- Submissions

Full Text

Approaches in Poultry, Dairy & Veterinary Sciences

GGSHELLS: Are they a Waste or a Continuously Produced Natural Resource?

Hamilton RMG*

Formerly Employed by Atlantic Food and Horticulture Research Center, Agriculture and Agri- Food Canada, Canada

*Corresponding author: Hamilton RMG, Formerly Employed by Atlantic Food and Horticulture Research Center, Agriculture and Agri-Food Canada, Kentville, Nova Scotia, Canada

Submission: May 13, 2025;Published: November 13, 2025

ISSN: 2576-9162 Volume 10 Issue 1

Abstract

The primary purpose of avian eggs is for the reproduction of the species. They are integrated seamless ellipsoidal chambers that are essentially an external uterus who in the case of the domestic hen (Gallus galllus sp.) have a volume that ranges between 44.0 and 63.2cm3, surface area from 64.2 to 86.1cm2 [1]. However, humans have highjacked the hen’s egg as an inexpensive source of highly nutritious food [2]. As a result, billions of eggs are produced to meet the consumer’s demand; China, United States of America, India, Indonesia, and Brazil account for 66.7% of the annual global production [3]. In terms of eggshell waste, the global production was estimated in 2006 to be about 50,000 tonnes annually [4].

Keywords:Eggshells; Waste; Natural resource; Construction materials; Foodstuffs; Medical applications; Cosmetics; Catalysis; Water treatment

Abbreviations:CaCO3: Calcium Carbonate; CaO: Calcium Oxide; ESM: Eggshell Membrane; FTIR: Fourier- Transform Infra-red; SEM: Scanning Electron Microscopy; TEM: Transitional Electron Microscopy; WCES: Waste Chicken Eggshells; XRD: X-ray Diffraction

Introduction

Eggs are composed of the yolk, albumen which is commonly called the white, and the shell. They weight in the range 47-67g of which 8-11% is the shell [1]. The shell is about 95% Calcium Carbonate (CaCO3) and 3.5% of an organic matrix of proteins, glycoproteins, and proteoglycans [5]. In addition, there are small quantities (<1%) of Magnesium Carbonate, Magnesium Phosphate, Calcium Phosphate and Silicon Dioxide [6]. Calcium Carbonate contains 40.1% Calcium or in terms of Calcium Oxide, 71.5%.

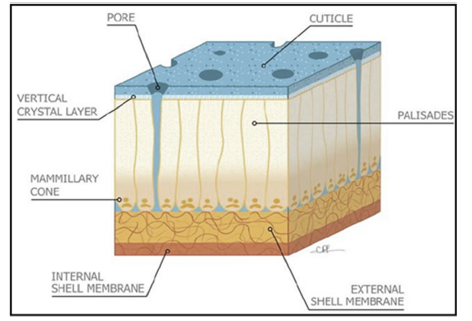

Although the shell of an egg appears to be solid, electron photomicrographs of a cross section show it consists of five distinct layers. These are, from the interior out, inner, and outer membranes, mammillary, palisade, phosphate-rich layer, and finally the cuticle, a layer organic material. A very thin membrane that surround the egg’s content lies against the inner membrane layer, whereas the outer membrane is the “foundation” on which shell formation begins by the deposition of amorphous CaCO3 at specific site on it. As continuous deposition occurs these depositions enlarge and immerge with each other to form the palisade layer. The CaCO3 in this layer form calcite crystals in which an organic matrix of proteins can be found; this layer is the thickest, however, it contains thousands of pores that are formed as the calcite crystals merge. These allow gaseous exchange between the embryonic chick and the exterior and allow transfer of gases (carbon dioxide out ↑ and oxygen ↓ in). About 2 hours before the egg is to be laid, a layer phosphate-rich crystal deposited followed a thin coating of organic material over the egg’s surface. This layer, known as the cuticle, covers the pores and prevents the entry of microbes into the interior but resolves after incubation begins [7]. The addition of the components of the egg (thick and thin albumen and the shell) as it passes down the fallopian tube is tightly orchestrated while at the same time more than 900 matrix proteins, many of which have antibacterial or antibiotic properties [8].

Since it is the yolk and albumen that are used by humans, the shell becomes a residue, a waste. Basically, eggs are used either 1) In the home, 2) The production of liquid egg products, or 3) For the hatching of chicks; these later two uses generate large quantities of shell wastes. The shell waste from home use is to a limited extent included in food wases that are generally composited otherwise they become part of the garbage in land fill sites. However, very large volumes of shell residues are generated by both the liquid egg trade and hatching egg industry.

Equipment uses in the liquid egg trade break at least 7,200 eggs per hour and thus 57,600 eggs in an 8-hour shift, this rate produces daily about 330kg of shell residue per breaker unit. Several breaker units operated at the same time to produce liquid whole egg, liquid albumen, or liquid yolk, each of these are available in liquid, frozen or dried state. In the case of the hatchery industry, eggs from three different sources are hatched: those to produce replacement chicks for table egg stocks, to produce meat-type chickens, and to produce turkey poults. To fill an order for 25,000 “table” egg pullet chicks about 54,000 eggs should initially be placed in incubators. Over the next 21-day incubation period this number of eggs will generate about 300 kg of shell material (Note: Twice the number of eggs need to be set in the case of “table” egg chicks because only the female birds are kept, the males are discarded.) However, if 25,000 meat-type (broiler) chicks are ordered, the about 27,500 eggs need to be set which after 21 days would generate 150kg of waste. Since commercial hatcheries operate many incubators at a time, the amount of eggshell waste generated daily is several multiples of the foregoing amounts. Eggshell residues are reported to be the 15th highest source pollution and cause of major environmental deterioration [3]. In 2012, the annual global production of shell waste was reported to be about 250,000 tonnes [9].

The liquid egg trade produces an array of products that include liquid whole egg, liquid albumen, or liquid yolk, each of which are sold as liquid, frozen or dried. In the case of the hatchery industry, eggs from three different sources are hatched; those to produce chicks for replacement table egg stocks, to produce meat-type chickens; or to generate turkey poults. Eggshell residues are reported to be the 15th highest source of pollution and cause of major environmental deterioration [3]. In 2012, the annual production of eggshell waste was reported to be about 250,000 tonnes [9].

Concerns about the use of land fill sites for the disposal of these wastes and their impact on the environment motivated scientists and engineers to identify other possible avenues for their disposal. Over at least the last three decades numerous alternatives have been identified as evident by the extensive number of published scientific papers. This presentation very brief identifies a few applications that have been published but it barely scratches the surface of what has become a very active area of research.

Since the published literature on this topic is very extensive and the space allotted for this presentation is somewhat limited, emphasis is given to review papers that concisely summarize the essential details and major results obtained. Tables in the following publications summarized published results according to purpose and main findings: Awogbemi et al. [3,5,10]; from among other papers. However, to illustrate some of these applications extracts from this publication are summarized in the following are tables according to the published format (Tables 1-3).

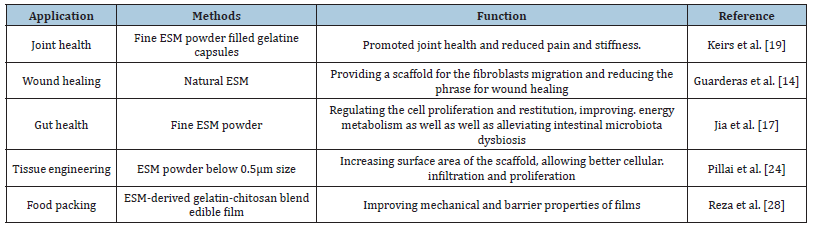

Table 1:Applications for use of eggshell waste from Shi et al. [5].

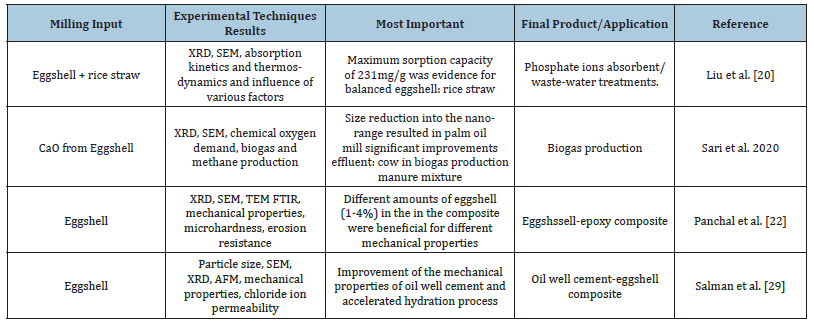

Table 2:Examples of the use of eggshell waste reported by Baláž et al. [10].

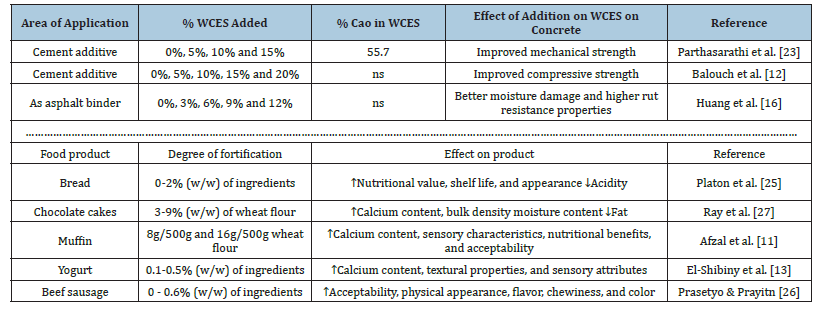

Table 3: Potential for the use of eggshell wastes in the construction and food industries adapted from Awobbemi et al. [3].

The source of eggshell for these and other applications determines where eggshell wastes are used. This is because how the eggs have been handled before the shell wastes are generated. Eggs sourced for the egg breaker industry are washed (Figure 1), passed over a light table for the removal of rejects (blood or meat spots), dried before they are broken and eggs content divided to produce the liquid components and the shell. In contrast, eggs used for hatching meat-type chickens are placed in trays and set in the incubator where they remain for 21-days at 37.5 °C and initial relative humid about 60% which gradually increased to 70%. The shell material intended for human application It is fortunate that there are two different hatchery sources of eggshell waste - “table egg” hatcheries and meat-type chicken hatcheries [11-29].

Figure 1:A schematic diagram of the cross-section hen’s eggshell. This figure was originally.

There are numerous, numerous other applications where eggshell waste has been used to produce “value added” products. This presentation only scratches the “tip” of what has been developed based on eggshell wastes. It is now obvious that shell residues are no longer wastes but rather a “natural resource” that is continuously being produced. Further, some components prepared from residual eggshells are very valuable such as purified collagen which is reported to be worth US$1,000 per gram.

References

- Hamilton RMG (2022) A comparison of the various equations published for the estimation of characteristics of the hen’s egg, importance of reporting the compression rate for shell strength measurements, and distinction between egg specific gravity and density. World's Poultry Science Journal 2: 447-466.

- Réhault GS, Guyot N, Nys Y (2019) The golden egg: Nutritional value, bioactivities, and emerging benefits for human health. Nutrients 11(3): 684.

- Awogbemi O, Von Kallan DV, Algbodion VS (2022) Pathways for sustainable utilization of waste chicken eggshell. J Renew Mat 10(8): 2217-2246.

- Palka K (2006) Chemical and functional properties of food components. In: Sikorski ZE (Ed.), Chemical and function properties of food components. Boca Raton, FL, USA, pp. 15-28.

- Shi Y, Zhou K, Li D, Guyonnet V, Hincke M, et al. (2021) Avian eggshell membrane as a novel biomaterial: A Review. Foods 10(9): 2178.

- Laohavisuti H, Boonchom B, Boonmee W, Chaiseeda K, Seesanong S (2022) Simple recycling of biowastes eggshells to various calcium phosphates foe specific industries 11: 15143.

- Le Roy N, Stapane L, Gautron J, Hinck MT (2021) Evolution of the avian eggshell biomineralization protein toolkit - New insights from multi-omics. Front Genet 12: 672433.

- Moreau T, Gautron J, Hincke MT, Monget P, Réhault GS, et al. (2022) Antimicrobial proteins and peptides in avian eggshell: Structural diversity and potential roles in biomineralization. Immul Front 13: 946428.

- Faridi H, Arabhosseini A (2018) Application of eggshell wastes as valuable and utilizable products: A Review. Res Agr Eng 64(2): 104-114.

- Baláž M, Boldyreva EV, Rybin D, Pavlović S, Rodriguez PD, et al. (2021) State-of-the-art of eggshell waste in material science: Recent advances in catalysis, pharmaceutical application, and mechanochemistry. Front Bioeng Biotechnol 8: 6125.

- Afzal F, Mueenud Din G, Nadeem M, Murtaza MA, Mahmood (2020) Effect of eggshell powder fortification on the physicochemical properties and organoleptic characteristics of muffins. Pure Appl Biol 9(2): 1488-1496.

- Balouch N, Rashid K, Javed S, Ahmad T (2017) Experimental study on com pressive strength of concrete by partial replacement of cement with eggshell powder. Tech J Univ Engin Technol 22(3): 21-27.

- El-Shibiny S, Abd-El-Gawad MAM, Assem FM, El-Sayed SM (2018) Use of nano-sized eggshell powder for calcium fortification of cows and bufflos milk yogurt. Acta Sci Polon Tech Alim 17(1): 37-49.

- Guaderas F, Leavell Y, Sengupta T, Zhukova M, Megraw TL (2016) Assessment of chicken-egg membrane as a dressing for wound healing. Adv Ski Wound Care 29(3): 131-134.

- Harish K, Reddy Ch S, Yuvaraju A, Prabhudeva P, Hemalatha K, et al. (2023) A study on the stabilization of soil using eggshell powder. Int J Innov Res Engin Man 10(2): 96-98.

- Huang J, Shiva KG, Ren J, Sun Y, Li Y, et al. (2021) Towards the potential usage of eggshell powder as bio-modifier for asphalt binder and mixture: Workability and mechanical properties. Int J Pavement Engin 23(10): 1-13.

- Jia H, Hanate M, Aw W, Itoh H, Saito K, et al. (2017) Eggshell membrane powder ameliorates intestinal inflammation by facilitating the restitution of epithelial injury and alleviating microbial dysbiosis. Sci Rep 7: 43993.

- Kalman DS, Hewlings S (2020) The effect of oral hydrolyzed eggshell membrane on the appearance of hair, skin, and nails in healthy middle-aged adults: A random double-blind placebo-clinical trail. J Cosmet Dermatol 19(6): 1463-1472.

- Kiers JL, Bult JHF (2020) Mildly natural eggshell membrane alleviates joint pain associated osteoarthritis of the knee: A randomized double-blind placebo-controlled study. J Med Food 24(3): 292-298.

- Lui XN, Shen F, Qi XH (2019) Adsorption recovery of phosphate from aqueous solution by CaO-bichar composites prepared from eggshell and rice straw. Sci Total Enviro 666: 694-702.

- Mensah RA, Jo SB, Kim H, Park SM, Patel KD, et al. (2021) The eggshell membrane: A potential biomaterial of corneal wound healing. J Biomater Appl 36(5): 912-929.

- Panchal M, Raghavendra GM, Rahul RA, Omprakash M, Ojha S (2020) Experimental investigation of mechanical and erosion behavor of eggshell nanoparticle epoxy biocomposite. Polym Polym Compos 29(7): 897-908.

- Parthasarathi N, Prakash M, Satyanarayana KS (2017) Experimental study on partial replacement of cement with eggshell powder and silica fume. Rayayan J Chem 10: 442-449.

- Pillai MM, Gopinathan J, Senthil KR, Sathish KG, Shanthakumari S, et al. (2018) Tissue engineering of human knee meniscus using functionalized and reinforced silk-polyvinyl alcohol composite three-dimensional scaffolds: Understanding the in vitro and in viva J Biomed Mater Res Part A 106(6): 1722-1731.

- Platon N, Arus VA, Geogescu A, Nistor ID, Barsan N (2020) White bread fortified with calcium from eggshell powder. Revista de Chemie 71(7): 299-306.

- Prasetyo B, Prayitno AH (2021) The sensory characteristics of fortified beef sausage with duck eggshell nano-calcium. IOP Conf Series Earth Enviro Sci 672(1): 012042.

- Ray S, Barman AK, Roy PK, Singh BK (2017) Chicken eggshell powder as a dietary source in chocolate cakes. The Pharma Innovatopn 6(9): 1-4.

- Reza M, Mohammad AM, Milad R, Mohaddeseh K, Amir MM, et al. (2018) Physico-mechanical and structural properties of eggshell membrane geltin-chosan blend edible films. Int J Biol Macrmol 107(Pt A): 406-412.

- Salman AD, Juzsakova T, Al-Mayyahi MA, Ibrahim RI, Abdullah TA, et al. (2010) Improvement of oil well cement by incorporate Nano-CaCO3 prepared from eggshell waste. IOP Conf Series Matr Sci 765: 12006.

© 2025 Hamilton RMG. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)