- Submissions

Full Text

Progress in Petrochemical Science

Conversion of Coal Fired Furnaces into Piped Natural Gas (PNG) Based Furnaces in Steel Re-Rolling Mills

Jatinder Kaur Arora*, Pritpal Singh, Ranjit Singh and Amit Kumar

Punjab State Council for Science & Technology, Chandigarh (UT), Indi

*Corresponding author: Jatinder Kaur Arora, Punjab State Council for Science & Technology, Chandigarh (UT), Indiaa

Submission: February 01, 2023;Published: February 13, 2023

ISSN 2637-8035Volume 5 Issue1

Introduction

Background

Asia’s biggest Steel town Mandi Gobindgarh falls in Fatehgarh Sahib District of Punjab in India. This city produces 25 percent of the toproductionroductions of the Country. The cluster is over 50 years old and has been constantly growing since its inception. The city is a hub of Steel Re-Rolling Mills (SRRM), induction furnaces, cupola units, refractory and forging units and comprises around 400 secondary steel units. The Mandi Gobindgarh cluster is importing all the raw material and other resource materials from other states resulting in high input cost. In spite of this, the cluster is sustaining its existence and competing with other steel clusters by reducing processing cost through implementation of Energy Conservation Measures and adoption of energy efficient technologies over the last 25 years. This cluster has about 300 coal-based re-rolling mills which consume around 3,00,000MT of coal for manufacturing of around 5MMT of steel products like angle, channel, girder, round, flat, TMT, patra etc, annually. Although, these rolling mills have achieved a benchmark w.r.t. energy efficiency and pollution control in comparison to other SRRM clusters in the Country but use of solid fuel i.e., coal emit around 600ton of stack particulate emissions and release around 7.7 lakh ton of associated Green House Gas (GHG) emissions annually even after achieving the SPM emission standards below 150mg/Nm3. Therefore, inspite of significant improvement in air pollution control from industries, operationalization of large number of industries in this cluster in a confined area remained one of the sources of air pollution in Mandi Gobindgarh..

Cluster scenario in adopting PNG

During field visits, Council Engineers observed that the challenges faced by the industry

included the following: non-availability of complete technology package for conversion to

PNG.

a. Piecemeal technological solutions provided by vendors without any backup support.

b. Industry’s initial focus by switching over to PNG was to meet the regulatory

requirement with minimal cost without considering the actual technical requirements.

c. Industry’s focus had primarily been limited to replacement of burners only and

adoption of partial automation.

d. Adoption of incomplete technological solutions by industry was leading to high PNG

consumption thereby discouraging the industry to switchover to PNG.

Inferences drawn from the field observations

a. The PNG technology in Mandi Gobindgarh was at a

nascent stage which needed to be further fine-tuned.

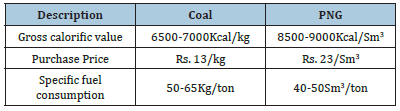

b. The baseline values regarding two fuels were as under

c. Adoption of PNG by rerolling mills would only be technoeconomically

feasible if the gas consumption is less than

40Sm3/ton. Presently, many technology suppliers are offering

piecemeal solutions to cut down the investment, thus creating

confusion in the minds of industry regarding appropriate

technology.

d. Instrumentation has a major role in making the PNG

technology techno-economically viable (Table 1).

Table 1:The baseline values regarding two fuels.

Technology package finalized for PNG furnace//

After extensive onsite studies and brainstorming with all

the equipment manufacturers working in this domain, a holistic

technological package comprising following interventions required

for adoption of PNG.

a. Design of furnace and its insulation

b. High Efficiency Heat Recovery System

c. Burners with high combustion efficiency

d. Mass based Automation and control (in contrast to

volume/pressure-based automation adopted by other units

which have tried converting to PNG)

Based on this Novel tech intervention, three demonstration units having different types of raw material and production capacity were set up in Mandi Gobindgarh.

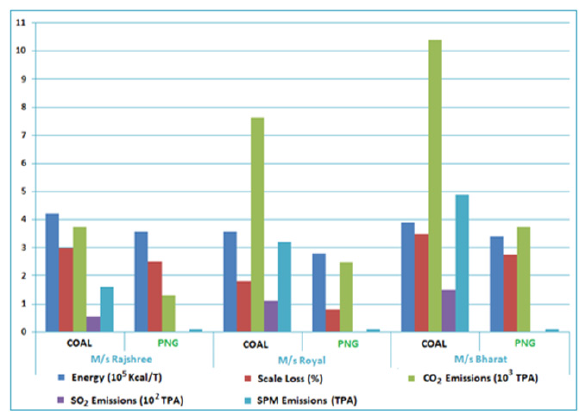

Benefits achieved in the model demonstration units/

The development and demonstration of the above technological innovations has resulted in the reduction of Green House Gas emission to the tune of 40% and particulate matter emission reduction by more than 90%. Further, it has provided a cleaner work zone environment to the industrial workforce which is around 100-125 workers per industrial unit. The Energy, production & environmental benefits achieved by different demonstration units are as compared in the following chart (Figure 1). The industry has invested about 30-125 lakh per unit in technology which has a payback period of about one year only. Thus, the industry is reaping economic benefits as the technological intervention developed and demonstrated by PSCST has established low PNG consumption (31-40Sm3/ton) and reduction in scale loss bringing in material saving of about 300 ton per year for a unit with average capacity of 10-15ton per hour leading to monitory saving of more than Rs. 1 million per annum to the industry. The working of these units has also been assessed by the State Pollution Control Board which served as model units for promoting wide scale replication of technology for all steel rerolling mills of Mandi Gobindgarh and Khanna cluster from coal to PNG.

Figure 1:The Energy, production & environmental benefits achieved by different demonstration units.

Recommendations for getting the optimum PNG consumption in re-heating furnace

a. A holistic technological approach should be adopted

by industries to maximize the furnace efficiency so that PNG

consumption can be achieved.

b. Combustion equipments of reputed equipment

manufactures should be installed.

c. Mass flow-based automation should be preferred over

volume-based automation.

d. High efficiency waste heat recovery should be installed.

e. Balanced draft should be preferred over natural draft

furnace operation.

f. Fibrous insulation should be preferred o

g. Safety measures in furnace operations should not be

compromised.

h. Training to furnace operator should be given.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)