- Submissions

Full Text

Academic Journal of Engineering Studies

Laboratory Investigations on Cement- Kiln-Dust Stabilized Soils for Rural Road Pavement Construction in Eastern Nigeria

Oduola RO

Department of Civil Engineering, Nigeria

*Corresponding author: Oduola RO, Department of Civil Engineering, Nigeria

Submission: March 14, 2021 Published: April 15, 2021

.jpg)

ISSN:2694-4421 Volume2 Issue1

Abbreviations: GDI: Green Development Initiative; DIFRRI: Directorate of Food, Roads and Rural Infrastructures; CBR: Californian Bearing Ratio; UCS: Unconfined Compressive Strength; CBR: Californian Bearing Ratio

Introduction

situation giving serious concerns to the stakeholders. Many factors have been adduced

to the poor conditions of the rural roads which include lack of fund, lack of political will of

the government to tackle it, poor soil materials and construction methodology. Rural roads

network form about 65% of the estimated 200,000km total road network in the country [1]

and they form the major access through which the rural dwellers communicate with the urban

centres. The rural areas are the agricultural base for most agricultural products, and they

service the industries in the cities with the raw materials especially the agricultural-based

industries. There have been concerted efforts by government over the years to address the

problems of rural roads by providing funds and creating agencies for rural road developments

especially the creation of the Directorate of Food, Roads and Rural Infrastructures (DIFRRI)

in 1986 during the military regime but these efforts have not been able to yield substantial

improvement in the conditions of most rural roads in Nigeria. The roads constructed often

experience premature failures making rural roads more difficult than before they were

constructed. The reason for the poor performance of rural roads constructed may be due to

lack of proper understanding of the road soil materials employed in their construction.

The problem of poor soil materials and the challenges they pose to road construction

particularly rural roads have been receiving research attention in the last 30 to 40 years in

different parts of Nigeria. There have been studies conducted to evaluate the subgrade soil

materials in the country to understand the various soils available in different locations by

characterizing their engineering properties and to determine their suitability for economic

road pavement design and construction. Some of these studies showed the distribution of

low-strength or poor soil materials across the country [2-5]. Some of these soil materials were

found to be highly susceptible to erosion forming gullies and creating geohazards in many

parts of the country [6] particularly in the eastern parts of Nigeria.

Many rural roads traverse these poor soil terrains, and they contribute to the poor state

of the rural areas in terms of road infrastructures. The need to incorporate stabilization

techniques in the construction of rural roads across the country to improve the performance

of these poor soil materials has become obvious from the present performance of rural roads

built on these poor soil terrains. The application of stabilization has been practiced for well

over 5000 years in different parts of the world [7] and the application of soil stabilization is

still gaining attention as a means of improving, modifying and upgrading the properties of

weak soil materials to meet the requirements of road pavement construction. Many methods

of soil stabilization that have been used are application of cement, lime, bitumen, polymers,

etc., although these methods have been found to be very effective but their impacts on the

construction costs of roads have not encouraged their use. This situation now led to a search for alternative but equally economic ways of stabilizing soils for

road construction particularly the rural roads which do not carry

high traffic volume.

The application of industrial wastes to soil in civil engineering

construction has recently been receiving attention in both research

and field application in many parts of the world particularly in the

United States of America, Britain, Europe, India, etc. The idea of

utilizing industry wastes in productive construction is a sustainable

strategy and is being promoted under Green Development Initiative

(GDI) to conserve the environment from their negative impacts [8-

10]. These industrial wastes include lime kiln dust, flyash, cement

kiln dust, foundry sand, marble dust, quarry dust, etc. Other wastes

from agricultural based activities are rice-husk ash, corn-husk ash,

baggase ash, etc. The use of cement kiln dust, a waste generated

from cement plants in Nigeria, has not been studied for productive

application over the years in Nigeria and the waste is generated

continuously and stockpiled creating environment hazards. There

have been efforts by some of the cement plants to introduce

recycling of the waste into the cement production process to

reduce their generation but this effort have been faced with other

challenges such as cost of installation and maintenance of the

recycling systems resulting in higher energy and general operation

costs.

These problems as well as the need to improve the transportation

infrastructures in the rural areas in the country form the basis of

these research programs currently being conducted. Also, this study

is aimed at finding a way of using the cement-kiln-dust produced

during the manufacture of cement for civil engineering construction

to reduce their negative environmental impact on the society

particularly the pollution of air, surface and groundwater resources.

These studies are aimed at finding an economic and more durable

solutions to rural road pavement problems affecting rural road

transportation and mobility in Nigeria, particularly in the eastern

Nigeria where rural accessibility have been a serious challenge

due to poor soil materials used in constructing them. These rural

roads experience rapid deterioration and failure resulting to loss

of investments, and thereby aggravate the sufferings of the rural

dwellers.

This paper therefore presents some results of laboratory

studies on the engineering properties of soil samples and the CKD

stabilized soil samples conducted on the eastern Nigerian soil

from Amatutu/Agulu, Anambra State, Nigeria where there have

been occurrences of soil failures such as landslides, gully erosion

and disruption to road infrastructures. And with this contribute to

the current knowledge on the search for effective and productive

potential use of CKD waste in stabilizing soils for rural earth and

flexible road pavement construction.

Review of Previous Research

There have been intensive studies into the application of industrial wastes that constitute environmental hazards in civil engineering construction in many parts of the world such as India, America, Britain, etc. Several industrial wastes such as cement kiln dust, lime kiln dusts, waste tyres, foundry sand, sludge wastes, etc., are being studied experimentally as well as in field application as potential stabilizers in pavement construction [11-14] and particularly for rural roads. A brief review of these research on the use of CKD in stabilizing low-quality soil materials from different parts of the world is presented.

Soil materials for rural roads

The construction of rural roads in Nigeria has been a serious

challenge over the years due to many factors such as poor funding,

poor soil materials, poor construction methodology, and so on. The

impact of poor soil materials is focused in this review since these

affect significantly the design as well as the cost of construction

and maintenance of rural roads. Rural roads in Nigeria traverse

different soil terrains of different engineering qualities. The soil

materials often encountered vary from good lateritic gravel to poor

lateritic clays. Other soil materials found along the rural road routes

are clay, shale, sand, silt, organic soils such as peats and black cotton

soils. Several poor soil materials in Nigeria commonly referred to

as problem soils have been studied with a view of identifying and

evaluating their engineering qualities so as to determine what type

of road pavements to be built on them or what type of stabilizing

treatment to give to them.

Ackroyd LW [15] studied some western Nigerian soils and

their qualities in road construction development in the area. Madu

RM [16] conducted studies on the geotechnical and engineering

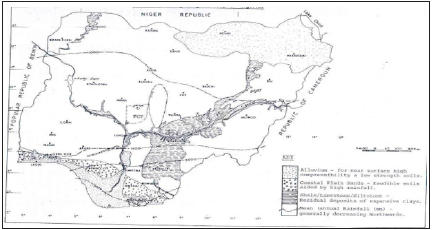

properties of some eastern Nigerian laterite soil materials. Figure 1

shows the results of studies conducted on the distribution of problem

soils in Nigeria [2]. Aitsebaomo FO [3] studied some subgrade

soils in south eastern Nigeria to determine their properties and

their impact on road infrastructures development. The extensive

Igunmale shale soil material in Benue state, in the central part of

Nigeria was studied by Agbede [4] to evaluate their geotechnical

and engineering properties for infrastructures development in the

area. Okeke OC [17] studied some gravel soils in Ihiagwa area in

the eastern Nigeria for potential use as construction materials. The

characteristics of soils of the eastern Nigeria and their role in soil

erosion particularly as it relates to Nanka and Ekwulobia areas in

Anambra state has also been studied [1-20].

Figure 1:Map of Nigeria showing distribution of problem soils [2].

Ugbe [21] has shown from studies conducted on 152 soil

samples from parts of Edo and Delta states in the mid-western and southern Nigeria that the soil contains high fine materials ranging

from 14% to 56% and gravel contents ranging from 0 to 6%. [5]

showed that similar results were obtained for subgrade soils from

some other parts of mid-western Nigeria and that the major soil

materials in the study area contains 52.94% of sandy clay with and

15.44% of clay. From all these investigations, it is clear that the soil

materials based on their geology, geological formation, geotechnical

and engineering characterization, have varying engineering

qualities ranging from good to poor, and these influence their

performance as subgrade, subbase and base materials under road

pavement especially rural roads. The use of these poorly rated soil

materials require improvement by the application of stabilization

techniques for economic and durable performance under traffic

loads. The rural roads are divided into two-paved and unpaved. The

paved rural roads are mainly asphalt concrete surfaced or bitumen

surface-dressed (flexible) pavement roads. The concrete paved

surface is seldom used for rural roads except for some special

conditions. The unpaved roads consist of the earth or gravel roads.

According to Shagaya L [1], the earth roads constitute about 65%

of the total estimated 200,000km of road networks in Nigeria. The

gravel roads are not common except on some quarry roads where

they are employed due to the nature of traffic experienced and of

course to check dust.

The earth roads form the major access through which rural

dwellers transport their goods, mainly agricultural products, to the

urban areas for marketing and as well obtain goods and services

needed in the rural area. The agricultural products are the second

largest of the goods and products from which the country derives

its gross domestic product earnings apart from oil. With the present

fall in oil price over the world, the country’s attention is now being

focused on agricultural products which are cultivated in the rural

areas. The conditions of rural roads are deplorable and thus require

urgent attention if the goal of the government to derive maximum

benefits is going to be realized. Figures 2(a) & 2(b) show typical

conditions of rural roads built on lateritic clay soils in Amatutu area

in the eastern part of Nigeria.

Figure 2: Typical failed paved and unpaved earth rural roads at Amatutu in eastern Nigeria.

The earth roads in Nigeria are not usually properly engineered and constructed to the required standards and so they are often characterized by flooding, potholing and erosion. The application of stabilization techniques such as the use of industrial wastes appear to be the best cost-effective alternative of developing rural roads in the different parts of the country especially in the eastern part of Nigeria where the soil erosion and landslide which occur in the area due to the nature of the soil existing there create serious problem and thus constitute a great threat to rural road development. The potential use of low-quality soil materials in rural roads construction in many parts of tropical Africa has received tremendous research attention [18-21] and that marginal or low-strength soils have been used in countries such as Australia, South Africa, Mozambique, Kenya, Bangladesh, etc, for constructing low-volume roads. Some roads in Malawi were also reported to have been constructed using substandard soil materials and have performed satisfactorily under low-volume traffic.

Stabilization of soils for rural road construction

Stabilization of soils for road pavement construction has been a

major technique employed in improving the engineering properties

of soil that fail to meet the acceptable criteria of plasticity index,

shrinkage, density and strength. The method has been used on

many soil terrains during construction of major roads in different

parts of the country. The construction of Apapa-Wharf road through

Ijora in Lagos was constructed using cement stabilization of fine

grained sandy-silty soils [15].

A number of researchers have studied stabilization of problem

laterite soils in different parts of Nigeria. Osula (1989;1996)

studied the use of admixtures such as cement and lime in stabilizing

some problem laterites and further used chemical additive such

as sodium chloride together with cement to understand the

performance of the stabilized laterite [21]. Onyelowe KC [22]

recently reported the results of studies conducted on cement and also bagasse ash stabilization of lateritic soil from Akwuette in

eastern Nigeria. However, the application of stabilization for rural

roads has not been a usual practice due to its cost implications on

the construction of rural roads.

The potentials of CKD in stabilizing soils for rural roads in

Nigeria are not yet studied. The studies on the potential productive

application of CKD in Nigeria for road construction in Nigeria

started sometimes in 2007 with an intensive research program at

the University of Lagos [23,24] and since this work started, some

researchers have also been showing keen interest on the subject.

Okafor & Egbe [25] studied the potential of CKD in improving soils

in some parts of eastern Nigeria for flexible pavement construction.

The potential of CKD in stabilizing problem soils in the eastern

Nigeria to enhance the development of rural roads in the area is

studied in this paper.

Material and Experimental Methods

The material location, sampling and experimental procedures adopted in this study are presented in the following sections.

Geology of the study area and material sampling

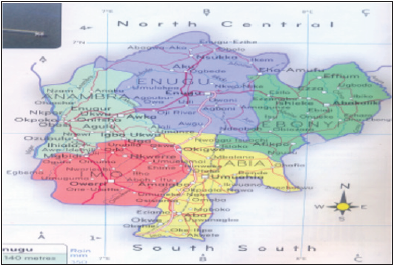

The study area is Amatutu/Agulu area of Anambra state in

the eastern part of Nigeria, a few kilometers from Akwa, the state

capital. The soil in the area is known to be erosive and susceptible

to collapse and several areas of the town have been affected by gully

erosion and landslides. Figure 3 shows the study area.

The geology of the study area can be described as located

within the Anambra basin consisting of Transgressive Lower

Tertiary Sediments (Paleocene-Eocene) and partly regressive

upper cretaceous sediments (Camparian-Paleocene) [3]. The soil of

Amatutu can be described as reddish brown, fine-grained silty sand

with little or no clay content. Due to lack of fines or binder content

in the soil, the soil appears to lack cohesion. This makes it to be

subject to high erosion vulnerability.

Figure 3:Map showing location of study area [38].

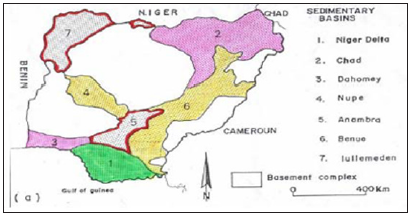

The Anambra Formation of Southern Nigeria was reported to have been formed during the Santonian tectonic event that affected the Southern Benue Trough, of which the first lithic fill of the basin is the marine Nkporo Group, and this include the Nkporo Formation, the Owelli sandstone Formation, and the Enugu Shale [26]. According to Kogbe [27] cited in Okeke CO [28], the soil of Amatutu/Agulu/Nanka area has been described as “Nanka sand because of its peculiar properties. The soil belongs to Bende-Amaki Formation and the lithology of the soil consists of fine to coarse sandstone with abundant intercalation of calcareous shale and thin shally limestone below and of loss cross bedded white and yellow sandstone with bands of fine grained sandstone and sandy clay above.” Because of the loose or weak bond between the soil particles, it quickly loses strength and gets eroded easily. Figure 4 shows the geological map of Nigeria showing the location of the study area. The sampling of the soil was done by using digger and shovels to remove the soils from two sampling points. Disturbed samples of the soil were taken at two selected points, placed in polythene bags and transported to the Materials Laboratory of the Department of Civil Engineering, University of Lagos. Cement Kiln Dust (CKD) used for the stabilization of the soil samples was obtained from Lafarge/ West African Portland Cement, Shagamu Plant, Ogun State, Nigeria.

Figure 4:Geological map of the study area [34]].

Experimental procedures

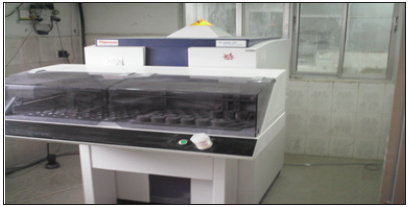

Figure 5:AARL 900 Cement analyzer used for chemical analysis of cement-kiln-dust samples.

The tests conducted on the soil samples are divided into two.

These are engineering tests and chemical/mineralogical tests on

the soil samples. The engineering tests conducted on the samples

of soils were the particle size sieve analysis, specific gravity, soil

classification, Atterberg limits, compaction test, Californian Bearing

Ratio (CBR) and Unconfined Compressive Strength (UCS). The

experimental procedures adopted for testing the soils without the

CKD stabilizer were as specified in BS 1377 [29] and the procedures

for testing the CKD-stabilized soil samples were as specified in

BS 1924 [30]. The chemical analysis of the CKD sample was done

using AARL 900 cement Analyzer shown in Figure 5 at the Quality

Control Laboratory of the Lafarge/WAPCO Portland Cement Plant Shagamu, Ogun State. The soil samples were stabilized with CKD

by increasing the stabilizer content at intervals of 2% by weight.

The maximum addition of the CKD is set at 30% but the tests so far

conducted are from 0% to 10% CKD addition. The remaining tests

which involve increasing the CKD to 30% are still being conducted.

Other tests conducted but not reported here are the

mineralogical analysis of the soil samples, CKD and the CKDstabilized

soil samples. These tests include the X-ray Flourescence

using Energy Dispersive Spectrometer (EDS), X-ray Diffraction

test and Scanning Electron Microscopy (SEM). These tests were

conducted to determine the mineral compounds in the soils as

well as the stabilized soil samples so as to understand the reaction

and mechanisms that occurred in the samples which affect the

engineering properties of stabilized samples. The results of these

will be reported when completed.

Result and Discussion

The results of the engineering tests conducted using the standard procedures of BS 1377 [30] and BS 1924 [29] are presented as follows.

Results of engineering tests conducted

Particle size analysis, atterberg limits and soil classification

Table 1:Natural moisture content, atterberg limits and soil classifications.

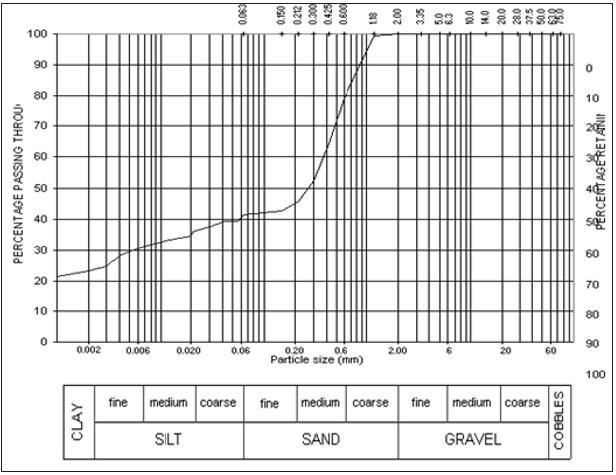

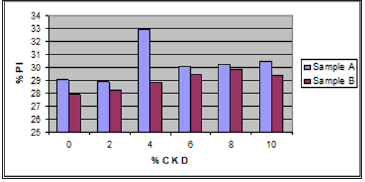

The results of the natural moisture contents conducted on the two soil samples are shown in Table 1 together with the Atterberg limits and soil classification. The values obtained for the natural moisture contents are 9.80% and 13.20% for samples A and B respectively. The grain size analyses for the two soil samples A and B were carried out and the results of the grain size analysis conducted using the procedure in BS 1377 [30] are shown in Figures 6 & 7 for the two soil samples. The results of Atterberg Limits tests conducted on the two soil samples and the addition of Cement-Kiln- Dust (CKD) in the range of 0% to 10% are shown in Table 1. The variation of the Plasticity Index (PI) index with percentage CKD added is shown in Figure 8. From the particle size analysis and the Atterberg Limits test results on the unstabilized soil samples, the soil samples A and B were classified based on AASHTO procedures as A-7-6 (9). Based on the Nigeria Highway Manual (NHM, 2013), the soil samples are classified as S5 subgrade. According to the AASHTO chart used in the classification of the soils, the samples are rated as fair to poor subgrade soils and so are not excellent materials for subgrade soils under road pavement. Garber and Hoel [31] also have stated that soils having coarse grain materials are excellent subgrade soil although they have high permeability.

Figure 6:Particle size analysis for soil sample A.

Figure 7:Particle size analysis of soil sample B.

Figure 8:Plasticity index vs. percent cement-kilndust for samples A and B.

Specific gravity and permeability test results

The results of the specific gravity of the two soil samples A and B measured are shown in Table 2. The results are 2.65 for soil sample A while soil sample B has a value of 2.652. These values fall within 2.6 and 3.4, the range of specific gravity generally reported for lateritic soil materials. But according to Bowles [32], the values of specific gravities ranging from 2.52 to 2.66 are reported for inorganic clay soils. This indicates that the soil samples actually fall into the range of lateritic clay. The specific gravity is an important parameter in determining the clay content of soil samples, the void ratio as well as the soil porosity which are required in determining the drainage properties of soils. The permeability property of the soil samples was measured using falling head permeameter. This property normally indicates the behavior of the soil when subjected to high ground water under road pavement. The results of hydraulic conductivities of the two soil samples are 2.670 x 10-4cm/s and 2.840x10-4cm/s for samples A and B respectively as shown in Table 2. From the permeability results, it shows that the soil samples have low permeability and therefore are fine-grained soils likely to be affected by plastic property.

Table 2:OPermeability and specific gravity of soil samples.

Compaction and California bearing ratio tests

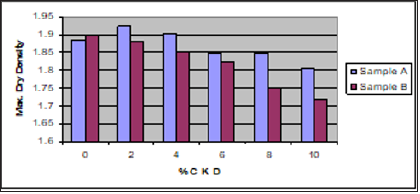

The compaction test carried out in this study is the West African Heavy compaction procedure since the soils will be subjected to vehicular loads. The results of the compaction tests for the unstabilized soil samples and CKD-stabilized soils samples are presented in Table 3. The dry density of the soil samples A and B before stabilization was found to be 1.886Mg/m3 and 1.90Mg/m3 respectively. The dry density for the CKD stabilized samples of the two soils ranged from 1.864Mg/m3 for soil sample A at 2% CKD addition to 1.666Mg/m3 for the same soil sample at 10% CKD.

Table 3:Dry density and Californian bearing ratio of the soil samples.

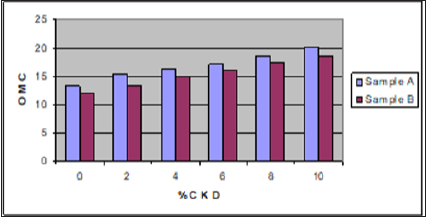

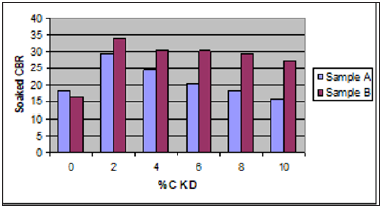

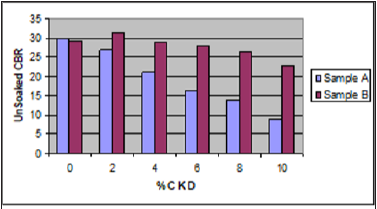

However, as the samples were stabilized with CKD, there was a progressive reduction in the dry densities but the optimum moisture contents of the soil samples increased. There are variations of optimum moisture contents with percent increase of CKD and also of dry density with percent increase in CKD respectively (Figures 9 & 10). The results of the Californian Bearing Ratio (CBR) are presented in Table 4 showing the soaked (for 4 days) and unsoaked CBR of the two soil samples with their corresponding CKD-stabilized samples. The soaked CBR of soil sample A and B are 18.0% and 16.33% respectively. The unsoaked CBR of the two samples are 30.0% and 29.33%. From the test results, it was found that the soaked CBR of the samples increased as the percentage increase of the CKD stabilizer. The increase in strength as measured by the CBR values may have been connected with the hydration reaction of calcium oxide (lime) which is the predominant oxide in the CKD in the presence of water during the curing of the samples. Figures 11 & 12 show the variations of the soaked and unsoaked CBR properties of the stabilized soil samples A and B with increasing percentage of CKD. The 4-day soaked CBR values of the unstabilized soil samples A and B are 18.0% and 16.33% respectively. These are found to be lesser than 30% as required by the Nigerian Highway Specifications [33] for subbase materials under road pavement. However, the soil samples meet the requirement of subgrade materials of not less than 15%. The soil samples when stabilized with 2% to 10% CKD showed impressive increase in soaked CBR especially soil sample B meeting the requirement of subbase materials [33-36].

Table 4:Unconfined compression strength results on soil samples and cement-kiln-dust stabilized soil samples.

Figure 9:Optimum moisture content vs. percent cement-kiln-dust of samples A and B.

Figure 10:Maximum dry density vs. percent cement-kiln-dust of samples A and B.

Figure 11:Soaked Californian bearing ratio vs. percent cement-kiln-dust of samples A and B.

Figure 12:Unsoaked California bearing ratio vs. percent cement-kiln-dust of samples A and B.

Based on unsoaked CBR, the strength of the soil did not increase but a gradual decrease in strength was noted as the percent increase in CKD stabilizer. This observation may be due to lack of water for the continued hydration reaction of lime in CKD-soil mixture to continue during the unsoaked curing. However, the soaked samples experienced increase in strength and this is possibly due the hydration and cementation reactions from the lime-rich CKD with the soil samples [37-41]. The further chemical and mineralogical analyses which are to be conducted at the second stage of these studies will capture the cause of this behavior of the stabilized soil samples. According to Lebo & Schelling [10], the design of rural roads based on unsoaked criteria for the soil materials results in uneconomical design because the rural roads are often subject to low traffic unlike the main urban roads. Therefore, it was suggested that the unsoaked CBR can be used to design rural roads.

Unconfined compression strength

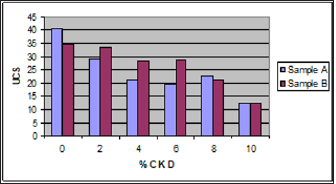

The results of Unconfined Compression Strength (UCS) tests

conducted on the soils and the CKD stabilized soil samples are

shown in Table 4. The results show both the uncured and cured (in

air) for 7, 14, 21, and 28 days for the two soil samples A and B with

their corresponding CKD-stabilized samples. All the CKD-stabilized

soil samples show a general increase in strength as the days of curing

increased. The unconfined compressive strength has been used to

classify soils into different categories for the purpose of determining

their properties and suitability for engineering purposes. Different

ranges of soils are known based on some set criteria. For instance,

soils having UCS values ranging from 0 to 25kN/m2 are classed

as very soft clay soils while those with values ranging from 25-

50kN/m2 are classed as soft clay soil. Medium soft clay soils have

unconfined compression strength values ranging from 50-100kN/

m2 while stiff clay soil have values ranging from 100-150kN/m2.

Very stiff clay soils have unconfined compression strength values

ranging from 200-400kN/m2 while values greater than 400kN/m2

are classed as hard clay soils. Based on these criteria, soil sample A

and B (without stabilizer) have unconfined compression strength

value of 40.67kN/m2 and 34.57kN/m2 respectively. This indicates

that the soil falls into the soft clay category. But as the soil samples

were stabilized with CKD, the strength increased with increase in

curing age [42,43].

Generally, soil sample A increased from 40.67kN/m2 for

uncured condition to 98.60kN/m2 at 28 days of curing at 0% CKD

addition. However, the strength of the soil samples reduced as

the percentage of cement-kiln-dust are added to the soil samples.

Similar observations were noted for sample B. The reduction in

strength may be due to the chemical reactions and mineralogical

influence in the soil-CKD mixtures but this will be understood

when the mineralogical and chemical analyses of the soil and the

CKD-stabilized mixtures are carried out during the second stage of

these investigations. Figure 13 shows the variation of unconfined

strength of the soil with the percent addition of CKD for uncured

condition of the stabilized samples [44].

Figure 13:Unsoaked California bearing ratio vs. percent cement-kiln-dust of samples A and B.

Chemical analysis of cement-kiln-dust

The results of the chemical analysis of the CKD used in the experiment was conducted using the AARL 900 Cement Analyzer and is presented in Table 5. The purpose of this test is to determine the oxide elemental contents of the CKD stabilizer which will influence the engineering behavior of the CKD-stabilized soil samples. During the second stage of these investigations, the elemental contents and mineralogical analyses of the stabilized soil samples will also be determined. From the results of these elemental oxide contents, it was found that the major elements present in the CKD are silica, aluminium oxide, ferric oxide and calcium oxide. The calcium oxide (lime) was found to be the predominant oxide in CKD with a mean value of 57.65% and lime being a good pozzolanic material can increase the strength properties of the stabilized soils particularly soils with high clay content.

Table 5:Results of chemical analysis of cement-kiln-dust.

Conclusion

From the results of tests conducted on the soil samples obtained

from Amatutu/Agulu area of Anambra State in the eastern part of

Nigeria, which are presented, analyzed and discussed in the above

sections, the following conclusions can be made.

1. Based on the particle size analysis of the two soil samples

and the Atterberg limits, the soil samples were classified

according to AASHTO Chart as A-7-6(9). These soil samples

were further classified according to the Nigerian Highway

Manual (2013) to be S5 subgrade class. These further confirm that the soils are not excellent materials for subgrade or

subbase soils; however, they meet the criteria for subgrade, and

can be employed as base materials for rural roads.

2. The specific gravity of the soil samples and the

permeability test results showed that soil samples have low

hydraulic conductivity which means that the soils are finegrained

and so are not excellent materials for subgrade under

pavement since excellent subgrade materials must be highly

permeable. However, if the road crossfalls are constructed to

meet the specifications for rural road, the materials can be

employed for their construction since the traffic is usually low.

3. The dry-density which measures the strength based on

grain-to-grain contacts in the soil samples and the presence of

voids in the soils shows that the density of the soils were fairly

high and this can be attributed to the amount of clay material in

the soil.

4. From the Californian Bearing Ratio (CBR) test results, soil

samples A and B cannot be used as subbase or base materials

under road pavement. However, with stabilization with CKD,

the soil material properties increased to meet the requirements

for subbase. For rural roads since the traffic are usually low, the

use of unsoaked CBR for design of the pavement have been

suggested by Lebo & Schelling [10], and so if this specification is

applied, then all the soil samples can be used as both subgrade

as well as subbase under rural road traffic condition.

5. The unconfined compressive strength of the soils showed

that soil sample A and B belong to very soft clay, however with

stabilization, the strength of the soils increased with increasing

CKD content and as the air-curing days increased. This

increasing trend was observed for the two soil samples studied.

This can be attributed to the bonding action of the fine-grained

clay sizes present in the soils sample by the hydration reaction

of CKD with the soils.

6. Results of the chemical analysis of CKD show that it is

rich in lime and so can provide the needed pozzolanic and

hydration reactions with the clay content of the soil samples

with a resulting material with lower plasticity index.

7. These results show that CKD can be productively used in

improving low-grade soils to meet the criteria for application in

rural road construction in the eastern part of Nigeria where this

soil has been posing problem.

8. Further work is still on-going particularly on more

addition of cement kiln dust and on the influence of soil chemical

and mineralogy on the properties of the CKD-stabilized soil

mixtures.

References

- Shagaya L (2006) Private sector participation in road development and management in Nigeria. A contribution by the Nigerian society of engineers (NSE) at a one-day workshop organized by the NSE in collaboration with Federal Ministry of Works on Making Nigerian Roads Motorable (Federal, State, & Local Roads, 13th January).

- Adesunloye MO (1987) Investigating the problem soils of Nigeria. proceedings, 9th regional conference for africa on soil mechanics and foundation engineering, Lagos, Nigeria, pp. 103-110.

- Aitsebaomo FO (1999) Geotechnical characterization of subgrade soils in south eastern Nigeria. Construction and Materials Technology, Nigerian Building & Road Research Institute 1(1): 52-72.

- Agbede AA (1999) Geotechnical properties of igunmale shale. PhD thesis, Department of Civil & Environmental Engineering, University of Lagos, Nigeria.

- Aitsebaomo FO, Matawal DS, Fakeye AM (2013) Engineering properties of subgrade soils in mid-western Nigeria for economic pavement design. Journal of Engineering Research 18(1): 1-11.

- Akpokodje EG, Tse AC, Ekeocha N (2010) Gully erosion geohazards in southeastern Nigeria and management implications. Scientia Africana 9(1): 20-36.

- Chmeisse C (1992) Soil stabilization using some pozzolanic industrial and agricultural products. PhD thesis, Department of Civil and Mining Engineering, University of Wollongong, Australia.

- LCS (2002) Low-Cost Road Surfacing (LCS) Project of global mekong subregion. Academic and Research Network (GMSARN) Seminar on Rural Road, 23rd to 24th, May.

- Lee M, Cheong TP, Daud WDQ (2010) Green approach to rural roads construction-stabilization of In-situ soils and construction wastes. 7th Asia Pacific conference on transportation and the environment, Semarang, Indonesia, 3rd-5th, June.

- Lebo J, Schelling D (2001) Design and appraisal of rural transport infrastructure-ensuring basic access for rural communities. World Bank Technical Paper No. 206.

- Button JW (2003) Kiln dust for stabilization of pavement base and subgrade materials. Texas transportation institute, college station, Texas, TTI-2003-1, USA.

- Parsons RL, Kneebone E (2004) Use of cement kiln dust for the stabilization of soils. Proceedings of Geotechnical Engineering for Transportation. Los Angeles, USA, pp. 1124-1131.

- Miller GA, Azad S (2000) Influence of soil type on stabilization with cement kiln dust, construction and building materials 14(2): 89-97.

- Chandra S, Kumar P, Berhanu AF (2002) Use of marble dust in road construction. International Journal of Road Materials & Pavement Design 3(3): 317-329.

- Ackroyd LW (1970) The engineering classification of some western Nigerian soils and their qualities in road building. overseas bulletin, no. 10, road research laboratory, department of the environment, reprint, Crowthorne, UK.

- Madu RM (1976) An investigation into the geotechnical and engineering properties of some laterites of eastern Nigeria, University of Nigeria, Nsukka.

- Okeke OC, Agbasoga JC (2001) Evaluation of ihiagwa gravel deposit as aggregates for concrete and highway pavements. Journal of Mining and Geology 37(1): 77-84.

- Cook JR, Bishop EC, Gourley CS, Elsworth NE (2001) Promoting the use of marginal materials. Transport research laboratory, DFID, project report No. PR/INT/205/2001.

- Toole T, Newill D (1987) The first seven years performance of Calcrete base in botswana. TRRL, Overseas Unit Working Paper No. 215, Transport and Road Research Laboratory, Crowthorne, UK.

- Petts R, Cook J, Tuan PG (2006) Rural road paving for manageable maintenance. Revue THE No. 134, September, pp. 21-30.

- Osula DOA (1993) Laboratory trial of soil-sodium chloride-cement stabilization for problem laterites. Journal of Transportation Engineering ASCE 119(1): 149-158.

- Onyelowe KC (2012) Cement-stabilized akwuette lateritic soil and the use of bagasse ash as admixture. International Journal of Science & Engineering Investigations 1(2): 16-20.

- Oduola RO (2009) Discussion of study of the effectiveness of cement kiln dusts in stabilizing na-montmorillonite clay. Journal of Materials in Civil Engineering, American Society of Civil Engineers 21(11): 706-707.

- Oduola RO (2017) Experimental studies on cement kiln dust stabilized soils for rural road pavement construction in Eastern Nigeria. Proceedings of International Road Federation (IRF) Middle East Regional Congress, Dubai.

- Okafor FO, Egbe EA (2013) Potentials of CKD in subgrade improvement. Nigerian Journal of Technology 32(1).

- Umeji OP, Nwajide CS (2007) Age control and designation of the standard stratotype of Nsukka formation of Anambra Basin, Southeastern Nigeria. Journal of Mining and Geology 43(2): 147-166.

- Kogbe CA (1976) The cretaceous and paleogene sediments of Southern Nigeria, Geology of Nigeria. Elizabethan Co., Surulere, Lagos, Nigeria, pp. 273-282.

- Okeke CO (1991) The socio-economic effect of gully erosion in Nanka, Orumba L. G. A. of Anambra State. B. Sc. Thesis, department of geography and regional planning, University of Benin, July.

- BS 1377 (1990) Method of testing soils for civil engineering purposes. British standard institution, UK.

- BS 1924 (1990) Test for stabilized soil. British standard institution, UK.

- Garber NJ, Hoel LA (1999, 2002) Traffic and highway engineering. (2nd edn), PWS Publishing/Brooks/Cole Publishing Co., USA.

- Bowles J (1990) Foundation engineering. McGrawHill Publishing Co., New York, USA.

- FMWH (1997) Nigerian general specification for bridges and roadworks. Federal Ministry of Works, Housing & Development, Abuja, Nigeria.

- FMWH (1969) Geological map of Nigeria. Federal ministry of works & housing, federal surveys. Lagos, Nigeria.

- Ogunribido THT (2012) Geotechnical properties of saw dust ash stabilized southwestern nigerian lateritic soils. Environmental Research. Engineering & Management 60(2): 29-33.

- Miller GA, Zaman MM, Rahman J, Tan NK (2003) Laboratory and field evaluation of soil stabilization using cement kiln dust, ORA No. 125-5693, University of Oklahoma, Norman, Okla.

- NHM (2013) Nigerian highway manual part I: Design, Vol. III: pavements & materials design, federal ministry of works, power and housing, Nigeria.

- NPC (2006) National population commission census data sheet, Abuja, Nigeria.

- Okagbue CO (1992) The 1988 Nanka landslide, Anambra State, Nigeria. Bulletin of engineering geology and the environment. Springer Berlin/Heidelberg 46(1): 79-87.

- Okagbue CO, Ezechi JI (1988) Geotechnical characteristics of soils susceptible to severe gullying in Eastern Nigeria. Bulletin of international association of engineering geologists 38: 111-119.

- Onwuka SU, Okoye CO, Nwogbo N (2012) The place of soil characteristics on soil erosion in Nanka and Ekwulobia communities in Anambra State. Journal of Environmental Management and Safety 3(3): 37-50.

- Osula DOA (1989) Evaluation of admixture stabilization for problem laterite. Journal of Transportation Engineering ASCE 115(6): 674-687.

- Osula DOA (1996) A comparative evaluation of cement and lime modification of problem laterite. Engineering Geology 42(1): 71-81.

- Ugbe FC (2011) Basic engineering geological properties of lateritic soils from western Niger delta. Research Journal of Environmental and Earth Sciences 3(5): 571-577.

© 2021 Oduola RO. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)