- Submissions

Full Text

Evolutions in Mechanical Engineering

Application of Machine Learning to Frontiers in Mechanical Engineering

Mahesh S1, Anil Chandra AR1, Ravikumar L1 and Srivatsan TS2*

1Department of Mechanical Engineering, BMS College of Engineering, Bangalore, India

2Department of Mechanical Engineering, The University of Akron, USA

*Corresponding author:Srivatsan TS, Department of Mechanical Engineering, The University of Akron, USA

Submission: April 13, 2024;Published: May 20, 2024

ISSN 2640-9690 Volume5 Issue3

Abstract

Mechanical engineering has over the years evolved from mere “chassis-on-wheels” to “luxury-on-move” with the introduction of advanced design and manufacturing sectors, such as additive manufacturing, Computer-Numerically Controlled (CNC), mechatronics, robotics and more recently the Internet-of-Things (IoT). However, challenges in terms of optimizing the process parameters, selection of materials, standardization of the processes used and quality control, have gained increased importance and attention. Hence, a multi-disciplinary approach involving both data science and data analytics have helped in synergizing the application of Machine Learning (ML) techniques to address the aforementioned challenges. In recent years, several technical publications have surfaced in this direction and show much promise and excitement towards a future which will essentially be “intelligence-on-the-move”. In this technical paper, an attempt is made to look at the current scenario in terms of application of machine learning to the various sectors in the field of mechanical engineering.

Keywords:Additive manufacturing; Machine learning; Data mining; Quality control

Introduction

The origin of human use of fire is unknown but evidence specific to the use of fire dates back to at least over a million years. Initially what began as a source of protection did eventually lead to both fueling the economy and concurrently revolutionizing the landscape of every aspect on this planet up until the current day. It is certain that initially there was little scientific knowledge and the numerous intricacies specific to heat transfer and thermodynamics. However, there definitely did exist some logical understanding of an object being either hot or cold. These observations in synergism with a series of experiments eventually motivated the people involved to take advantage of these processes over time for the primary purpose of increasing human comfort. Similarly, is the case with the other elements of nature resulting in the emergence and growth of concepts, such as (i) hydraulics and pneumatics, (ii) fluid mechanics, and (iii) fluid dynamics, to name just a few. Throughout this course of evolution, man has seen various stages of development. Methods similar to subtractive manufacturing were developed and used to shape stones as tools in the era of the stone age. With better understanding coupled with an application of improved processing techniques specific to metals did result in a spectrum of advanced machining operations that are in use today. More observations and better understanding of the material along with material behavior did eventually result in alloying, casting, forging and other aspects of materials science and metallurgy. Invention of the wheel, lever mechanism, concepts of pulleys, screw, and the gear mechanism did result in the design of complex drive-trains and the emergence and acceptance of concepts specific to both kinematics and dynamics.

A continuous sharing of knowledge gained over the centuries did result in integrated research along with massive scale of development culminating in establishing both a better design and manufacturing. It is obvious that the core knowledge specific to science and mathematics has significantly elevated each of these fields of study to levels never imagined before. The invention of an analytical engine did transform the eco-system of science and engineering by speeding up the progress. A machine that used to perform simple calculations has transformed both itself and the world to a stage where arguments of it being sentient is not applicable. This transformation did fuel and carry every other field of science and technology, which in turn has led to its development and exciting emergence. An increased power of computation did introduce new avenues of science and engineering that enabled critical evaluation and newer ways of thought process coupled with an approach to various problems. Techniques, such as finite element methods and fracture mechanics, were integrated into engineering design. Concepts specific to (i) automation, (ii) inspection, (iii) quality control, and (iv) design of experiments, did bring about noticeable changes in the manufacturing sector.

Today, both Artificial Intelligence [AI] and Machine Learning [ML]

are gradually taking over the world. Machine learning can be safely

categorized to be an inter-disciplinary field of statistics, computer

science and mathematics that is both concerned and involved in

building algorithms from the data fed to the machine(computer).

The machine aids in identifying the dependencies of the various

parameters of any random process, with the patterns identified

in the data. Similar to various other inventions the inspiration for

Machine Learning (ML) was taken from nature coupled with the

cognition capability of animal brain, which continuously learns

and improves its decision-making ability based on experience.

The ability of Machine Learning (ML) to automate a task and make

surprisingly accurate predictions did result in the following:

A. Predictive analytics

B. Recommendation systems

C. Image recognition and computer vision

D. Natural language processing

E. Anomaly detection and fraud prevention

F. Drug discovery and medical diagnosis

G. Personalized learning and education

H. Financial forecasting and trading

I. Scientific discovery and research in the field of robotics

J. Other automation

K. Various creative and artistic tasks

This review paper does provide a clean, clear and cohesively complete overview of the various possible applications of Machine Learning (ML) in mechanical engineering.

Current Research in Mechanical Engineering

From the previous discussion it is clear that mechanical engineering is an ever-evolving and constantly adapting field that attempts to embrace new challenges and opportunities. Artificial Intelligence [AI] can cater to all of the problems currently prevailing and even more. All the data that has been collected over the years can be valuable in classifying, clustering, predicting and automating the numerous processes in various sectors. Many algorithms are being continuously developed for the purpose of practical use to achieve useful methods of learning. Data mining engineers have used Machine Learning (ML) algorithms to find and extract useful data from large commercial databases that contain the following: (i) process information, (ii) equipment and maintenance information, (iii) medical records, (iv) financial records, and few others [1]. The current or ongoing research being actively pursued in the domain specific to mechanical engineering can be broadly grouped under these categories:.

Additive manufacturing

Additive Manufacturing (AM), or 3-D printing, has enabled a revolution in engineering due to its unique “user friendly approach”. Production of customized products on-demand is a noteworthy advantage of the Additive Manufacturing process over the conventional subtractive manufacturing process. It allows for the physical components to be made from virtual Three- Dimensional (3D) computer models by successfully building the component layer-by-layer until the part is complete [2-5]. The American Society for Testing and Materials (ASTM) F42 has broadly listed the following under the category of AM processes: (i) VAT photopolymerization, (ii) material jetting, (iii) binder jetting, (iv) powder bed fusion, (v) material extrusion, (vi) sheet lamination, (vii) direct energy deposition. and (viii) robotics, can result in realizing the industry 5.0. However, a number of challenges arise not only from the complexity specific to manufacturing systems but the concurrent demand for increasing complexity and highquality products, in terms of the following: (i) design principles, (ii) standardization and (iii) quality control. Integrating additive manufacturing (AM) with artificial intelligence (AI) / machine learning (ML) does certainly seem to be the future for the purpose of addressing these challenges and well-reviewed in the published literature [6-9].

Robotics and automation

Integrating digital technology to manufacturing and industrial processes is the current trend. This is made possible by implementing Artificial Intelligence (AI) powered robots for a spectrum of processing-related tasks. Automation of various repetitive tasks coupled with tasks that could prove to be dangerous for humans by the introduction of robots could contribute to increasing the productivity while concurrently ensuring a safe working environment. Applications of Machine Learning (ML) in advanced robotics has made possible the following: (i) autonomous navigation, (ii) object recognition and manipulation, (iii) natural language processing, (iv) predictive maintenance, (v) optimizing robotic manufacturing, (vi) military robotics, (vii) service robots, and (viii) robotic surgery possible [10]. A visual of AI powered robots in the industry is as shown in Figure 1. An Internet-of-Things [IoT]-based implementation monitoring energy consumption in machines and appliances coupled with prediction of future anomalous behavior using decision tree algorithm providing 78% efficiency in the prediction was reported by Sujatha and co-workers [11,12].

Figure 1:Applications of Artificial Intelligence (AI) powered robots [11].

Unmanned vehicles: Aerospace industry is always at the fore-front of all technologies and innovation. The current research focuses on building technologies for faster and safer travel across the globe and beyond. The recent endeavor specific to space travel did introduce new avenues to reduce the cost while concurrently increasing safety of the passengers. Use of sustainable energy, sustainable materials and implementing innovative methods of damage tolerance design and structural health monitoring is of prime focus. Driverless cars and robotic delivery systems are also being introduced in certain parts of the world for the purpose of short distance commuting. A drone delivery system in action is shown in Figure 2. This eases both the effort and requirement for man-power that could be put to effective use elsewhere. Sensing technologies, such as (i) image sensing, (ii) acoustic sensing, (iii) radar, and (iv) lidar, are being increasingly used with an integration of the machine learning (ML) algorithms, such as (i) CNN, (ii) autoencoders, (iii) DBN, and (iv) reinforcement learning, to achieve the following: (i) Navigation. (ii) Object recognition, (iii) Scene classification, (iv) Path planning, and (v) Feature extraction [13,14].

Figure 2:Artificial Intelligence-based robotic delivery system in action [14].

Sustainable energy: Depleting fossil fuels in synergism with increasing pollution and global warming have provided the muchneeded incentive while concurrently demanding newer, renewable and sustainable energy sources. Solar, wind, tidal energy has always been abundantly available but harnessing it for everyday use often gets increasingly expensive and complicated. Therefore, the hunt for newer and novel technologies to both harness and extract power are the vital current generation problems specific to research. Search for alternate ways to power automobiles is also another thriving area of research currently centered around the use of hydrogen power. Therefore, search for cleaner and eco-friendly technologies did capture the focus of scientists and researchers towards sustainable materials. Ahmad and co-workers have proposed the use of smart power grids developed using Machine Learning (ML) techniques in synergism with smart meters and sensors providing real-time energy consumption. Further, the smart grid mitigates issues specific to failure of the grid, thereby enabling users to avoid service interruptions. Also, energy forecast made using neural network-based models can be used to conserve both energy and resources in the event or need for renewable energy generation [15].

Structural health monitoring

Structural Health Monitoring (SHM) is a process of extensively and continuously assessing the health and integrity of structural components. The sole purpose of Structural Health Monitoring (SHM) is to detect and diagnose any damage, or deterioration, in the structure before it reaches a critical stage that often culminates in failure. Major focus of structural health monitoring (SHM) includes the following: (i) aero-space, (ii) naval, (iii) nuclear, and (iv) predictive maintenance. Adopting SHM techniques has proven to be beneficial as it led to the following: (i) optimized design, (ii) reduced maintenance cost, (iii) extended service life, and even (iv) improved safety. Machine Learning (ML) integrated inspection for the purpose of SHM in pipelines does have the capability to pinpoint the location of defect, while earlier an inspection gauge had to be manually moved through the entire length of the pipeline to identify and/or locate a defect [16]. Machine Learning (ML) algorithms are being used at every stage of Structural Health Monitoring (SHM), i.e., damage detection, damage assessment and damage prediction [16-19]. The Machine Learning (ML) models are being increasingly used for the purpose of predictive maintenance in the manufacturing industry by monitoring the vibration in machine drives and shafts.

Popular algorithms

Machine learning is rapidly transforming the field of

mechanical engineering, providing powerful tools for design,

analysis, and optimization across a wide range of applications.

Its ability to analyze large datasets, identify patterns, and make

useful predictions is proving to be invaluable for the following:

(i) optimizing processes, (ii) enhancing product performance and

(iii) solving complex engineering problems. Machine Learning

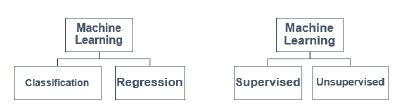

(ML) algorithms in general can be categorized into two separate

classifications:

a) Based on type of prediction the algorithm is supposedly

going to make, and

b) Based on the type of data fed to the algorithm for training.

Both these classifications are shown in Figure 3. In the first type of classification, the ML algorithms are used for either classification or regression tasks. When the algorithm predicts the outcome as one of the predetermined classes based on the patterns identified in the data then it is referred to as classification algorithm. In the case of regression algorithms, the patterns identified are used to predict a continuous value. Similarly, the other classification for Machine Learning (ML) algorithms are the supervised learning algorithms and unsupervised learning algorithms. The supervised learning algorithms are fed with training data wherein both the input and the output are available. However, for the case of unsupervised learning, the input data fed to the algorithm for the purpose of training are only the input parameters. In this case, clusters are formed based on the identified patterns in the data to make further prediction. Each of the algorithms in Machine Learning [ML] identify and form a unique representation from the patterns identified in the data. These representations are adopted from the various concepts of mathematics and statistics, such as (i) linear algebra, (ii) probability and information theory, and (iii) other basic numerical computations. The algorithms based on (i) Bayesian learning, (ii) Decision trees, (iii) Instance-based learning, (iv) Genetic algorithms, (v) Reinforcement learning, and (vi) Deep learning (DL) are often used. Various restrictions and drawbacks of regular machine learning algorithms are overcome by using deep learning (DL) algorithms. Artificial neural networks (ANN) are the core of Deep Learning. Neural networks, such as (i) the back propagation neural networks, (ii) radial basis function network, (iii) extreme learning machine, and (iv) convolutional neural networks are currently being chosen for use in various applications in the domain of the field of mechanical engineering. Combinations of multiple algorithms are being used for research to achieve certain representations that would be difficult for any of the standard algorithms to achieve [2-5].

Figure 3:Categories specific to classification of machine learning.

Conclusion

A. This technical manuscript provides a cohesively complete

summary of Machine Learning (ML) technologies that are

currently on demand and their integration with various core

problems in the field of ever-evolving mechanical engineering.

B. The discussions provided also highlight the capability and

potential of Machine Learning (ML) in solving these problems.

C. It is certain that an implementation of Machine Learning

(ML) can improve the current technologies by several order

while concurrently reducing the risk and burden of several

professions, and thereby creating a safe working environment.

D. The techniques of Machine Learning (ML) also ensure an

efficient use of energy, resources and available capital thereby

improving the stability of both the process and the organization.

E. Overall, it is evident that the ongoing era of Machine

Learning (ML) integrated technologies in emerging frontiers of

mechanical engineering is promising a simpler, easier, efficient

and well-connected “intelligence-on-move” environment for

humanity.

References

- Mitchell TM (2019) Machine learning. (1st edn), McGraw Hill Education, USA, p. 432.

- Jian Qin, Fu Hu, Ying Liu, Paul Witherell, Charlie CL, et al. (2022) Research and application of machine learning for additive manufacturing. Additive Manufacturing 52: 102691.

- Wang C, Tan XP, Tor SB, Lim CS (2020) Machine learning in additive manufacturing: State-of-the-art and perspectives. Additive Manufacturing 36: 101538.

- Sachin Kumar, Gopi T, Hari Keerthana N, Munish Kumar G, Vidit Gaur, et al. (2023) Machine learning techniques in additive manufacturing: A state of the art review on design, processes and production control. Journal of Intelligent Manufacturing 34: 21-55.

- Grierson D, Rennie AEW, Quayle SD (2021) Machine learning for additive manufacturing. Encyclopedia 1: 576-588.

- Soori Mohsen, Behrouz Arezzo, Rosa Dastres (2023) Artificial intelligence, machine learning and deep learning in advanced robotics: A review. Cognitive Robotics 3: 54-70.

- Sujatha M, Priya N, Beno A, Blesslin Sheeba T, Manikandan M, et al. (2022) IoT and machine learning-based smart automation system for industry 4.0 using robotics and sensors. Journal of Nanomaterials 2022: 6.

- Carrio Adrian, Carlos Sampedro, Alejandro Rodriguez R, Pascual Campoy (2017) A review of deep learning methods and applications for unmanned aerial vehicles. Journal of Sensors 2017: 13.

- Kocić Jelena, Nenad Jovicic, Vujo Drndarević (2019) An end-to-end deep neural network for autonomous driving designed for embedded automotive platforms. Sensors 19(9): 2064.

- Ahmad Tanveer, Rafael Madonski, Dingdong Zhang, Chao Huang, Asad Mujeeb (2022) Data-driven probabilistic machine learning in sustainable smart energy/smart energy systems: Key developments, challenges and future research opportunities in the context of smart grid paradigm. Renewable and Sustainable Energy Reviews 160: 112128.

- Saurabh Z, Tushar J, Bishakh B (2019) Application of wavelet analysis and machine learning on vibration data from gas pipelines for structural health monitoring. Procedia Structural Integrity 14: 712-719.

- Bao Tuan Pham, Vein Le Ngoc, Luan Vuong C, Nhi Ngo K (2023) Damage assessment in beam-like structures by correlation of spectrum using machine learning. Fracture and Structural Integrity 17(65): 300-319.

- Renuka VP, Sornalatha S, Roopsta DM, Ashokan R (2022) Prediction of fatigue crack growth of aluminum alloy 7075t6 using machine learning techniques 14(1): 99-104.

- Zhang L, Wang Z, Wang L, Zhang Z, Chen X, et al. (2021) Machine learning-based real-time visible fatigue crack growth detection. Digital Communications and Networks 7(4): 551-558.

- Liu, Jiantao, Xiaoxiang Yang (2018) Learning to see the vibration: A neural network for vibration frequency prediction. Sensors 18(8): 2530.

- Espinoza Sepúlveda, Natalia F, Jyoti K Sinha (2021) Blind application of developed Smart Vibration-Based Machine Learning (SVML) model for machine faults diagnosis to different machine conditions. Journal of Vibration Engineering & Technologies 9: 587-596.

- Umbrajkaar AM, Krishnamoorthy A, Dhumale RB (2020) Vibration analysis of shaft misalignment using machine learning approach under variable load conditions. Shock and Vibration 2020: 1-12.

- Josh Patterson AG (2017) Deep learning: A practitioner’s approach. (1st edn), Shroff/O'Reilly, India, p. 532.

- Ian G, Yoshua B, Aaron C (2018) Deep learning.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)