (mean(Bo) - mean(Rs)*mean(Bg))/((mean(Bo)-

BoInitial)+((RsInitial-mean(Rs))*mean(Bg)));

Phig = (mean(Bg))/((mean(Bo)-BoInitial)+((RsInitialmean(

Rs))*mean(Bg)));

Pass = 0;

Rp = 820;

while Pass == 0

DelN = (1)/(Phin + Rp*Phig);

DelG = DelN*Rp;

Np = Npold+DelN;

Gp = Gpold+DelG;

OilSat = (1-Np)*mean(Bo)/BoInitial*(1-Srw);

ko = ((OilSat-0.2)/0.8)^4;

kg = ((0.8-OilSat)/0.6)^2*(1-((OilSat-0.2)/0.8)^2);

Rpcalc = mean(Rs)+(kg*mean(miuo)*mean(Bo))/

(ko*mean(miug)*mean(Bg));

if abs(Rp-Rpcalc) > 1

Rp = Rpcalc;

else

Pass = 1;

end

end

VolRes = twoxe*twoye*h*0.1781;

OIP = VolRes*prst*(1-Srw)/Bo(1);

CumOilProd = DelN*OIP;

time = CumOilProd/mean(qo);

Within this function, the initial reservoir pressures and properties are analyzed to determine the pressure drop dynamics. The variables such as oil formation volume factor (Bo), gas formation volume factor (Bg), solution gas ratio (Rs) and oil and gas production rates (qo) are pivotal inputs. The function then calculates the initial fluid saturations, employing mass balance equations to determine the relationship between pressure, saturation and production rates. The simulation iterates through a series of calculations to derive cumulative oil production and the time required to achieve the desired pressure drop. This iterative process continues until the pressure calculations converge, ensuring accuracy in the model’s predictions.

About simulator

The production system simulator is implemented in MATLAB,

leveraging a combination of m-files and functions derived from

the previous project, along with three additional files developed

specifically to meet the requirements of this project. The following

elaborations provide guidance on the execution of these essential

files:

A. ReservoirPressureForecast.m: This script establishes the

initial pressures of both the lower and upper reservoirs. It also

delineates the arbitrary pressure drop for each calculation

iteration, setting the stage for the simulation’s iterative

calculations.

B. Time.m: Serving as a function file, Time.m calculates the

duration required for the reservoir pressure to decrease by a

specified amount. It incorporates the principles of oil reservoir

material balance, ensuring that the time calculations align with

the physical behaviors expected in reservoir dynamics.

C. HoldupStudy.m: This script focuses on determining the

minimum wellhead pressure necessary to facilitate production

at any given moment during the production period. By

analyzing various production scenarios, this file aids in

optimizing operational strategies to minimize liquid hold-up

and maximize oil recovery.

In addition to these scripts, it is imperative to specify the wellhead pressure in the Master.m file. Once the necessary parameters are set, the simulator can be executed by running the ReservoirPressureForecast.m file, thereby initiating the production forecast analysis. This structured approach allows for systematic exploration of production dynamics, providing valuable insights into reservoir behavior and operational efficiency.

Output of the Work

The results presented in this study were derived from a comprehensive simulation that utilized the reservoir and well properties outlined in previous subsections. These properties, which include essential parameters such as reservoir dimensions, fluid characteristics and initial pressure conditions, serve as the foundational inputs for the numerical simulator. By meticulously selecting and defining these properties, we ensure that the simulation closely mimics real-world conditions, thereby enhancing the reliability of the results obtained. In this particular simulation, the wellhead pressure was set at 1000psi, a crucial parameter that significantly influences the overall performance of the well and the behavior of the reservoir. This specific pressure setting was chosen as a baseline for the analysis, allowing us to observe the dynamics of fluid flow and pressure changes within the reservoir under controlled conditions. By maintaining a consistent wellhead pressure, we can effectively isolate its effects on key performance indicators such as oil production rates, reservoir pressure changes and liquid holdup.

The interaction between the wellhead pressure and the reservoir properties is fundamental to understanding the production dynamics within a multilateral oil well system. As the simulation progresses, the impact of this pressure setting becomes evident through the calculated outcomes, including the time required for pressure drops, the cumulative oil production over the designated period and the overall efficiency of the extraction process. By leveraging the defined reservoir and well properties in conjunction with the established wellhead pressure, we can draw meaningful conclusions from the simulation results. These conclusions not only enhance our understanding of the reservoir’s behavior but also inform operational strategies for optimizing production in similar real-world scenarios. Ultimately, the results obtained from this simulation provide valuable insights that can guide future research and development efforts in the field of reservoir engineering and production optimization (Figure 2).

Figure 2:Reservoir Pressure vs Time Elapsed.

The simulation forecasts a significant decline in the pressure of the lower reservoir, projecting a decrease of 1000psi over an estimated period of 750 days, which is roughly equivalent to two years. In contrast, the upper reservoir is anticipated to experience a slightly greater pressure reduction of 1157psi during the same timeframe. This disparity in pressure changes between the two reservoirs highlights the differing dynamics at play, potentially influenced by factors such as fluid properties, reservoir connectivity and flow characteristics. However, it is essential to note that the graphical representation of the upper reservoir pressure exhibits a jagged appearance, a result of low calculation resolution in the simulation process. This irregularity may obscure the true behavior of the pressure changes, suggesting that finer resolution in the calculations could yield a smoother and more accurate depiction of pressure dynamics, thereby improving the interpretability of the results.

As shown in Figure 3, the oil production rates of the upper and lower reservoirs over time are presented. The lower reservoir starts at a production level of 2600 STB/day and decreases to approximately 1400 STB/day over the span of about two years. In contrast, the upper reservoir begins at a production rate of 500 STB/day and drops to 60 STB/day within the same timeframe. In Figure 4, the cumulative production rates can be observed. (Figure 5 & 6) The previous section provided a comprehensive forecast of oil production from the well over a span of approximately two years. While this extensive timeframe allows for a detailed understanding of reservoir behavior, it poses challenges for optimization, as the effects of various parameters may become less pronounced over such an extended period. To address this issue, we have opted to concentrate on optimizing the liquid holdup during the initial 150 days of production, a critical phase where immediate operational decisions can significantly impact overall performance. The base case for this analysis is established with a wellhead pressure of 1000psi, serving as a reference point for comparison. Within this timeframe, it is noted that the lower reservoir experiences a pressure drop of about 400psi, transitioning from an initial pressure of 4500psi down to 4100psi. By focusing on this shorter duration, the analysis can provide actionable insights into optimizing well performance and minimizing liquid hold-up, ultimately leading to enhanced oil recovery during the early stages of production.

Figure 3:Oil Production vs Time Elapsed.

Figure 4:Cumulative Oil Production vs Time Elapsed.

Figure 5:Holdup vs Time Elapsed.

Figure 6:Total Oil-in-Place vs Time Elapsed.

The Figure 7 presented above illustrates the relationship between the maximum wellhead pressure required for production and the corresponding pressure levels of the lower reservoir. Specifically, when the lower reservoir is at a pressure of 4100psi, the analysis indicates that a wellhead pressure of approximately 1850psi is essential to maintain production effectively. This crucial threshold highlights the interplay between reservoir pressures and the operational settings at the wellhead, underscoring the importance of accurately determining these parameters for optimal production efficiency. In light of these findings, the subsequent holdup analysis will explore a range of wellhead pressures, commencing from the calculated minimum of 1850psi and extending down to the established base case of 1000psi. This range allows for a systematic investigation of how variations in wellhead pressure influence liquid hold-up, enabling the identification of the most effective operational conditions to enhance production while minimizing inefficiencies related to liquid accumulation. By examining this spectrum of pressures, we can gain valuable insights into the operational strategies that can maximize oil recovery in the context of varying reservoir dynamics (Figure 8-11).

Figure 7:Minimum Required Well Head Pressure vs Lower Reservoir Pressure.

Figure 8:Holdup through 150 days for different wellhead pressures.

Figure 9:Oil production through 150 days for different wellhead pressures.

Figure 10:Cumulative oil production through 150 days for different wellhead pressures.

Figure 11:Reservoir pressures (upper and lower) through 150 days for different wellhead pressures.

The analysis presented in the diagrams suggests that setting the wellhead pressure at 1800psi is optimal for minimizing liquid hold-up during the initial 150 days of production. This finding is significant, as excessive liquid accumulation can hinder production efficiency, leading to suboptimal recovery rates. However, it is crucial to recognize that while this wellhead pressure effectively reduces liquid hold-up, it does not correspond to the highest achievable oil production rates. To achieve greater production, operators may need to consider lowering the wellhead pressure even further, which could enhance flow rates but may lead to increased liquid accumulation. This situation highlights a critical operational dilemma: a balance must be struck between maximizing oil production and minimizing liquid hold-up. Therefore, decision-makers must carefully evaluate the trade-offs involved, considering not only the immediate production benefits but also the longer-term implications for reservoir performance and overall recovery efficiency. Such considerations are essential for developing a comprehensive production strategy that aligns operational goals with the reservoir’s dynamic behavior, ultimately ensuring sustainable and efficient resource extraction.

Conclusion

In conclusion, this research presents a comprehensive numerical simulator developed in MATLAB for forecasting oil production from a multilateral saturated reservoir. By employing a systematic approach that incorporates key physical assumptions and detailed modeling techniques, the simulator effectively predicts reservoir pressures, oil production rates and liquid holdup over specified time intervals. The findings demonstrate that wellhead pressure settings significantly influence both production efficiency and liquid management, emphasizing the need for careful optimization in operational strategies. Specifically, the analysis highlights a critical trade-off between minimizing liquid hold-up and maximizing oil production, with an optimal wellhead pressure of 1800psi identified for the initial 150 days of production. This study underscores the importance of utilizing advanced simulation tools to inform decision-making in oil production operations, paving the way for enhanced resource recovery strategies. Future work could explore the integration of additional reservoir dynamics and environmental factors, further refining the simulator’s predictive capabilities and contributing to more sustainable practices in the oil and gas industry.

References

- Alagoz E, Giozza GG (2023) Calculation of bottomhole pressure in two-phase wells using beggs and brill method: Sensitivity analysis. International Journal of Earth Sciences Knowledge and Applications 5(3): 333-337.

- Alagoz E, Mengen AE, Bensenouci F, Dundar EC (2023) Computational tool for wellbore stability analysis and mud weight optimization v1.0. International Journal of Current Research Science Engineering Technology 7(1): 1-5.

- Amin RS, Abdulwahab IM, Rahman NM (2024) Maximization of the productivity index through geometrical optimization of multi-lateral wells in heterogeneous reservoir system. Paper presented at the International Petroleum Technology Conference, Dhahran, Saudi Arabia.

- Alagoz E, Dundar EC (2024) A comparative analysis of production forecast for vertical gas wells: Fractured vs. Non-fractured. International Journal of Earth Sciences Knowledge and Applications 6(2): 333-337.

- Aranguren C, Araque CR, Cuervo S, Fragoso A, Aguilera R (2023) Reducing simulation time in a huff-and-puff gas injection project in complex shale reservoirs: Sequence-based proxy multi-porosity reservoir simulator. Paper Presented at the SPE Canadian Energy Technology Conference and Exhibition, Calgary, Alberta, Canada.

- Liu W, Zhao H, Sheng G, Li HA, Xu L, et al. (2021) A rapid waterflooding optimization method based on INSIM-FPT data-driven model and its application to three-dimensional reservoirs. Fuel 292: 120219.

- Alagoz E, Dundar EC (2024) Forecasting gas well production and analyzing pressure dynamics: A study of transient flow and pressure drop in natural gas formation. Journal of Energy & Environmental Science 2(1): 1-7.

- Alagoz E, Dundar EC, Krmagi MA (2024) Numerical simulation of a multilateral saturated reservoir using MATLAB-based simulator. Petroleum and Petrochemical Engineering Journal.

- Laalam A, Khalifa H, Ouadi H, Benabid MK, Tomomewo OS, et al. (2024) Evaluation of empirical correlations and time series models for the prediction and forecast of unconventional wells production in Wolfcamp a formation. Paper Presented at the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, Texas, USA.

- Dehdouh A, Bettir N, Khalifa H, Kareb A, Krmagi MA (2024) Optimizing recovery in unconventional reservoirs by advancing fishbone drilling technology in the bakken formation, williston basin. Paper Presented at the 58thS. Rock Mechanics/Geomechanics Symposium, Golden, Colorado, USA.

© 2024 Ekrem Alagoz. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)