- Submissions

Full Text

Aspects in Mining & Mineral Science

Experimental Evaluation of Cement Suspensions Injectability into Sands

Christodoulou Dimitrios*

Department of Environmental Sciences, University of Thessaly, Greece

*Corresponding author: Christodoulou Dimitrios, Assistant Professor, Department of Environmental Sciences, University of Thessaly, Campus Gaiopolis, Larissa, Greece

Submission: December 16, 2021;Published: January 06, 2022

ISSN 2578-0255Volume8 Issue3

Abstract

A laboratory investigation was conducted in order to evaluate the injectability of cement suspensions. Four gradations from CEM II/B-M (according to EN 197-1) type of cement were used having nominal maximum grain sizes of 100μm, 40μm, 20μm and 10μm. The properties of suspensions, with water to cement (W/C) ratios of 1:1, 2:1 and 3:1 by weight, were determined in terms of bleeding and setting times. Injectability was evaluated by conducting one-dimensional injections into five different, clean sands using a specially constructed device. Injectability of cement suspensions increases with increasing cement fineness and water to cement (W/C) ratio. Microfine cement suspensions with water to cement (W/C) ratios of 2:1 and 3:1 can penetrate into medium to fine sands.

Keywords: Grouting; Suspensions; Injectability; Microfine cements; Laboratory investigation; Grouted sand

Introduction

The design related on the shear behavior of a soil material is of particular interest because it has a direct impact on practical problems of bearing capacity [1,2], stability of slopes and embankments [3-5] as well as permanent seismic movements of slopes [6-8]. The safe construction and operation of many technical projects often requires the improvement of the properties and mechanical behavior of the soil formations that appear in their area. Various methods are used to improve the soils, such as: the lowering of the well horizon, the vibrational condensation, the dynamic condensation, the preloading and the injections. The category of injections includes:

a. permeation grouting,

b. compensation grouting,

c. condensation injections and

d. high pressure vein injections.

Permeation grouting is one of the oldest methods for improving soil formations and have a wide range of applications [9]. Suspensions have lower cost and are harmless to the environment but cannot be injected into soils with gradations finer than coarse sands. Chemical solutions can be injected in fine sands or coarse silts but are more expensive and some of them pose a health and environmental hazard. Efforts have been made to extend the injectability range of suspension grouts by developing materials with very fine gradations. As a result, a number of fine-grained cements, called microfine or ultrafine cements, has been developed and manufactured. The behavior of microfine cements in permeation grouting is the objective of many research efforts.

Materials and Procedures

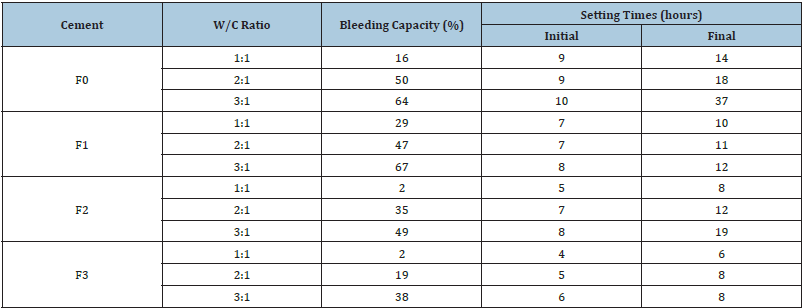

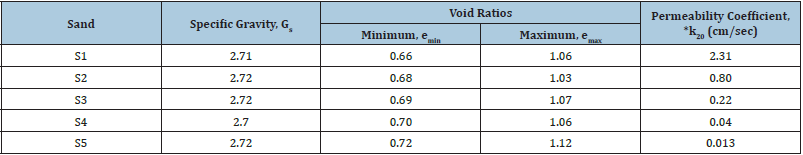

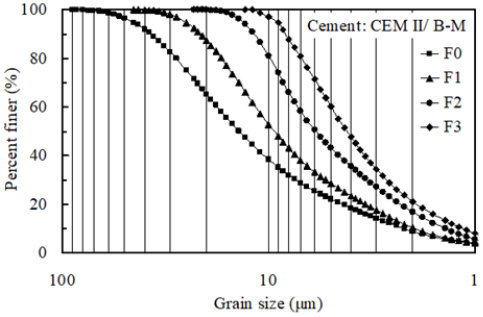

For the purposes of this investigation, a cement of type CEM II/B-M, according to EN 197-1, was used. The ordinary cement (designated as F0) was pulverized in order to produce three additional cements with nominal maximum grain sizes of 40μm, 20μm and 10μm, which are designated as F1, F2 and F3, respectively. The grain size distributions of all cements are shown in Figure 1. All suspensions were prepared using potable water since it is considered appropriate for preparing cement–based grouts. A dosage of superplasticizer equal to 1.4% by weight of dry cement was added to F1, F2 and F3 cement suspensions. The water to cement (W/C) ratios of all suspensions used, was equal to 1:1, 2:1 and 3:1 by weight. The properties of suspensions were evaluated in terms of bleeding capacity and setting times. The values of suspension properties presented in Table 1 indicate that fine (F1) and microfine (F2 and F3) cement suspensions enhanced with superplasticizer can be used in permeation grouting for soil improvement. The grouted soils were clean, uniform sands with angular grains. Five different sand gradations were used with grain sizes limited between sieve sizes (ASTM E11) Nos. 5 and 10, 10 and14, 14 and 25, 25 and 50, and 50 and 100, and designated as S1, S2, S3, S4 and S5, respectively. The sands were grouted in dense condition (mean value of relative density, Dr, 98±1%) and were dry prior to grouting. The values of other properties of sands are presented in Table 2. The groutability of suspensions was evaluated by performing injections into sand columns of a diameter equal to 7.5cm and a length equal to 36.5cm. A special device (Figure 2) consisting of a pressurized feed tank with a stirring shaft, an air pressure regulator and a line to the PVC grouting column, was used. Injection was stopped when either the volume of the injected grout was equal to two void volumes of the sand in the column or when the injection pressure became equal to 200kPa [10-14].

Table 1: Cement suspension properties.

Table 2: Sand properties. *Sands in dense condition.

Figure 1: Grain size distribution of cements.

Figure 2: Laboratory equipment for grouting sand columns [10-13].

Injectability

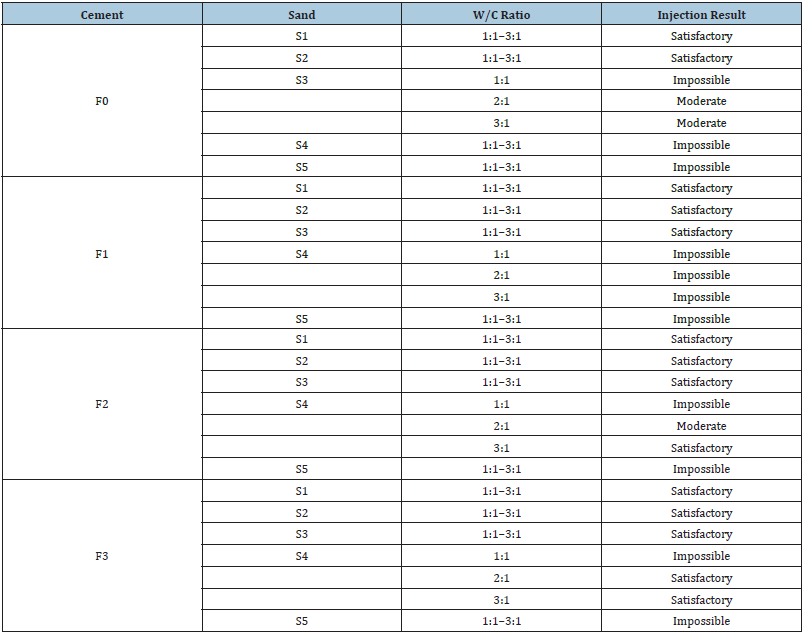

For the purposes of the experimental investigation reported herein, injectability was evaluated by conducting injection tests with the apparatus shown in Figure 2. Injectability was characterized as “satisfactory” when the predetermined quantity of grout (two void volumes of the sand column) could be injected, as “moderate” when the volume of injected grout was approximately equal to one void volume of the sand column and as “impossible” when the quantity of the injected grout was very small. From the results of the injection tests presented in Table 3, it can be observed that injectability was “satisfactory” in S1 and S2 (Nos. 5-10 and 10-14) sands for all combinations of suspension composition. Injectability in S3 (Nos. 14-25) sand was “moderate” or “impossible” for F0 (ordinary) cement suspensions and “satisfactory” for the finer cement suspensions. The S4 (Nos. 25-50) sand was grouted “satisfactorily” only with microfine cement F2 suspensions having W/C ratio equal to 3:1 and microfine cement F3 suspensions having W/C ratios of 2:1 and 3:1. Injectability of all suspensions with W/C ratio equal to 1:1 was “impossible” in S4 sand. Penetration in S5 (Nos. 50-100) sand was negligible for any cement suspension used. Accordingly, it can be stated that the increase of cement fineness and/or W/C ratio significantly improves the injectability of cement suspensions. On a quantitative basis, microfine cement suspensions with W/C ratios of 2:1 and 3:1 can be injected in medium to fine sands.

Table 3: Experimental results.

Discussion and Conclusion

Based on the results obtained and the observations made during

this investigation, the following conclusions may be advanced:

a. The increase of cement fineness improves the injectability

of cement suspensions rendering them effective for grouting of

medium to fine sands.

b. The increase of water to cement (W/C) ratio significantly

improves the injectability of cement suspensions.

c. On a quantitative basis, microfine cement suspensions

with water to cement (W/C) ratios of 2:1 and 3:1 can be injected

in medium to fine sands.

Funding

The research effort reported herein is part of the research project (PENED) which is co-financed by E.U.– European Social Fund (80%) and the Greek Ministry of Development – GSRT (20%).

References

- Lokkas P, Papadimitriou E, Alamanis N, Papageorgiou G, Christodoulou D, et al. (2021) Significant foundation techniques for education: A critical analysis. WSEAS Transactions on Advances in Engineering Education 18(2): 7-26.

- Lokkas P, Chouliaras I, Chrisanidis T, Christodoulou D, Papadimitriou E, et al. (2021) Historical background and evolution of soil mechanics. WSEAS Transactions on Advances in Engineering Education 18: 96-113.

- Alamanis N (2017) Failure of slopes and embankments under static and seismic loading. American Scientific Research Journal for Engineering, Technology and Sciences (ASRJETS) 35(1): 95-126.

- Papageorgiou GP, Alamanis N, Xafoulis N (2020) Acceptable movements of road embankments. Electronic Journal of Structural Engineering 20(1): 30-32.

- Nikolaos A, Christos Z, Grigorios P, Nikolaos X, Ioannis C (2020) Risk of retaining systems for deep excavations in urban road infrastructure with respect to work staff perception. International Journal of Scientific & Technology Research 9(2): 4168-4175.

- Zachos D, Bakalis G, Bakalis K, Alamanis N, Papageorgiou G, et al. (2021) A methodology for selecting the required cross‑section of a self‑supporting retaining bulkhead, on a vertical excavation front, of an energy conduit passage trench. Energy Systems 12: 989-1002.

- Alamanis N, Dakoulas P (2019) Simulation of random soil properties by the local average subdivision method and engineering applications. Energy Systems 12: 841-861.

- Alamanis N, Dakoulas P (2021) Effect of spatial variability of soil properties on permanent seismic displacements of slopes with uniform load. 14th Baltic Sea Geotechnical Conference, Helsinki, Finland.

- Zebovitz S, Krizek R, Atmatzidis D (1989) Injection of fine sands with very fine cement grout. Journal of Geotechnical Engineering 115: 1717-1733.

- Christodoulou DN, Droudakis AI, Pantazopoulos IA, Markou IN, Atmatzidis DK (2009) Groutability and effectiveness of microfine cement grouts. In: Hamza et al. (Ed.), 17th International Conference on Soil Mechanics and Geotechnical Engineering: The Academia and Practice of Geotechnical Engineering, Alexandria, IOS Press, Egypt, 3: 2232-2235.

- Pantazopoulos IA, Markou IN, Christodoulou DN, Droudakis AI, Atmatzidis DK, et al. (2012) Development of microfine cement grouts by pulverizing ordinary cements. Cement and Concrete Composites 34(5): 593-603.

- Markou IN, Christodoulou DN, Petala ES, Atmatzidis DK (2018) Injectability of microfine cement grouts into limestone sands with different gradations: Experimental investigation and prediction. Geotechnical and Geological Engineering Journal 36(2): 959-981.

- Markou IN, Christodoulou DN, Papadopoulos BK (2015) Penetrability of microfine cement grouts: Experimental investigation and fuzzy regression modeling. Canadian Geotechnical Journal 52(7): 868-882.

- Christodoulou D, Lokkas P, Markou I, Droudakis A, Chouliaras I, et al. (2021) Principles and developments in soil grouting: A historical review. WSEAS Transactions on Advances in Engineering Education 18(18): 175-191.

© 2021 Christodoulou Dimitrios. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)