- Submissions

Full Text

Novel Research in Sciences

Thorsten Hickmann: Cost Reduction Through Innovation: How New Material and Production Processes for Bipolar Plates Can Make an Important Contribution to the Energy Transition

Thorsten Hickmann*

Managing Director of Eisenhuth Gmbh & Co. KG, Germany

*Corresponding author: Thorsten Hickmann, Managing Director of Eisenhuth Gmbh & Co. KG, Germany

Submission: December 12, 2021;Published: December 22, 2021

.jpg)

Volume10 Issue2December, 2021

Introduction

The energy transition aims to reduce the share of fossil fuels such as oil, natural gas, coal and nuclear energy in Germany’s energy mix in favour of renewable energies. All industrialised countries around the world are currently addressing this issue. This topic has also arrived in Europe[1]. However, a changeover is not quite so simple, as capital investment costs in particular will play a significant role in the transition.

One contribution to cost reduction is consistent innovation management, illustrated here by the production of bipolar plates for electrolysers [2]. Polymer electrolyte membrane water electrolysis is considered particularly suitable for this type of application.

In polymer electrolyte membrane water electrolysis, the water to be split is fed via socalled porous transport layers to the catalyst layer where the water splitting takes place. These porous transport layers must ensure the outward transport of the water, the outward transport of the produced gas, and the electrical contacting of the electrode [3].

While a few years ago the topic of liquid metal injection molding made a furor and became established in some industrial sectors, the technologies presented here to produce composite materials from metallic powders has been able to establish itself in the energy storage media, i.e., especially in hydrogen production [4].

Here Innovation process and technology plays an imminent role as will be explained in Chapter III. Before that the importance of innovation is outlined (chapter II).

The Role of Innovations

TInnovations are an important driver for changes in processes. But what actually are innovations? An analysis of the current definitions shows that the criterion of novelty is a central feature. It is necessary to determine the perspective from which the novelty of a service, a performance or a business model is evaluated. There is much to be said for describing products and processes as innovative if they are introduced into a company for the first time.

A characteristic feature to distinguish an innovation from an invention is the aspect of its economic exploitation and its use on a company level. An innovation introduces an invention (a new product or process) to the market (innovation in the narrower sense) and makes it competitive on the market (innovation in the broader sense) [5].

Furthermore, innovations differ from inventions in that they do not refer to a point in time, but are process-related. A variety of concepts and models for structuring innovation processes can be found at the company level and in the literature. Such models help to visualize and control the process in its entirety. Models aim to map tasks that are typical for a certain process phase and thus enable a targeted use of methods [6].

Together with innovations, innovation management is an important aspect. What is understood by this? Innovation management is understood as the targeted control and design of innovation activities in a company. It requires structured and coordinated activities aimed at the successful introduction of an innovation on the market or for internal use in the company. These activities are subsumed under the term innovation management. They comprise a series of strategic and operational tasks for planning, organizing and controlling innovation processes and for creating the necessary operational framework conditions [7]. The following tasks are among the core tasks of innovation management:

A. Definition of innovation goals and strategies

B. Planning, management and control of innovation

processes

C. Establishment and maintenance of an information system

as the basis for targeted innovation control

D. Establishing an organizational structure and environment

conducive to innovation [7].

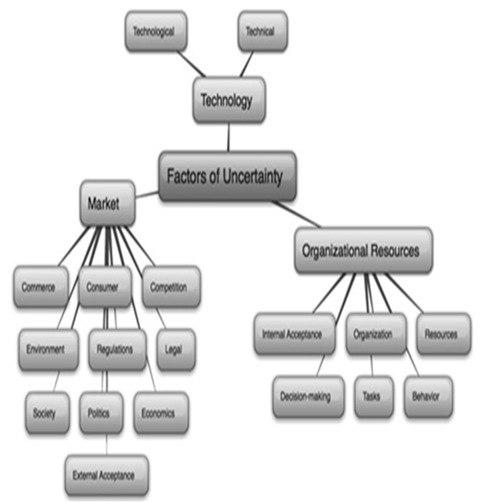

E. But an innovation is no guarantee of success. On the

contrary, there are a large number of risks that can lead to an

innovation not being successful. The risks involved can be seen

in Figure 1 [8].

Figure 1: Uncertainty factors [10].

The multitude of risks virtually demands that prudent innovation management be carried out.

The current development in the field of renewable energies shows that, in addition to the above-mentioned factors of uncertainty, the time dimension is extremely important. While the novelty of the innovation was already given in the past, an enormous market potential has now been opened up due to a new perception and the changed framework conditions [9].

The Innovation: Production of Endless Plates Made of Titanium

To which area does this apply? In particular, the new development of bipolar fuel cell plates and bipolar electrolyser plates should be mentioned here.

The innovation consists of 2 elements: On the one hand the material, on the other hand the process

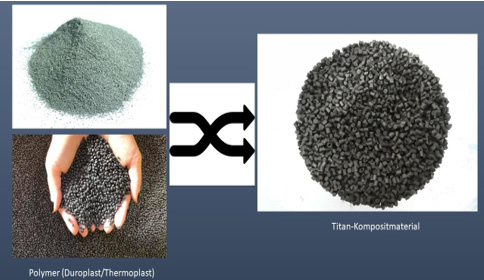

As far as the material is concerned, it is a mixture of polymet and titanium powder, a so called titanium composit material (Figure 2). The mixture of the polymer and the titanium powder is realized on special extrusion machines.

Figure 2: Titanium Compound powder.

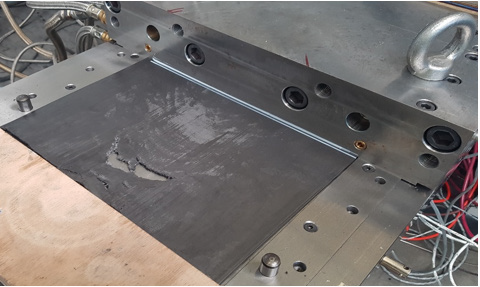

In the next step, the production of plates in an „endless“ process is realized (Figure 3). By means of a revised process, plates for electrolysis and fuel cells can now be produced with a material thickness of less than 1mm. The idea was developed several years ago, but due to the changed framework conditions the topic has now received much more attention and demand.

Figure 3: Extrusion process.

The next step is the extrusion process with the die shown in Figure 2. Here it is important that the temperature control is very homogeneous. This should also be investigated in advance. After the extrusion process, the melt must be cooled and, if necessary, smoothed. Figure 3 shows a corresponding smoothing unit.

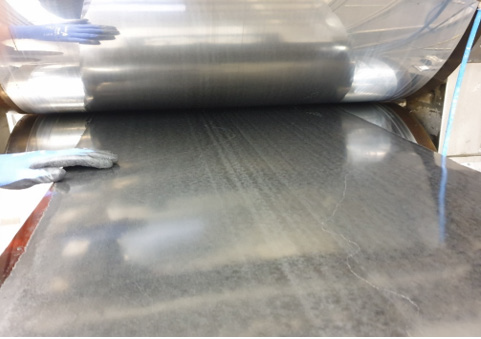

Figure 3 shows that temperature control is a decisive factor not only in the distribution block, but also in the extrusion cooling phase and in the calender. With these process steps, it is possible to produce suitably homogeneous titanium composite plates. The plate thickness can be varied between 2 and 5mm according to the tool (Figure 2). Plates with a thickness of about one millimeter require an additional process step¬, namely that of the smoothing unit (Figure 4).

Figure 4: Smoothing unit after extrusion die and cooling section in the extrusion process.

Summary

The role of the energy transition has now reached all industrialised nations of the world. Several paths are being taken - and hydrogen production plays an important role here. The capital costs of the electrolysers play a role in future hydrogen production that should not be underestimated.

In the electrolyzers, the bipolar plates are the most frequently used component next to the membranes and thus also contribute significantly to the total costs. Cost-effective production is therefore eminently important. This is where the new process comes in.

A continuous production of the plates is possible. In the process, it is also possible to vary the permeability of the plates. Thus, both impermeable and permeable plates are possible. The latter are particularly interesting for PEM electrolysis.

The works were created in the project «Autark Elyss BB». The project is funded by the state of Brandenburg via the ILB under the funding code 80257166, for which Eisenhuth, located in Wildau, would like to express its sincere thanks. The project is co-financed by the European Regional Development Fund (EFRE).

References

- (2019) Communication from the commission to the European parliament, the European council, the council, the European economic and social committee and the committee of the regions: The European Green Deal, Brussels, Belgium.

- Höh M (2017) Porous transport layers for polymer electrolyte membrane water electrolysis, Jülich, Germany, pp. 3.

- Höh M (2017) Porous transport layers for polymer electrolyte membrane water electrolysis, Jülich, Germany, pp. 3.

- Hickmann T (2008) Plastic applications in PEM fuel cells. VDI Reports, No 2035, Berlin, Germany, pp. 81-83.

- Kaschny M, Nolden M, Schreuder S (2015) Innovations management in Mittelstand, Strategien, Implementierung, Praxisbeispiele, Springer Verlag, Wiesbaden, Germany.

- Bell D (2002) On the threshold of new communication technology, Hard Manager: Innovation Management, Volume 1, New York, USA.

- Leonard-Barton D, Kraus WA (2002) The introduction of new technologies, Hard Manager: Innovation Management, Volume 1, New York, USA.

- Gaubinger K, Rabl M, Swan S, Werani T (2014) Innovation and product management - A holistic and practical approach to reducing uncertainty, Springer Verlag, Heidelberg, Germany.

- Hughes EC (2002) What can research and development actually achieve, Hard Manager: Innovation Management, Volume 1, New York, USA.

© 2021 Thorsten Hickmann. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)