- Submissions

Full Text

Evolutions in Mechanical Engineering

Effect of Electric Current on Phase Formation in Tungsten Monocarbide in the Process of Electro Consolidation of Nano Powders

Edvin Hevorkian1*, Athanasios G Mamalis2, Volodymyr Nerubatskyi3, Mirosław Rucki4, Waldemar Samociuk1 and Volodymyr Chishkala5

1Faculty of Production Engineering, University of Life Sciences in Lublin, Poland

2Project Center for Nanotechnology and Advanced Engineering, Greece

3Department of Electrical Energetics, Electrical Engineering and Electromechanics, Ukrainian State University of Railway Transport, Ukraine

4Faculty of Mechanical Engineering, Casimir Pulaski Radom University, Poland

5Department of Reactor Engineering Materials and Physical Technologies, VN Karazin Kharkiv National University, Ukraine

*Corresponding author:Edvin Hevorkian, Faculty of Production Engineering, University of Life Sciences in Lublin, Poland

Submission: June 18, 2024;Published: July 01, 2024

ISSN 2640-9690 Volume5 Issue3

Abstract

The tendency of content gain of tungsten semi carbide (di-tungsten carbide) W2C after rapid sintering of compact ceramic structures on the base of tungsten carbide (monocarbide) WC from nano powders technology-based on electro consolidation under pressure is been considered. The issues of the genesis of W2C expansion in new technologies for producing nanostructured single-phase WC ceramics have been formulated and explained. The mechanisms of W2C carbide formation have been examined. By completely eliminating W2C, a single-phase tungsten monocarbide was obtained, with a fracture toughness of 10 MPa·m1/2 and a hardness of HV10=31GPa.

Keywords:Electro consolidation; Nano powders; Tool materials; Tungsten monocarbide

Introduction

The demand for tungsten monocarbide among other refractory ceramic materials used in instrumental applications is due to the combination of a unique set of operational properties in this compound, among which are wear resistance, resistance to thermal shock (temperature jump) and resistance to oxidation. Tungsten carbide is the hardest binary carbide, maintaining an effective level of properties at temperatures of about 1000 °C [1-3]. Therefore, the production of tungsten carbide retains priority in the modern development of nanomaterials for instrumental purposes and the corresponding nanotechnologies [4,5]. The most problematic operational property of metal-ceramic hard alloys, including tungsten-carbide ceramics, is recognized as insufficiently high hardness and heat resistance, which limits their use in the processing of hardened alloy steels with high cutting speeds. The presence of cobalt in hard steels reduces the hardness of the cutting material, which also limits their use in the processing of various high-hardness steels [6,7]. In 2003, a cutting tool material obtained by the SPS method based on tungsten monocarbide nano powders without the use of binder metals was patented for the first time [8].

In this case, a nano powder synthesized by Wolfram (Austria) was used. The conducted studies of the obtained cutting material showed a fairly high wear resistance when processing hardened alloy steels and other high-hardness alloys. However, further studies of this material showed that along with tungsten monocarbide (WC), there is an insignificant amount of W2C, which is known to reduce the strength of the material. It was obvious that further improveAbstract ment of the properties of the cutting material based on tungsten monocarbide is associated with the process of understanding the mechanism of W2C formation [9] and it is necessary to find a way to obtain a material without this compound. Moreover, with the proposed study, have attempted to move away from the established stereotype of a rather passive, actually conformist perception of the refractory compound W2C in general and especially for tool material. To examine the possible reasons for the increase in the W2C content in products of electro consolidation under pressure-an advanced high-speed method, a developed and patented electro sintering installation was used, described in detail in [10,11], which has significant economic advantages in the production of products with high-density submicron and nanosized structures [12]. The processes of electro consolidation of powder media under pressure are by their nature particularly sensitive to changes in the area of intergranular boundaries of sintered nano powders. It is assumed that there is a direct proportional relationship between the yield of W2Cх phases and the total area of intergranular boundaries of the initial nano powder tungsten monocarbide.

In our opinion, the process of W2C synthesis is primarily due to electric discharge effects in gas pores along the grain boundaries of the sintered powder and the formation of low-temperature electric discharge plasma in their zone, causing local temperature spikes of a level sufficient for the decomposition of the main WC carbide. Another important factor in the intensification of the yield of W2Cх phases in the process of using electro consolidation of nano powders is the increased area of intergranular boundaries-potential electrodes of spark discharge contacts. The combination of these two factors in nano powder sintering under pressure with direct current supply to the consolidated medium is the main source of the extended presence of the W2C phase in the final product based on WC monocarbide. In this regard, it is advisable to study the microstructure, phase and chemical composition of the obtained tool materials based on tungsten monocarbide nano powders. When significant negative manifestations are established, caused by increased release of the W2C phase in the decomposition of WC activated by electrophysical action and its consequences, additional experimental studies should be conducted and economically balanced decisions should be made regarding step structures and parameterization of cyclograms by current, temperature and pressure in technological processes of sintering under pressure with the participation of direct action of electric current, ensuring the production of high-density finely dispersed structures. It is this approach that allows us to obtain tungsten monocarbide with high mechanical properties, which can replace tungsten-cobalt alloys and compete with tool materials based on cubic boron nitride. This also explains the growing interest in this problem [13-15].

Materials and Methods

To manufacture the plates, used tungsten monocarbide powders produced by Wolfram (Austria), obtained by the plasma-chemical method (Catalog number 74-0601, lot number IMC6002-2, purity 99.95 %), with a grain size of 40…70nm. The viscosity coefficient of destruction, characterizing the crack resistance of the sample, was determined from the following expression [16,17]:

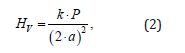

Where HV is the micro-hardness, GPa; E is the young module, GPa; F-a constant, F≈3; l is the length of the crack from the angle of the Vickers pyramid, m; a is the half-band fingerprint of the Vickers pyramid, the average distance from the center of the imprint to the end of the crack, m. The microhardness value was calculated according to the formula [18,19]:

Where P is the load on the indenter, kg; 2·а is the average value of the lengths of both diagonals of the imprint, μm; k is the coefficient depending on the shape of the indenter, for the Vickers pyramid k=1.854. Structural studies were carried out by scanning electron microscopy (JSM-840) on fractures of hot-pressed samples, slides, as well as initial powders. X-ray phase analysis was carried out on the XRD unit with monochromatic Cuα radiation.

Result and Discussion

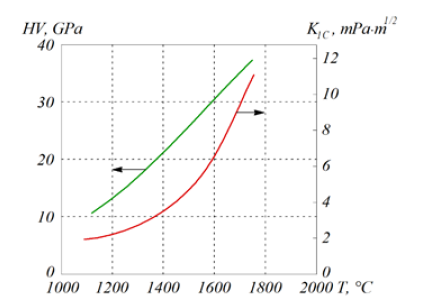

It is known that in the W-C system, the diagram of which is shown in Figure 1, along with WC monocarbides of low-temperature hexagonal and high-temperature cubic, respectively α and β modifications, W2Cx polymorphism is observed [20]. The increased presence of W2Cx phases in the products of our developing nanotechnologies of electro consolidation under pressure of tungsten monocarbide WC and composites based on it, including those for instrumental purposes [21], prompts us to pay special attention to possible operational consequences (including a decrease in strength, anticipated by a comparison of the properties of WC and W2C and the reasons for the increased secondary carbonization of tungsten with the transformation of the main monocarbide WC into tungsten semi carbide W2C, explaining its synthesis. In this context, consider it especially important to determine the possible consequences of such a synthesis and its expansion, to pay attention to the properties of incomplete tungsten carbides using the example of its semi carbide, to the role forecast of the influence of the increased presence of incomplete carbides on the operational properties of the final ceramic product, including with the prospect of subsequent research into possibly necessary optimization technological control mechanisms for the purpose of regulating the presence of incomplete carbides in it.

Figure 1:Phase diagram of the tungsten-carbon system [20].

The need for experimental and analytical developments in this direction is also dictated by the fact that previous works, which drew attention to the relationship between the operational properties of cermet’s based on tungsten carbide and the presence of W2C semi carbide in them, among which one can single out [22], were carried out with an eye to the relatively small presence of W2C (usually less than 3wt.%) and accordingly, the a priori anticipated insignificant influence of this presence on the properties of the object of presence as a whole. With the transition to the use of nano powders and the formation of nanosized phase structures in the production of hard-alloy WC-Co powder composites, increased attention is paid to the accompanying chemical processes and their impact on the quality of the final product of technological implementations. New technologies are being developed for spraying new hard-alloy compositions with increased adhesive capacity, supported by an increased Co content [23-25]. Without contradicting this path in the development of instrumental materials science, draw attention to the opportunities provided in improving traditional approaches by the expanding industrial development of the production of nano powder materials [26], in the problem under consideration-WC monocarbide, work in practice with WC nano powders produced by Wolfram (Austria).

In constructing our experimental studies, take into account the dramatic effect [27] of the compaction of nano powders by heating, observed in sintered WC-Co systems with a liquid component and avoid it, taking into account the recommendations [28]. Complete and low-temperature compaction by accelerated sintering in the dimensional nano range can only ensure sintering of solid WC-Co states. WC-Co nano powders can be fully consolidated with minimal grain growth by traditional sintering, but the final grain size will still be in the order of 100…200nm [29,30]. Comparable results using non-traditional sintering methods, including those related to the group of sintering methods supported (activated) by an electric field [31] that are developing, are achievable at lower temperatures and in a shorter time. In studies of diffusion processes in consolidation technologies for nano powder ceramic materials [32,33], their increasing role is indicated. At the same time, among other characteristic features of working with nano powders, in generalizing world experience, lower activation energy levels are distinguished than required by surface diffusion. For example, in the case of tungsten powder with an average grain size of 40nm, respectively [34] 134 kJ/mol and ~340 kJ/mol. Therefore, improving volume diffusion in nanostructures is already ensured if, as a result of additional energy exposure, under direct electric heating, the launch of structure-compacting diffusion processes in the surface layer is achieved.

The proposed study is an attempt to move away from the existing, not entirely correct perception of W2C in tungsten carbide- based ceramics in general and especially, for instrumental purposes, by identifying and examining possible reasons for the increase in W2C content in products of electro consolidation under pressure in a vacuum-an advanced high-speed method that provides the manufacturer with serious economic advantages in the production of products with a high-density sub micro and nano- sized structure.

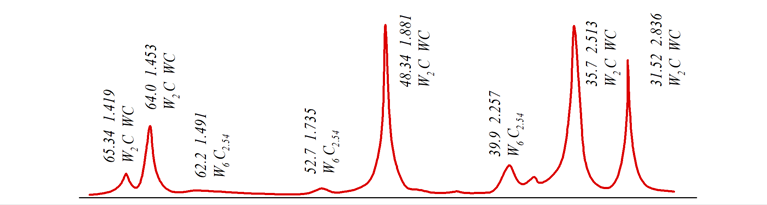

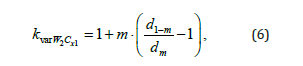

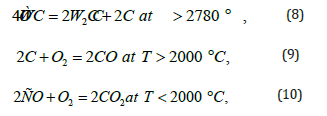

The presence of W2Cх phases in the products of electro consolidation involving WC monocarbide powder, characteristic of its decomposition with the release of carbon, was recorded by X-ray diffraction, for example, in our composite samples of Al2O3-WC nano powder mixtures [35,36] and in experiments on hard-alloy production based on the standard WC-8wt.% Co powder combination reinforced with WC monocarbide nano powder additives (Figure 2). It was noted that the introduction of WC nanograin additives into the standard tungsten-cobalt powder combination increases the yield of W2Cх phases in the final product. The explanation of local temperature spikes up to the threshold limit (at normal pressure- 2780 °C), opening “channels” for WC decomposition with the release of W2Cх and carbon phases, in traditional sintering technologies seems complicated. But with the involvement of the factor of mutual compression of grains striving for thermal growth and the tribological aspect of intensification of friction along their boundaries sliding along each other, in our technological solutions by applying a current of up to 6000 A, understanding of such a possibility is completely natural [37].

Figure 2:X-ray diffraction patterns of WC-8wt.% Co samples with the addition of 15wt.% WC nano powder after hot vacuum pressing by electro consolidation.

The increased temperature regime outside the recorded average heating temperature of the sintering chamber volume corresponds to low-temperature plasma [38] in the zone of local electric discharges, for example, short-lived in sliding spark discharges in an alternating electric field at the boundary of the gaseous and solid medium between the pore and the powder grains [39]. Areas with a predominance of charge of any sign, arising in an electric field covering a powder mixture that does not conduct electric current, or connected sets of components of a powder mixture that do not conduct electric current, initiate charges of the opposite sign on the dielectric surfaces, as a result of which spark channels of spark discharges slide along these dielectric surfaces. This leads, firstly, to effective heating due to Joule heat and compaction of the consolidated medium [40], which is caused by significant electrical resistance in the power transmission zone; secondly, to thermal cleaning of intergranular boundaries. In simulation model approximations, the high-energy specificity of the action of electrical discharges is accompanied by high-speed shock-wave micro-effects of additional pressure. For example, in [41] an attempt is made to increase the shock pressure from the outside, which leads to quite good results.

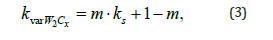

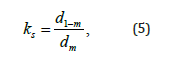

According to various estimates, for electrical discharge micro destruction these speeds reach from several hundred meters per second to 500…1000m/s [42]. In mixtures sintered under the action of electric current of nanosized powders, such effects are expected primarily at the boundaries of nanosized pores, simultaneously with the formation of short-term low-temperature plasma. The occurrence of thermal shocks accompanied by shock-wave dynamics logically fits into the initiation of the known high-temperature (T>2780 °C) thermal decomposition of WC by a chemical mechanism with the formation of W2C and C [43]. In this case, the pulsed and probabilistic nature of the occurrence of the electric discharge specificity in the pores between grains along their boundaries and in inter crystalline contacts is obvious. In a powder medium compacted under pressure, it is similar in electrophysical essence to movable electric contacts [44,45]. High-speed local pulsed heating along the discharge channel trace and fast (due to the locality of the effect) cooling contribute to the extended manifestation of W2Cх polymorphism. This can be explained by the fact that the heat and energy support of the thermal decomposition of WC is not stable enough for a complete transition to a homogeneous single-phase semi carbide structure. The processes of electro consolidation of powder media under pressure are, by their nature, especially sensitive to changes in the grain boundary area of the sintered powders. Assuming a direct proportionality of the yield of W2Cх phases to the total grain boundary area of the consolidated powder mixture, can consider an approximate model of the influence of the initial introduction of nano additives into conventional powder media prepared for electro consolidation. Let us further define, as an estimate of such influence, the coefficient of change (variation) of the quantitative presence of W2Cх phases, which identify as. Obviously, in the context of the put forward assumption of direct proportionality, can write:

where m is the concentration of the additive in a chemically identical filling, 0 < m<1 in non-trivial cases; ks is the coefficient of change in the surface area of grains per unit mass or volume in a vacuum, thereby ensuring the indifference of the choice in view of the equivalence. From the transformation (3), reduced to a more convenient form

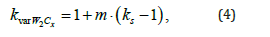

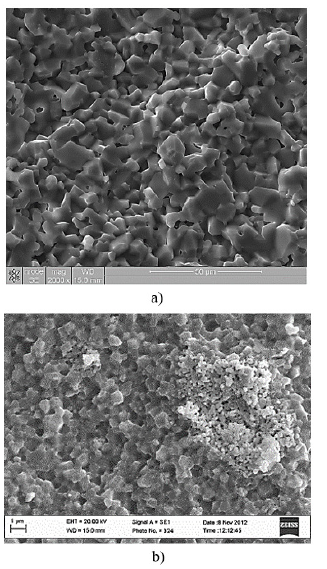

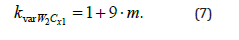

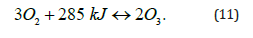

It follows that in the interval 0 < m < 1 the values i.e. in the case of nano additives under consideration should expect an increase in the yield of W2Cх in the final product. This is precisely the result that obtained in experimental practice according to Figure 3, when the yield of W2Cх phases was approximately 5…8wt.% compared to the yield of 2…3wt.% of the same structures during sintering of the traditional WC-8wt.% Co alloy. Sintering of the samples, the microstructures of which are shown in Figure 3, was carried out at a temperature of 1650 °C, a pressure of 45MPa and a holding time of 3min. The change in microhardness and crack resistance value of the material obtained by sintering tungsten monocarbide WC nano powders can be seen in Figure 4. Conversely, in a general hypothetical consideration, from the addition of a large-sized powder additive to a fine-grained powder base, one should expect a decrease in the yield of W2Cх in the final product of electro consolidation under pressure. For example, further from a simple and maximally energetically stable spherical (strictly speaking, in crystallographic descriptions, quasi-spherical) model of an elementary powder grain, when simulating grains with equal-sized spheres

Figure 3:Microstructure of ceramics obtained by electro consolidation of WC (Wolfram, Austria) (a) and WC-8wt.% Co (b) nano powders with grain size (0.5…1μm)-15wt.% nano WC.

where and are the grain diameters of the base powder and additive, respectively. By substituting (5) into (4) obtain:

Or, in a particular case, when the grains of the introduced additive are one order of magnitude smaller in size than the grains of the main powder, as was the case in the case illustrated in Figure 2,

Then, approximately estimating the introduced 15wt.% of WC nano carbide to the WC-8wt.% Co matrix as 1/6 of the total tungsten carbide content in it, in the context of our model calculations from (7) for the one shown in Figure 2, it should be expected that with a basic value of 2…3wt.% of W2Cх phases in the implementation of the main technology, this means expecting 5…7.5wt.% of W2Cх phases in the experimental one under consideration, which is practically identical to the 5…8wt.% announced above, established by X-ray diffraction. Since the electrical resistance and, accordingly, the intensity of the thermal effect of the current increase with an increase in the concentration of equipolar lines (a decrease in the cross-section of the conductor), a higher temperature is observed in the region of disruption of the consolidated conducting medium by a gas-air pore than in zones of complete continuity. In this regard, it is obvious, and this is used in model theoretical interpretations of the formation of dense structures by sintering powders with the application of an electric current [46], that the larger the pore, the higher the temperature on the boundary surface of the sintered powder medium and the greater the kinetic and chemical activity of the pore contents, especially at its periphery. Consequently, the probability is also greater, firstly, of the movement of this content toward coalescence with less heated pores of smaller sizes; secondly, of the primary binding of the pore contents activated by increased heating in chemical reactions involving the powder compact material caused by high-temperature heating.

Figure 4:Dependence of microhardness and crack resistance on the sintering temperature of nano WC during electro consolidation (maximum pressure 45MPa, sintering time 3min).

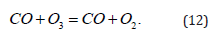

One example of such a linkage is the possible chain of reactions in the case of hot pressing of tungsten monocarbide powder:

Representing the production of tungsten semi carbide (6), and also, with a decrease in temperature (9), the formation of carbon monoxide (carbon monoxide) that binds oxygen from the air, the displacement of which from the pre-pressed powder, compared to air, requires less effort due to its lower density. Lighter, it tends to evaporate into the less dense upper layers of the atmosphere, without requiring additional mechanical or other forced action under conditions of connectivity with the external air environment of the pores compacted by hot pressing of sintered powders. The elimination of porosity under pressure, as is practiced by us [47,48], with correct control of the pressing force in the sintering cycle, prevents the growth of grains into the pore space, as is usually observed [49]. At the same time, the presence in the gas-air environment of pores of potential reagents of chemical reactions, possible as a result of thermodynamic phase transformations, stabilizes their course [50] and is an additional factor in local and general compactions. In addition, the additional energy of spark discharges introduced into the gas-air environment of intergranular pores during direct current supply, in movable intergranular contacts during powder pressing, in electro consolidation technologies acting as analogues of conventional electrical contacts [51], is reversibly absorbed by molecular oxygen in the air with the formation of ozone O3:

It is obvious that the atomic oxygen released in the reverse reaction of spontaneous decomposition of ozone, which is known [52] for its instability, increases the activity of its binding with the same yield (9):

Reactions (9) and (12) in systems (or fragments of systems) with open porosity consolidated by pressing additionally intensify their compaction in an air environment, as well as with the opening of previously closed pores into an environment of even denser argon, which counteracts the undesirable spontaneous adhesive agglomeration of nanosized powders before activated sintering. The prevention of the closure of porosity before its complete elimination by the combined action of electric current and pressing that have chosen [53] is facilitated by a certain gradualness (stepwise) heating and control (control) of its speed [54,55]. This ensures the gradual displacement of gas pores to the surface. At the same time, the process of suppression (displacement) of gases from the pores of the sintered powder should not be understood as a one-act process, automatically resolved, for example, by a reaction of type (9) in systems with open porosity, since it is known that the level of absorption of gases such as CO and СО2 by nano powders can be quite high, i.e. in the general case, the process can develop in both directions, and it is precisely the continuity of certain pressure and electro consolidation modes in the system until complete or sufficient compaction of the powders that is intended to ensure the effectiveness of compaction.

It is known from experimental practice [56] that with a decrease in the granularity of the initial powders, the degree of shrinkage of hard-alloy ceramic composites increases in any sintering technologies, in particular, during sintering both in the solid phase and in the presence of a liquid phase. As in our studies [57,58], this shows a higher density (less porous) not only of the initial potential of small grains (with a smaller volume of intergranular gaps), but also of consolidation (with a smaller volume of large pores in place of missing crystallites and a smaller volume of vacancy agglomerates in their joints) [59]. In a series of characteristic defects of sub micro- and nanocrystalline tungsten ceramics, which include, in addition to the aforementioned large pores and vacancy agglomerates in intergranular joints, the state of grain boundaries with vacancies along their contact lines, the presence of undesirable phases and microcracks, the influence of local porous formations is facilitated, especially large pores, partially suppressed with the formation of tungsten semi carbide according to the reaction scheme (8)-(10), including taking into account the smaller volumes of integrated gaseous reaction products in relation to the sum of the volumes of the reagents.

Conclusion

The formation of W2C in tungsten carbide tool composites of hot pressing with electro consolidation of nano powders is primarily due to the electric discharge effects in gas pores along the grain boundaries of the sintered powder and the formation of low-temperature electric discharge plasma in their zone, causing local temperature spikes of a sufficient level for the decomposition of the main carbide (WC). Another important factor in the intensification of the yield of W2Cх phases in electro consolidation work with powders of smaller grain sizes is the increased area of intergranular boundaries - potential electrodes of spark discharge contacts. The combination of these two factors in the process of sintering nano powders under pressure with direct current supply to the consolidated medium is the main source of the extended presence of the semi carbide phase in the final product based on WC monocarbide. In this regard, it is advisable to study the properties of tool materials based on tungsten monocarbide obtained by the method of electro consolidation under pressure, which are most significant in practical application and determine stability in mechanical, thermal, electrical and combined loads (hardness, strength, crack resistance, etc.). When establishing significant negative manifestations caused by increased release of the semi carbide phase, activated electrophysical action and its consequences of WC decomposition, additional experimental studies should be carried out and economically optimal decisions should be made regarding step structures and parameterization of cyclograms by current, temperature and pressure in technological processes of sintering under pressure with the participation of direct action of electric current. This will ensure the production of high-density, finely dispersed structures of increased functionality. Thanks to this approach to the structure formation of tungsten monocarbide during electro consolidation, nanostructured tungsten monocarbide was obtained, the crack resistance of which is 10MPa·m1/2, and the hardness HV10=31GPa.

Acknowledgment

This project has received funding through the MSCA4Ukraine project, which is funded by the European Union.

References

- Samsonov GV, Upadkhaya GS, Neshpor VS (1974) Physical material management of carbides. Scientific Opinion, Kyiv, Ukraine, p. 455.

- Bolgar AS, Turchanin AG, Fesenko VV (1973) Thermodynamic properties of carbides. Naukova Duma, Kyiv, Ukraine, p. 270.

- Panov VS, Chuvilin AM (2001) Technology and properties of sintered hard alloys and products made from them: Textbook for universities. Moscow, Russia, p. 428.

- Sun J, Zhao J, Huang Z, Yan K, Shen X, et al. (2019) A review on binder less tungsten carbide: Development and application. Nano-Micro Letters 12(1): 13.

- Dong H, Li B, Liu B, Zhang Y, Sun L, et al. (2022) Extraordinary high-temperature mechanical properties in binder-free nanopolycrystalline WC ceramic. Journal of Materials Science & Technology 97: 169-175.

- Tretyakov VI (1976) Fundamentals of metal science and technology for the production of sintered hard alloys. Metallurgy, Moscow, Russia, p. 527.

- Gevorkyan ES, Nerubatskyi VP, Vovk RV, Zinchenko OY, Komarova HL, et al. (2023) Investigation of the features of blade processing of steels with ceramic composites based on chromium oxide. Low Temperature Physics 49(4): 433-438.

- Kodash VY, Gevorkian ES (2003) Tungsten curbide cutting tool materials. USA.

- Gevorkyan E, Rucki M, Sałaciński T, Siemiątkowski Z, Nerubatskyi V, et al. (2021) Feasibility of cobalt-free nanostructured WC cutting inserts for machining of a TiC/Fe composite. Materials 14(12): 3432.

- Hevorkian ES, Nerubatskyi VP, Rucki M, Kilikevicius A, Mamalis AG, et al. (2024) Electro consolidation method for fabrication of fine-dispersed high-density ceramics. Nanotechnology Perceptions 20(1): 100-113.

- Siemiatkowski Z, Morozow D, Rucki M, Prokopiv M, Nerubatskyi V, et al. (2023) Hevorkian E study in durability of Cr2O3-based ceramic cutting tools. 22nd International Scientific Conference, Engineering for Rural Development. Latvia, pp. 269-274.

- Hevorkian ES, Nerubatskyi VP, Vovk RV, Szumiata T, Latosińska JN (2023) Foamy ceramic filters and new possibilities of their applications. Ceramics International 50(4): 6961-6968.

- Kornaus K, Rączka M, Gubernat A, Zientara D (2017) Pressure less sintering of binder less tungsten carbide. Journal of the European Ceramic Society 37(15): 4567-4576.

- Gubernat A, Rutkowski P, Grabowski G, Zientara D (2024) Hot pressing of tungsten carbide with and without sintering additives. International Journal of Refractory Metals and Hard Materials 43: 193-199.

- Nanda Kumar AK, Watabe M, Kurokawa K (2011) The sintering kinetics of ultrafine tungsten carbide powders. Ceramics International 37(7): 2643-2654.

- Gevorkyan E, Nerubatskyi V, Chyshkala V, Gutsalenko Y, Morozova O (2021) Determining the influence of ultra-dispersed aluminum nitride impurities on the structure and physical-mechanical properties of tool ceramics. Eastern-European Journal of Enterprise Technologies 6(12): 40-52.

- Mamalis AG, Hevorkian ES, Nerybatskyi VP, Rucki M, Krzysiak Z, et al. (2023) Effect of nano additives on the properties of partially stabilized zirconia. Nanotechnology Perceptions 19(3): 26-46.

- Gevorkyan E, Nerubatskyi V, Chyshkala V, Morozova O (2021) Revealing specific features of structure formation in composites based on nano powders of synthesized zirconium dioxide. Eastern-European Journal of Enterprise Technologies 5(12): 6-19.

- Krzysiak Z, Gevorkyan E, Nerubatskyi V, Rucki M, Chyshkala V, et al. (2022) Peculiarities of the phase formation during electro consolidation of Al2O3-SiO2-ZrO2 powders mixtures. Materials 15(17): 6073.

- Pilyankevich AN (1988) Tungsten carbides. Chemical Encyclopedia Moscow, Russia, pp. 420-421.

- Tsai KM (2011) The effect of consolidation parameters on the mechanical properties of binder less tungsten carbide. International Journal of Refractory Metals and Hard Materials 29(2): 188-201.

- Wachowicz J, Fik J, Bałaga Z, Stradomski G (2023) Testing for abrasion resistance of WC-Co composites for blades used in wood-based material processing. Materials 16(17): 5836.

- He J, Ice M, Lavernia EJ, Dallek S (2000) Synthesis of nanostructured WC-12 pct Co coating using mechanical milling and high velocity oxygen fuel thermal spraying. Metallurgical and Materials Transactions A 31: 541-553.

- Stewart DA, Shipway PH, McCartney DG (1999) Abrasive wear behavior of conventional and nanocomposite HVOF-spayed WC-CO coatings. Wear 225-229(Part 2): 789-798.

- Verdon C, Karimi A, Martin JL (1998) A study of high velocity oxy-fuel thermally sprayed tungsten carbide-based coatings. Part 1: Microstructures. Materials Science and Engineering: A 246(1-2): 11-24.

- Nerubatskyi VP, Gevorkyan ES, Vovk RV, Krzysiak Z, Nazyrov ZF, et al. (2023) Peculiarities of obtaining nanocomposites with organic additives and consolidated nanomaterials with given properties. Low Temperature Physics 49(11): 1283-1288.

- Kuzmin V, Gulyaev I, Sergachev D, Vashchenko S, Lysakov A, et al. (2021) Supersonic air-plasma spraying of carbide ceramic coatings. Materials Today: Proceedings 38(4): 1974-1979.

- Porat R, Berger S, Rosen A (1996) Dilatometric study of the sintering mechanism of nanocrystalline cemented carbides. Nanostructured Materials 7(4): 429-436.

- Wang X, Fang ZZ, Sohn HY (2008) Grain growth during the early stage of sintering of nanosized WC-Co powder. International Journal of Refractory Metals and Hard Materials 26(3): 232-241.

- Fang Z, Eason JW (1995) Study of nanostructured WC-Co composites. International Journal of Refractory Metals and Hard Materials 13(5): 297-303.

- Nerubatskyi VP, Gevorkyan ES, Komarova HL, Morozova OM, Tsybulnyk VR (2023) Peculiarities of obtaining cutting tool material based on nano dispersed powders by electric sintering. Collected scientific works of Ukrainian State University of Railway Transport 205: 14-24.

- Mishin Y, Herzig C (1995) Diffusion in fine grained materials: Theoretical aspects and experimental possibilities. Nanostructured Materials 6(5-8): 859-862.

- Atkinson A (1994) Diffusion in ceramics. Materials Science and Technology 11: 299-338.

- Trusov LI, Lapovok VN, Novikov VI (1989) Problems of sintering ultrafine powders. Science of Sintering, Plenum Press, New York, USA, pp. 185-192.

- Sakaki M, Bafghi MSh, Vahdati Khaki J, Zhang Q, Saito F (2013) Conversion of W2C to WC phase during mechano-chemical synthesis of nano-size WC-Al2O3 powder using WO3-2Al-(1+x)C mixtures. International Journal of Refractory Metals and Hard Materials 36: 116-121.

- Gevorkyan E, Nerubatskyi V, Gutsalenko Yu, Melnik O, Voloshyna L (2020) Examination of patterns in obtaining porous structures from submicron aluminum oxide powder and its mixtures. Eastern-European Journal of Enterprise Technologies 6(6): 41-49.

- Ratov BT, Mechnik VA, Bondarenko NA, Kolodnitskyi VM, Gevorkyan ES, et al. (2023) Features structure of the С diamond-(WC-Co)-ZrO2 composite fracture surface as a result of impact loading. Journal of Superhard Materials 45(5): 348-359.

- Prokhorova AM (1938) Physical encyclopedic dictionary, Soviet Encyclopedia, Moscow, Russia, p. 928.

- Anderson KR, Groza JR, Fendorf M, Echer CJ (1999) Surface oxide debonding in field assisted powder sintering. Materials Science and Engineering: A 270(2): 278-282.

- Bernard F, le Gallet S, Spinassou N, Paris S, Gaffet E, et al. (2004) Dense nanostructured materials obtained by spark plasma sintering and field activated pressure assisted synthesis starting from mechanically activated powder mixtures. Science of Sintering 36(3): 155-164.

- Zhao K, Feng P, Tan J, Zhong W, Liu J, et al. (2023) A new route to fabricate high-performance binder less tungsten carbide: Dynamic sinter forging. Journal of the American Ceramic Society 106(6): 3343-3350.

- Livshits AL, Volkov Yu SO (1974) Physical mechanism for evacuating metal from the hole. Electrophysical and Electrochemical Processing Methods 12: 1-4.

- Garcia Ayala EM, Tarancon S, Ferrari B, Pastor JY, Sanchez Herencia AJ (2021) Thermomechanical behavior of WC-W2C composites at first wall in fusion conditions. International Journal of Refractory Metals and Hard Materials 98: 105565.

- Groza JR, Garcia M, Schneider JA (2001) Surface effects in field-assisted sintering. Journal of Materials Research 16: 286-292.

- Tokita M (2021) Progress of Spark Plasma Sintering (SPS) method, systems, ceramics applications and industrialization. Ceramics 4(2): 160-198.

- Raichenko AI (1987) Basics of the process of sintering powders by passing electric current. Metallurgy, Moscow, Russia, p. 128.

- Gevorkyan E, Rucki M, Krzysiak Z, Chishkala V, Zurowski W, et al. (2021) Analysis of the electro consolidation process of fine-dispersed structures out of hot pressed Al2O3-WC nano powders. Materials 14(21): 6503.

- Gevorkyan ES, Rucki M, Nerubatskyi VP, Żurowski W, Siemiątkowski Z, et al. (2022) Remanufacturing and advanced machining processes for new materials and components. Taylor & Francis, p. 204.

- Liu Y, Patterson BR (1993) Grain growth inhibition by porosity. Journal of Metallurgy and Materials 41(9): 2651-2656.

- Porter DA, Easterling KE (1992) Phase transformations in metals and alloys. (3rd edn), CRC Press, Florida, USA, p. 528.

- Mayo MJ, Hague DC (1993) Porosity-grain growth relationships in the sintering of nanocrystalline ceramics. Nanostructured Materials 3(1-6): 43-52.

- Knunyants IL (1983) Chemical encyclopedic dictionary. Soviet Encyclopedia, Moscow, Russia, p. 792.

- Gevorkyan ES, Nerubatskyi VP, Chyshkala VO, Morozova OM (2021) Cutting composite material based on nano powders of aluminum oxide and tungsten monocarbide. Modern Engineering and Innovative Technologies 15(2): 6-14.

- Skorokhod VV, Uvarova ІV, Ragulya AV (2001) Fiziko-khіmіchna kinetics in nanostructured systems, Academic Periodics, Kyiv, Ukraine, p. 180.

- Andrievski RA (1994) Compaction and sintering of ultrafine powders. International Journal of Powder Metallurgy 30: 59-66.

- McCandlish LE, Kear BH, Kim BK (1990) Chemical processing of nanophase WC-Co composite powders. Materials Science and Technology 6(10): 953-957.

- Gevorkyan ES, Nerubatskyi VP, Kislitsa MV (2022) Composite materials based on alumina and silicon carbide. LLC Voskhod-Print, Kharkiv, Ukraine, p. 92.

- Gevorkyan ES, Nerubatskyi VP (2022) Technological and scientific aspects of consolidation of refractory composites: Monograph. LLC Voskhod-Print, Kharkiv, Ukraine, p. 73.

- Koch C (2002) Nanostructured materials: Processing, properties and potential applications. Taylor & Francis, USA, p. 176.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)