- Submissions

Full Text

COJ Reviews & Research

Effect of Commercial Level Modified Atmospheric Storage for Paddy (Oryza sativa)

Gunathilake DMCC1 and Senadeera W2*

1Department of Agro-Technology, IARS, University of Colombo, Sri Lanka

2Department of Engineering, University of Southern Queensland, Australia

*Corresponding author: Senadeera W, Department of Engineering, University of Southern Queensland, Australia

Submission: May 25, 2022; Published: August 18, 2022

ISSN 2639-0590Volum4 Issue1

Abstract

Studies conducted in developing countries have shown that nearly 10% to 15% of paddy is lost during postproduction operations due to improper post-harvest techniques. These studies also found; major component of these losses occurred during storage due to practices. Hermetically sealed storage can be used as an alternative method for commercial scale paddy storage with a view to cut down post-harvest losses. Very less research studies have been conducted in this important area. Therefore, this study was conducted to evaluate the effect and impacts of commercial scale modified atmospheric storage conditions for altering of physical properties and quality parameters of paddy under tropical climatic conditions prevailing in Sri-Lanka. In the study storing paddy under commercial level modified atmospheric storage conditions for 9 months and compared quality changes of paddy such as physical properties, milling characteristics and other quality parameters compared against, paddy stored in conventional warehouse. Moreover, oxygen level, temperature inside the modified atmospheric storage and warehouse were also measured. It was observed modified atmospheric storage took 6 weeks to reduce oxygen level from 20.5% to 3.2%. Temperature fluctuation inside the modified atmospheric storage was very low in comparison with warehouse storage. Moisture content of initial warehouse samples and modified atmospheric storage were not significantly different. Modified atmospheric storage paddy samples reported similar initial values in terms of quality parameters such as impurities percentage, immature seed (Bol) percentage and damaged seed percentage even after 9 months of storage. Whereas those values were significant changed in warehouse samples. Weight/mass loss of grain during storage period was significantly low in cocoon (modified) samples. Bulk density and paddy kernel hardness values were significantly reduced in both storage methods against its initial values. Rice kernel whiteness was preserved by modified atmospheric storage in comparison to conventional storage. Germination percentage of paddy was significantly reduced from its initial value in both storage methods. Paddy kernel resistance against milling stress increased during modified atmospheric storage. It can be concluded that modified atmospheric storage has more advantages in comparison to conventional warehouse storage for large quantity commercial grain storage. However, modified atmospheric storage condition must be maintained throughout storage period to gain those advantages

Keywords: Commercial paddy storage; Modified atmospheric storage; Paddy quality

Introduction

Loss assessment studies conducted in developing countries have shown that nearly 10 to 13% of paddy is lost during postproduction operations. It is also found that major component of paddy harvest is losses during storage practices. On the other hand, paddy price drops even less than cost of production at the harvesting season due to high supply. It needs to promote farmers to store paddy till the off-season for overcome this problem. Modified atmospheric storage is one of the suitable storage methods for grain storage because it can be overcome most of storage quality problems. However, paddy should be dried up to 12% moisture content before modified atmospheric storage [1]. Many research studies carried out in different countries revealed that growth of fungus, insects and pests can be inhibited under the hermetic storage conditions and metabolic rate of grain will be decreased due to lack of oxygen [1]. A very few research studies have been performed in Sri Lanka for evaluation of physical and quality changes of paddy under commercial level modified atmospheric storage of paddy under tropical conditions. Therefore this research study is focused on to evaluate and compare conditions (such as temperature, oxygen percentage), change of initial physical properties, grain qualities and milling qualities (such as bulk density, thousand kernel weight/mass, kernel hardness, impurity percentage, immature grain percentage (Bol), moisture content, kernel color, husk content percentage, degree of polish percentage, total yield, broken grain percentage, head rice yield percentage and germination percentage between commercial scale modified atmospheric storage and conventional warehouse storage for 09 month storage period.

Methodology

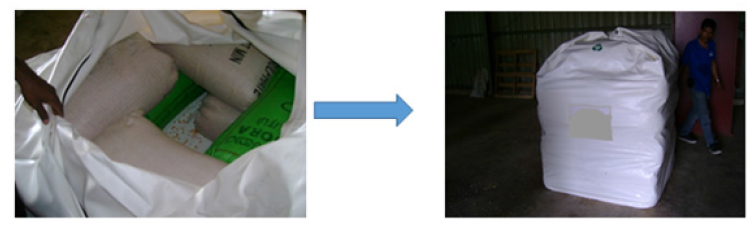

Freshly harvested paddy variety BG 352 was used for the experimentation. Paddy seed was dried up to 12% moisture content before the experiment. Modified atmospheric conditions to the paddy was given using the Grain Pro cocoon bag manufactured by Grain Pro Inc. USA. As shown in the Figure 1., 1150kg of paddy seeds bagged in 22 poly-sack bags and they were storaged in the Grain Pro cocoon bag, sealed and placed in the warehouse. Same amount of paddy seeds bagged in same poly-sack bags and placed in a warehouse under ambient condition. The 300g paddy samples from the two treatments were used in initially and after the storage trial to measure following mentioned physical properties for quality parameters and milling characteristics. Inside oxygen level of the hermetically sealed cocoons was measured using an oxygen meter manufactured by Grain Pro Inc, USA once in two weeks till the end of the experiment. Inside temperature of hermetically sealed cocoon and outside warehouse temperature were measured using thermocouples placed inside sealed cocoon and outside warehouse. Grain quality parameters of paddy such as impurity percentage, immature grain percentage (Bol), moisture content damaged seed percentage and milling characteristics such as husk content percentage, degree of polish percentage, total yield, broken grain percentage and head rice yield percentage were measured before and after storage trail. Milling characteristics were measured using the methodology outline by Bal et al. [2]. Other physio-chemical properties of paddy such as germination percentage, bulk density, thousand seed mass, kernel hardness and seed color were measured initially and after 8 months’ storage by following methods.

Figure 1: Filling sealing and placing of cocoon bag.

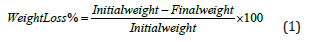

Measuring of grain weight loss during storage

Total weight loss percentage under different storage methods was calculated by dividing final weight losses from initial weight (equation 01). The final total weight of paddy bags under 2 different storage method was recorded for calculating weight loss percentage.

Measuring of germination percentage

Standard germination test, 50 paddy seeds placed in germination paper wrapped with adequate water and covered with polyethylene sheet and kept room temperature for 7 days was performed.

Measuring of moisture percentage

Moisture content of paddy subjected to different storage treatments was measured using the method suggested by Association of Official Analytical Chemists (AOAC 2000) that drying of paddy sample for 24 hours at 120 ℃. Accordingly, moisture content of seeds was calculated using the equation 2. It was replicated 3 times.

Bulk Density is defined as the mass of the sample per unit bulk (seed + air space) volume. The volume of laboratory, bulk density apparatus was filled by soybean. Mass of filled soybean was measured and bulk density was determined using equation 3. It was replicated three times.

Measuring of 1000 seed mass

10 seeds were selected from the sample and their mass were measured. It was replicated ten times and average mass of 10 seeds was taken. Thousand (1000) seed mass value obtained by multiplying the average mass value of 10 seed by 100. Precision laboratory top loading balance was used to measure the mass of the seed.

Measuring of seed hardness

A compression test was carried out to measure seed hardness (yield stress). The Instron, TA, XT2 texture analyzer has been adapted to perform a compression test. Force at rupture was considered as the seed hardness. Three replicates were considered for each measurement and the measured compression force was averaged.

Measuring of seed color

Paddy seed color was measured by using Mini-scan XE plus Hunter Lab Colorimeter. Hunter scale ‘L’ ‘a’ ‘b’ values were measured. ‘L’ stood for lightness (black=0, white=100), ‘a’ represented for greenness and redness (+a, redness; -a; greenness), ‘b’ indicated blueness and yellowness (-b, blueness; +b, yellowness).

Statistical analysis

Minitab statistical software was used for analyzing the data. Each treatment was replicated two times. Analysis of Variance (ANOVA) on Complete Randomized Design (CRD) by General Liner Model (GLM) procedure was performed and treatment means were separated by the Duncan’s Multiple Range Test (DMTR) at α=0.05 level of significance.

Result and Discussion

Change of oxygen level and temperature inside the hermetically sealed cocoon

Oxygen level reduced inside cocoon from environment O2 level i.e., 20.5% to 3.0% within 6 weeks of storage. It was reported minimum oxygen level 1.8% after 6 months sealed storage. However, oxygen level fluctuated in the range of 1.8% to 3.5% inside of sealed cocoon after 6 weeks. Figure 2 shows the temperature fluctuation inside the hermetically sealed cocoon and warehouse. The temperature fluctuation was low inside the cocoon in comparison to warehouse.

Figure 2:Change of temperature inside cocoon and outside environment (warehouse).

Comparison of quality parameters, milling qualities and physical properties of paddy between hermetic cocoon and warehouse storage

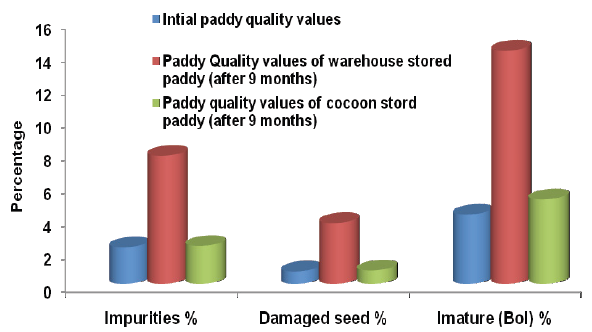

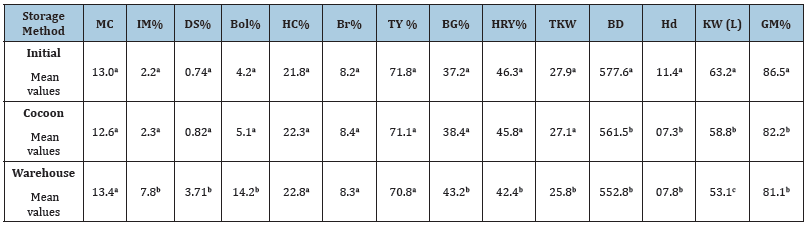

Paddy kernel moisture content was not observed significant difference between hermetically sealed sample and warehouse. Average moisture content was 12.66 and 13.3% in hermetically sealed and warehouse samples respectively. Comparison of initial paddy quality values such as impurities %, immature seed (Bol)% and damaged seed % with warehouse sample and cocoon sample after trial period is shown in Figure 3. Warehouse samples showed significant changes from initial values. However, no significant differences were observed between initial samples and hermetically sealed storage samples with respect to quality values. Due to high respiration rate of seed in warehouse sample immature seed (Bol) % was increased significantly comparison to the sealed cocoon sample. Insect pest and fungal attacks are major causes that alter quality values of warehouse paddy seed sample. But Insect pest and fungal attacks were not observed in hermetically sealed cocoon samples. Growth of fungus, insect and pests were inhibiting under the hermetic storage conditions and metabolic rate of grain is also be decreased due to lack of oxygen [1,3]. And impurity percentage increase due to secretions of insect and totally damaged seed by insect. Milling characteristics such as husk content percentage, bran content percentage and total milling yield did not change significantly with storage practices. However, it is clear from Table 1 significant variation can be observed between cocoon sample and warehouse stored samples with respect to broken grain percentage and head rice yield percentage. It was not observed significant difference between initial values of broken grain and head rice yield percentage with cocoon stored samples. Cocoon stored samples reported similar values as its initial value. But values were significantly different in warehouse sample. Hence it can be concluded that the paddy stored under hermetically sealed conditions (modified atmospheric) withstand /resistant to milling stress. Kernel weight/mass significantly reduced in conventional warehouse storage compared to hermetically sealed cocoon.Hermetically sealed cocoon preserved kennel weight/mass due to slow metabolic rate of seeds [1,3]. Results showed that the initial bulk density and paddy kernel hardness values were significantly reduced from its initial values in both storage methods. Rice kernel whiteness was significantly reduced from its initial value in both storage methods; however, kernel whiteness was significantly lower in warehouse paddy in comparison to cocoon paddy for 9 months of storage. Germination percentage of paddy was not significantly affected by both storage methods, but it is significantly reduced from its initial value [4]. MC moisture content, IM impurities%, DS damaged seed%, Bol immature seed%, HC husk content, Br bran, TY total yield, BG broken grain, HRY head rice yield, TKW thousand kernel weight, BD bulk density, Hd kernel hardness, KW kernel whiteness and GM germination [5].

Figure 3:Change of quality parameters of paddy with different storage conditions.

Table 1: Columns having same letter are not significantly different at =0.05 by DMRT.

Conclusion

It was observed that paddy stored in cocoon took 6 weeks to reduce constant oxygen level to 3.2% The inside temperature of the hermetic cocoon had less fluctuated in comparison to outside environment temperature fluctuation. It also was observed that hermetically sealed cocoon paddy sample reported similar values as its initial values in terms of quality parameters such as impurities %, immature seed (Bol) % and damaged seed % after 9 months of storages. Results also revealed that weight loss percentage was minimum in sealed cocoon in comparison to conventional warehouse storage. Paddy kernel had more resistance to milling stress when stored under hermetically sealed cocoon. Hermetically sealed storage preserves kennel mass and whiteness over time. Hardness (textural characteristics of paddy) and bulk density were reduced even in hermetically sealed storage. Finally, it can be concluded that hermetically sealed cocoon storage method has more advantages compared to conventional warehouse storage. However, hermetically sealed condition must be maintained throughout the storage period to gain those advantages.

References

- Donahaye E, Navarro S, Ziv A, Blasuschild Y, Weerasinghe D (1991) Storage of paddy in hermetically sealed plastic liners in Sri Lanka. Trop Sci 31: 109-121.

- Bal S (1974) Measurement of milling quality of paddy REPC publication.

- Villers P, Bruin T de, Navarro S (2009) Development and applications of the hermetic storage technology. 9th International Working Conference on Stored Product Protection, pp. 719-729.

- Chin DV, Kieu TT (2006) Study on hermetically sealed storage system for rice seed. J of Omonrice 14: 64-70.

- Villers P, Navarro S, De Bruin T (2008) Development of hermetic storage technology in sealed flexible storage structures, Citation for Controlled Atmosphere and Fumigation (CAF) Conference in Chengdu, China.

© 2022 Senadeera W. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)