- Submissions

Full Text

Academic Journal of Engineering Studies

Possible Way to Protect Spacecraft Optics from Micrometeor Erosion

Victor T FEDOROV*

Doctor of Technical Science, Russia

*Corresponding author:Victor T FEDOROV, Doctor of Technical Science, Concern “Nanoindustry”, ul. Bardina, 4, Astrakhan, Astrakhan Oblast, Moscow 119334, Russia

Submission: August 10, 2023; Published: January 25, 2024

.jpg)

ISSN:2694-4421 Volume3 Issue4

Abstract

Spacecraft optics are exposed to micrometeoroids and cosmic dust. How long can optics last in space and provide high-resolution images? A new method for protecting optical instruments from micrometeoroid erosion is proposed. The method is based on the use of a self-healing thin layer of a protective liquid applied to the outer side of a lens or mirror. The liquid must be resistant to solar and cosmic radiation and vacuum. For example, it can be one of the types of oligoorganosiloxanes. The regeneration of the protective liquid consists in cleaning it from microscopic products of the destruction of meteoric particles and removing high-molecular compounds with a molecular weight greater than 50,000. The implementation of the method is possible due to the combined use of the physics of interfacial phenomena and microgravity

Keywords:Space; Optics; Micrometeorite erosion; Protective liquid; Radiation; Microgravity

Heat Waves in Diffuse Thermoelectrics

Space photography allows you to explore large and hard-to-reach areas, especially in the Arctic zone of Russia. Analysis of images, which contain about 200 spectral bands in the visible and infrared ranges, helps to determine the type and characteristics of the rock on the surface with accurate coordinates on the ground [1]. The most famous space systems for remote sensing of the Earth are: Landsat 7, Landsat 8, Terra/Aster and WorldView-3 [2]. For example, Landsat 8, for surveying a geological area with a field of view angle of 1.28 degrees, has a main mirror with a diameter of 110cm and a focal length of 13.3m.

Optics for remote sensing of the Earth (ERS) can be structurally lens (refractor), mirror (reflector) and mirror-lens. In general, all mentioned types of optical devices are used for ERS. They are made to the highest quality standards. Therefore, they are expensive, for example, a meter-long mirror with a carbon fiber base costs about one million dollars.

How long can lens optics last and provide high-quality images when exposed to a micrometeor shower? First, let’s deal with the terms. What is a meteoroid, meteor and meteorite? A meteoroid is an object much smaller than an asteroid, usually measuring from 30 microns and up to one meter in diameter. Sometimes such a grain of sand, much smaller than 1mm in size, can knock out a large crater in thick glass. True, the probability of such a meeting in space is negligible. Nevertheless, cosmonauts Dzhanibekov and Savinykh, who in 1985 rescued the Salyut-7 station, upon arrival at the station, discovered on the outside of the porthole a cavern from a micrometeorite about 8mm deep. And the windows themselves had a thickness of only 10mm [3].

In 2017, the International Astronomical Union decided that objects smaller than 30μm are classified as micrometeoroids and interplanetary dust [4]. The Minor Planet Center (NASA) does not use the term “meteoroid” [5]. Meteoroids that burn up in the atmosphere, the so-called “shooting stars”, are called meteors. Meteors burn up in the atmosphere at an altitude of 76 to 100km. The remains of unburned meteoroids that have reached the Earth’s surface are called meteorites. Every year, about 15,000 tons of cosmic bodies enter the Earth’s atmosphere - from grains of sand to large stones [6].

The impact velocity of a micrometeor stream with a spacecraft (SC) is from 10 to 72km/s [7], if the meteoroid did not arrive from interstellar space. Then its speed theoretically can be even more. The speed of impact with the obstacle depends on the addition of the vector velocities of the micrometeor shower and SC.

Micrometeor particles damage the surface of any material, regardless of its mechanical strength and hardness. Indeed, the kinetic energy of the collision of most micrometeor particles with an obstacle is such that it is sufficient not only for the destruction and evaporation of the particle itself, but also for the material of the obstacle at the point of impact. Therefore, the extent of damage is more often determined by the thermophysical properties of the barrier than by its mechanical strength.

In the zone of impact of micrometeor particles with a speed of more than 10km/s on the glass of an optical device, a pressure of more than 15GPa (150 thousand bar) arises [8]. Glass at the point of impact turns into a powder consisting of micron fragments. The volume of fragments is usually 100...1000 times greater than the volume of a micrometeor. These particles accompany the SC in the form of a dust cloud for some time (from 15 minutes to a day), creating optical interference for photography due to the reflection of sunlight [9]. Gradually diffusing into the surrounding space, these fragments become a man-made component of space debris in orbit.

The probability of meeting meteor particles with SC is high enough only for very small particles with a mass of the order of 10- 6g (1μg) and for a flight duration of more than a year. When the mass of particles decreases to 10-11...10-12kg, the density of the micrometeor stream sharply increases hundreds and thousands of times [10]. In addition, an increasing number of submicron highvelocity particles of artificial origin accumulate in near-Earth orbit, which, when colliding with SC optics, also damage its surface [11].

The most detrimental effect of micrometeor and technogenic particles on the lenses of cameras, optical-electronic devices (OED) for astroorientation and navigation, portholes and solar panels. Prolonged action of meteor particles leads to clouding of lenses and windows. Meteor bombardment of external optical surfaces leads to an increase in scattering, which can reach up to 50% for astroorientation and SC navigation OED, operating in the visible range of the spectrum, in 2 years from the start of bombardment. For OED astroorientation and SC navigation operating in the infrared range, the effects of matting on the surfaces of optical parts are less pronounced. For multispectral imaging in the interests of geological exploration, including the entire visible part of the spectrum, the matting effect of optical surfaces from a micrometeor stream has a very negative effect.

Reducing the performance of optical instruments below a known limit means the end of practical use for the purpose of ERS in the interests of geological exploration, meteorology and ecology. The use of various protective screens and shutters to protect lenses solves the problem only partially. The use of shutters counteracts erosion only when the appliance is not in operation. Of course, when the camera lens is looking straight down (nadir) and the lens’ field of view is limited to the visible horizon of the Earth, then meteor showers cannot hit the lens. But working in high orbit, when the entire field of view of the lens is not shielded by the Earth, then meteor particles can damage the surface of the lens.

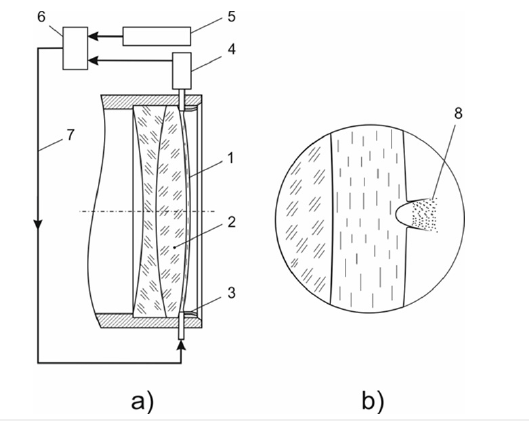

A possible way to protect optical instruments and other SC elements from micrometeor erosion is based on the use of a selfhealing surface of a thin layer of a special liquid applied to the protected surface. The implementation of the method is possible due to the joint application of the physics of interfacial phenomena and such a phenomenon as weightlessness (see Scheme).

The fact is that a specially selected liquid in zero gravity forms a uniform thin layer due to good wetting of the protected surface within the lyophobic perimeter. The lyophobic perimeter of the lens or other surface is made of a non-wettable material such as Teflon or other suitable material. The thickness of the protective liquid layer in the range of 0.5...1mm is sufficient to absorb the kinetic energy of the micrometeor particle.

The energy of a particle is spent on its destruction, on the evaporation of the particle material and the protective liquid, and also on the creation of a shock wave in the liquid. For example, if the mass of a stone-iron meteor particle is 10-10g, its transverse size will be about 3 microns. With a protective liquid layer thickness of 1mm, the particle size is more than 300 times smaller than the protective liquid layer thickness. The pressure in the front of the shock wave decreases in inverse proportion to the cube of the distance from the point of impact of the meteor particle on the liquid. Consequently, the shock wave will approach the lens surface strongly weakened and the lens glass will remain intact. The perturbation caused by the particle impact does not affect the image quality. Since such a rare phenomenon as the simultaneous impact of many particles on the lens is unlikely. After a fraction of a second, the surface of the liquid becomes molecularly smooth due to surface tension forces. Part of the fragments of the destroyed micrometeor particle will fall into the liquid. With periodic regeneration of the protective liquid, they remain on the fine filter.

Research is needed to find a protective liquid that would satisfy

the conditions of long-term work in outer space. The protective

liquid must have the following properties:

1. It must have a vapor pressure of no higher than 10-7Pa,

which would exclude a noticeable loss of mass during a long time of

operation in high vacuum conditions;

2. The liquid must wet well the surface to be protected,

including the anti-reflective coating. The contact angle of wetting

of the antireflective coating of the lens should tend to zero [12,13];

3. The liquid must be lyophobic to the material of the ring that

limits the spread of the protective liquid.

4. The liquid must be resistant to solar and cosmic radiation -

not subject to thermal degradation, not be prone to polymerization.

This is the most difficult requirement in finding the right fluid;

5. It must maintain satisfactory fluidity over a wide range of

operating temperatures and have a low dependence of viscosity on

temperature;

6. Have minimal absorption in the region of optical or infrared

radiation that is important for this device;

7. The liquid must be non-toxic and non-flammable;

8. The liquid must be inert with respect to the structural

materials of the spacecraft and the destruction products of

micrometeors.

9. Must retain service properties during long periods of storage

under the conditions of SC operation in orbit.

To a sufficient extent, these requirements are met by some organosilicon liquids - oligoorganosiloxanes. Some brands of them work in high vacuum pumps [14,15]. Many of them remain fluid in the temperature range from 143K to 573K and above. Most organosilicon liquids wet quartz, glasses, and other materials under normal conditions; however, studies are needed to determine the wetting angles of these liquids for glasses and antireflection coatings in a wide temperature range under conditions of high vacuum and intense solar irradiation (Figure 1).

Figure 1:Scheme of possible protection of SC optics from micrometeor erosion. a) Diagram of the device: 1 - a thin layer of protective liquid; 2 - lens; 3 - lyophobic Teflon ring; 4 - micropump operating in zero gravity and in vacuum conditions; 5 - stock of protective liquid; 6 - fine filter; 7 - supply of protective liquid to the protected surface after regeneration. b) The work of the protective liquid: 8 - high-speed impact of the micrometeor particles on the protective liquid.

The refractive index of organosilicon liquids for the sodium D-line (wave 589.3nm) is in the range from 1.38 to 1.42. For comparison, the refractive index for most optical glasses of various brands lies in the range of 1.45 ... 1.9. The vapor pressure of oligoorganosiloxanes at normal temperature is in the range of 10-7...10-9Pa [16], which is comparable to the pressure in space at an altitude of 500 km - 9•10-7Pa. That is, oligoorganosiloxanes can work in space without evaporating. Other synthetic fluids are also known, the properties of which are of interest for their possible use in space.

The device for protecting optical surfaces begins to work after the SC is put into orbit and all maneuvers are completed, accompanied by various kinds of accelerations. In weightless conditions, the objective lens is automatically supplied with a metered amount of liquid from the storage tank. Due to wetting, the liquid spreads over the surface of the lens in a uniform layer of a given thickness within the lyophobic ring. Under weightless conditions, the liquid layer on the entire surface is strictly the same in thickness and does not depend on the orientation of the protected surface in space.

The thickness of the protective layer is determined solely by the ratio of the amount of liquid to the area of the protected surface. In general, the features of the work of the protective layer in weightless conditions make it possible to increase its thickness, if necessary, up to 2mm. The upper limit of the thickness of the protective layer is limited by the physical characteristics of the liquid at the moment of occurrence of capillary waves on its surface in case of accidental occurrence of vibrational or other accelerations.

The regeneration of the protective liquid consists in cleaning it from microscopic products of the destruction of meteoric particles, as well as in removing traces of macromolecular compounds from it above a certain molecular weight. These compounds can appear in oligoorganosiloxanes under the action of hard solar ultraviolet and cosmic radiation. Periodic circulation of the protective liquid is also necessary to prevent the formation of thin polymer films at the “liquid-solid” interface under the action of various types of irradiation. The fine filter uses molecular sieves to purify the protective liquid from polymer molecules above a certain molecular weight. Losses of protective fluid due to polymerization are replenished from onboard reserves.

How much liquid are we talking about to protect against micrometeor erosion of one lens? The density of organosilicon liquid grade is on average 1100kg/m3. Only 8.6g of liquid is needed to obtain a protective layer 1mm thick on an objective with an entrance lens, for example, with a diameter of 100mm. It is obvious that the optimal thickness of the protective layer and the type of protective liquid for various optical systems and spacecraft devices can be determined on the basis of appropriate research. To do this, small samples of optical surfaces can be exposed for a long time with various protective liquids on the SC.

Before performing SC maneuvers in orbit, accompanied by accelerations, protective fluids must be temporarily removed from the optical surfaces into tanks. Under conditions of weightlessness and vacuum, conventional liquid suction is impossible. Therefore, liquid sampling from the optical surface before performing maneuvers and for its subsequent regeneration should be carried out by a micropump, the operation of which is based on wetting and impregnation of a porous moving element that transfers liquid to a fine filter. To facilitate the movement of liquid into the regeneration system, include during those periods when the temperature helps to reduce the viscosity of the liquid.

The second way of operation of the protective liquid is possible, if the liquid in the solid phase (frozen) retains all its optical properties. In this case, the micrometeor particle leaves its impact on the frozen protective layer. After some time, the electric heating is turned on or the sun heats up the surface of the lens. The protective liquid melts and evens out any damage caused by a long period of low temperatures.

References

- Connor JJO, Robertson EF (1997) Jean Baptiste Joseph Fourier, University of St Andrews, Scotland.

- Isachenko VP, Osipova VA, Sukomel AS, Heat Transfer, Third Publishing House, Moscow, Russia, p. 486.

- Anatychuk LI (1979) Thermoelements and thermoelectric devices, Naukova Dumka, Kyiv, Ukraine, p. 766.

- Snarsky AA, Palti AM, Ascheulov AA (1997) Anisotropic thermoelements. Semiconductors 31(11): 1281-1298.

- Ordin SV (2011) In: Optical Lattices: Structures, Atoms and Solitons, “Giant spatial dispersion in the region of plasmon-phonon interaction in one-dimensional- incommensurate crystal the higher silicide of manganese (HSM)”, Benjamin J Fuentes (Ed.), Nova Science Publishers, pp. 101-130.

- Ordin SV (1995) Thermoelectric waves in anisotropic cristal of higher manganese silicide, Proc. XV the Int. Conf. on Thermoelectrics, (ICT'95), St.-Petersburg, Russia, pp. 212-214.

- Ordin SV (1997) Optimization of operating conditions of thermocouples allowing for nonlinearity of temperature distribution. Semiconductors 31(10): 1091-1093.

- Ordin SV (1997) Peltier Heat as a Volume Property and Optimization of Working Regimes of Thermoelements in Real Conditions, Abstracts [PEL-P.2] of the XVI Int. Conf. on Thermoelectrics (ICT'97), Dresden, Germany, pp. 96-97.

- Okamoto Y, Ordin SV, Miyakawa T, Fedorov MI, Miida Y, Miyakawa T (1999) IR-characterization of sintering SiC thermoelectric semiconductors with use of 4-component effective medium model. Journal of Applied Physics 85(9): 6728-6737.

- Ordin SV (2002) Contact Thermopowers, Abstract, Proceedings of ICT'02 XXI International Conference on Thermoelectrics Long Beach, CA, USA.

- Ordin SV, Sokolov IA, Zjuzin AJ (2006) Thermoelectric processes in p-n junctions, Works of X interstate seminar: Thermoelectrics and their application, A.F. Ioffe PhTI of the Russian Academy of Sciences, St.-Petersburg, Russia, pp. 41- 47

- Ordin SV, Wang WN (2008) Thermoelectric properties nano structures, PH-TI of A.F. Ioffe of the Russian Academy of Sciences, St.-Petersburg, Russia Works of XI interstate seminar: Thermoelectrics and their application, pp. 55-60

- Ordin SV, Zjuzin A Yu, Ivanov Yu, Yamaguchi S (2009) Nano-structured materials for thermoelectric devices, NATO Workshop "Advanced Materials and Technologies for Micro/Nano-Devices, Sensors and Actuators", St Petersburg, Russia.

- Ordin SV, Zjuzin AJ, Yu Ivanov, Yamaguchi S (2010) Nano-structured materials for thermoelectric devices, The 29th International Conference on Thermoelectrics, Shanghai, China, p. 1-14.

- Ordin SV, Wang WN (2011) Thermoelectric Effects on Micro and Nano Level. J Advances in Energy Research 9: 311-342.

- Ordin SV, Yu V Zhilyaev, Zelenin VV, Panteleev VN (2017) Local thermoelectric effects in wide-gap Semiconductors. Semiconductors 51(7): 883-886.

- Ordin SV (2017) Refinement and Supplement of Phenomenology of Thermoelectricity. American Journal of Modern Physics 6(5): 96-107.

- Ordin SV (2017) Cardinal increase in the efficiency of energy conversion based on local thermoelectric effects. International Journal of Advanced Research in Physical Science 4(12): 5-9.

- Ordin SV (2018) Experimental and theoretical expansion of the phenomenology of thermoelectricity. Global Journal of Science Frontier Research- Physics & Space Science (GJSFR-A) 18(1): 1-8.

- Ordin SV (2018) Cardinal increase in the efficiency of energy conversion based on local thermoelectric effects. J Mater Eng Appl (JMEA) 1(1): 17-20.

- SV Ordin (2018) Anomalies in thermoelectricity and reality are local thermo-EMFs. Journal of Materials Engineering and Applications.

- SV Ordin, Mistakes in the theory of p-n junction and fundamentals of thermophotoelectronics. World Journal of Condensed Matter Physics (WJCMP).

- SV Ordin (2023) Foundations of Thermoelectronics. International Journal of Physics and Mathematics. IJPM 5(1): 15-19.

- SV Ordin (2023) Introduction to thermo-photo-electronics. Journal of Electronic & Information Systems 5(1): 51-66.

- SV Ordin (2023) Ballistic thermoelectricity. International Journal, Advanced Energy Conversion Materials 4(2):139-146.

- SV Ordin, Sharrupin BN (1998) Normal lattice oscillations and crystalline structure of non-isotropic modifications of a boron nitride. J Semiconductors (FTP) 32(9): 924-932.

- Okamoto Y, Ordin SV, Miyakawa T (1999) IR-characterization of sintering SiC termoelectric semiconductors with use of 4-component effective medium model. Journal of Applied Physics 85(9): 6728-6737.

- Ordin SV, Shelykh AI (2010) Optical and dielectric properties of rare-earth oxide Lu2O3. J Physics and Technics of Semiconductors 44: 558-563.

© 2023 Stanislav Ordin. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)