- Submissions

Full Text

Academic Journal of Engineering Studies

Research and Development of Smart Factory for Biotech Products in the Kyrgyz Republic

Zhu BH1, Lin SS2*, Liao YP3 and Zhu KY2

1Stantec Consulting Services lnc, Taiwan Branch, Taiwan

2Chung Yuan Christian University, Taiwan

3Microsoft Corporation, Washington, USA

*Corresponding author: Oman A Abyshev, ITMO University, Saint- Petersburg, Russia

Submission: June 18, 2021 Published: June 24, 2021

.jpg)

ISSN:2694-4421 Volume2 Issue2

Abstract

The paper describes a general overview of a Kyrgyz-Russian research project for the SCO member states agro-industrial sector. The project objective and key ideas have been highlighted. Premixes as biologically active substances have been taken as a biotech product. Have been shown the role of humic acids in the composition of premixes as livestock feeding additives. The Industrial cyber-physical systems and cloudbased service for premix composition design models for Smart Factory for biotech products have been proposed and described.

Keywords: Humic acids; Nutrition premixes; Smart manufacturing; Smart factory; ICPS; Industrial cyber physical system

Introduction

The current situation in the Kyrgyz agro-industrial sector shows weakness to new global

challenges due to the pandemic situation. There are many issues, which demand fundamental

investigation and search for new ideas and practical-oriented results. New multidisciplinary

research based on advances in the latest state-of-the-art innovation fields would create new

opportunities for development of SCO-member states industrial sector. Today, agricultural

sectors such as livestock, poultry, and fish farming have become almost completely dependent

on high technologies needed to improve, accelerate, increase the growth, development, and

productivity of livestock, poultry, or fish. Feed additives play a special role in the success of

the breeding process and innovative feeding methods. The current state of the problem that

has developed in the Kyrgyzstan agro-industrial sector indicates that only through the active

development of domestic scientific potential can the development of agriculture be possible.

The research project objective is to create a technological framework and an architecture

model for biotechnological Smart Factory in order to support and encourage exponential

growth of SCO-member states sustainability and prosperity. Thus, there are several key ideas,

which navigates our research:

1. Apply the ICPS paradigm to transform traditional solutions and technologies for

bioengineering industries, at particular agro-industrial sector.

2. Ensure high production processes efficiency and respect for the unique natural

environment of the Kyrgyz Republic.

3. Apply the proposed technical solutions for organizing the production process of

biotechnological synthesis of complex compounds – multifunctional premixes based on

humic substances, isolated from brown coal Kyzul-Kia/Kara-Keche (Kyrgyzstan).

4. Create a flexible manufacturing enterprise that can produce customized products in

a wide range and batch size (multifunctional premixes) for the agro-industrial sector.

Background. Premixes and Humic acids

Premix is a homogeneous mixture of biologically active

substances in the filler, which is used in the production of readymade

compound feeds, feed mixes or as an independent component

of the diet. The composition of the premix, depending on the recipe,

includes vitamins, trace elements, some amino acids, enzymes,

preventive and therapeutic drugs, as well as other biologically

active substances [1,2]. The main tasks of the premix production

of premixes are accurate dosing, high-quality mixing and uniform

distribution of the BAS minimum doses of in each portion of the

mixture, as well as maintaining the activity of the added additives

during the product life cycle. These tasks determine the specifics

and technology of premix production.

The general production process consists of 6 stages:

components preparation (sorting, milling, cleaning), additives

injection, filler matrix injection, diluent injection, premix dozing

and mixing, product packaging.

In the production of premix, the choice of filler is important. The

filler must be well combined with vitamins and salts, but also retain

biologically active substances on its surface as much as possible in

order to maintain the homogeneity of the mixture during mixing

and transportation and prevent self-sorting. It should also have

a low humidity, which ensures the flowability of the mixture and

better preservation of biologically active substances [3,4]. The

prospects of using humic acid macromolecules for obtaining

biologically active substances of a wide spectrum of action are

determined by their polyfunctionality, which causes high reactivity

and sorption capacity, as well as the presence of protective,

transport and accumulative properties. The ability of humic acids to

bind both metal ions and organic ecotoxicants in polluted and soil

environments into strong complexes should be noted. In addition

to these properties, they have such qualities as hydrophilicity,

ion exchange ability, surface activity, which positively affect the

absorption of feed nutrients in the animal body [2-4]. Humic acids

from oxidized brown coal of the Kyzyl-Kiya deposit (Kyrgyzstan)

have been used in the research study as premix matrix. Native

humic materials were obtained using sodium humate from brown

coal.

Results. Industrial cyber-physical systems for Smart Factory for biotech products

Industrial Cyber-Physical Systems (ICPS) are a state-of-the-art

innovative field of research and development of new generation

production systems engineering. In general, ICPS is understood as

a technical systems network, which consists of the next interacting

subsystems: digital (virtual) and physical (operational) components

[5,6]. Applicable for bioengineering and biotechnology, as parts of

engineering sciences, the I-CPS technology could provide a new

way for multidisciplinary collaboration between the wide scope

of engineers and specialists form chemistry, biology, production

automation, data analysts and many others. In particular, new I-CPS

design approaches and the Smart Factory paradigm could become

extremely efficient in biotechnology industries taking into account

its complexity, safety regulation, and dynamics. These industries

will be able to create new personalized products for users based on

new information and operational technologies, in accordance with

the high dynamics of changing consumer requirements and market

expectations [7,8].

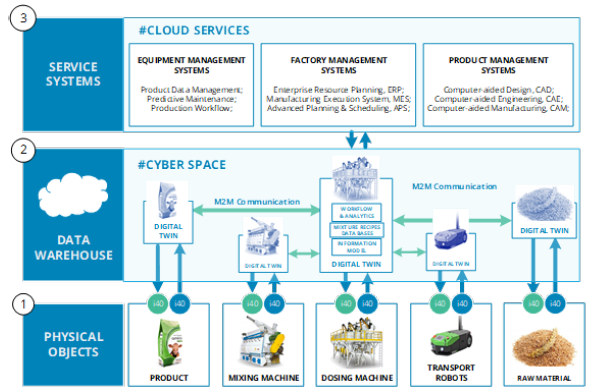

Proposed Smart Factory model Figure 1 consists of three layers

– service systems, data warehouse, and physical objects [9]. This is

a key for I-CPS organization and understanding. Physical entities

have their real-time digital representations-digital twins. It’s

important, that every of the digital twin should has its embedded

feedback loop due to update its status, their own workflow logic,

data bases, informational models, and interfaces. It allows to

communicate in united digital ecosystem as intellectual agents. It is

equal for raw materials, products, production cells with equipment

units, and robots. The cyber layer forms a digital space for the

Smart Factory ecosystem. The cyber level is dedicated to support

intellectual agents to communicate, integrate, and exchange their

data and services throw the industrial network.

The core of the solution consists of a United data model, which

is stored in products, processes, and resources Data warehouse.

This data units are also stored in cyber layer. Integration topology

is the main aspect for establishing communication in decentralized,

flexible, and Reconfigurable production model. On this slide

you can see that our production cells, assets, and technological

equipment is going to be connected via Machine-to-machine (M2Mcommunication

Net). Human and any machine, or product, which

are connected to the united digital ecosystem through standardized

M2M and Human-machine interfaces (HMI). The standardized

semantic and syntax become important requirements.

The cloud service layer forms the last layer which allows to use

general and special services for design, engineering, management,

and etc. Most of the services has general specialization, which

could be interoperable for any industrial application. Hence,

each industrial application forms its special list of services –

requirements for a cloud service layer composition. In agroindustry

it’s important to have a way to create non-standard

products, which could face to special requirements formed by agrotech

engineers. It means that we need be capable to produce special

premixes for special purposes, for example, mineral-enriched cattle

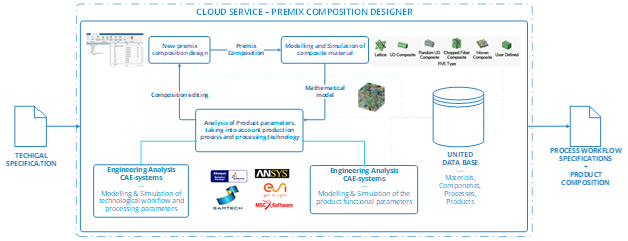

feeding premixes or medical premixes. Proposed cloud service

for premix composition designer is illustrated on Figure 2. This

service has been designed to develop and virtually test new premix

composition and its processing technology. Based on Computeraided

design and simulation software, this service would provide

finite process workflow specification with optimized parameters.

Figure 1: The model of Industrial cyber physical system for Biotech Smart Factory.

Figure 2: The model of cloud service “Premix composition designer”.

Discussion & Conclusion

ICPS could be understood as a technical systems network, which consists of the next interacting subsystems: digital (virtual) and physical (operational) components. ICPS could form a platform for cross-industrial multifunctional applications, due to its flexibility, pluggability and interoperability. Current project research cooperation is based on two major research partners: Kyrgyz National University n.a. J. Balasagyn, Bishkek, The Kyrgyz Republic and ITMO University, Saint-Peterburg, The Russian Federation. Both partners have formed a collaboration based on a distributed research team. The first research group from Kyrgyz National University under professor Anar A. Zaripova scientific supervising is working on the next research domains-chemical technology of premixes, processing workflow and technological operations, material design fundamentals. The second research group from ITMO University under professor Eugeny I. Yablochnikov scientific supervising is working on the next research domains technological processes automatization, Smart Factory model and architecture, digital design, and industrial engineering. The research team tactical objective is to finish a Smart Factory prototype on the testbed and validate theoretical hypothesizes. The project collective is open to research and industrial cooperation with institutions and organizations from SCO-member states.

References

- Popkov NA, Egorov IV, Fisinin VI (2005) Feed and biologically active substances: Monograph. Belarusian Navuka, p. 882

- Zaripova AA (2013) Obtaining and investigation of the properties of magnetically active nanoremediates based on derivatives of humic acids, monograph, Bishkek. University, KNU im J Balasagyn, p. 208.

- Zapipova AA, Kenenbaeva ZhA, Li SP (2007) Development of a technology for obtaining a soil conditioner, bulletin of the KNU im J Balasagyn Works of young scientists: Natural sciences, Materials of the scientific conference of the Center MANOP Science and Education: Problems and Prospects, p. 238-242

- Zaripova AA, Kerimbekova Zhh, Balasagyn J (2007) Works of young scientists: Natural sciences, Materials of the scientific conference of the Center MANOP. Science and Education: Problems and Prospects, p.246-250

- Dazhong Wu, David W Rosen, Lihui Wang, Dirk Schaefer (2015) Cloud-based design and manufacturing: A new paradigm in digital manufacturing and design innovation. Computer-Aided Design 59, pp. 1-14.

- Azaiez S, Boc M, Cudennec L (2016) Towards flexibility in future industrial manufacturing: A global framework for self-organization of production cells. The 2nd International Workshop on Recent Advances on Machine-to-Machine Communication 83, pp. 1268-1273.

- Lopes Nunes M, Pereira AC, Alves AC (2017) Smart products development approaches for industry 4.0 manufacturing engineering society international conference 2017. Procedia Manufacturing 13, pp. 1215-1222.

- Frolov E, Iscanderov R (2011) Effective management of small-scale production. Russian Engineering Researce 31(№2), pp.166-168.

- Demkovich N, Yablochnikov E, Abaev G (2018) Multiscale modeling and simulation for industrial cyber-physical systems. IEEE Industrial Cyber-Physical Systems (ICPS), p. 291-296.

© 2021 Oman A Abyshev. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)