- Submissions

Full Text

Aspects in Mining & Mineral Science

Changing Geological and Mining Conditions in Hard Coal Mines in Poland as Mining Activities Progress

Eugeniusz Jacek Sobczyk*

Associate Professor, Mineral Energy and Economy Research Institute of the Polish Academy of Sciences, Poland

*Corresponding author: Eugeniusz Jacek Sobczyk, Mineral and Economy Research Institute Polish Academy of Sciences, Krakow, Poland ORCID iD: 0000-0003-3968-2312;

Submission: January 26, 2022;Published: February 04, 2022

ISSN 2578-0255Volume8 Issue4

Abstract

This publication presents the research aimed at showing the change hard coal mining conditions in Poland. In total 499 longwalls in 7 coal mines were analysed, including 240 longwalls that were mined in the period of 2010 to 2021 and 259 longwalls scheduled for exploitation in the years 2022 to 2030. It has been shown that the geological and mining conditions deteriorate as mining operations progress. In the case of underground mining, the occurring natural hazards result in increases in technical problems and in the cost of coal production, and consequently affects the assessment of the economic efficiency of mining plants.

Keywords: Polish mining sector; Longwall production and costs; Geological and mining conditions

Introduction

Dynamic changes taking place in the economic environment in Poland cause that the future of hard coal mining is characterized by a high degree of uncertainty. This industry is currently in a very difficult situation both in terms of mining and economics. This is due to the dynamically changing conditions in which the sector operates, and its long-term role is dependent on factors originating both at the national and international level. First of all, climate packages adopted in the European Union are the biggest challenge for Poland, due to the greenhouse gas emission standards, which are very difficult to meet. Mining is a key supplier of primary fuels to the domestic economy. Thanks to this, Poland is one of the countries in the European Union which are least dependent on the import of energy-producing raw materials. This is a result of a large share of hard coal and lignite (79%) in the Polish energy mix. This share is decreasing from year to year at the cost of increasing importance of other energy carriers, including those from renewable sources. As recently as in 2000, the energy security index in Poland was 10.7%. In 2018, as much as 44.8% of strategic energy-producing raw materials (mainly crude oil and natural gas) needed for the functioning of the economy were imported from abroad. Nevertheless, this percentage is not high. For comparison, the average energy dependence (percentage of energy-producing raw materials imported from abroad) in European Union countries is 58%. Very high rates are found in countries such as Belgium (82%), Italy (76%) and Germany (63.6%) [1].

In addition, coal mining has recently come under pressure from falling world coal prices and rising service prices (U.S.EIA). At the same time, coal mining conditions are deteriorating, the resources more readily available in active mines are being depleted, mining depths are increasing, temperature levels are rising, transportation routes for staff and materials are lengthening, effective working time is decreasing, the number of hazards is increasing, and seams with increasing waste rock content are being mined [2]. For many years, restructuring processes have also been carried out to improve the economic efficiency of the entire hard coal industry [3-5]. These conditions make coal mining increasingly unprofitable and highly dependent on business cycles [6].

Changing Hard Coal Mining Conditions

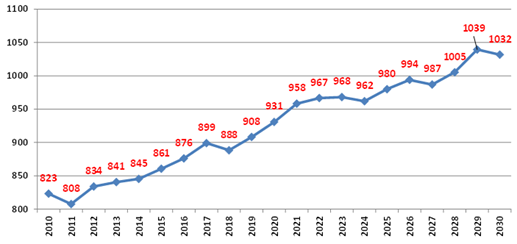

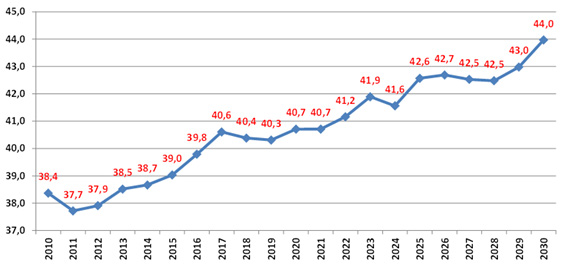

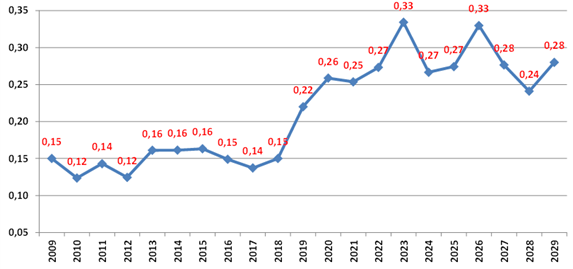

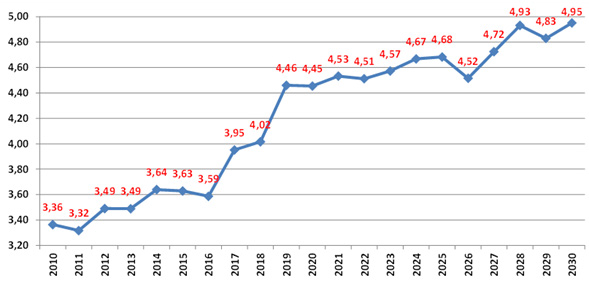

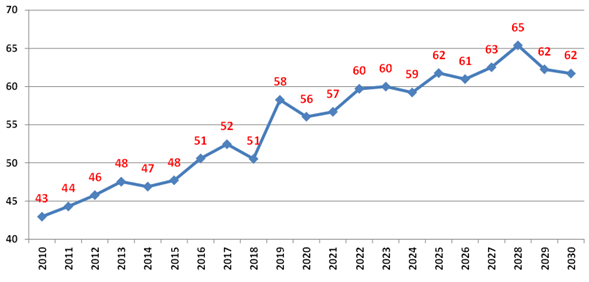

Geological and mining conditions in mines deteriorate as mining activities progress, which, in the underground mining method and with the occurrence of natural hazards, increases technical problems and coal mining costs, and consequently affects the assessment of the economic efficiency of mining plants. In the research concerning the determination of the impact of onerous geological and mining conditions on the process of exploitation in selected hard coal mines, a total of 499 longwalls were analyzed, including 240 longwalls that were operated in the years 2010-2021 and 259 longwalls that are scheduled to be operated in the years 2022-2030. The average mining depth at these mines has been consistently increasing. While it was 823m in 2010, the projected depth in 2030 will increase to 1032m. This means that every year the average depth of mining operations in these mines will increase by 11m (Figure 1). A consequence of increasing depth will be an increase in the initial temperature of the rock mass. In the nearest future, further deterioration of climatic conditions in hard coal mines should be expected as a result of increased concentration of mining activity and moving to deeper levels. In the analyzed mines, the initial temperature of the rock mass is expected to increase from 38, 4 °C in 2010 to 44 °C in 2030 (Figure 2). With depth, an increase in the strength of the rocks surrounding the seams is noted, which is due in part to the compaction of the rock material under gravitational pressure [7]. High values of stress components in the seams and surrounding rocks (the so-called stress concentration areas), especially in the layers characterized by high compressive and/or bending strengths, are one of the reasons for seismic and bump (decompression) hazards [8]. Illustrated in (Figure 3), the average changes in coalbed burst hazard, according to the adopted scale: 0 – coal beds not at risk, 0.1-1st level, 0.3-2nd level, and 0.7- 3rd level of bump hazard, show that the onerousness resulting from bump hazards after 2017 has a sustained upward trend.

Figure 1: Average mining depth at the analyzed mines (m).

Figure 2: Average initial temperature of the rock mass at the analyzed mines (°C).

Figure 3: Average bump hazard at the analyzed mines (0 – coal beds not at risk, 0.1-1st level, 0.3-2nd level, and 0.7-3rd level of bump hazard).

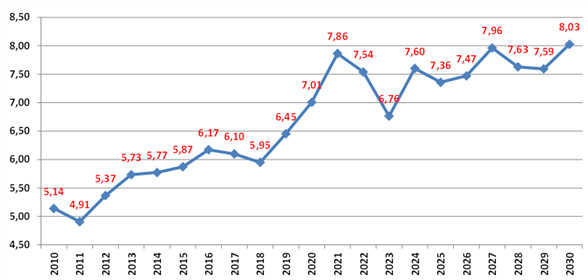

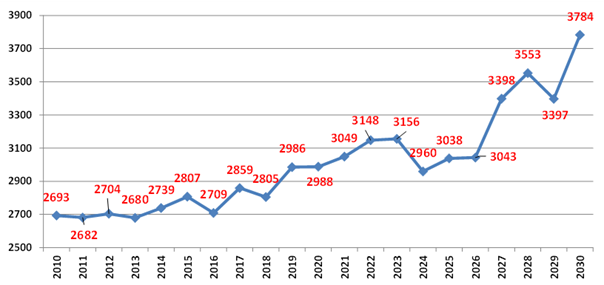

The overall depth-dependent methane bearing capacity of seams and the occurrence of free methane at considerable depths under high pressure increase the methane hazard (in terms of potential explosiveness) and the burst hazard (in terms of gas and rock ejections). The magnitude of the threat of gas and rock ejections is also adversely affected by the decrease in the strength of most coals in the seams, which is recorded with depth, as well as by the lower fracture density of the coal/rock structure, which, while lowering their permeability to gas, favors the occurrence of significant amounts of free methane [9]. Methane hazard, which has been clearly increasing in recent years at the analyzed mines, will maintain this trend in the next years of their operation (Figure 4). The average methane bearing capacity will increase by 56% in 2030 compared to 2010. The analysis of the selected mines has shown that the design of the mining activities in the coming years will result in the location of the longwall fields being further and further away from the shafts. This has a significant impact on the mining costs in these mines. It mainly concerns the length of the output haulage (Figure 5), as well as the time needed for the mine workers to reach the longwall (Figure 6). Between 2010 and 2030 the average output haulage length and the time needed for the mine workers to get to the longwall will increase by over 30%. The distance to the ventilation shaft affects two main aspects of work organization. Firstly, the ventilation of the longwall face: fresh air travels a shorter distance with less resistance and more effectively vents the longwall; this is a particularly important aspect if there is a risk of methane. Secondly, air conditioning of the workings: in the case of high initial temperature of the rock mass, the air does not heat up at a shorter distance from the intake shaft (where central air-conditioning systems are more and more frequently installed), which contributes to better working comfort of the mine workers and reduces the possibility of shortened working hours, which further reduces the effective working time. The average distance from the intake shaft (main current) will increase from 2693m in 2010 to 3784m in 2030 (Figure 7).

Figure 4: Average methane bearing capacity at the analyzed mines (m3/Mgcsw).

Figure 5: Average output haulage length at the analyzed mines (km).

Figure 6: Average time the mine workers need to reach the longwall at the analyzed mines (min).

Figure 7: Average distance from the intake shaft (main current) at the analyzed mines (m).

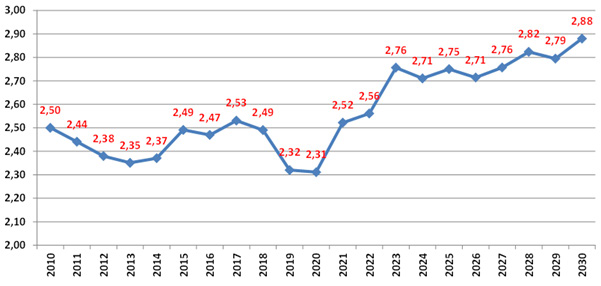

Figure 8: Average assessment of the impact of mining events.

A significant problem of hard coal mines (with particular emphasis on those which have largely depleted their resources) is the necessity to conduct mining in irregular residual areas. These are usually resources located in protection and support pillars of liquidated shafts and capital workings (sometimes surface facilities), including also parts of seams left as a result of the decision to temporarily or completely abandon exploitation. The necessity of conducting mining works in residual areas is characterized by the impact of the edges/remnants of neighboring seams on the current mining activity. This translates into an increased risk of bumps and bursts, mainly due to the local concentration of stresses, while the possibility of the occurrence of fracture zones within unmined coal, and therefore the infiltration and migration of air in the fractured medium, contribute to an increased fire hazard [10]. In order to quantify the impact of the mining events on the mining process in the analyzed mines, a five-level verbal scale was adopted (1-very small, 5-very large). The change in the assessment of mining events onerousness is shown in Figure 8. There is a clear upward trend from 2020 onwards, with the highest value of the impact of mining events onerousness is projected for 2030 (2.88).

Conclusion

The analysis shows that the deteriorating geological and mining conditions will to a large extent limit the achievement of the assumed production capacities by hard coal mines [11]. The onerousness of mining and geological conditions, increasing year by year, will significantly impact the limitations of the exploitation process. This means that coal mining in a deteriorating longwall environment should have its consequences in the recorded costs and, consequently, in the assessment of the economic efficiency of mining plants.

References

- (2021) Eurostat - Source of data Eurostat.

- Kicki J, Sobczyk EJ (2016) Legal, technical, economic and environmental aspects of waste rock management in hard coal mines. Kraków, Poland.

- Szlązak J (2004) Restructuring of hard coal mining in Poland in the years 1990-2002. Analysis of the effectiveness of implemented programs, IGSMiE PAN, Kraków, Poland.

- Ney R, Sokołowski A, Sobczyk EJ, Kicki J, Jarosz J, et al. (2006) Hard coal mining restructuring strategy-experiences and forecasts. Kraków, Poland.

- Sobczyk EJ, Kaczmarek J, Fijorek K, Kopacz M (2020) Efficiency and financial standing of coal mining enterprises in Poland in terms of restructuring course and effects. Gospodarka Surowcami Mineralnymi – Mineral Resources Management 36(2): 5-30.

- Fałtyn M, Naczyński D (2018) The factors shaping the demand, supply, and prices on the hard coal market. Modelling of possible changes in the long-term horizon, Polityka Energetyczna – Energy Policy Journal 21(3): 47-68.

- Goszcz A (1999) Elements of rock mechanics and rock bursts in Polish coal and copper mines. Kraków, Poland.

- Kidybiński A (1982) Fundamentals of mine geotechnics. Silesian Publishing House, Katowice, Poland.

- Konopko W (2013) Work safety in hard coal mines. Central Mining Institute, Katowice, Poland.

- Zorychta A, Burtan Z (2008) Conditions and directions of development of the technology of underground mining of deposits in the Polish hard coal mining industry. Mineral Raw Materials Management 1(2): 53-70.

- (2020) US Energy Information Administration (EIA): Short-Term Energy Outlook.

© 2022 Eugeniusz Jacek Sobczyk. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)