- Submissions

Full Text

Aspects in Mining & Mineral Science

Lightweight Ceramic Materials Based on Industrial Waste of Uzbekistan

Usmanov KL, Nimchik AG, Kadyrova ZR* and Khomidov FG

Institute of General and Inorganic Chemistry of the Academy of Sciences of the Republic of Uzbekistan, Uzbekistan

*Corresponding author: Kadyrova ZR, Institute of General and Inorganic Chemistry of the Academy of Sciences of the Republic of Uzbekistan, Uzbekistan

Submission: August 05, 2022;Published: August 25, 2022

ISSN 2578-0255Volume9 Issue5

Abstract

The possibility of obtaining a high-quality porous material with high physical and mechanical properties based on local clay raw materials and man-made waste has been established. It is shown that the chemical industry wastes used accelerate the process of glass formation during firing, reducing the temperature of agglomeration and swelling by 20-40 °C, while obtaining a durable porous material. Regularities of the influence of physical and chemical features, used clay materials and flotation wastes of the Almalyk Mining and Metallurgical Plant on the mechanism of pore formation during the production of aggloporite are revealed.

Keywords:Lightweight; Flotation waste; Phosphogypsum; Solid waste from soda production; Mechanism; Sintering; Swelling; Roasting

Introduction

In connection with the rise in the cost of energy carriers, there is an urgent need to store the generated heat in buildings and structures. And in regions with a hot climate, reduce the cost of air conditioning and ventilation. To implement these important tasks, new inexpensive heat-insulating materials are needed using local natural and technogenic raw materials. One of the building materials obtained exclusively with the use of industrial waste as a raw material component is agloporite, an artificial porous aggregate obtained by sintering sandy-clay materials on the grate of a sintering machine [1-3]. It can be obtained by replacing valuable natural raw materials - highly plastic clays with local industrial wastes: aluminosilicate flotation wastes from copper and lead processing plants of the Almalyk MMC, unenriched kaolin from the Angren deposit, and inorganic wastes from the chemical industry - solid waste from soda production and phosphogypsum. In industrial practice, there are a number of projects to create a technology for the production of expanded clay based on slightly intumescent clays and man-made waste [4,5]. In a number of scientific sources, the main criterion for the suitability of the raw materials used is the ability to swell during heat treatment in the range of 1050-1200 ℃ and form a material with a cellular structure with a density in the range of 200-1000kg/m3. In addition, attempts are being made to solve the problem of obtaining an effective porous lightweight filler based on slightly intumescent clays and aluminosilicate wastes by adding burnable additives in the form of diesel oil, coal, thermal power plant ash, etc. [6-8].

Mini Review

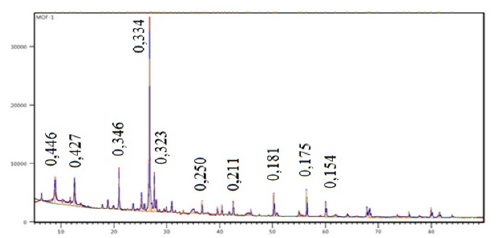

The purpose of our research is to develop a technology for obtaining granular porous sintered material (agloporite), using technology using effective swelling intensifiers, in the role of which chemical production wastes - phosphogypsum and solid waste from soda production can be used. Of the variety of natural and technogenic raw materials of Uzbekistan, the most interesting as raw materials for the production of aggloporite can be aluminosilicate waste - flotation waste from the Almalyk Mining and Metallurgical Plant, the amount of which in dumps is hundreds of millions of tons. Flotation wastes from copper and lead (CCP and LCP) concentrating plants are used as a clay-replacing component in the synthesis of agloporite. The study of the characteristics of the used components of raw mixtures was carried out by X-ray phase, petrographic and infrared-spectroscopic, petrographic and other modern methods of physical and chemical analysis. The temperature of the beginning of the formation of the liquid phase and swelling of the aggloporite, the degree of swelling and a number of other physico-chemical processes occurring during the agglomeration of silicate mixtures. The CCP flotation waste is a gray sandy powder with a fractional grain size ranging from 1.00-0.01 mm. The main amount is grains 0.25-0.01mm in size, containing mainly quartz and feldspar crystals. The chemical composition of the flotation waste is mainly quartz SiO2 - 65%, Al2O3 - 14.12%, Fe2O3 - 9.05% (Table 1). The flotation waste from the enrichment of Lead- Containing Ore (LCP) contains residual amounts of lead and zinc in the amount of 0.24 and 0.20%, respectively. The main chemical component is silica, the content of which reaches 45% by weight. X-ray diffraction analysis of raw materials [9] was performed on an XRD-6100 diffractometer (Shimadzu, Japan) with a vertical 4-90°. The study of flotation waste by the X-ray phase method revealed the presence of the following main crystalline phases, the interplanar distances of which correspond to: quartz with d=(0.369; 0.334; 0.181; 0.153)nm, CaCO3 with d=0.303; 0.191; 0.181nm, feldspars with d= (0.202; 0.166)nm and hydromicas with d=(0.442; 0.254; 0.148)nm (Figures 1 & 2).

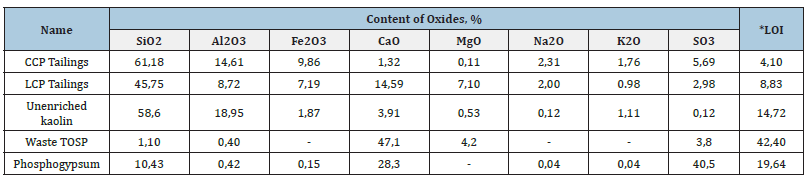

Table 1:The chemical composition of the materials used. LOI*- weight loss on ignition.

Figure 1:Radiographs of flotation waste CCP.

Figure 2:Radiographs of flotation waste LCP.

The characteristics of the chemical production wastes used are as follows. Phosphogypsum is a solid waste from the production of phosphoric acid by the sulfuric acid method. For 1 ton of phosphoric acid, from 3.5 to 6 tons of phosphogypsum are obtained in terms of dry matter. Depending on the conditions for obtaining phosphoric acid, CaSO4 2H2O dihydrate, CaSO4 0.5 H2O hemihydrate, or anhydrous calcium sulfate are formed in the precipitate, which determines the corresponding name of the products - phosphogypsum, phosphohemihydrate and phosphoanhydrite. Phosphogypsum is a gray fine-grained clumping powder with a moisture content of 25-30% containing up to 94% CaSO4 per dry matter. The main impurities in it are unreacted phosphates, fluorine and strontium compounds, as well as unwashed phosphoric acid, and organic substances. Solid waste from the soda production of the Kungrad soda plant is formed in the process of ammonia regeneration and brine purification, as well as overburning and other limestone calcination waste. The most voluminous waste from the production of soda ash by the ammonia method is the distiller suspension, which is formed in the amount of 8-10m3 per 1 ton of soda. It is a solution of calcium and sodium chlorides, calcium hydroxide and calcium sulfate. The solid residue of the distiller liquid (calcium carbonate sludge) in dry form is a light gray mass with a density of about 970kg/m3, 70-80% consisting of particles 0.1-0.2mm in size.

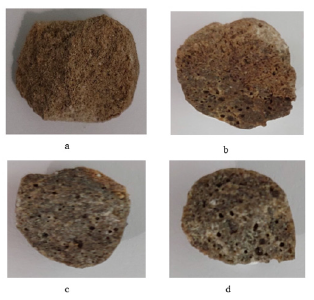

Figure 3: Photographs of light weight samples with CCP and LCP flotation waste: (a,b) charge No. 4, (c,d) charge No. 1.

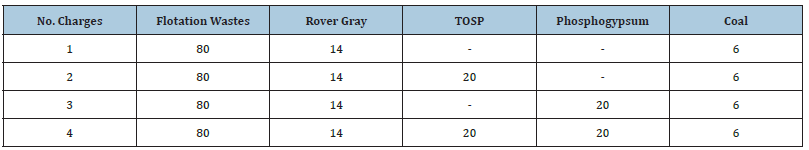

The raw materials were first dried and ground in a laboratory ball mill to a specific surface area of 1300-1500g/cm2. Then the components were weighed in stoichiometric quantities and mixed in a dry state. After that, water was added to the dry mixture. Granules with a diameter of 10-15mm were made from the resulting mixture and fired in an electric muffle furnace with silicate heaters to temperatures of 1050-1200 °C (Table 2). The temperature of the beginning of the formation of the glass phase and the completion of the sintering of raw mixtures based on flotation waste with the addition of kaolin clay, as well as phosphogypsum and solid waste from the production of soda, as a result of which the patterns of the influence of the physicochemical properties of the components on the process of sintering and swelling, were established. A number of physical and chemical studies carried out have established that raw mixtures with CCP flotation waste have a higher ability to expand. Table 3 reflects the technological parameters of the light weight obtained, synthesized on the basis of charges with CCP flotation waste, reflecting the intensifying effect of inorganic additives TOSP and phosphogypsum on the optimal firing temperature, bulk density, expansion coefficient, expansion interval (Figure 3). The minimum volumetric weight of the optimal charge composition - sample No. 4 with the addition of 25% TOSP and phosphogypsum together, approaches 1.35 and the expansion coefficient increases to 1.95, in addition, the synthesis temperature decreases by 25 -35 °C.

Table 2:The compositions of the studied raw materials for the production of porous silicate filler, in %.

Table 3:Swelling of batches based on CCP flotation waste.

Conclusion

Photographs of the lightweight samples obtained with flotation waste used as the main raw material show the formation of a material with a large number of pores ranging in size from 0.5 to 0.01mm. when phosphogypsum and TOSP wastes are added as a pore formation intensifier in an amount of 20%, while in samples without chemical additions of pores much less and the density of the material is higher. Photographs of the lightweight samples obtained with flotation waste used as the main raw material show the formation of a material with a large number of pores ranging in size from 0.5 to 0.01mm when phosphogypsum and TOSP wastes are added as a pore formation intensifier in an amount of 20%, while in samples without chemical additions of pores much less and the density of the material is higher.

References

- Petrov VP, Tokareva SA (2011) Porous aggregates from industrial waste. Building Materials 12: 46-50.

- Abramov AK, Efimov VI, Nikulin IB (2013) Agloporite obtained from coal preparation waste as a filler for lightweight concrete. Mining sciences and Technologies 11: 3-11.

- Nimchik AG, Usmanov HL, Kadyrova ZR (2019) Physical and chemical processes for obtaining aggloporite from industrial wastes of Uzbekistan. Universum Chemistry and Biology 11(65): 39-46.

- Roshchupkina IY, Abdrakhimov VZ, Denisov DY (2010) Investigation of the phase composition of expanded clay based on the waste of a mining and processing plant during coal enrichment. Bashkir Chemical Journal 17(2): 136-138.

- Vasilenko A, Jafer AS (2015) The use of calcium-containing man-made materials in the production of expanded clay gravel. Proceedings of the Siberian Branch of the Section of Earth Sciences of the Russian Academy of Natural Sciences. Geology, exploration and development of mineral deposits 2(51): 106-112.

- Itkin YV, Cherkinskaya KT, Grekhov IT (1997) Proceedings of the Institute of Combustible Minerals of the Ministry of Coal Industry of the USSR, Russia, 32: 126-128.

- Abdrakhimov VZ, Abdrakhimova ES (2013) Phase composition of ceramic products based on oil shale waste, coal preparation, oil production and ash and slag materials. Proceedings of the Samara Scientific Center of the Russian Academy of Sciences 1: 14-18.

- Itkin YV, Cherkinskaya KT, Grekhov IT (1997) Phase composition of aggloporite based on the enrichment of coals from various deposits. Proceedings of the Institute of Combustible Fossils of the USSR Ministry of Coal Industry 32: 126-128.

- Pushcharovsky DY (2000) Radiography of minerals. p. 288.

© 2022 Kadyrova ZR. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)