- Submissions

Full Text

Evolutions in Mechanical Engineering

Study on the Characteristic of Eucalyptus Wood Combustion in the Different Models of Improved Cooking Stove

Lelis Gonzaga Fraga*, Evangelino Candido Gaio, Domingos de Sousa Freitas, Lazaro Maria José Soares and Cosme Barbosa Pinto

Faculty of Engineering, Science and Technology Universidade Nacional Timor-Lorosa’e, Dili Timor-Leste

*Corresponding author:Lelis Gonzaga Fraga, Faculty of Engineering, Science and Technology Universidade Nacional Timor-Lorosa’e, Dili Timor-Leste

Submission: July 21, 2025;Published: August 06, 2025

ISSN 2640-9690 Volume6 Issue2

Abstract

Wood combustion has an important role in a household for cooking and heating purpose. In some countries this type of fuel is still applied among other fuels such as gas and kerosene. In Timor-Leste most household apply eucalyptus firewood for their daily usage. This study was conducted to understand the characteristic of eucalyptus wood combustion in different models of improved cooking stove. Firewood mass of 1.5kg was combusted, the flame and water temperature and time applied during combustion was recorded. The results show that the cooking stove with one and two holes for the secondary air space has a higher temperature and lowest burning time than smokeless cooking stove or without secondary air mixing. The burning time and flame temperature for water temperature reaching at 91 oC was 9 min and 345 oC, 9 min and 378 oC and 36 min and 107 oC respectively.

Keywords:Cooking stove; Eucalyptus firewood; Flame temperature; Water temperature

Introduction

Biomass is an abundant renewable resource which contribute to economic and social development [1]. In converting biomass into useful energy can provide several benefits such as reduce negative impacts to environment, create job opportunity and provide more optional for the energy utilization [2]. Wood biomass is utilized for cooking and heating purpose [3]. This condition can be observed in various development countries [4]. In Uganda, firewood is considered as the most significant source of energy, with the majority of the people employ it for domestic use and small-scale industries [5]. Tanzanian households also employ firewood as the primarily source of energy [6]. Including Timor-Leste, mostly in rural areas, firewood as a primarily energy source using in households. Woody biomass is split into two, such as softwoods and hardwoods. Softwoods are evergreen trees with needles, and hardwoods refer to broad-leaf trees and are generally denser than the softwoods [7]. Dry wood consists of cellulose (C6H10O5), hemicelluloses (C5H8O4), lignin (C40H44O6), resin (extractives) and ash-forming minerals [8,9]. During the combustion, decomposition of hemi-celluloses occurs at 220-320 oC, cellulose at 320-370 oC and the lignin gradually decomposes over the temperature range of 250-500 oC [8,10].

In order to convert wood into useful energy mostly applied direct combustion and also through appliance by considering combustion efficiency and economy [11]. Different methods and appliance can be applied. In some households are still using traditional method with three stone [4]. There are several types of stoves including Metal Stove, Fired Clay Stove and Combination Clay/Metal Stoves, Mud-stove mixtures [12]. Converting biomass to useful energy through combustion need to be in efficient an effective manner. To achieve this condition, research need to be intensified and explored significantly as in response. This study is aiming to investigate the characteristic of eucalyptus firewood combustion in a different model of improved cooking oven. Three different stove models with and without Secondary Air (SA) are applied. Besides, flame and water temperature and burning time are measured to identify the optimum stove using in this experiment.

Materials and Methods

Research material

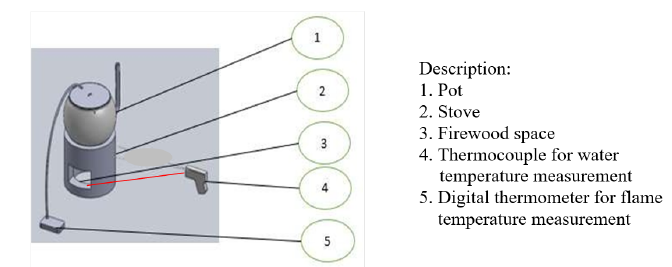

In this study, three different models of an improved cooking stove are applied, one was known as smokeless wood stove [13] or without secondary air entrance, others two named as an un smokeless oven with one and two holes of secondary air entrance. The cooking stove applying in this study were manufactured from cement-based material which is considered as a water resistance material compared to peat soil material which is now utilizing as presented in Resleo N [14]. The size of the stove was upgraded from improve cooking stove with peat soil material available in the commercial market in TL and was applied by Resleo N [14]. Three different stove model used in this study is presented in Figure 1. The eucalyptus firewood was applied to conduct the combustion during the experiment. Several apparatuses are applied in this study include stove, pot, electrical balance and thermometers. The stove is 32cm height, 30cm diameter and 10cm thick.

Figure 1:Stove models: (a) smoke less stove, (b) stove with 1 hole for SA mixing, (c) stove with 2 holes for SA mixing.

Research method

Wood biomass with diameter of 3.8-4mm were collected and cut into 20cm length. Then, the wood was weighted on the electrical balance. In this experiment, the mass of sample was applied 1.5kg. This mass of wood was more efficient when combusted in this type of stove [14]. To conduct the experiment, wood sample were put into the stove, pot with 3L of water was mounted on the stove. The thermocouples were introduced on the water and combustion point to measure their temperature, the flame temperature was measured at the firewood space as shown in Figure 2. The data were start collected when flame was stabilized or within 2 minutes. Time is recorded during the experiment and temperature reference was set to 91 oC. When the temperature was reached, then the data were all recorded. In order to observe the ash from the combustion, then the combustion was continued until all the wood sample were burned.

Figure 2:Experimental set up.

Results and Discussion

Experimental on smokeless stove

The data of experiment using smokeless stove is presented in Figure 3. The water and flame temperature were increased very slow. It takes about 36 minutes for water to reach at targeted temperature or 91 oC. In this experiment, more smoke was produced as the result of poor combustion or most unburned gas were expel to the atmosphere (Figure 4).

Figure 3:Flame and water temperature profile with smokeless stove.

Figure 4:Flame visualization of smokeless stove.

Experimental on stove with 1 hole of SA

The data of experiment using 1 hole of Secondary Air (SA) is presented in Figure 5. The time requires to reach at 91 oC was 9 minutes after about 2 minutes of the flame stabilization. It shows on the measurement point; the flame temperature was increased rapidly from 43 oC up to 404 oC within 8 minutes of time. In this range of temperature, the combustion is including moisture released, devolatilization and char combustion [3,15-17]. Figure 6 shows that the flame was larger than that of smokeless stove. These phenomena indicated that more gases were burned before expelling to the environment.

Figure 5:The flame and water temperature profile with 1 hole of SA stove.

Figure 6:Flame visualization of 1 hole of SA stove.

Experimental on stove with 2 holes of SA

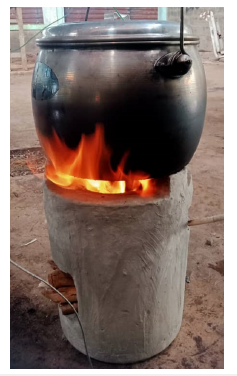

The data of experiment using 2 holes of SA is presented in Figure 7. The time requires to reach at 91 oC was also at 9 minutes after about 2 minutes of the flame stabilization. Although, from the measurement point, the flame temperature was increased very rapidly from 51 oC up to 556 oC within only 6 minutes of time. In this range of temperature, the combustion is including three phases such as drying, devolatilization and char combustion, [3,15- 17]. Figure 8 shows that the flame was larger than that of 1 hole of SA stove, because this flame occurred on both holes of SA. This phenomenon is also indicated that more gases were burned before expelling to the environment.

Figure 7:The flame and water temperature profile with 2 holes of SA stove.

Figure 8:Flame visualization of 1 hole of SA stove.

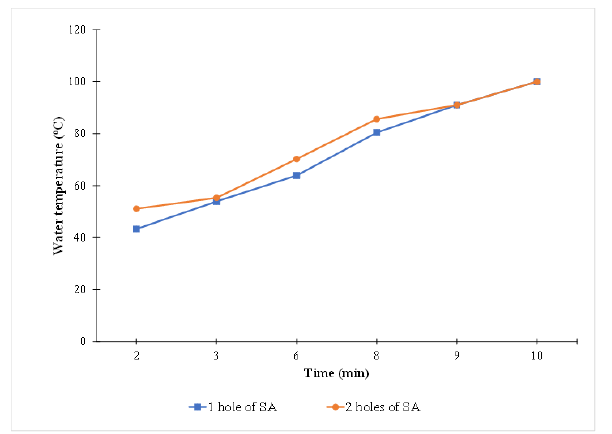

Visualization of flame and water temperature for 1 and 2 holes of SA stove

Figure 9 shows that the water temperature for both stoves were increased linearly, even though the water temperature for the stove of 2 hole of SA were higher than the other stove. Figure 10 shows that after 4 minutes the flame temperature of 2 hole of SA were also higher than the other stove. This phenomenon shows that the stove with 2 holes of SA was more efficient than that of stove with only 1 hole of SA.

Figure 9:The water temperature profile for both 1 and 2 holes of SA stove.

Figure 10:The flame temperature profile for both 1 and 2 holes of SA stove.

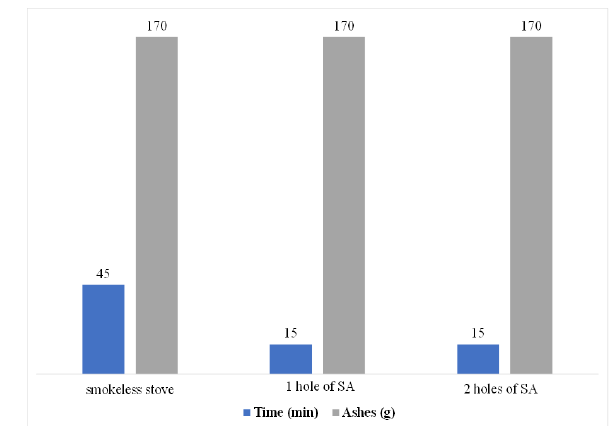

Mass remaining

The mass remaining of eucalyptus combustion in this study was presented in Figure 11. The mass remaining was obtained after all the wood were burned and fire were extinguished. The result shows that in smokeless stove, it took longer time or approximately 45 minutes in order to terminate the combustion. In both 1 and 2 holes of SA and for terminating the combustion was within 15 minutes. The mass remaining was approximately 170g or 11.33%, which was the same for all three experiments. The mass remaining composed of ash with composition including Silicium (SiO2), Phosphorus (P2O5), Potassium (K2O), Calcium (CaO), Sodium (Na2O), Magnesium (MgO), Aluminum (Al2O3), Iron (Fe2O3) and Aerosols [17-19].

Figure 11:The mass remaining of eucalyptus firewood combustion in three different models of improved cooking stove.

Conclusion

Eucalyptus firewood was burned in three different models

of the improved cooking stove. The mass 1.5kg of firewood was

burned and the flame and water temperature were measured. the

water temperature measure indicated was defined at 91 oC from

this study several conclusions are presented as follow.

A. For smokeless stove poor combustion occurs, the flame and

water temperature were increased very slow and more smoke

were expelled to the environment.

B. For the stove of 1 and 2 holes of SA mixing, the flame and water

temperature were increased very fast, took only 9 minutes to

reach the water temperature of 91 oC.

C. The water and flame temperature for the stove of 2 holes of SA

were higher than the other stoves and also have a larger area

of combustion and higher flame temperature.

It took approximately 45 minutes to terminate the combustion for smokeless stove and 15 minutes for stove with 1 and 2 holes of SA and the mass remaining for all stove models was approximately 170g.

References

- Fraga LG, Teixeira JC, Ferreira ME (2019) The potential of renewable energy in Timor-Leste: An assessment for biomass. Energies 12(8): 1441.

- Castro C, Fraga L, Ferreira E, Martins J, Ribeiro P, et al. (2021) Experimental studies on wood pellets combustion in a fixed bed combustor using Taguchi method. Fuels 2(4): 376-392.

- Yorulmaz SY, Atimtay AT (2009) Investigation of combustion kinetics of treated and untreated waste wood samples with thermogravimetric analysis. Fuel Process Technol 90(7-8): 939-946.

- Fraga LG (2022) The study on the use of fuel for cooking in a household in Dili 5: 41-49.

- Agea JG, Kirangwa D, Waiswa D, Okia C (2010) Household firewood consumption and its dynamics in Kalisizo sub-county, central Uganda. Ethnobot Leafl 14: 841-855.

- Adili YZ, Ogossy GS (2018) Economics of using improved firewood cooking stove and its contribution on climate change adaptation and mitigation. Int J Environ Sci Nat Resour 14(2): 555888.

- Borman LG, Ragland WK (1998) Combustion engineering. McGraw-Hill.

- Vassilev SV, Baxter D, Vassileva CG (2013) An overview of the behaviour of biomass during combustion: Part I. phase-mineral transformations of organic and inorganic matter. Fuel 112: 391-449.

- Fraga LG (2019) Wood pellets combustion in a fixed bed combustor. University of Minho, Portugal.

- Fraga L, Silva J, Soares DF, Ferreira M, Teixeira SF, et al. (2017) Study of devolatization rates of pine wood and mass loss of wood pellets. International Mechanical Engineering Congress and Exposition, p. 9.

- Han J, Kim H, Minami W, Shimizu T, Wang G (2008) The effect of the particle size of alumina sand on the combustion and emission behavior of cedar pellets in a fluidized bed combustor. Bioresour Technol 99(9): 3782-3786.

- Cooking fuel options help guide. UNJLC, United Nations Joint Logistic Centre.

- (2025) Smokeless cook stove.

- Resleo NB (2024) Analysis of biomass burning characteristics using clay furnace. Universidade Nacional Timor Lorosa’e.

- Fraga LG, Silva J, Teixeira S, Soares D, Ferreira M, et al. (2020) Influence of operating conditions on the thermal behavior and kinetics of pine wood particles using thermogravimetric analysis. Energies 13(11): 2756.

- Fraga L, Silva J, Teixeira SF, Ferreira ME, Delfim F, et al. (2018) The effect of the heating and air flow rate on the mass loss of pine wood particles.

- Stahl R, Henrich E, Gehrmann HJ, Vodegel S, Koch M (2004) Definition of a standard biomass Definition of a standard biomass. RENEW-Renewable Fuels for Advanced Power Trains, pp. 1-14.

- Ghafghazi S, Sowlati T, Sokhansanj S, Bi X, Melin S (2011) Particulate matter emissions from combustion of wood in district heating applications. Renew Sustain Energy Rev 15(6): 3019-3028.

- Pastre O (2002) Analysis of the technical obstacles related to the production and utilisation of fuel pellets made from agricultural residues. Altener, pp. 51-107.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)