- Submissions

Full Text

Aspects in Mining & Mineral Science

Mining Simulation and Protocol Design for Saudi Arabian Soil Conditions Using Artificial Intelligence and Machine Learning Techniques

Haitham Hadidi1*, Abdulmajeed Sami Ali Nemri1, Bader Mohammed Mosa Hadadi1, Mohamed Salah Aldeen Haig1, Ziyad Hassan Wushayli1, Obaid Saleh Ba Yuosef1, Rajasekaran Saminathan1 and Divya Raju2

1Department of Mechanical Engineering, College of Engineering and Computer Science, Jazan University, Saudi Arabia

2College of Applied Health Sciences and Nursing, Jazan university, Saudi Arabia

*Corresponding author:Haitham Hadidi, Department of Mechanical Engineering, College of Engineering and Computer Science, Jazan University, Jazan, 45142, Saudi Arabia

Submission: July 01, 2025: Published: July 21, 2025

ISSN 2578-0255Volume14 Issue 51

Abstract

The 2030 vision of Saudi Arabia emphasizes the mining industry due to the country’s substantial mineral wealth potential. The Saudi Arabian soil sediments include substantial quantities of Iron, sulfate, copper, zinc, silver, and gold ores, among others. Recently, Artificial Intelligence and Machine Learning (AI & ML) have gained acclaim in improving engineering processes, resulting in enhanced cost-effectiveness and efficiency. This study focuses on developing the mining protocol by modeling the presence of ore in the soil conditions of Saudi Arbia. This may be implemented effectively employing underwater drones equipped with ore sensors. The examination of AI and ML is conducted with ORANGE machine learning software. The program distinctly delineates the mining procedure approach by illustrating the density fluctuations of ores in relation to survey sectors and ore types. The mining approach categorizes ferrous ores in high-density locations, while nonferrous are classified in low-density parts.

Keywords:2030 vision; Mining; AI and ML techniques; Mining protocol

Introduction

Many studies the use of Unmanned Aerial Systems (UAS) to map uranium mines because conventional survey methods fail in radiologically damaged locations. Unmanned Aircraft Systems (UAS) are creating high-resolution images of radioactive contamination in legacy uranium mines using gamma radiation mapping. The program includes environmental monitoring and radiological site evaluations, which help identify radioactive pollution [1]. Unmanned aerial vehicle technology may help the mining industry increase productivity and reduce remote sensing costs. The research is on exploration, development, exploitation, and reclamation of Unmanned Aerial Vehicles (UAVs) in mining. Slope management, including topographic surveys and reclamation monitoring, is crucial to mining [2]. These technique uses drone-based photogrammetry and remote sensing to overcome terrestrial mining research restrictions and improve exploration. Drone photogrammetry and satellite data (ASTER) create digital elevation models and analyses ore-dense locations in difficult environments. The findings are utilized to study metal ore to improve mining studies in challenging terrains [3]. Remote sensing in mining must be improved to increase productivity and cost-effectiveness. This study examines the mining industry’s various uses of Unmanned Aerial Vehicles (UAVs), focusing on exploration and reclamation, using photogrammetry as the main approach. Unmanned Aerial Vehicles (UAVs) are used in mining for topographic surveys, reclamation monitoring, and remote sensing [2]. Drone-based electromagnetic surveys are cost-effective and efficient compared to conventional methods, which are limited by weight, cost, and power consumption. They designed a lightweight magneto-inductive sensor for drone aeromagnetic surveys of an iron ore deposit. These surveys were compared to standard techniques. This method is used in mineral exploration to find ore deposit magnetic anomalies [4].

Hyperspectral remote sensing is being researched to improve polymetallic deposit studies in areas where conventional methods fail. Hyperspectral images and ground spectrums classify mineral resources and rock mass occurrence, focusing on gold-silverlead- zinc deposits. This method is used for mineral exploration and geological map enhancement, especially for polymetallic ore deposits [5]. UAV-based aeromagnetic surveys are needed in tough terrain or remote places to avoid ground-based issues. A UAV was used to aero magnetically examine iron ore deposits, finding irregularities that ground studies missed. UAV-based aeromagnetic surveys are used in mining prospecting to find hidden ore reserves [6]. Due to need for more efficient and flexible mineral exploration UAVs, hybrid fixed-wing UAVs have been created. With coppergold deposit survey, a hybrid fixed-wing UAV system with vertical takeoff and landing was designed and tested for aeromagnetic surveys. This technique makes mineral exploration fast and precise, especially for finding ore-bearing zones [7].

AI is being used in mining geological exploration to improve efficiency, accuracy, and cost. Data analysis and mineral resource finding employ machine learning and three-dimensional visualization. Artificial intelligence is used in geological exploration to automate data processing, improve 3D visualizations, and increase accuracy [8]. Research examines remote sensing methods and potential uses in metallic ore finding. This study discusses remote sensing techniques and their usage in mineral mining, focusing on Landsat and other satellite technologies. Remote sensing can identify metallic ores, map geological characteristics, and reconnaissance quickly [9]. Few techniques use hyperspectral remote sensing to scan rock formations and minerals more precisely for geological purposes. They used aerial hyperspectral and secondary airborne survey systems to identify mineralized zones in a Chinese gold-silver-lead-zinc mining region. This method helps identify mineralized alteration zones and create prospecting lithologic maps in mineral exploration [10]. Another effort is driven by the need for a cost-effective way to explore mineral deposits in complex terrain. The researchers used UAVs and aeromagnetic monitoring systems to study the Ma’anshan magnetite deposit. This technology is used for high-resolution mineral prospecting in areas where traditional methods are unsuccessful or too costly [11]. A study automates drones to conduct agricultural land-use surveys in mining leases using Artificial Intelligence (AI) to improve landuse analysis. AI controls drone movement and data collection to analyse agricultural land in mining leases. It incorporates GPS and machine learning. This approach is used in mining operations to undertake land-use surveys, especially to analyse mininginfluenced agricultural land [12].

UAVs can improve mining processes during exploration, exploitation, and reclamation. This study covers topographic surveys, geological mapping, and workplace monitoring using Unmanned Aerial Vehicles (UAVs) in mining. Unmanned Aerial Vehicles (UAVs) are employed throughout the mining lifecycle for mineral exploration, real-time site monitoring, and ecological restoration [13]. Because China needs more iron ore, deep mineral exploration has been done in previously explored places. Researchers conducted a High-Resolution Airborne Magnetic (HRAM) survey to seek for deep iron ore deposits near Jinling, China. Deep mineral prospecting with the HRAM survey helps find new iron ore deposits in previously investigated mining locations [14]. A study highlights on remote sensing for mineral extraction, particularly satellite and aircraft hyperspectral imaging technologies. This study examines remote sensing methods that map minerals and identify mineralization-related rock formation changes. Remote sensing is used in mineral exploration to find mineral deposits, especially on exposed rock surfaces [15].

Monitoring Acid Mine Drainage (AMD) areas is essential for environmental management and long-term damage reduction. They used drone-borne hyperspectral sensors to examine AMDrelated materials in lignite mining zones. Iron-bearing minerals like jarosite were prioritized. This approach is used for environmental monitoring in post-mining environments, notably AMD development and ecosystem impact [16]. Another work uses integrated remote sensing in hard-to-reach terrain to improve geological mapping and mining monitoring. They used drones and ground sensors to build detailed three-dimensional geological maps using hyperspectral and photogrammetric sensing. This technology makes mineral exploration and mining monitoring possible, resulting in more precise and safer data collection in tough terrains [17]. A process is driven by the demand for effective and affordable technology to examine surface mineral deposits. To find mineral deposits, they created a radiological system using UAVs and the inherent radiation of minerals like uranium and thorium. The strategy is used to explore mineral deposits in remote or costly areas [18]. Another work examines the benefits of deep learning, a newer technology that the mining industry has been wary about. The study examines deep learning in mining, including mineral extraction, mine safety, and reclamation. Deep learning improves mining sector decisionmaking in exploration, extraction, and reclamation by analyzing massive datasets powered by data [19].

Experimental Works

The geological survey was conducted using a ground metal detector following a precise methodology to ensure the collection of reliable and accurate data on mineral formations at the targeted sites. To ensure the survey was conducted effectively, several preparatory measures were taken before starting the fieldwork. The survey locations were determined based on geological criteria, including soil type such as sandy soil (saline soil), proximity to the Red Sea, and ease of access to the site. Each area was then divided into squares measuring 5×5 meters to ensure comprehensive coverage, and each square was further divided into smaller units measuring 1×1 meters, allowing for 25 separate readings per area. To ensure the organization of the data collection process, clear markers were placed at each measurement point, aiding in the accurate documentation of the survey locations. The survey was conducted using an underground metal detector following a systematic approach within each square. All points within the designated area were covered by walking methodically and evenly to ensure no region was missed. Twenty-five separate readings were recorded for each area, with data collected manually or using digital devices to obtain accurate information on the presence and distribution of metals. To ensure data consistency, the same methodology was applied across all targeted areas, allowing for the creation of a reliable database that can be analyzed later. After completing the field survey, the data was compiled and analyzed according to precise location coordinates. The analysis included comparing readings to identify areas with high mineral concentrations, as well as analyzing patterns in the data using advanced analytical tools to verify the accuracy and distribution pattern of the minerals. To ensure the accuracy of the compiled data, it was compared with available geological maps, which helped in evaluating the results in a scientific and systematic manner.

The accuracy of the results was verified by comparing the readings with the known standards for mineral compositions in the area. In some cases, additional field inspections were conducted at sites that recorded high metal readings to ensure there were no errors or data interference. Environmental factors that could affect the sensitivity of the metal detector, such as soil moisture, salinity levels, or the impact of natural interferences, were also analyzed to ensure the accuracy and validity of the final geological survey results. The data of the survey is fed to the AI and ML software to compute the mining protocol.

Results and Discussions

The machine learning analysis of the ore survey is carried out using the python associated ORANGE machine learning software. The flow chart of the machine learning analysis is done as furnished in the following sequence involving feeding the survey data as compatible file to the data sampler and then to various models of the software (Figure 1). Data sampler takes certain percentage of the fed data as the sampling and labeling by classifications and remaining data as test data. Linear projection to project the ore densities with concerned sectors, the tree viewer model is capable of achieving the decision tree AI and ML algorithm of various sectors analyzed. Scatter plotter identifies the degree of ore density scattering in the test region. Statistical analysis give rise to percentile variations of the ore densities in terms of classifications as well as quantifications. Box plot and violin plots furnish the probabilistic quantification of classified ore densities as a pictorial form.

Figure 1:The machine learning flow chart of the test run.

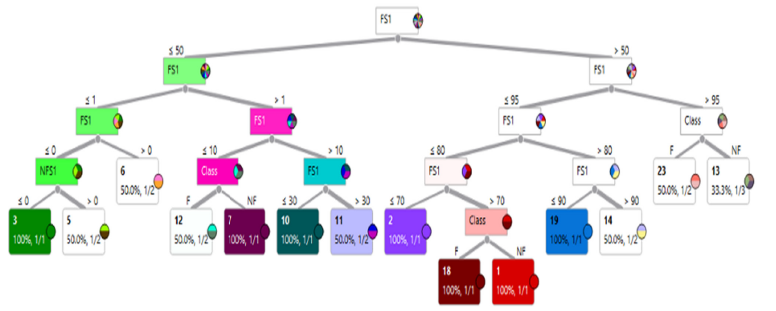

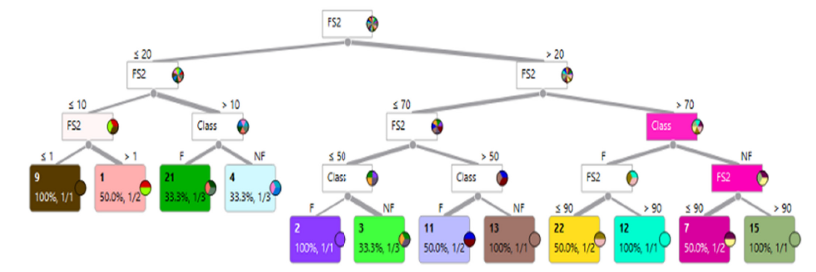

Figure 2 represents the decision tree AI and ML algorithm of machine learning test run when FS1 is taken as target parameter and NFS1 is taken as featured parameter. It reveals that the sector is divide into two namely one as less than or equal to 50% ferrous ore existence and second as more than 50% ferrous ore existence. The prior connects to the sectors 6, 10, 11 and 12 for the sequential mining protocol of ferrous ores and it indicates that the non-ferrous alloy ore existence in sector 7. The later connects to sectors greater than 50% ore concentration leading to the mining protocol route as 23, 14,19, 18 and 2 for ferrous ore mining. Nonferrous ore mining can also be done in sector 1. Figure 3 represents the decision tree AI and ML algorithm of machine learning test run when FS2 is taken as target parameter and NFS2 is taken as featured parameter. It reveals that the sector is divide into two namely one as less than or equal to 20% ferrous ore existence and second as more than 20% ferrous ore existence. The prior connects to the sectors 21, 9 and 1 for the sequential mining protocol of ferrous ores and it indicates that the non-ferrous alloy ore existence in sector 4. The later connects to sectors greater than 20% ore concentration leading to the mining protocol route as 12, 22,11 and 2 for ferrous ore mining. Nonferrous ore mining can also be done in sector 7, 13 and 3.

Figure 2:Decision tree algorithm of AI and ML test run with target parameter as FS1.

Figure 3:Decision tree algorithm of AI and ML test run with target parameter as FS2.

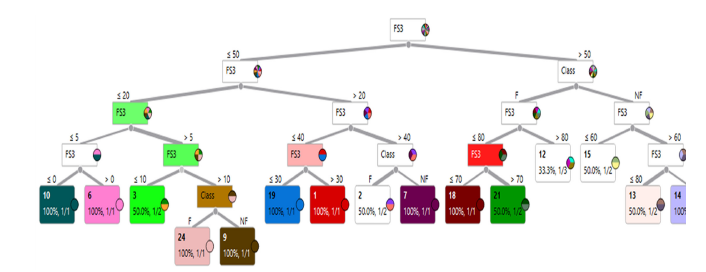

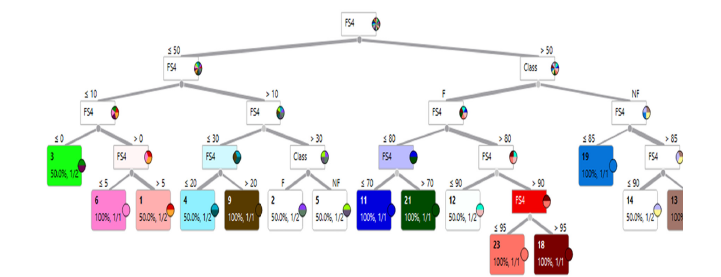

Figure 4 represents the decision tree AI and ML algorithm of machine learning test run when FS3 is taken as target parameter and NFS3 is taken as featured parameter. It reveals that the sector is divide into two namely one as less than or equal to 50% ferrous ore existence and second as more than 50% ferrous ore existence. The prior connects to the sectors 19,1, 2, 24, 3, 6 and 10 for the sequential mining protocol of ferrous ores and it indicates that the non-ferrous alloy ore existence in sector 9 and 7. The later connects to sectors greater than 50% ore concentration leading to the mining protocol route as 12, 21 and 18 for ferrous ore mining. Nonferrous ore mining can also be done in sector 14, 13 and 15. Figure 5 represents the decision tree AI and ML algorithm of machine learning test run when FS4 is taken as target parameter and NFS4 is taken as featured parameter. It reveals that the sector is divide into two namely one as less than or equal to 50% ferrous ore existence and second as more than 50% ferrous ore existence. The prior connects to the sectors 2, 9, 4, 1 and 6 for the sequential mining protocol of ferrous ores and it indicates that the non-ferrous alloy ore existence in sector 5. The later connects to sectors greater than 50% ore concentration leading to the mining protocol route as 18, 23, 12, 21 and 11 for ferrous ore mining. Nonferrous ore mining can also be done in sector 13, 14 and 19.

Figure 4:Decision tree algorithm of AI and ML test run with target parameter as FS3.

Figure 5:Decision tree algorithm of AI and ML test run with target parameter as FS4.

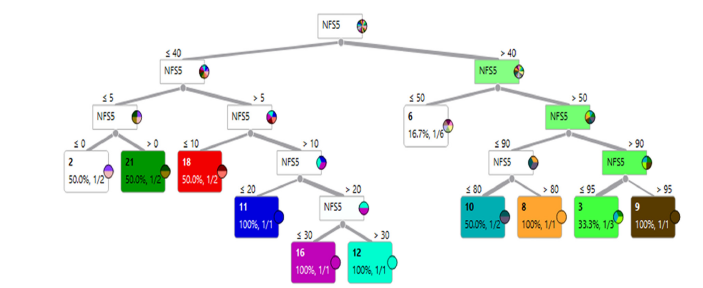

Figure 6 represents the decision tree AI and ML algorithm of machine learning test run when FS5 is taken as target parameter and NFS5 is taken as featured parameter. It reveals that the sector is divide into two namely one as less than or equal to 40% nonferrous ore existence and second as more than 40% nonferrous ore existence. The prior connects to the sectors 12, 11, 18, and 21 for the sequential mining protocol of nonferrous ores. The later connects to sectors greater than 40% ore concentration leading to the mining protocol route as 9, 3, 8, 10 and 6 for nonferrous ore mining.

Figure 6:Decision tree algorithm of AI and ML test run with target parameter as FS5.

Conclusion

Decision tree AI and ML algorithm of machine learning test run when FS1 is taken as target parameter reveals connecting sectors as 6, 10, 11 and 12 for the sequential mining protocol of ferrous ores and it indicates that the non-ferrous alloy ore existence in sector 7. The test run when FS2 is taken as target parameter reveals connecting sectors as 12, 22,11 and 2 for the sequential mining protocol of ferrous ores and it indicates that the non-ferrous alloy ore existence in sector 7, 13 and 3. The output of test run with FS3 as target parameter, connects to the sectors 19,1, 2, 24, 3, 6 and 10 for the sequential mining protocol of ferrous ores and it indicates that the non-ferrous alloy ore existence in sector 9 and 7. AI and ML algorithm of machine learning test run when FS3 is taken as target parameter reveals connecting sectors as 19,1, 2, 24, 3, 6 and 10 for the sequential mining protocol of ferrous ores and it indicates that the non-ferrous alloy ore existence in sector 9 and 7. The test run when FS4 is taken as target parameter reveals connecting sectors as 2, 9, 4, 1 and 6 for the sequential mining protocol of ferrous ores and it indicates that the non-ferrous alloy ore existence in sector 5.

References

- Martin PG, Payton OD, Fardoulis JS, Richards DA, Scott TB (2015) The use of unmanned aerial systems for the mapping of legacy uranium mines. Journal of Environmental Radioactivity 143: 135-140.

- Loots M, Grobbelaar S, van der Lingen E (2022) A review of remote-sensing unmanned aerial vehicles in the mining industry. Journal of the Southern African Institute of Mining and Metallurgy 122(7): 387-396.

- Al-Zubade MKH, Alkan O (2022) The role of drone photogrammetry, remote sensing, and GIS methods in the detection of ore areas and their surroundings. The Eurasia Proceedings of Science Technology Engineering and Mathematics 21: 380-387.

- Shahsavani H, Smith RS (2024) Aeromagnetic gradiometry with UAV: A case study on small iron ore deposit. Drone Systems and Applications 12(1): 1-9.

- Wan Y, Fan Y, Moushun J (2021) Application of hyperspectral remote sensing for supplementary investigation of polymetallic deposits in Huaniushan ore region, Northwestern China. Scientific Reports 11(1):

- Syasko AA, Grib NN, Imaev VS, Imaeva LP, Kolodeznikov II (2020) Conducting detailed airgeophysical works in complexly dislocated complexes of the Sutam terrain (Aldan Shield) in the study of iron ore deposits. Geodynamics and Tectonophysics 11(1): 141-150.

- Lu N, Xi Y, Zheng H, Gao W, Li Y, et al. (2023) Development of a hybrid fixed-wing UAV aeromagnetic survey system and an application study in Chating deposit. Minerals 13(1094).

- Zhang X, Nyamasvisva TE, Liu C (2024) Discussion on the application of artificial intelligence technology in mining geological exploration. Education Reform and Development 6(5): 1-6.

- Gregory AF (1979) Remote sensing in the search for metallic ores: A review of current practice and future potential. Proceedings of Exploration.

- Fan Y, Wan Y, Wang H, Yang X, Liang M, et al. (2021) Application of an airborne hyper-spectral survey system CASI/SASI in the gold-silver-lead-zinc ore district of Huaniushan, Gansu, China. Geologia Croatica 74 (1): 73-83.

- Jiang D, Zeng Z, Zhou S, Guan Y, Lin T (2020) Integration of an aeromagnetic measurement system based on an unmanned aerial vehicle platform and its application in the exploration of the Ma’anshan magnetite deposit. IEEE Access 8: 189576-189586.

- Kaushal H, Bhatnagar A (2023) Application of artificial intelligence in drones for the analysis of agricultural land use in the mining lease. International Journal of Environment and Climate Change 13(8): 1606-1614.

- Park S, Choi Y (2020) Applications of unmanned aerial vehicles in mining from exploration to reclamation: A review. Minerals 10(8): 663.

- Lu N, Liao G, Xi Y, Zheng H, Ben F, et al. (2021) Application of airborne magnetic survey in deep iron ore prospecting-A case study of Jinling Area in Shandong Province, China. Minerals 11(10): 1041.

- Agar B, Coulter D (2007) Remote sensing for mineral exploration: A decade perspective 1997-2007. Proceedings of Exploration 7: 109-136.

- Jackisch R, Lorenz S, Zimmermann R, Möckel R, Gloaguen R (2018) Drone-borne hyperspectral monitoring of acid mine drainage: An example from the Sokolov Lignite District. Remote Sens 10(3): 385.

- Kirsch M, Lorenz S, Zimmermann R, Tusa L, Möckel R, et al. (2018) Integration of terrestrial and drone-borne hyperspectral and photogrammetric sensing methods for exploration mapping and mining monitoring. Remote Sens 10(9): 1366.

- Martin PG, Connor DT, Estrada N, El-Turke A, Megson-Smith D, et al. (2020) Radiological identification of near-surface mineralogical deposits using low-altitude unmanned aerial vehicle. Remote Sens 12(21): 3562.

- Azhari F, Sennersten CC, Lindley CA, Sellers E (2023) Deep learning implementations in mining applications: A compact critical review. Artif Intell Rev 56: 14367-14402.

© 2025 Haitham Hadidi. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)